吉林大学学报(工学版) ›› 2021, Vol. 51 ›› Issue (1): 107-113.doi: 10.13229/j.cnki.jdxbgxb20190960

• 车辆工程·机械工程 • 上一篇

轮辐设计特征参数对整车气动特性的影响

- 吉林大学 汽车仿真与控制国家重点实验室,长春 130022

Influence performance with wheel spoke design parameters of vehicle aerodynamic

Chang SU( ),Ying HAN,Ying-chao ZHANG(

),Ying HAN,Ying-chao ZHANG( ),Zhen-hua MIAO

),Zhen-hua MIAO

- State Key Laboratory of Automotive Simulation and Control,Jilin University,Changchun 130022,China

摘要:

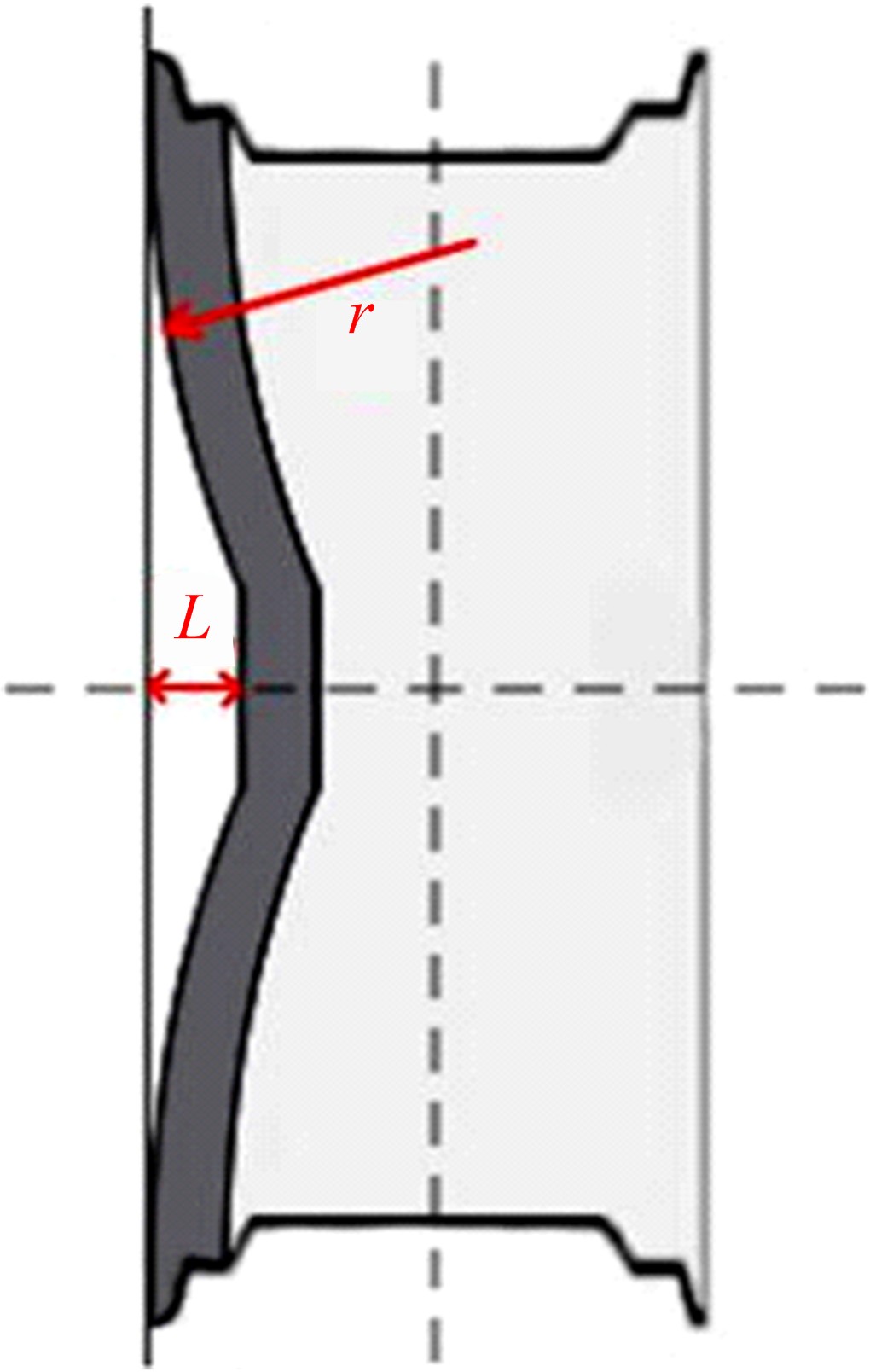

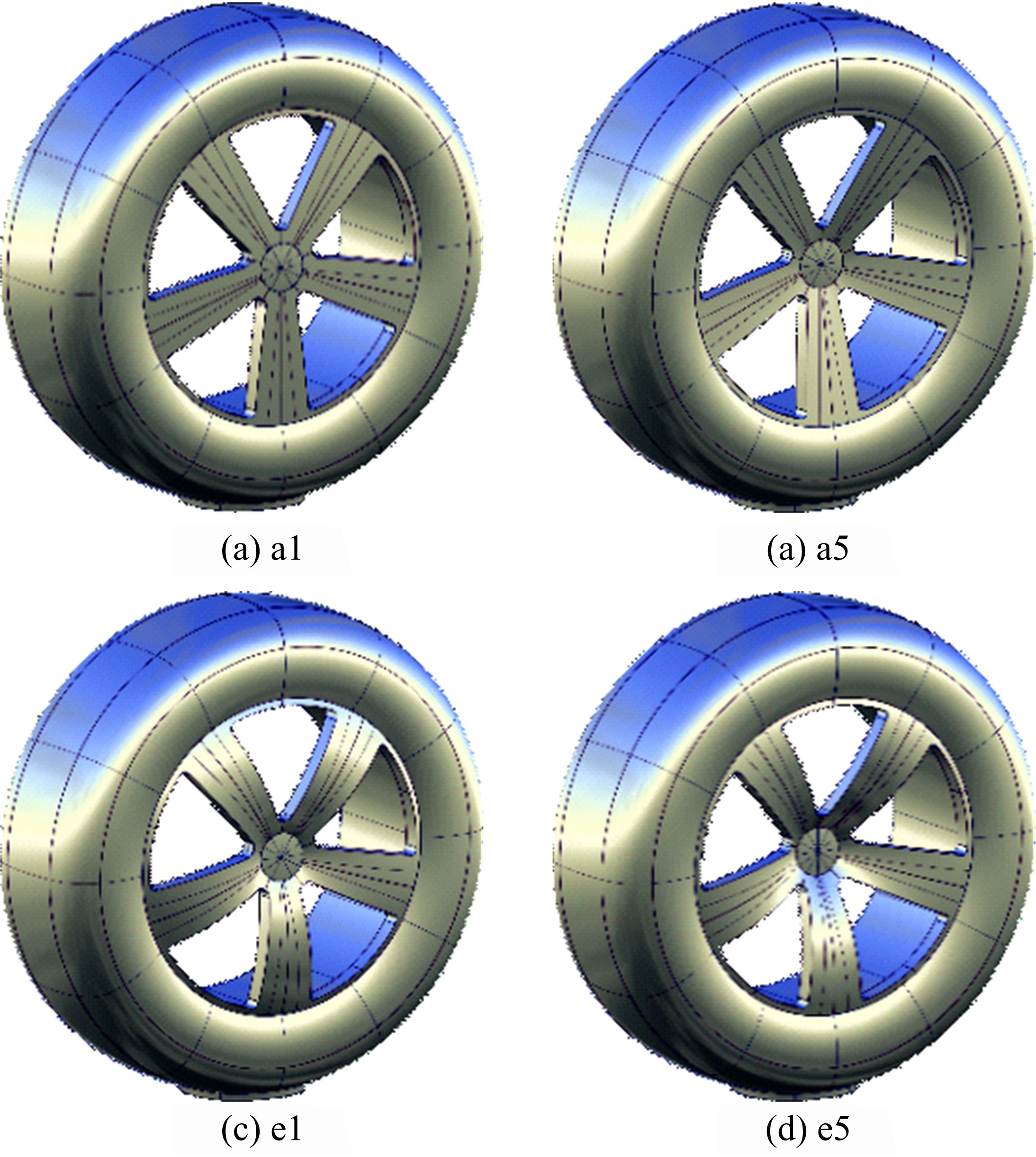

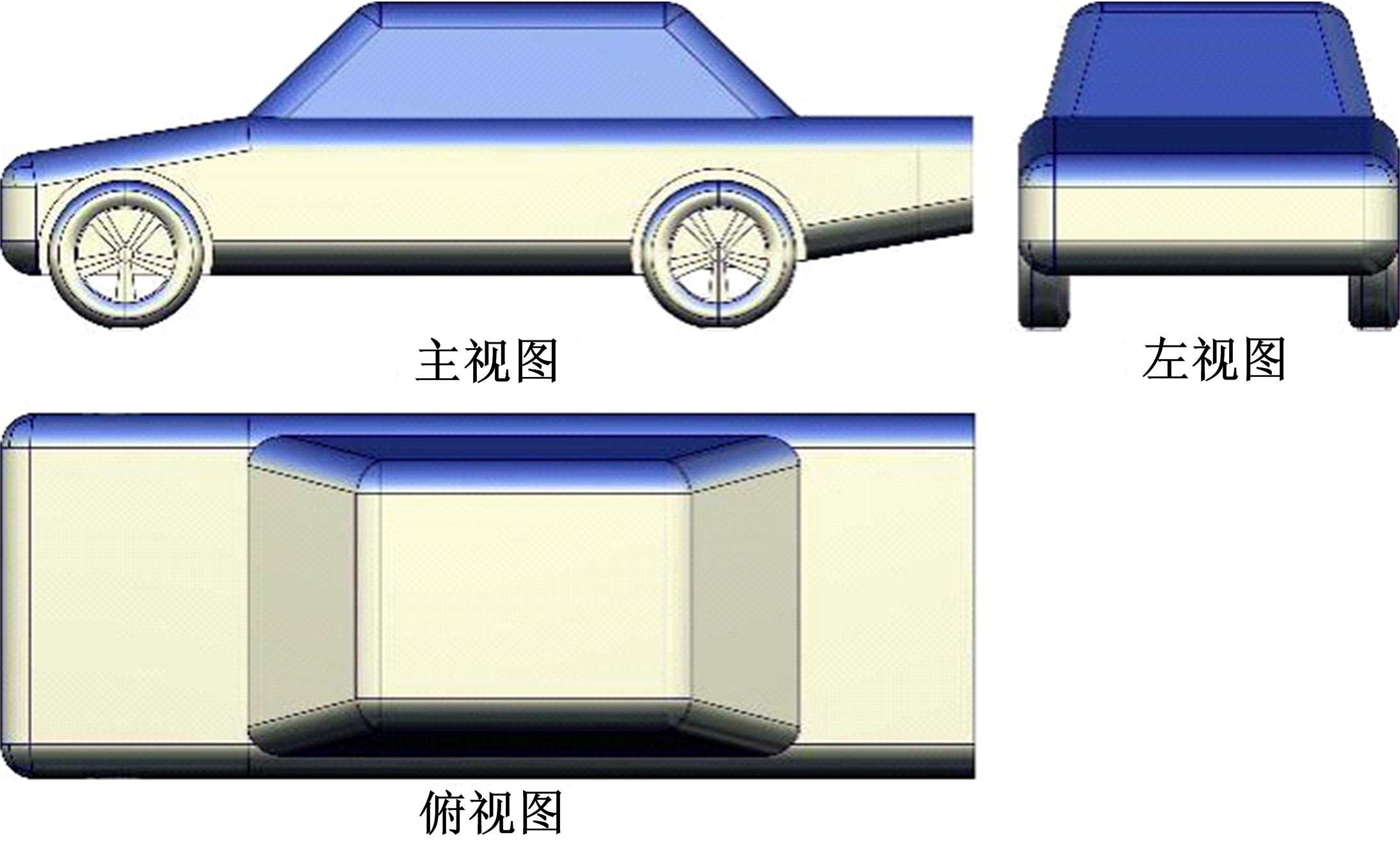

