吉林大学学报(工学版) ›› 2021, Vol. 51 ›› Issue (5): 1749-1755.doi: 10.13229/j.cnki.jdxbgxb20200508

• 交通运输工程·土木工程 • 上一篇

悬索桥主缆除湿的内部送气管道设计与性能

- 1.西南交通大学 土木工程学院,成都 610031

2.中铁大桥勘测设计院集团有限公司,武汉 430056

Design and performance of internal air supply conduit for dehumidification in main cables of suspension bridges

Wei CHEN1( ),Tian-bao WAN2,Zhong-bin WANG2,Xuan LI1,Rui-li SHEN1(

),Tian-bao WAN2,Zhong-bin WANG2,Xuan LI1,Rui-li SHEN1( )

)

- 1.School of Civil Engineering,Southwest Jiaotong University,Chengdu 610031,China

2.China Railway Major Bridge Reconnaissance & Design Institute Co. ,Ltd. ,Wuhan 430056,China

摘要:

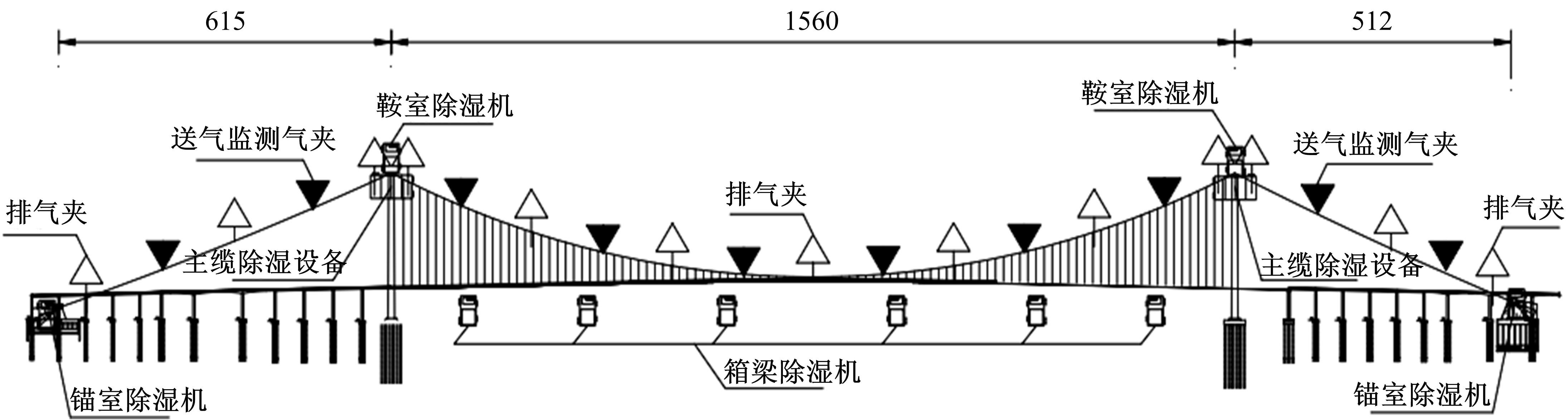

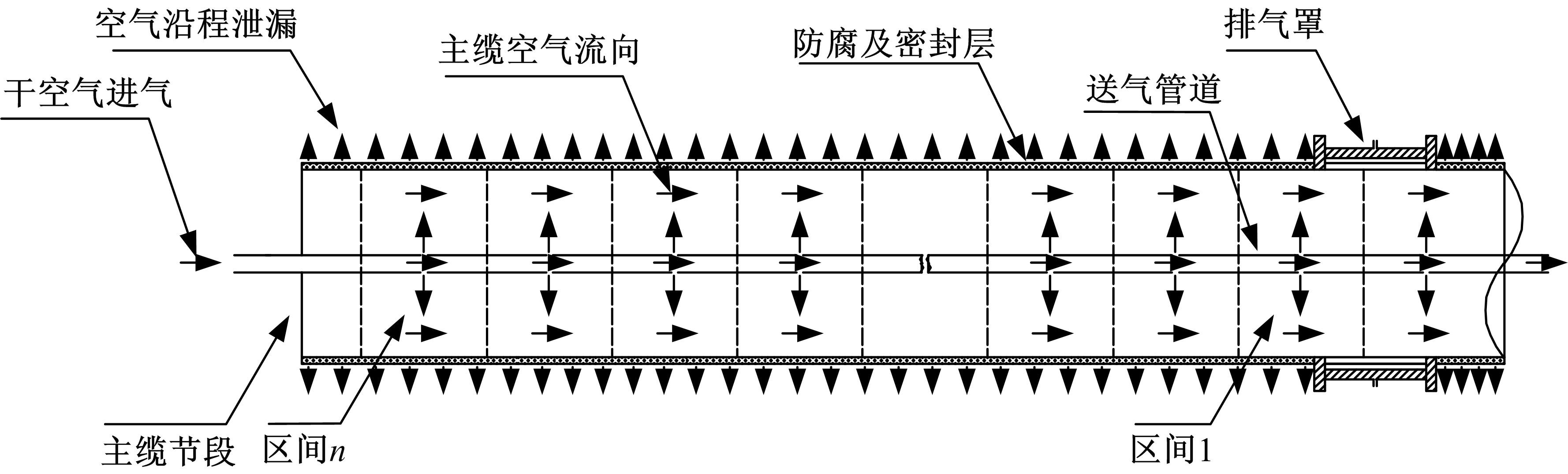

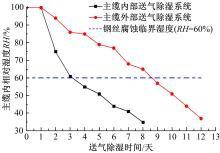

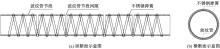

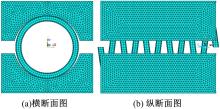

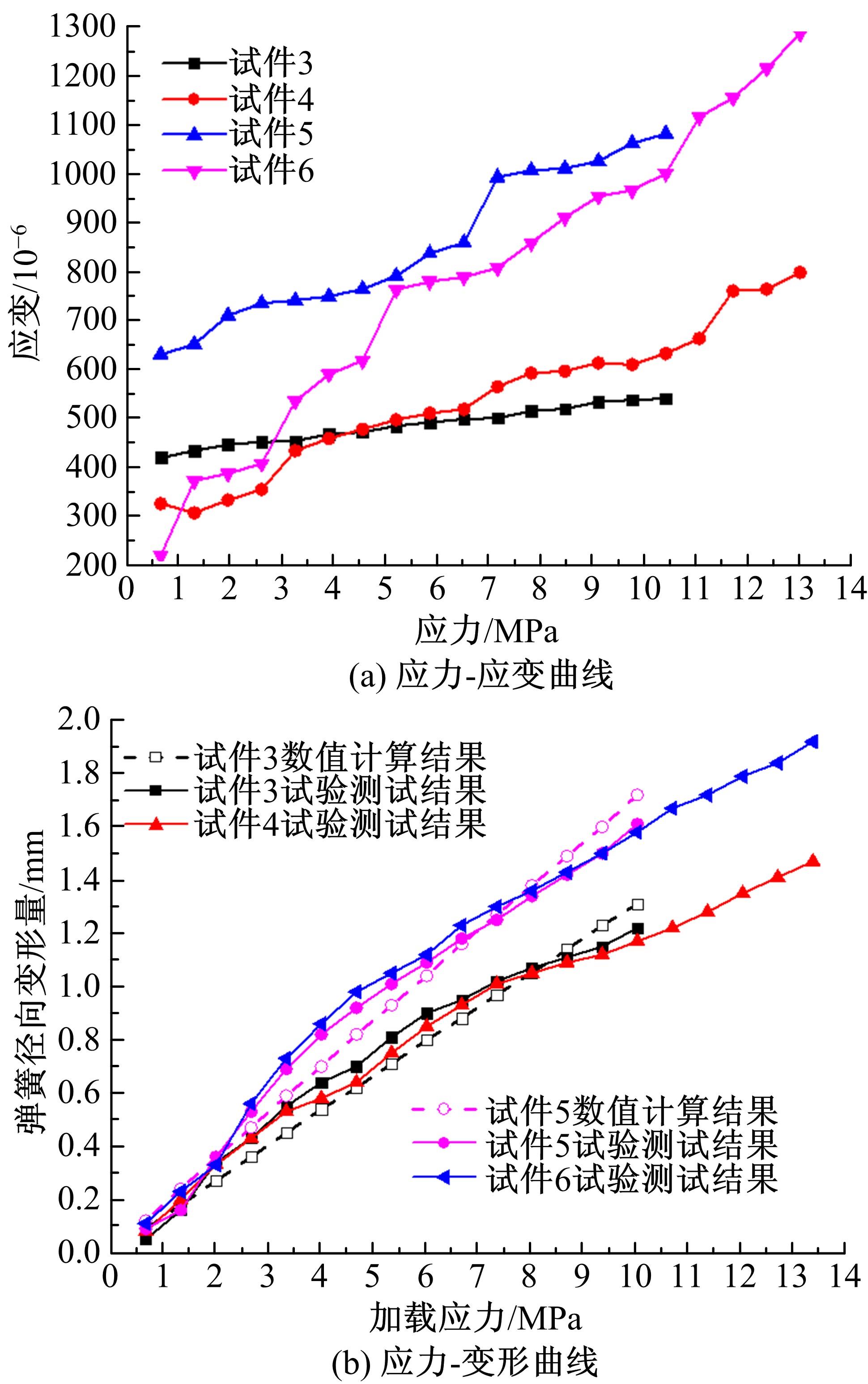

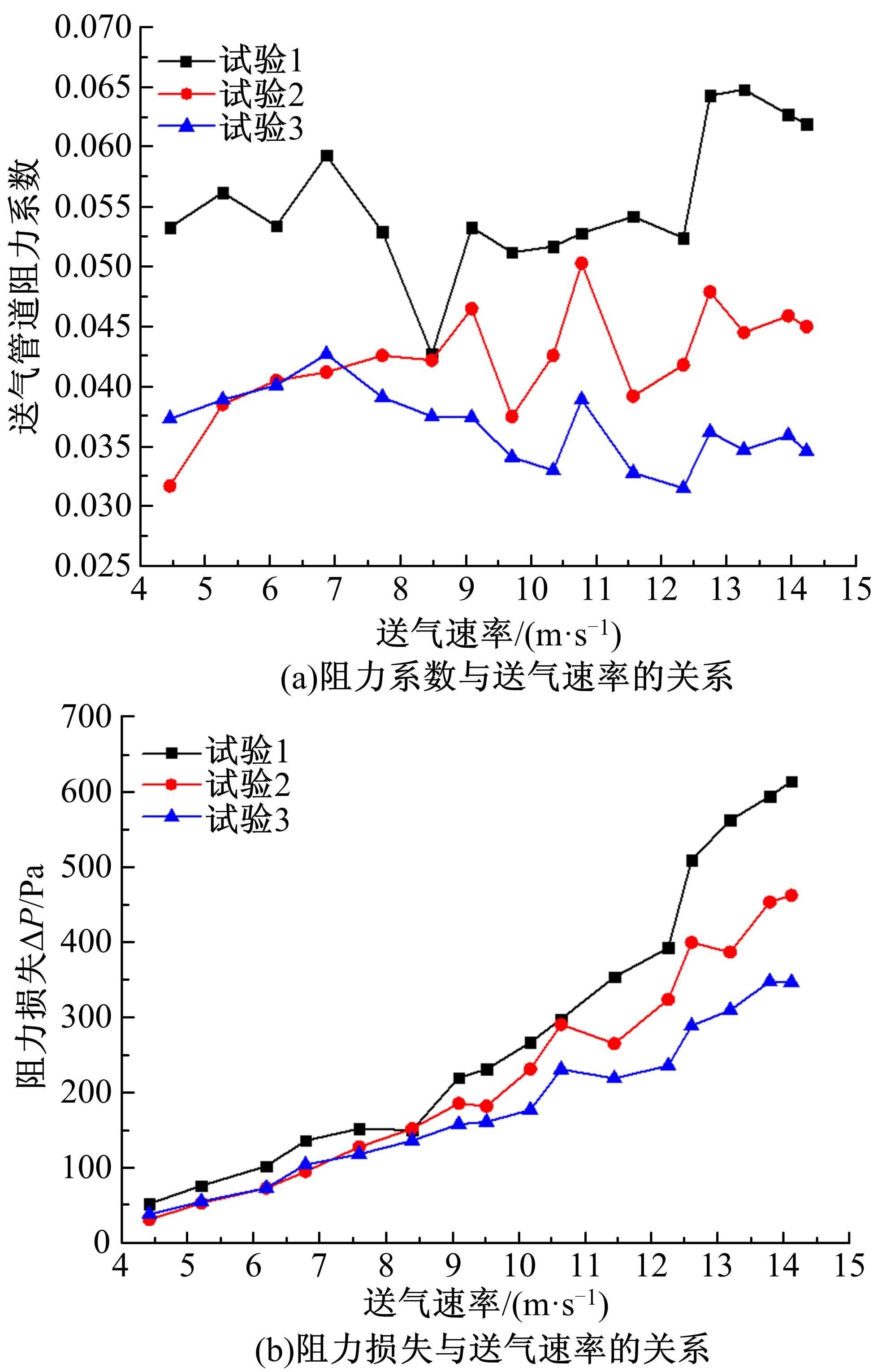

