吉林大学学报(工学版) ›› 2021, Vol. 51 ›› Issue (6): 2096-2107.doi: 10.13229/j.cnki.jdxbgxb20200591

• 交通运输工程·土木工程 • 上一篇

胶合竹板-钢管约束收尘石粉混凝土柱的偏压性能

- 1.湘潭大学 土木工程与力学学院,湖南 湘潭 411105

2.华南理工大学 亚热带建筑科学国家重点实验室,广州 510640

3.湖南工业大学 土木工程学院,湖南 株洲 412007

Eccentric compression behavior of bamboo⁃plywood and steel⁃tube dual⁃confined dust⁃powder concrete columns

Jing ZHOU1,2( ),Ya-jun LI1,Wei-feng ZHAO1,Zong-jian LUO1,Guo-bin BU3

),Ya-jun LI1,Wei-feng ZHAO1,Zong-jian LUO1,Guo-bin BU3

- 1.College of Civil Engineering and Mechanics,Xiangtan University,Xiangtan 411105,China

2.State Key Laboratory of Subtropical Building Science,South China University of Technology,Guangzhou 510640,China

3.College of Civil Engineering,Hunan University of Technology,Zhuzhou 412007,China

摘要:

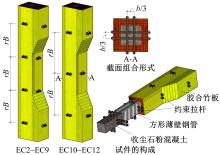

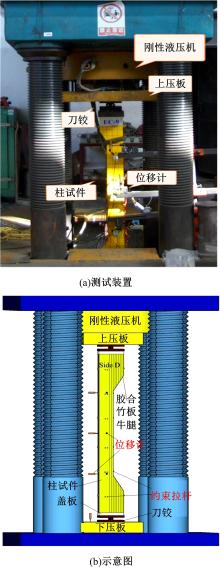

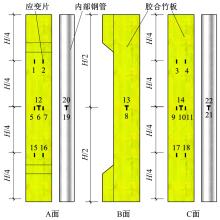

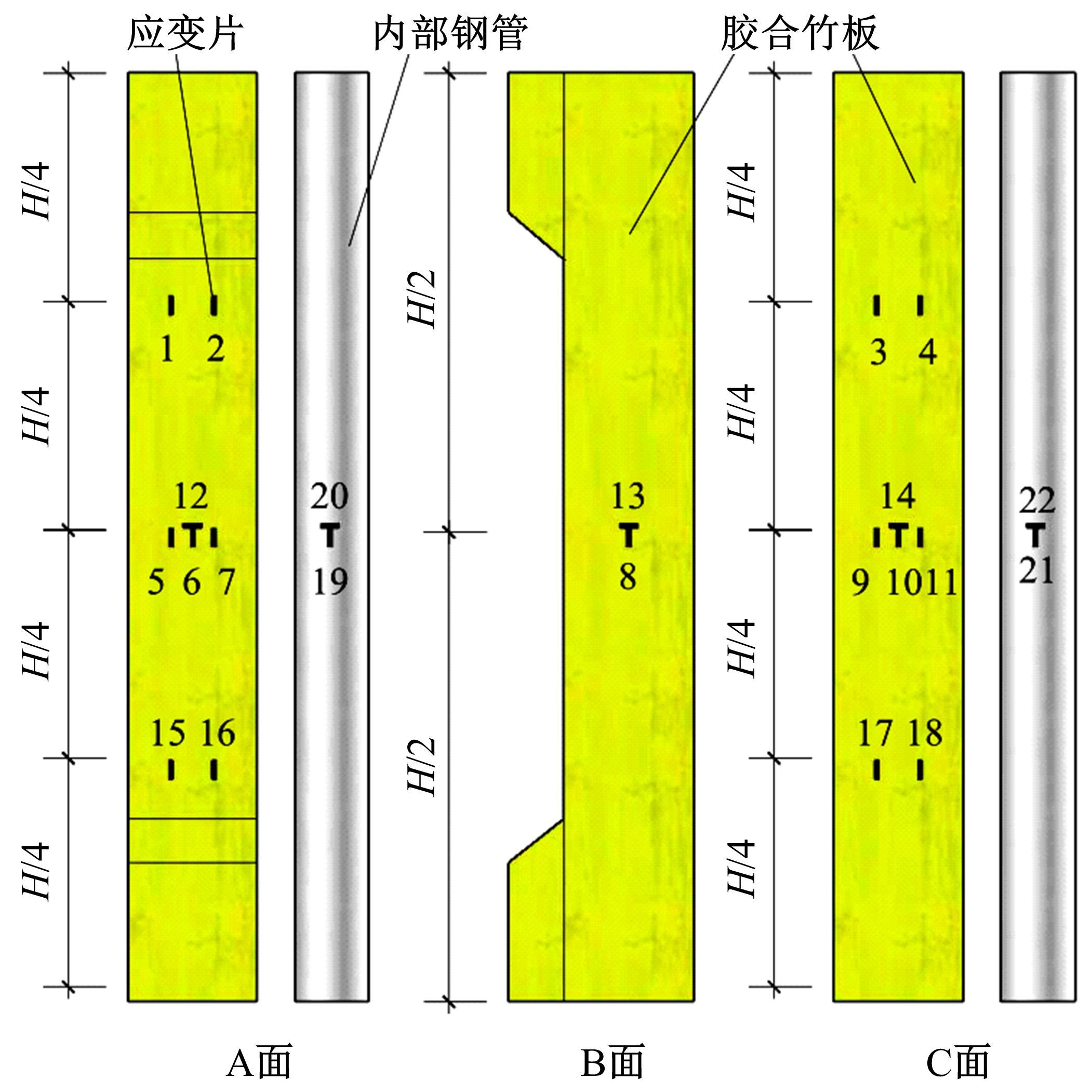