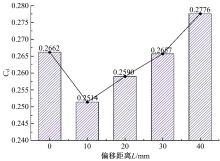

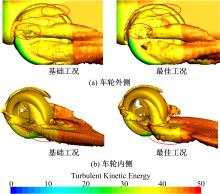

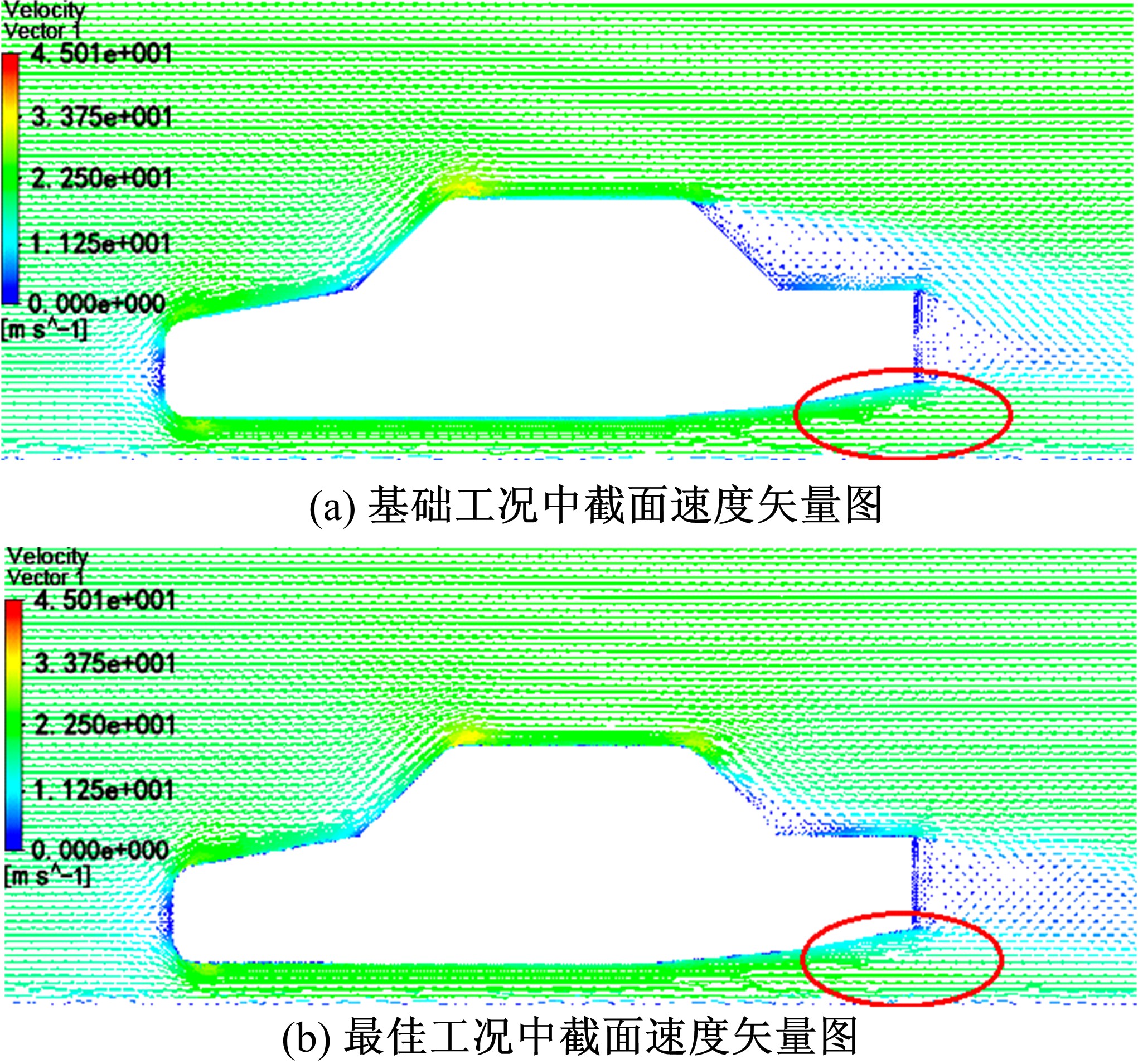

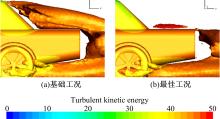

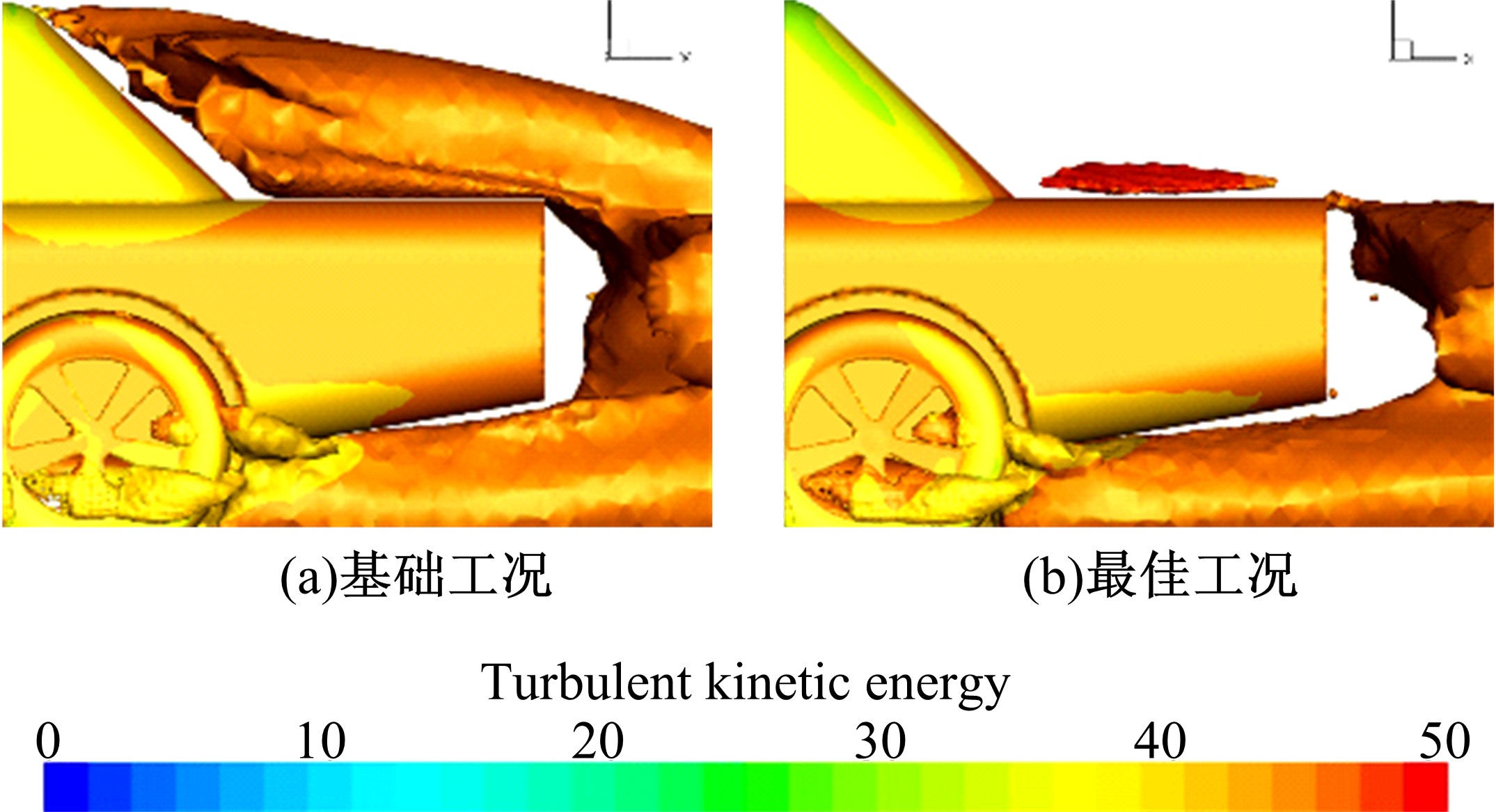