为满足在悬索桥主缆内部使用要求,设计了一种抗压和延伸性能均较好的干空气送气管道结构,采用数值模拟和试验测试的方法对送气管道的抗压性能及送气阻力特性进行了研究。结果表明:内径为50 mm、线径为5 mm、螺距为15~20 mm的304L不锈钢弹簧和波纹管组成的复合式送气管道能承受13.4 MPa的径向压应力作用,满足抗压强度要求;由弹簧和波纹管组成的复合式管道的送气阻力系数显著小于纯弹簧管道,最大可减小46.4%,即复合式送气管道可有效降低干空气输送过程中的压力损失。

中图分类号:

- U443.8

| 1 | 白伦华, 沈锐利, 张兴标, 等. 自锚式悬索桥的面内稳定性[J]. 吉林大学学报: 工学版, 2019, 49(5): 1500-1508. |

| Bai Lun-hua, Shen Rui-li, Zhang Xing-biao, et al. In-plane stability of self-anchored suspension bridge[J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(5): 1500-1508. | |

| 2 | 王保群, 张强勇, 张凯, 等. 自锚式斜拉-悬吊协作体系桥梁动力性能[J]. 吉林大学学报: 工学版, 2009, 39(3): 686-690. |

| Wang Bao-qun, Zhang Qiang-yong, Zhang Kai, et al. Dynamic characteristics for self-anchored cablestayed suspension bridges[J]. Journal of Jilin University(Engineering and Technology Edition), 2009, 39(3): 686-690. | |

| 3 | Shoichi S, Kazuhiko F. Corrosion protection of suspension bridge cables[J]. Construction of Civil Engineering Structures, 2003(7): 35-37, 63. |