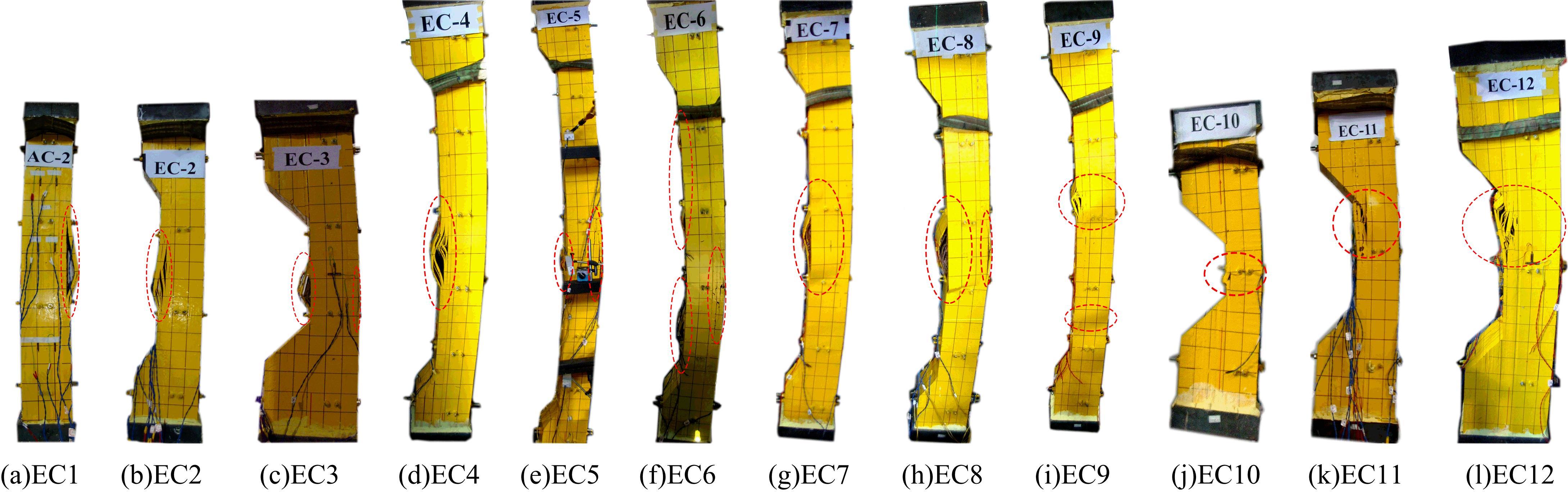

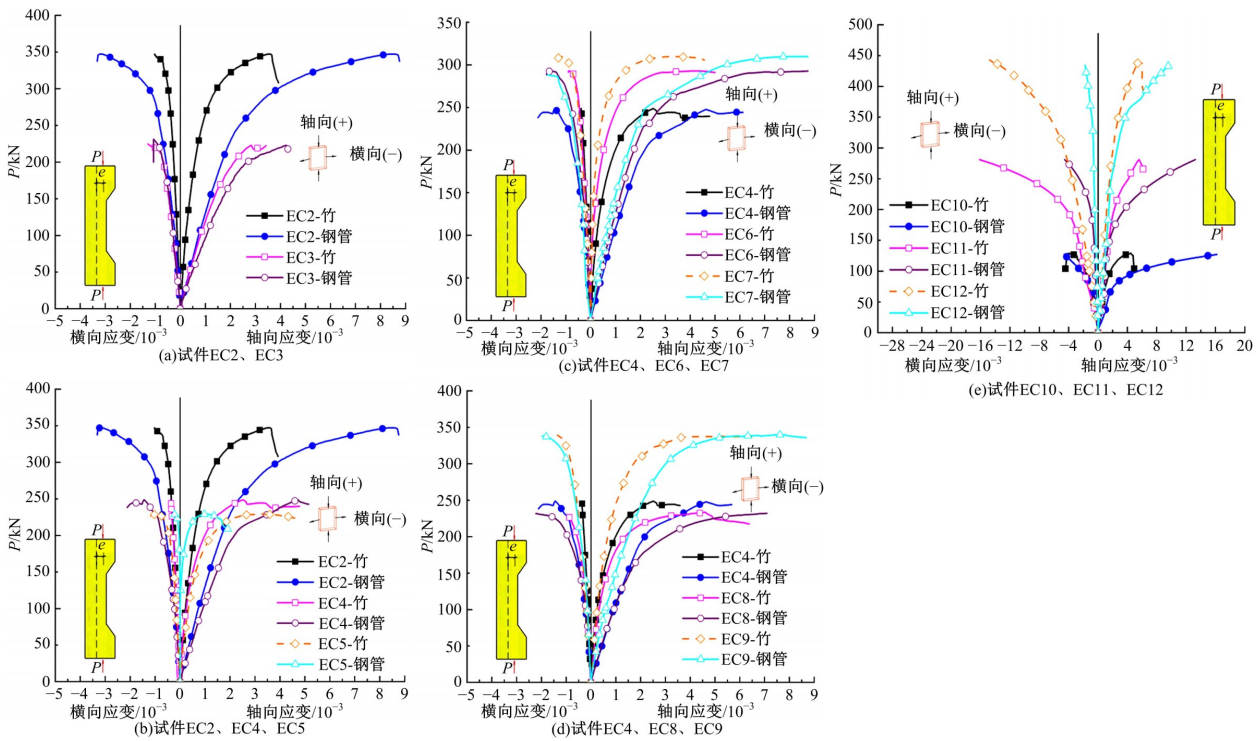

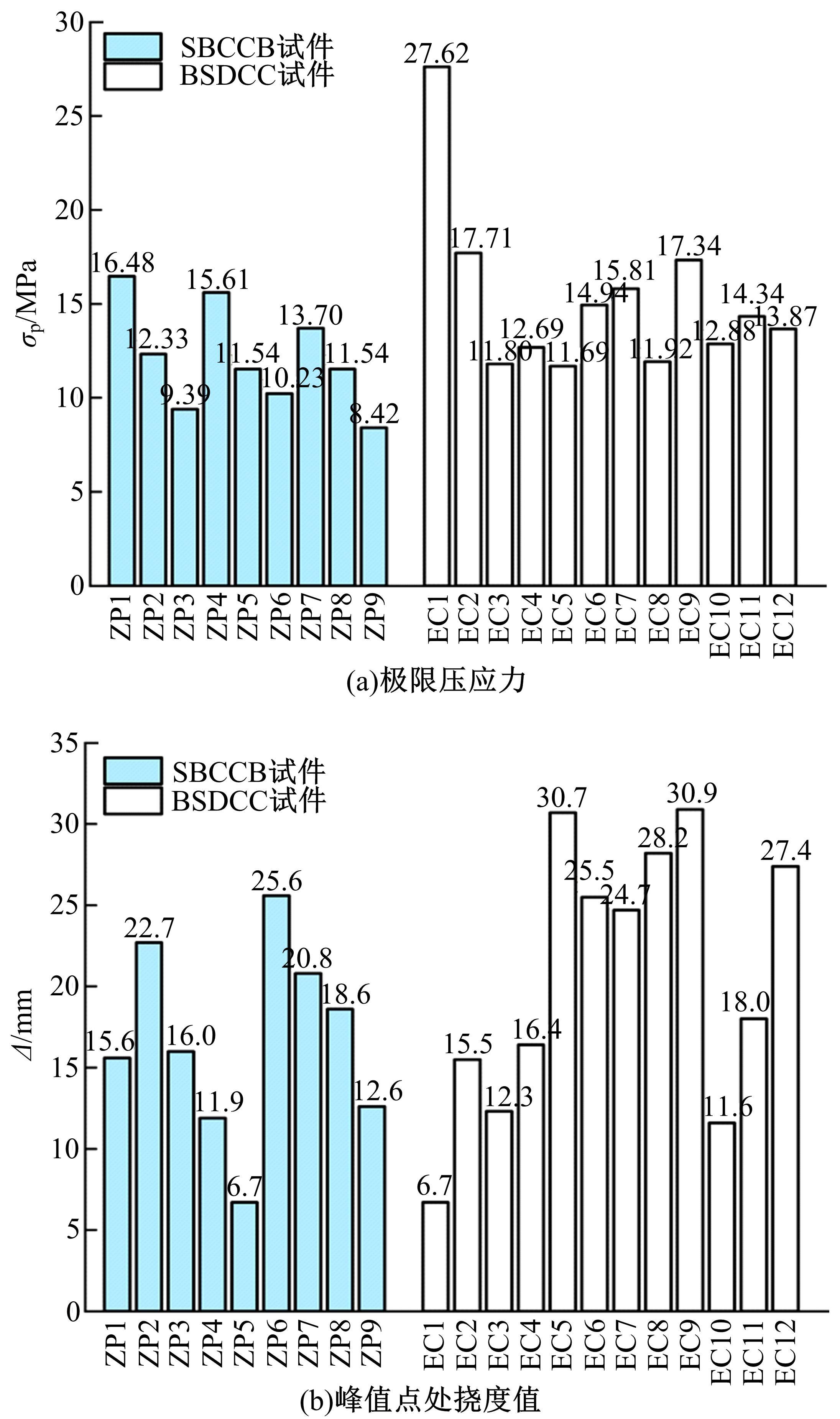

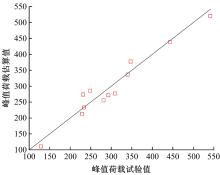

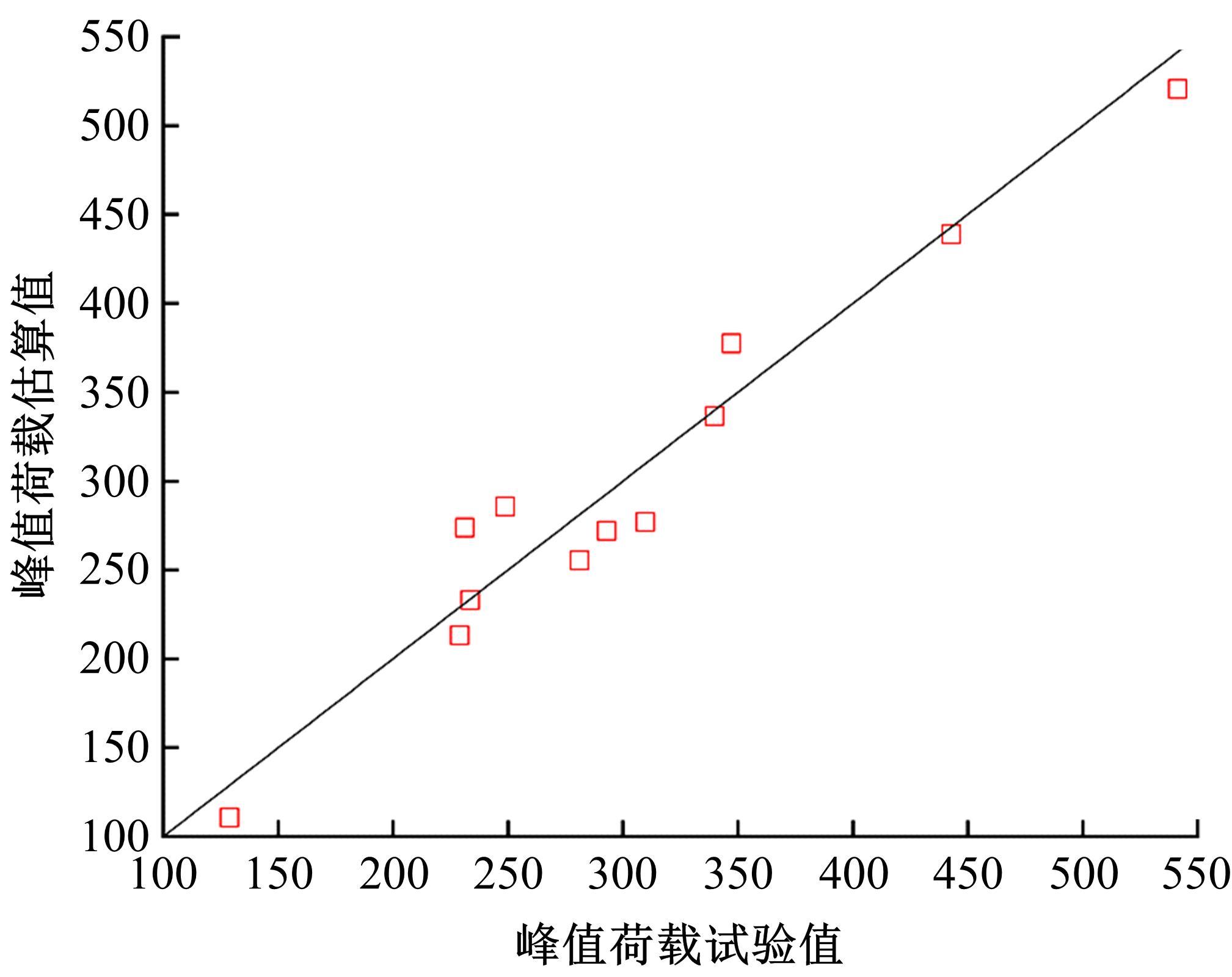

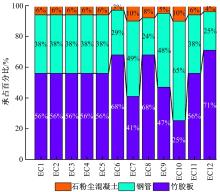

提出了一种新型的胶合竹板-钢管复合约束收尘石粉混凝土柱(BSDCC)构型,可集成开发利用工业固废物和竹材资源。对12根BSDCC试件进行了偏心抗压试验,从试件的表观破损全过程、薄壁钢管的失效形态、载荷-位移曲线以及各基体的应变发展规律等多个角度分析了其破坏机理。通过非线性回归分析,建立了BSDCC偏心抗压承载力计算公式。试验结果表明:BSDCC的偏心抗压破坏形态主要为柱身中部横向约束拉杆之间的胶合竹板开胶剥离破坏和胶合竹板材料局部压屈破坏,其极限载荷不仅与偏心距、长细比、截面积和含钢率相关,而且受约束拉杆间距比的影响明显;钢管内填充低强度的收尘石粉混凝土可有效改变试件的极限破坏模式,提高极限承载力;与胶合竹板-薄壁钢管空芯柱的极限压应力相比,BSDCC的极限压应力平均提高了25%。