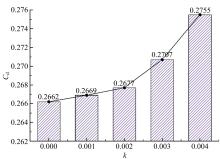

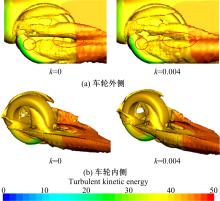

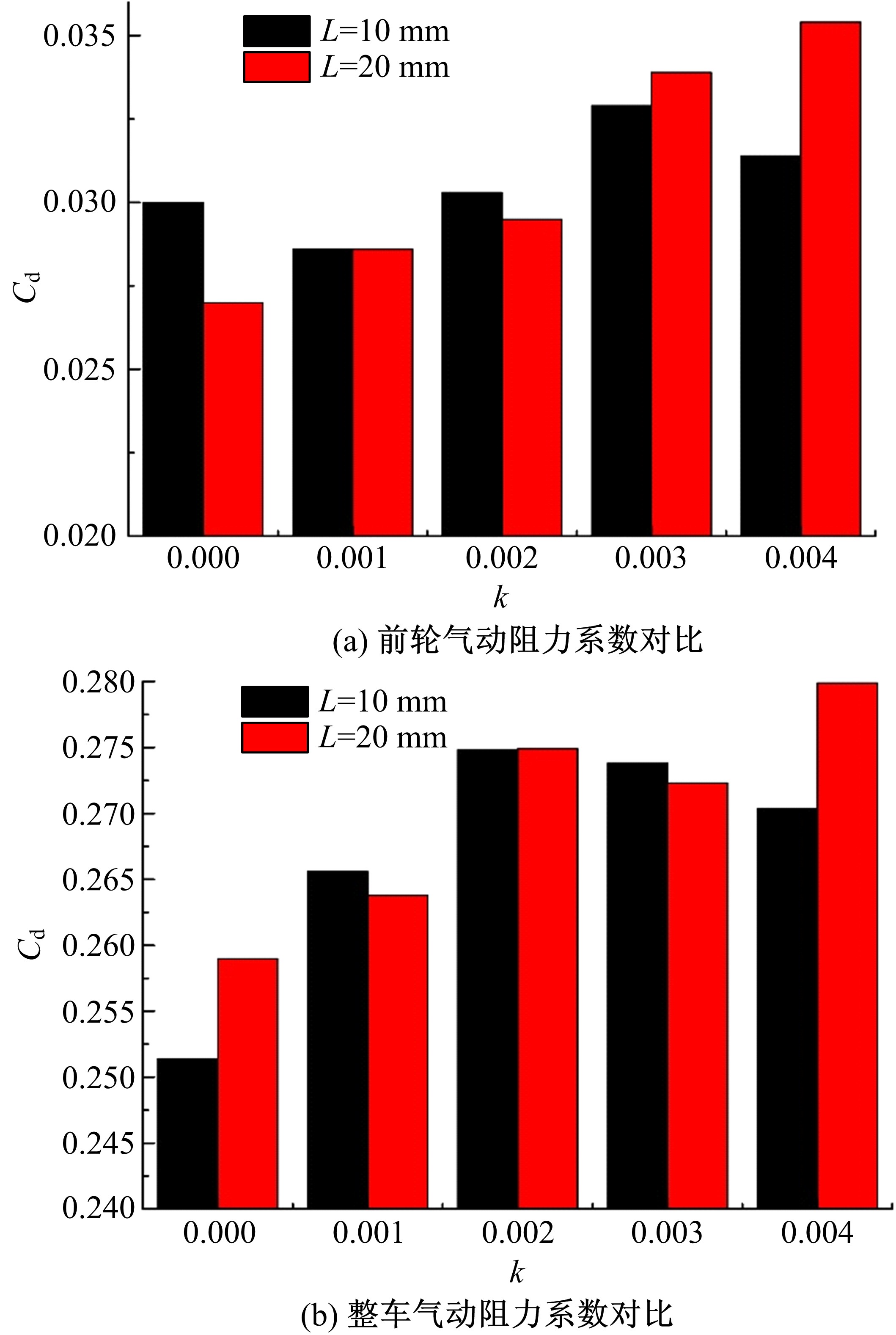

为探究车轮轮辐偏移距离和轮辐曲率对整车气动阻力系数的影响,以改进的MIRA模型为研究对象,在Fluent软件中首先分别探究不同轮辐偏移距离及不同曲率与整车气动阻力系数的关系,分析不同工况减阻及增阻原因;之后将各工况进行组合,探究各组合工况对整车气动阻力系数的影响。仿真结果表明:较小的轮辐偏移距离有利于整车气动阻力系数的降低,且当轮辐偏移距离为10 mm时,整车气动阻力系数最小,仅为0.2514,与基础工况相比减阻率达5.56%;但轮辐曲率的增大会使整车气动阻力系数增大。

