吉林大学学报(工学版) ›› 2020, Vol. 50 ›› Issue (2): 654-667.doi: 10.13229/j.cnki.jdxbgxb20181062

• 交通运输工程·土木工程 • 上一篇

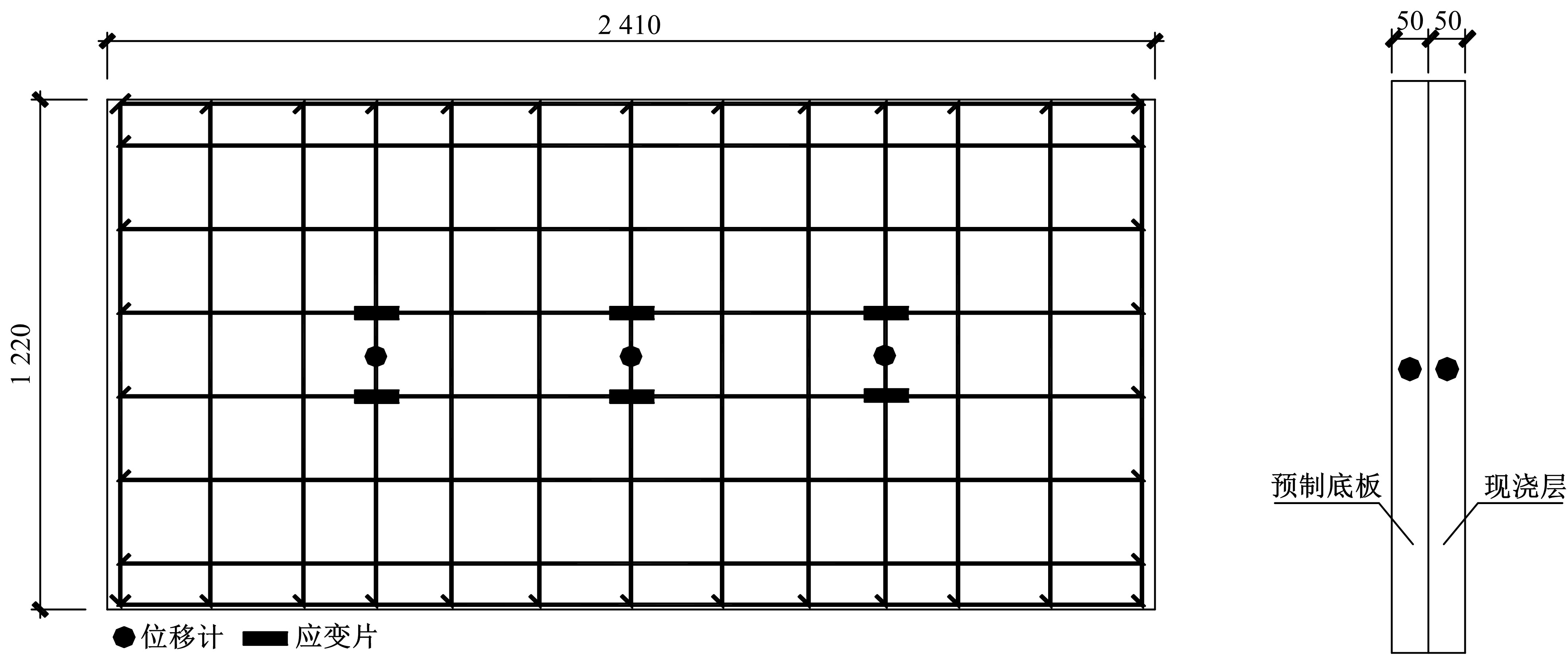

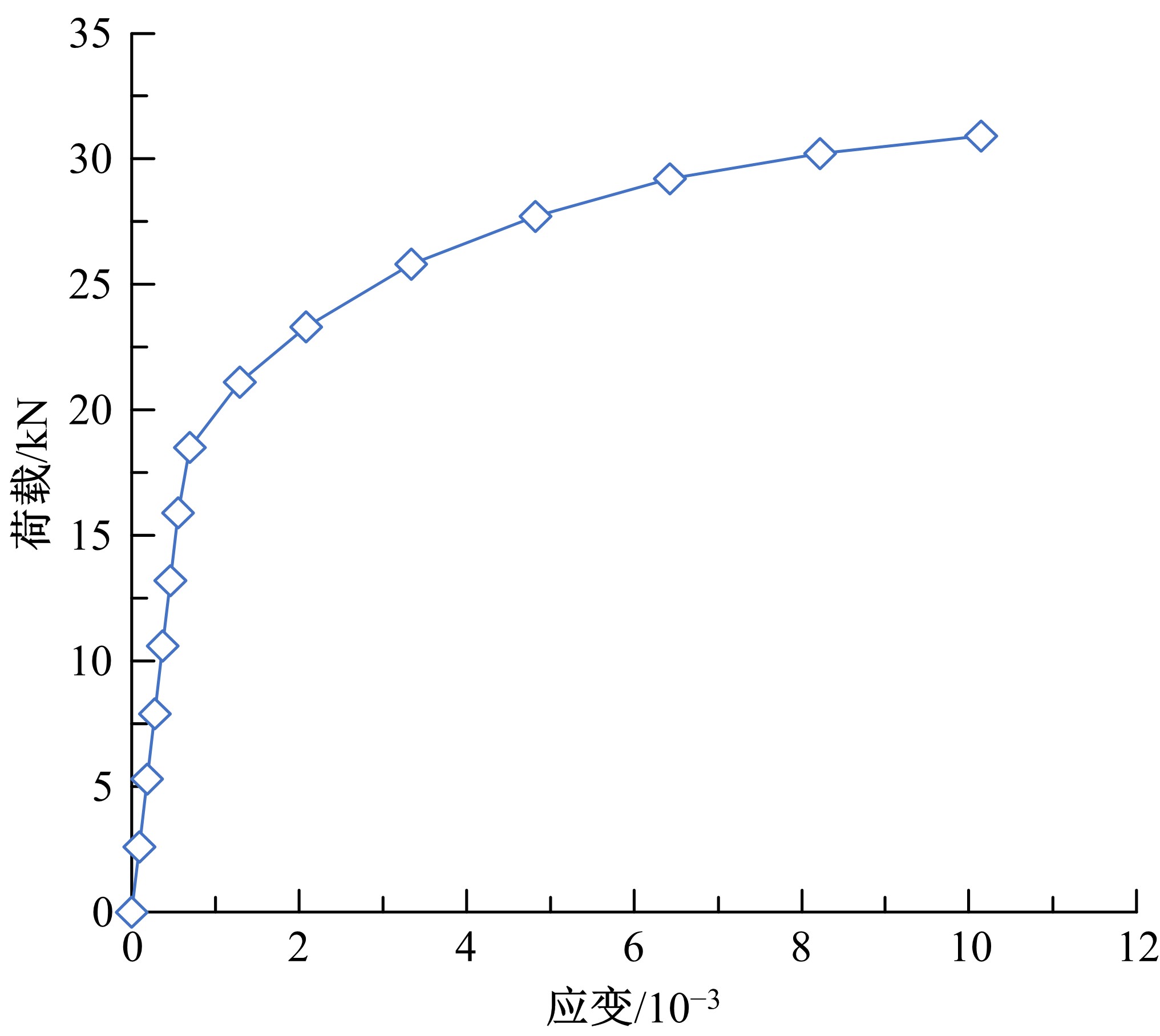

单向带抗剪键叠合板的受力性能试验

- 1.沈阳建筑大学 土木工程学院,沈阳 110168

2.浙江大学 建筑工程学院,杭州 310058

Experimental of loading-bearing capacity of one-way laminated slab with shear keys

Ming LI1( ),Hao-ran WANG1,Wei-jian ZHAO2

),Hao-ran WANG1,Wei-jian ZHAO2

- 1.School of Civil Engineering,Shenyang Jianzhu University,Shenyang 110168,China

2.College of Civil Engineering and Architecture,Zhejiang University, Hangzhou 310058,China

摘要:

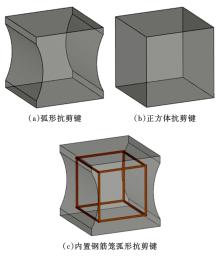

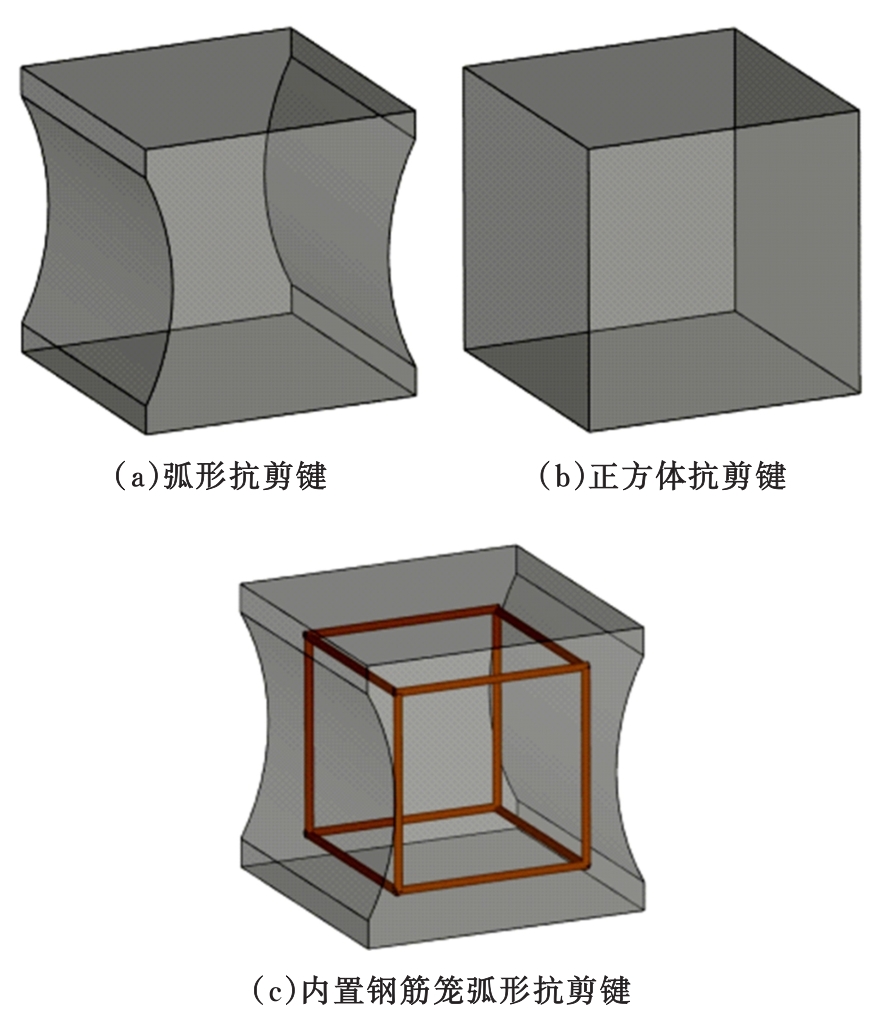