| 4 | Shunichi N, Keita S. Experimental study on repair methods of corroded bridge cables[J]. Journal of Bridge Engineering, 2012, 17(4): 720-727. |

| 5 | 陈小雨, 唐茂林. 悬索桥主缆钢丝腐蚀速率计算方法[J]. 公路交通科技, 2019, 36(2): 43-49. |

| Chen Xiao-yu, Tang Mao-lin. A method for calculating corrosion rate of main cable steel wires of suspension bridge[J]. Journal of Highway and Transportation Research and Development, 2019, 36(2): 43-49. | |

| 6 | 魏子杰, 彭福胜, 缪小平, 等. 悬索桥主缆通风除湿数值计算及实验研究[J]. 工程热物理学报, 2016, 37(12): 2495-2501. |

| Wei Zi-jie, Peng Fu-sheng, Miao Xiao-ping, et al. Numerical calculation and experiment on the dehumidification system for main cable of suspension bridge [J]. Journal of Engineering Thermophysics, 2016, 37(12): 2495-2501. | |

| 7 | 王鹏宇. 重庆几江长江大桥主桥设计[J]. 桥梁建设, 2017, 47(2): 72-77. |

| Wang Peng-yu. Design of main bridge of Jijiang Changjiang river bridge in chongqing[J]. Bridge Construction, 2017, 47(2): 72-77. | |