中图分类号:

- U461.1

| 1 | Blocken B, van Druenen T, Toparlar Y, et al. Aerodynamic drag in cycling pelotons: new insights by CFD simulation and wind tunnel testing[J]. Journal of Wind Engineering and Industrial Aerodynamics, 2018, 179: 319-337. |

| 2 | 张英朝, 杜冠茂, 田思, 等. 35°Ahmed模型气动射流减阻主动控制[J]. 吉林大学学报: 工学版, 2019, 49(2): 351-358. |

| Zhang Ying-chao, Du Guan-mao, Tian Si, et al. Active flow control of 35°Ahmed model to reduce aerodynamic drag with steady jet[J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(2):351-358. | |

| 3 | Hobeika T, Sebben S. CFD investigation on wheel rotation modelling[J]. Journal of Wind Engineering & Industrial Aerodynamics, 2018, 174: 241-251. |

| 4 | 傅立敏, 胡兴军, 张世村. 车轮辐板开孔对汽车外流场影响的数值模拟[J]. 农业机械学报, 2006, 37(1): 8-11. |

| Fu Li-min, Hu Xing-jun, Zhang Shi-cun. Numerical simulation of influence of holes in wheel spokes on automotive external flow-field[J]. Transactions of the Chinese Society for Agricultural Machinery, 2006, 37(1): 8-11. | |

| 5 | Schnepf B, Schütz T, Indinger T. Further investigations on the flow around a rotating, isolated wheel with detailed tread pattern[J]. SAE International Journal of Passenger Cars-Mechanical System, 2015, 8(1): 261-274. |

| 6 | 谷正气, 林肖辉, 李伟平, 等. 车轮辐板形状对汽车气动阻力影响分析[J]. 科技导报, 2011, 29(6): 57-61. |

| Gu Zheng-qi, Lin Xiao-hui, Li Wei-ping, et al. Effect of the shape of wheel spokes on vehicle aerodynamic performance [J]. Science & Technology Review, 2011, 29(6): 57-61. | |

| 7 | 胡兴军, 傅立敏, 张世村, 等. 具有不同辐板车轮的空气动力学特性研究[J]. 同济大学学报:自然科学版, 2006, 34(12): 1684-1688. |

| Hu Xing-jun, Fu Li-min, Zhang Shi-cun, et al. Research on aerodynamic characteristics of automotive wheels with different wheel spokes[J]. Journal of Tongji University (Natural Science), 2006, 34(12): 1684-1688. | |

| 8 | 王国华, 高青, 刘研, 等. 车轮轮辋内部流场特性分析[C]∥中国汽车工程学会年会论文集.长春:中国汽车工程学会, 2010: 705-708. |

| 9 | Hobeika T, Sebben S, Landstrom C. Investigation of the influence of tyre geometry on the aerodynamics of passenger cars[J]. SAE International Journal of Passenger Cars-Mechanical System, 2013, 6(1): 316-325. |

| 10 | Duncan B D, Kandasamy S, Sbeih K, et al. Further CFD studies for detailed tires using aerodynamics simulation with rolling road conditions[C]∥SAE Paper, 2010-01-0756. |

| 11 | Landstrom C, Josefsson L, Walker T, et al. Aerodynamic effects of different tire models on a sedan type passenger car[J]. SAE International Journal of Passenger Cars-Mechanical System, 2012, 5(1): 136-151. |

| 12 | 周华, 杨志刚, 朱晖. 基于整车风洞试验的MIRA车型数值计算[J]. 吉林大学学报:工学版, 2019, 49(4): 1043-1053. |

| Zhou Hua, Yang Zhi-gang, Zhu Hui. Aerodynamic calculation of MIRA model correlated with wind tunnel test[J]. Journal of Jilin University (Engineering and Technology Edition), 2019, 49(4): 1043-1053. | |