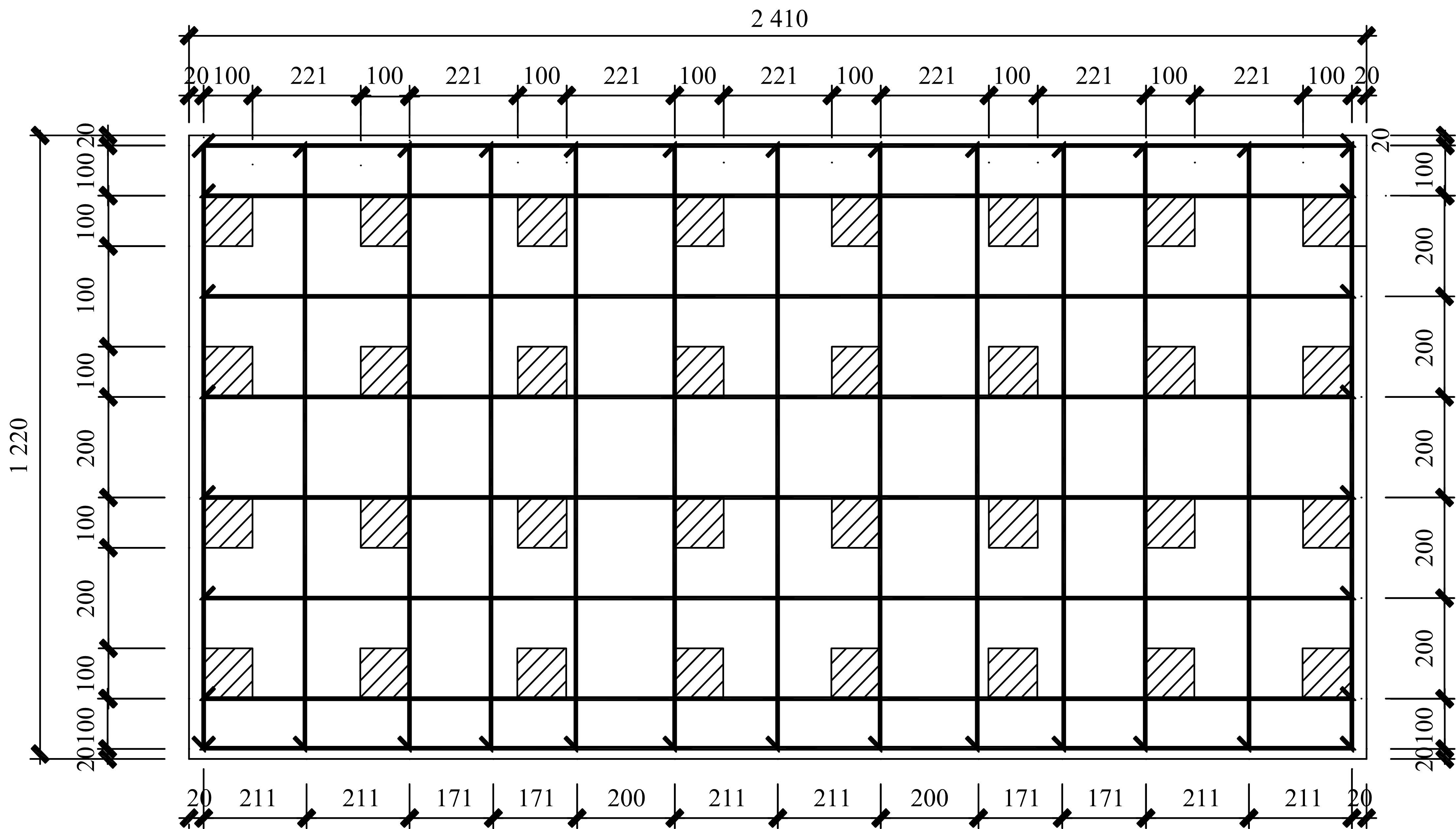

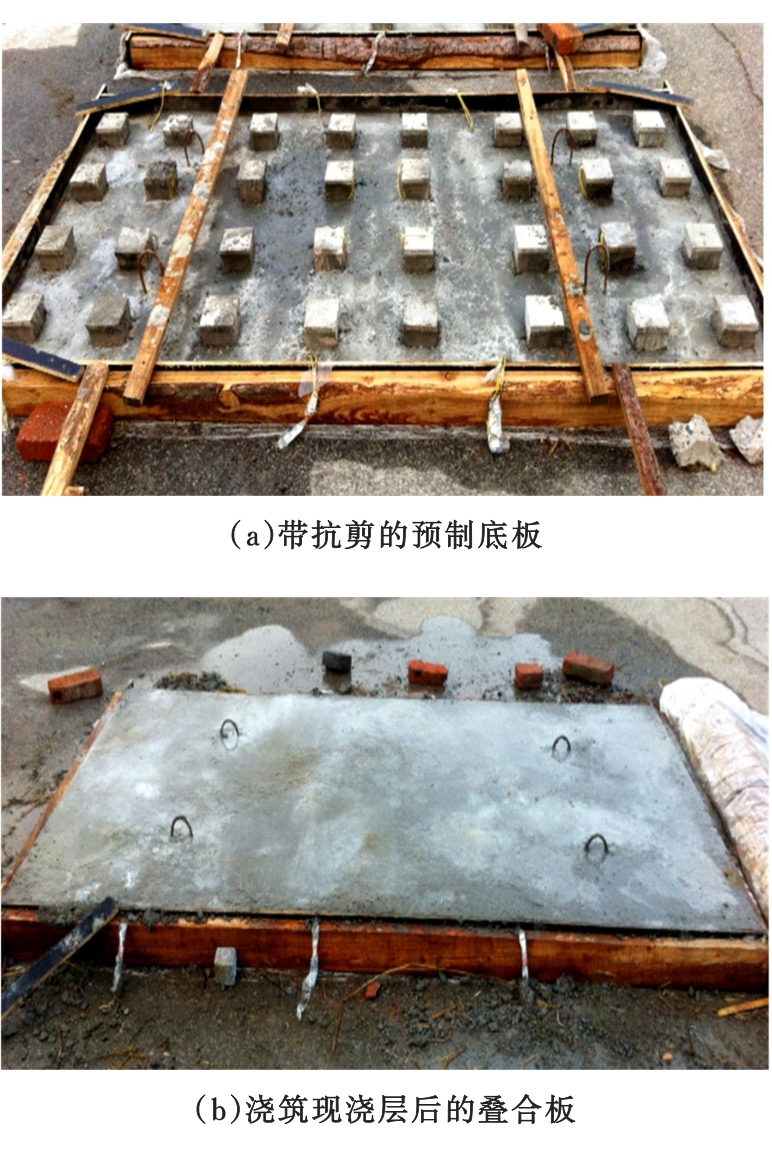

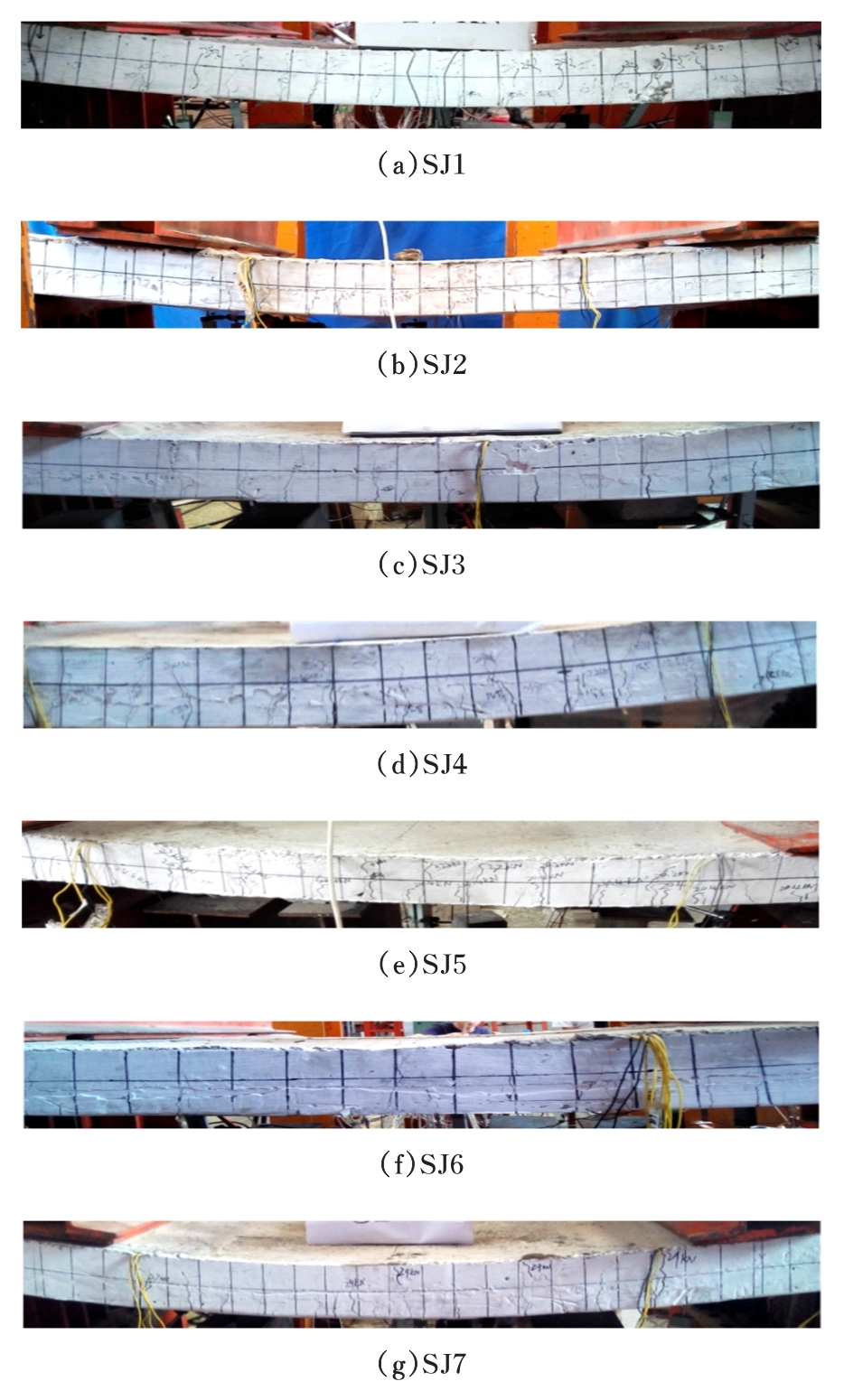