中图分类号:

- TU398.9

| 1 | Dehwah H A F.Mechanical properties of self-compacting concrete incorporating quarry dust powder,silica fume or fly ash[J]. Construction and Building Materials, 2011, 26(1):547-551. |

| 2 | Saghafi B, Nageim H A, Atherton W. Mechanical behavior of a new base material containing high volumes of limestone waste dust, PFA, and APC residues[J]. Journal of Materials in Civil Engineering, 2013, 25(4):450-461. |

| 3 | Kandolkar S, Mandal J. Behavior of reinforced stone dust walls under strip loading[J]. Advances in Civil Engineering Materials, 2015, 4(1):1-30. |

| 4 | Singh S, Nagar R, Agrawal V. A review on properties of sustainable concrete using granite dust as replacement for river sand[J]. Journal of Cleaner Production, 2016, 126(10):74-87. |

| 5 | Febin G K, Abhirami A, Vineetha A K, et al. Strength and durability properties of quarry dust powder incorporated concrete blocks[J]. Construction and Builing Materials, 2019, 228:1-9. |

| 6 | 郑大为, 韩红静, 郝连学. 回收粉尘的掺量对水泥稳定碎石基层的影响研究[J]. 硅酸盐通报, 2017, 36(7):2476-2480, 2491. |

| Zheng Da-wei, Han Hong-jing, Hao Lian-xue. Influence of the amount of recycled dust on cement stabilized crushed stone base[J]. Bulletin of the Chinese Ceramic Society, 2017, 36(7):2476-2480, 2491. | |

| 7 | Xiao Y, Chen G, Feng L. Experimental studies on roof trusses made of glubam[J]. Materials and Structures, 2014, 47(11):1879-1890. |

| 8 | Xu Q F, Chen L Z, Harries K A. et al. Combustion performance of engineered bamboo from cone calorimeter tests[J]. European Journal of Wood and Wood Products, 2017, 75(2):161-173. |

| 9 | Huang D S, Bian Y L, Zhou A P, et al. Experimental study on stress-strain relationships and failure mechanisms of parallel strand bamboo made from Phyllostachys[J].Construction and Building Materials, 2015, 77:130-138. |

| 10 | 马丽, 周凌, 何慧, 等. 竹粉高温蒸煮对竹粉/ABS木塑复合材料性能的影响[J]. 吉林大学学报:工学版, 2011, 41():205-209. |

| Ma Li, Zhou Ling, He Hui, et al. Effect on properties of bamboo/ABS composites by high-temperature cooking of bamboo[J]. Journal of Jilin University(Engineering and Technology Edition), 2011, 41(Sup.2):205-209. | |

| 11 | Yu D, Tan H, Ruan Y. A future bamboo-structure residential building prototype in China:life cycle assessment of energy use and carbon emission[J]. Energy and Buildings, 2011, 43(10):2638-2646. |

| 12 | Sharma B, Gatoo A, Bock M, et al. Engineered bamboo for structural applications[J]. Construction and Building Materials, 2015, 81:66-73. |

| 13 | 李海涛, 张齐生, 吴刚, 等. 竹集成材研究进展[J]. 林业工程学报, 2016, 1(6):10-16. |

| Li Hai-tao, Zhang Qi-sheng, Wu Gang, et al. A review on development of laminated bamboo lumber[J]. Journal of Forestry Engineering, 2016, 1(6):10-16. | |

| 14 | 肖岩, 杨瑞珍, 单波, 等. 结构用胶合竹力学性能试验研究[J]. 建筑结构学报, 2012, 33(11):150-157. |

| Xiao Yan, Yang Rui-zhen, Shan Bo, et al. Experimental research on mechanical properties of glubam[J]. Journal of Building Structures, 2012, 33(11):150-157. | |

| 15 | Sharma B, Gatóo A, Ramage M H. Effect of processing methods on the mechanical properties of engineered bamboo[J]. Construction and Building Materials, 2015, 83:95-101. |