| 13 | Yu X, Jia Q, Bao D, et al. A comparative study of different wheel rotating simulation methods in automotive aerodynamics[C]∥SAE Paper, 2018-01-0728. |

| 14 | Diasinos S, Barber T J, Doig G. The effects of simplifications on isolated wheel aerodynamics[J]. Journal of Wind Engineering and Industrial Aerodynamics, 2015, 146: 90-101. |

| 15 | 贾青, 李挺, 杨志刚. 旋转孤立车轮局部流场的影响评价[J]. 同济大学学报:自然科学版, 2014, 42(2): 287-291. |

| Jia Qing, Li Ting, Yang Zhi-gang. Influence of rotating wheels on isolated wheel aerodynamics[J]. Journal of Tongji University (Natural Science), 2014, 42(2): 287-291. |

| [1] | 兰巍,刘江,辛俐,李婧锡,胡兴军,王靖宇,桑涛. 后视镜造型对侧窗水相分布的影响[J]. 吉林大学学报(工学版), 2020, 50(5): 1590-1599. |

| [2] | 谷诤巍,陈琳,赵立辉,徐虹,李欣,于歌. 轨道车辆窗下补强板冲压成形模拟[J]. 吉林大学学报(工学版), 2020, 50(2): 504-511. |

| [3] | 陈鑫,王宁,沈传亮,冯晓,杨昌海. 后视镜造型对前侧窗气动噪声的影响[J]. 吉林大学学报(工学版), 2020, 50(2): 426-436. |

| [4] | 施卫平,赵旭,胡兴军,余天明,柳博文,段彦. 天然气开采阻水装置AICD的设计和数值模拟[J]. 吉林大学学报(工学版), 2019, 49(6): 1986-1991. |

| [5] | 辛俐,兰巍,刘江,万沁林,郭鹏,胡兴军,肖阳. 汽车涉水车身表面污染仿真及控制[J]. 吉林大学学报(工学版), 2019, 49(6): 1786-1794. |

| [6] | 宫亚峰,王博,谭国金,张立敏,吴文丁,毕海鹏. 吉林省两种典型装配式箱涵受力特性对比分析[J]. 吉林大学学报(工学版), 2019, 49(6): 1865-1870. |

| [7] | 胡兴军,惠政,郭鹏,张扬辉,张靖龙,王靖宇,刘飞. 基于流固耦合的汽车气动特性[J]. 吉林大学学报(工学版), 2019, 49(5): 1414-1419. |

| [8] | 依卓,付文智,李明哲. 双层剖分式超高压模具数值模拟及实验[J]. 吉林大学学报(工学版), 2019, 49(5): 1593-1599. |

| [9] | 李欣,孙延朋,王丹,陈军绪,谷诤巍,徐虹. 汽车前地板成形有限元数值模拟[J]. 吉林大学学报(工学版), 2019, 49(5): 1608-1614. |

| [10] | 张学广,贾明萌,刘纯国,何广忠. 基于增量控制的型材拉弯轨迹设计及有限元仿真[J]. 吉林大学学报(工学版), 2019, 49(4): 1272-1279. |

| [11] | 李欣,王丹,陈军绪,孙延朋,谷诤巍,徐虹. 手刹固定板冲压成形数值模拟[J]. 吉林大学学报(工学版), 2019, 49(4): 1258-1265. |

| [12] | 郭昊添,徐涛,梁逍,于征磊,刘欢,马龙. 仿鲨鳃扰流结构的过渡段换热表面优化设计[J]. 吉林大学学报(工学版), 2018, 48(6): 1793-1798. |

| [13] | 宫亚峰, 王博, 魏海斌, 何自珩, 何钰龙, 申杨凡. 基于Peck公式的双线盾构隧道地表沉降规律[J]. 吉林大学学报(工学版), 2018, 48(5): 1411-1417. |

| [14] | 梁晓波, 蔡中义, 高鹏飞. 夹芯复合板柱面成形的数值模拟及试验[J]. 吉林大学学报(工学版), 2018, 48(3): 828-834. |

| [15] | 刘纯国, 刘伟东, 邓玉山. 多点冲头主动加载路径对薄板拉形的影响[J]. 吉林大学学报(工学版), 2018, 48(1): 221-228. |

|

||