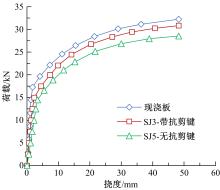

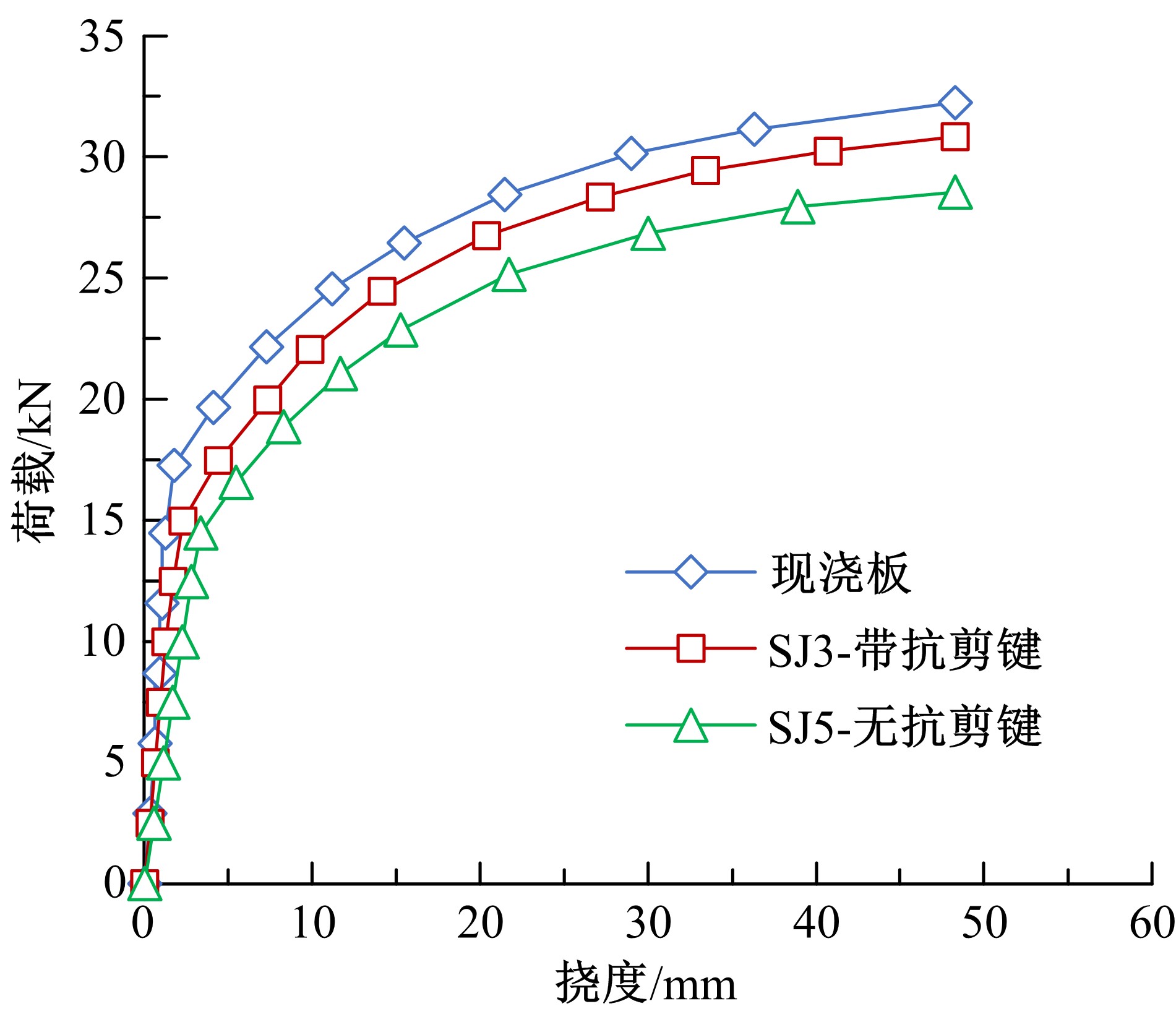