| 8 | 王凤存, 丁亚辉, 徐翾玄, 等. 清水河大桥主缆除湿系统安装施工技术[J]. 公路, 2018, 63(5): 120-124. |

| Wang Feng-cun, Ding Ya-hui, Xu Xuan-xuan, et al. Installation and construction technology of main cable dehumidification system of Qingshuihe Bridge[J]. Highway, 2018, 63(5): 120-124. | |

| 9 | 叶觉明, 李荣庆. 现代悬索桥主缆防护现状与展望[J]. 桥梁建设, 2009(6): 67-71. |

| Ye Jue-ming, Li Rong-qing. State-of-the-art and prospecting of main cable protection of modern suspension bridge[J]. Bridge Construction, 2009(6): 67-71. | |

| 10 | 李海. 润扬大桥悬索桥主缆除湿系统设计与施工[J]. 桥梁建设, 2005(1): 39-41. |

| Li Hai. Design and construction of dehumidification system for main cables of suspension bridge of Runyang Bridge[J]. Bridge Construction, 2005(1): 39-41. | |

| 11 | Miao R S, Shen R L, Wang L, et al. Theoretical and numerical studies of the slip resistance of main cable clamp composed of an upper and a lower part[J]. Advances in Structural Engineering, 2020, 24(4): 691-705. |