| 16 | 郭楠, 张平阳, 左煜, 等. 竹板增强胶合木梁受弯性能[J]. 吉林大学学报: 工学版, 2017, 47(3):778-788. |

| Guo Nan, Zhang Ping-yang, Zuo Yu, et al. Bending performance of glue-lumber beam reinforced by bamboo plyboard[J]. Journal of Jilin University(Engineering and Technology Edition), 2017, 47(3):778-788. | |

| 17 | Yu W K, Chung K F, Chan S L. Axial buckling of bamboo columns in bamboo scaffolds[J]. Engineering Structures, 2005, 27(1):61-73. |

| 18 | Lugt P, Dobbelsteen A A J F, Janssen J J A. An environmental,economic and practical assessment of bamboo as a building material for supporting structures[J]. Construction and Builing Materials, 2006, 20(9):648-656. |

| 19 | He M J, Li Z,Sun Y L, et al. Experimental investigations on mechanical properties and column buckling behavior of structural bamboo[J]. Structural Design of Tall and Special Buildings, 2015, 24(7):491-503. |

| 20 | Tian L M, Kou Y F, Hao J P. Axial compressive behaviour of sprayed composite mortar-original bamboo composite columns[J]. Construction and Building Materials, 2019, 215:726-736. |

| 21 | Li H, Su J W, Zhang Q, et al. Mechanical performance of laminated bamboo column under axial compression[J]. Composites Part B: Engineering, 2015, 79:374-382. |

| 22 | Li H T, Liu R, Lorenzo R, et al. Eccentric compression properties of laminated bamboo columns with different slenderness ratios[J]. Proceedings of the Institution of Civil Engineers:Structures and Buildings, 2019, 172(5):315-326. |

| 23 | 魏洋, 周梦倩, 袁礼得. 重组竹柱偏心受压力学性能[J]. 复合材料学报,2016,33(2):379-385. |

| Wei Yang, Zhou Meng-qian, Yuan Li-de. Mechanical performance of glulam bamboo columns under eccentric loading[J]. Acta Materiae Compositae Sinica, 2016, 33(2):379-385. | |

| 24 | Xiao Y, Zhou Q, Shan B. Design and construction of modern bamboo bridges [J]. Journal of Bridge Engineering, 2010, 15(5):533-541. |

| 25 | Li H T, Chen G, Zhang Q S, et al. Mechanical properties of laminated bamboo lumber column under radial eccentric compression[J]. Construction and Building Materials, 2016, 121:644-652. |

| 26 | 李冀, 陈思甜, 孟旭. 箍筋增强型胶合竹柱抗压试验[J]. 林业科技开发, 2014, 28(4):113-115. |

| Li Ji, Chen Si-tian, Meng Xu. Compression test of stirrup reinforced glued bamboo columns[J]. China Forestry Science and Technology, 2014, 28(4): 113-115. | |

| 27 | 赵卫锋, 张武东, 周靖, 等. 薄壁方型钢管/竹胶板组合空芯柱轴心抗压性能[J]. 农业工程学报, 2014, 30(6):37-45. |

| Zhao Wei-feng, Zhang Wu-dong, Zhou Jing, et al. Axial compression behavior of square thin-walled steel tube/laminated bamboo composite hollow column [J]. Transactions of Chinese Society of Agricultural Engineering, 2014, 30(6):37-45. | |

| 28 | 赵卫锋, 谷伟, 周靖, 等. 带约束拉杆钢管/竹胶板组合空芯短柱的偏心抗压性能[J]. 农业工程学报, 2016, 32(15):75-82. |

| Zhao Wei-feng, Gu Wei, Zhou Jing, et al. Eccentric compression behavior of thin-walled steel-tube/bamboo-plywood assembling short hollow column with binging bars[J]. Transactions of Chinese Society of Agricultural Engineering, 2016, 32(15):75-82. | |

| 29 | Zhao W F, Yang B, Zhou J. Axial compressive creep behaviour of a square steel tube/bamboo plywood composite column with binding bars[J]. Wood Research, 2019, 64(2):223-236. |