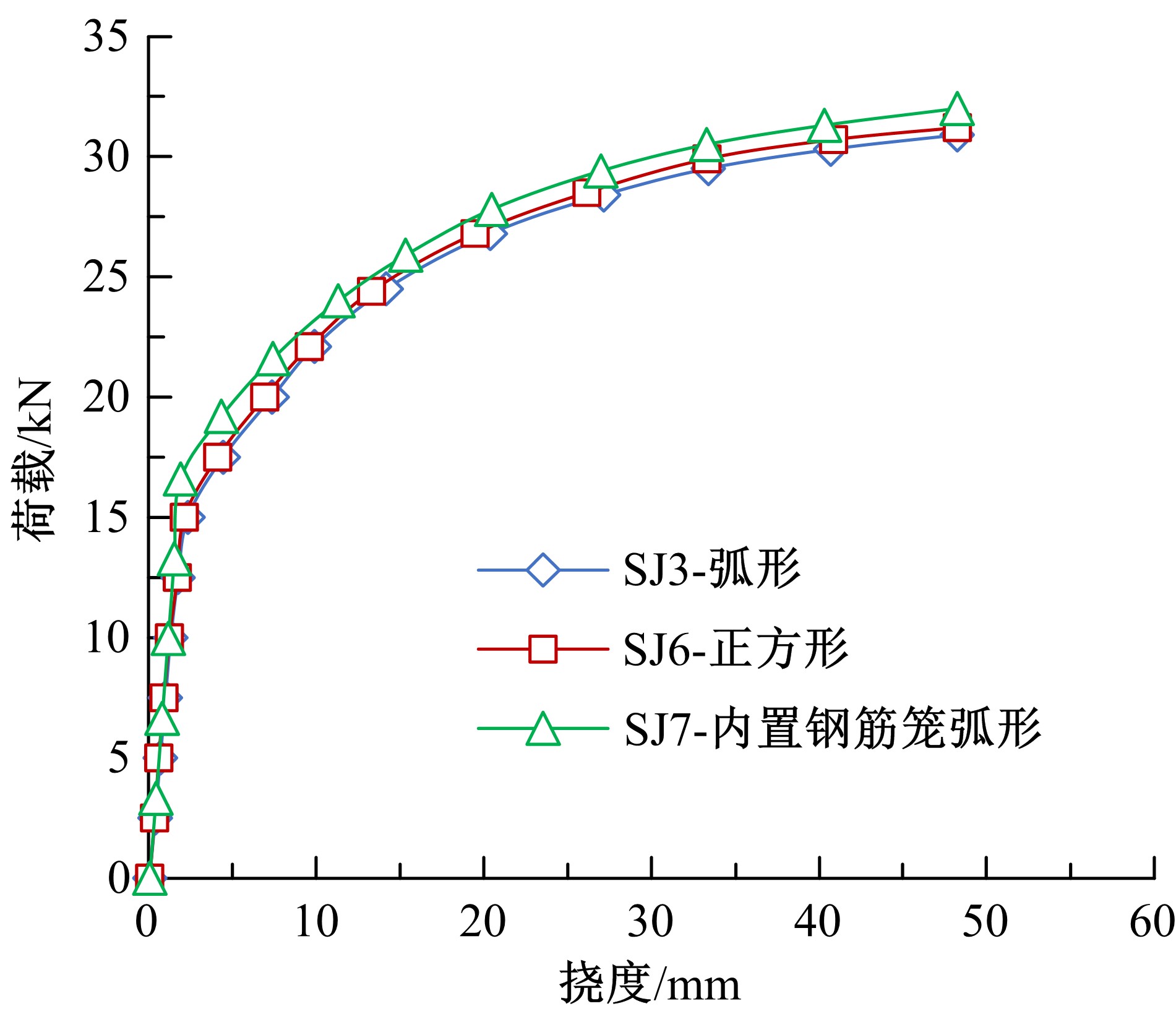

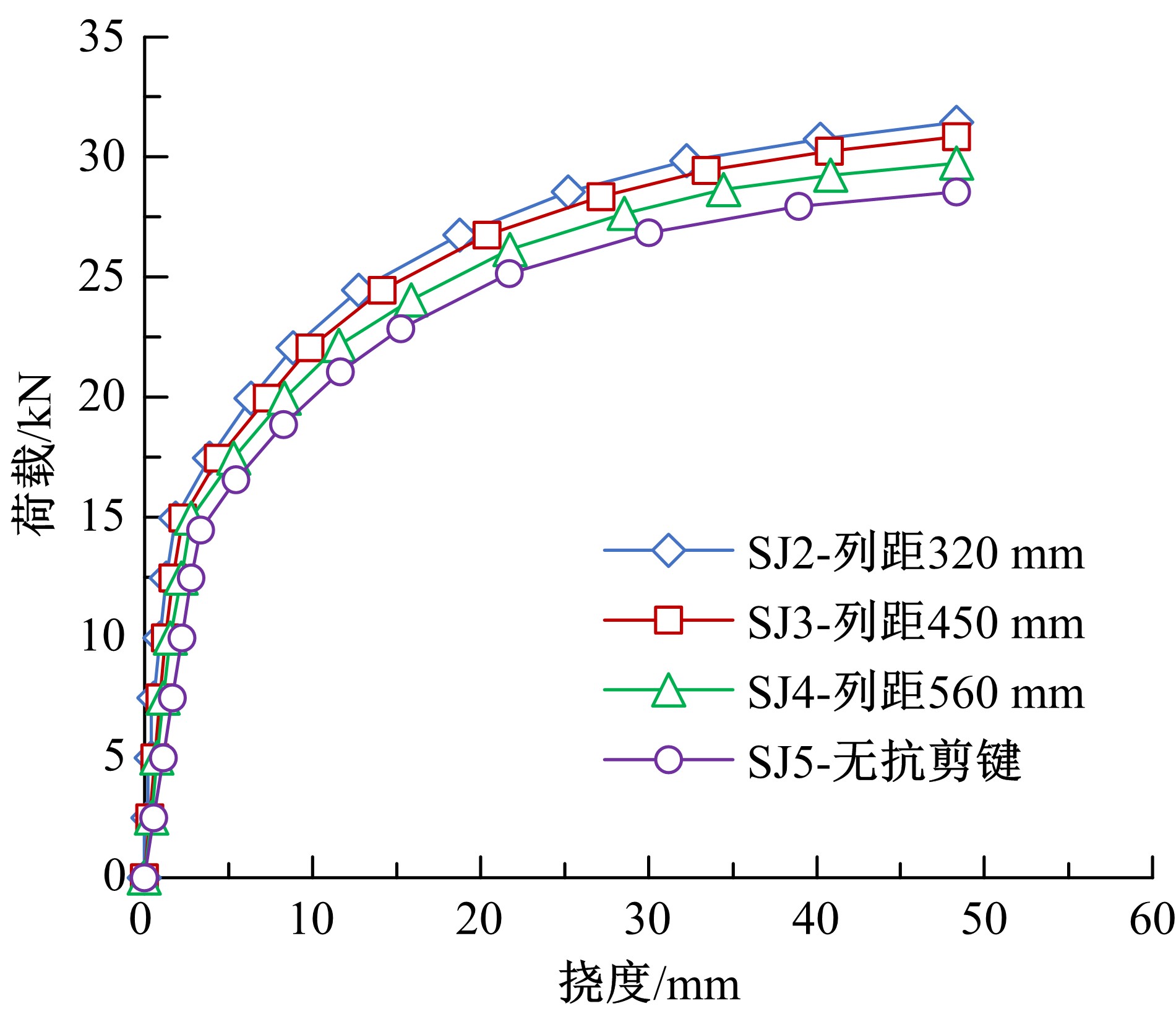