| 12 | 沈锐利, 陈巍, 陈鑫, 等. 一种高承压高伸长管道结构[P]. 中国: CN210088192U, 2020-02-18. |

| 13 | 苑磊. 山区公路大管径钢波纹管涵洞受力特征分析与工程应用[D]. 重庆: 重庆交通大学土木工程学院, 2016. |

| Yuan Lei. Force characteristics of mountain highway and engineering application of large diameter steel bellows Culvert[D]. Chongqing: School of Civil Engineering, Chongqing Jiaotong University, 2016. | |

| 14 | Elie P, Benoît T, Marc L. Irradiation-assisted stress corrosion cracking susceptibility and mechanical properties related to irradiation-induced microstructures of 304L austenitic stainless steel[J]. Journal of Nuclear Materials, 2020, 528: 151880. |

| 15 | 彭关中, 缪小平, 贾代勇, 等. 悬索桥主缆通风除湿系统的设计[J]. 深圳大学学报: 理工版, 2013, 30(2): 179-185. |

| Peng Guan-zhong, Miao Xiao-ping, Jia Dai-yong, et al. Design research on dehumidification system for main cable of suspension bridge[J]. Journal of Shenzhen University(Science & Engineering), 2013, 30(2): 179-185. |

| [1] | 高凯,刘纲. 全局临界强度分枝-约界法的有效强度改进[J]. 吉林大学学报(工学版), 2021, 51(2): 597-603. |

| [2] | 宫亚峰,宋加祥,谭国金,毕海鹏,刘洋,单承新. 多车桥梁动态称重算法[J]. 吉林大学学报(工学版), 2021, 51(2): 583-596. |

| [3] | 苏畅,韩颖,张英朝,苗振华. 轮辐设计特征参数对整车气动特性的影响[J]. 吉林大学学报(工学版), 2021, 51(1): 107-113. |

| [4] | 孔庆雯,谭国金,王龙林,王勇,魏志刚,刘寒冰. 基于有限元方法的裂缝箱梁桥自振特性分析[J]. 吉林大学学报(工学版), 2021, 51(1): 225-232. |

| [5] | 陈华,陈耀嘉,谢斌,王鹏凯,邓朗妮. CFRP筋粘结式锚固体系界面失效演化机制及粘结强度计算[J]. 吉林大学学报(工学版), 2020, 50(5): 1698-1708. |

| [6] | 宫亚峰,宋加祥,毕海鹏,谭国金,胡国海,林思远. 装配式箱涵结构缩尺模型静载试验及有限元分析[J]. 吉林大学学报(工学版), 2020, 50(5): 1728-1738. |

| [7] | 高昊,王君杰,刘慧杰,王剑明. 连续梁桥地震行为可控设计准则及实用装置[J]. 吉林大学学报(工学版), 2020, 50(5): 1718-1727. |

| [8] | 蒲黔辉,刘静文,赵刚云,严猛,李晓斌. 高性能树脂混凝土加固混凝土偏压柱承载力理论分析[J]. 吉林大学学报(工学版), 2020, 50(2): 606-612. |

| [9] | 张云龙,郭阳阳,王静,梁东. 钢-混凝土组合梁的固有频率及其振型[J]. 吉林大学学报(工学版), 2020, 50(2): 581-588. |

| [10] | 王伯昕,杨海涛,王清,高欣,陈小旭. 基于补充改进集合经验模态分析法⁃多尺度排列熵分析桥梁振动信号优化滤波方法[J]. 吉林大学学报(工学版), 2020, 50(1): 216-226. |

| [11] | 张淼,钱永久,张方,朱守芹. 基于增大截面法的混凝土加固石拱桥空间受力性能试验分析[J]. 吉林大学学报(工学版), 2020, 50(1): 210-215. |

| [12] | 贾毅,赵人达,王永宝,李福海. 多跨长联连续梁桥粘滞阻尼器参数敏感性分析[J]. 吉林大学学报(工学版), 2019, 49(6): 1871-1883. |

| [13] | 钟春玲,梁东,张云龙,王静. 体外预应力加固简支梁自振频率计算[J]. 吉林大学学报(工学版), 2019, 49(6): 1884-1890. |

| [14] | 白伦华,沈锐利,张兴标,王路. 自锚式悬索桥的面内稳定性[J]. 吉林大学学报(工学版), 2019, 49(5): 1500-1508. |

| [15] | 赵金钢,张明,占玉林,谢明志. 基于塑性应变能密度的钢筋混凝土墩柱损伤准则[J]. 吉林大学学报(工学版), 2019, 49(4): 1124-1133. |

|

||