| 30 | 解其铁, 张王丽, 蒋天元, 等. 钢-竹组合柱轴心受压性能的试验研究[J]. 工程力学, 2012, 29():221-225. |

| Xie Qi-tie, Zhang Wang-li, Jiang Tian-yuan, et al. Experimental study on performance of steel-bamboo composite column under axial compression[J]. Engineering Mechanics, 2012, 29(Sup.2):221-225. | |

| 31 | . 金属材料室温拉伸试验方法[S]. |

| 32 | . 木结构试验方法标准[S]. |

| 33 | Park R, Priestley M J N, Gill W D.Ductility of square-confined concrete columns[J]. Journal of the Structural Division, 1982,108(4): 929-950. |

| 34 | . 木结构设计标准[S]. |

| [1] | 钟昌均,王忠彬,柳晨阳. 悬索桥主索鞍承载力影响因素及结构优化[J]. 吉林大学学报(工学版), 2021, 51(6): 2068-2078. |

| [2] | 张广泰,张路杨,邢国华,曹银龙,易宝. 钢-聚丙烯混杂纤维混凝土剪力墙抗震性能[J]. 吉林大学学报(工学版), 2021, 51(3): 946-955. |

| [3] | 刘柳,冯卫星. 基于NNBR模型的隧道盾构施工地表沉降实测与计算分析[J]. 吉林大学学报(工学版), 2021, 51(1): 245-251. |

| [4] | 许卫晓,程扬,杨伟松,鞠佳昌,于德湖. RC框架⁃抗震墙并联结构体系拟静力试验[J]. 吉林大学学报(工学版), 2021, 51(1): 268-277. |

| [5] | 单德山,张潇,顾晓宇,李乔. 斜拉索悬链线构形的伸长量解析计算方法[J]. 吉林大学学报(工学版), 2021, 51(1): 217-224. |

| [6] | 薛素铎,鲁建,李雄彦,刘人杰. 跳格布置对环形交叉索桁结构静动力性能的影响[J]. 吉林大学学报(工学版), 2020, 50(5): 1687-1697. |

| [7] | 王勃,董元正,董丽欣. 基于短期风速资料的基本风压计算方法[J]. 吉林大学学报(工学版), 2020, 50(5): 1739-1746. |

| [8] | 李明,王浩然,赵唯坚. 单向带抗剪键叠合板的受力性能试验[J]. 吉林大学学报(工学版), 2020, 50(2): 654-667. |

| [9] | 王鹏辉,乔宏霞,冯琼,曹辉,温少勇. 氯氧镁涂层钢筋混凝土两重因素耦合作用下的耐久性模型[J]. 吉林大学学报(工学版), 2020, 50(1): 191-201. |

| [10] | 李明,王浩然,赵唯坚. 带抗剪键叠合板的力学性能[J]. 吉林大学学报(工学版), 2019, 49(5): 1509-1520. |

| [11] | 张军,钱诚,郭春燕,钱玉君. 基于多源时空数据的建筑宜居性动态设计[J]. 吉林大学学报(工学版), 2019, 49(4): 1169-1173. |

| [12] | 梁宁慧,缪庆旭,刘新荣,代继飞,钟祖良. 聚丙烯纤维增强混凝土断裂韧度及软化本构曲线确定[J]. 吉林大学学报(工学版), 2019, 49(4): 1144-1152. |

| [13] | 张磊,刘保国,储昭飞. 深厚孔隙砂岩含水层疏干排水对盾构斜井的 影响模型试验[J]. 吉林大学学报(工学版), 2019, 49(3): 788-797. |

| [14] | 郑一峰, 赵群, 暴伟, 李壮, 于笑非. 大跨径刚构连续梁桥悬臂施工阶段抗风性能[J]. 吉林大学学报(工学版), 2018, 48(2): 466-472. |

| [15] | 王腾, 周茗如, 马连生, 乔宏霞. 基于断裂理论的湿陷性黄土劈裂注浆裂纹扩展[J]. 吉林大学学报(工学版), 2017, 47(5): 1472-1481. |

|

||