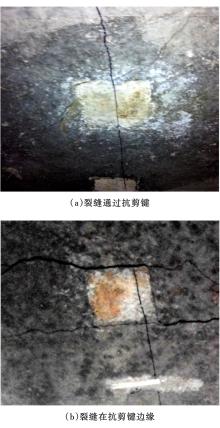

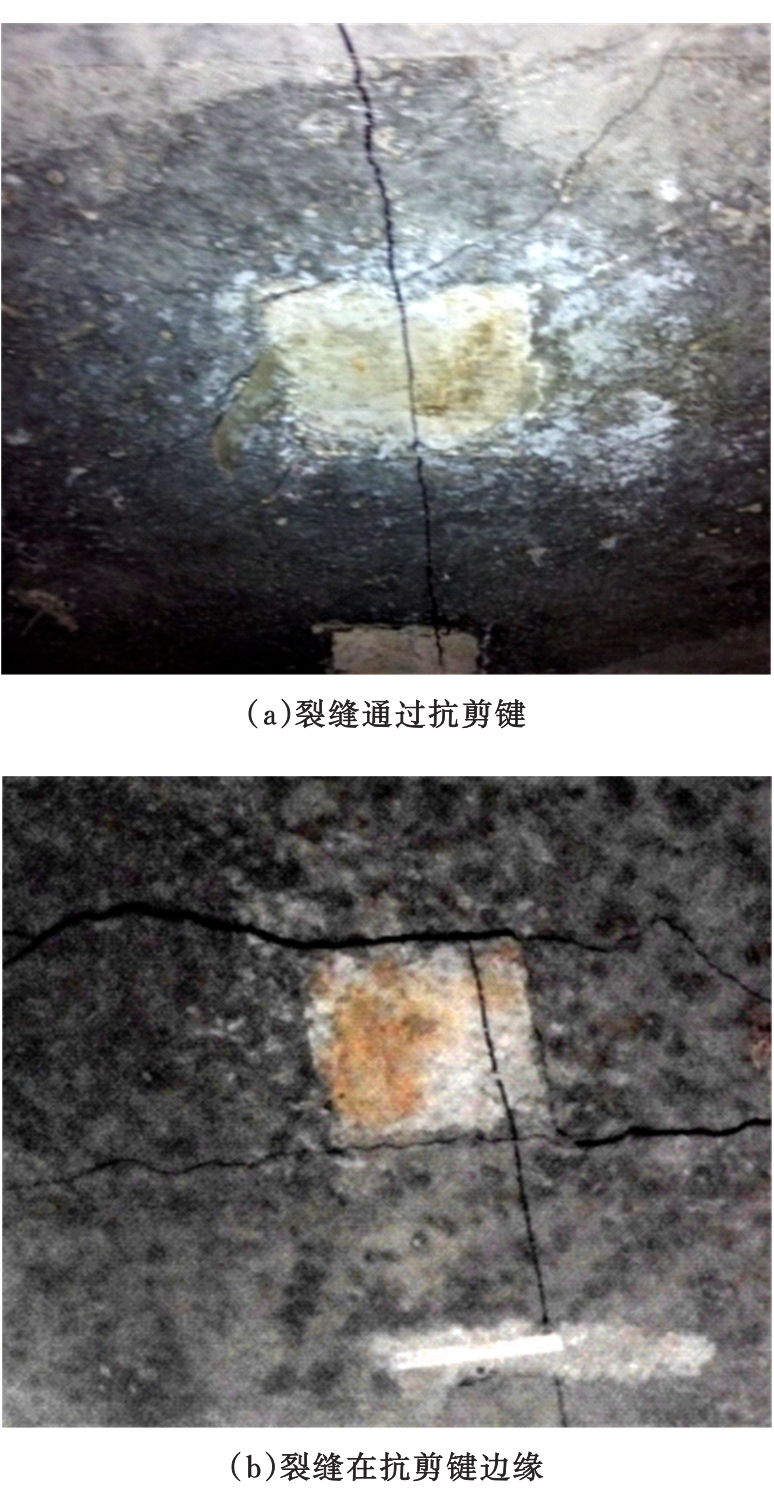

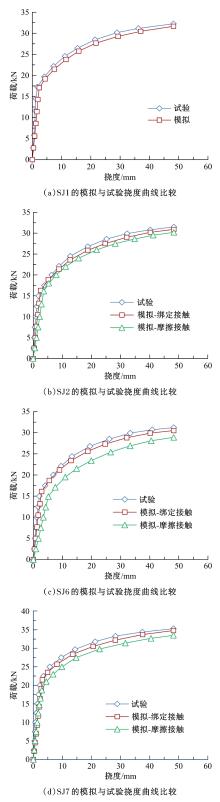

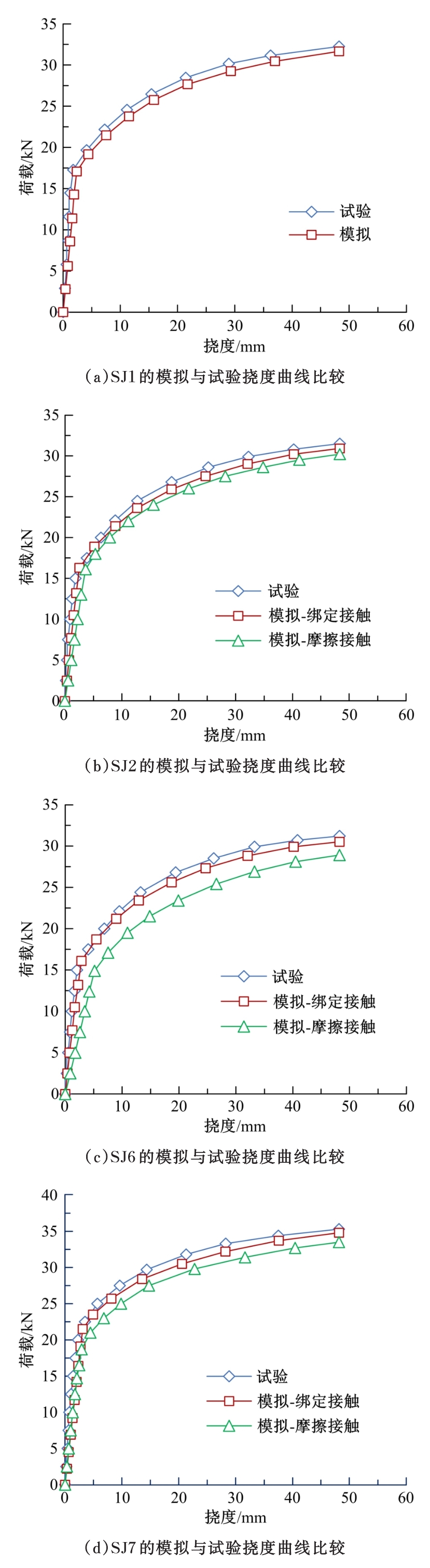

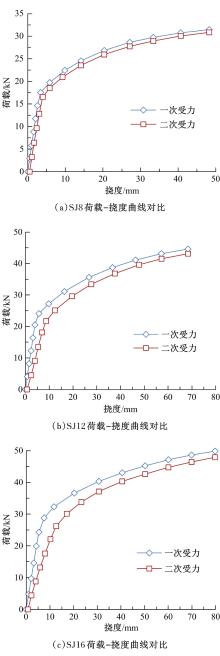

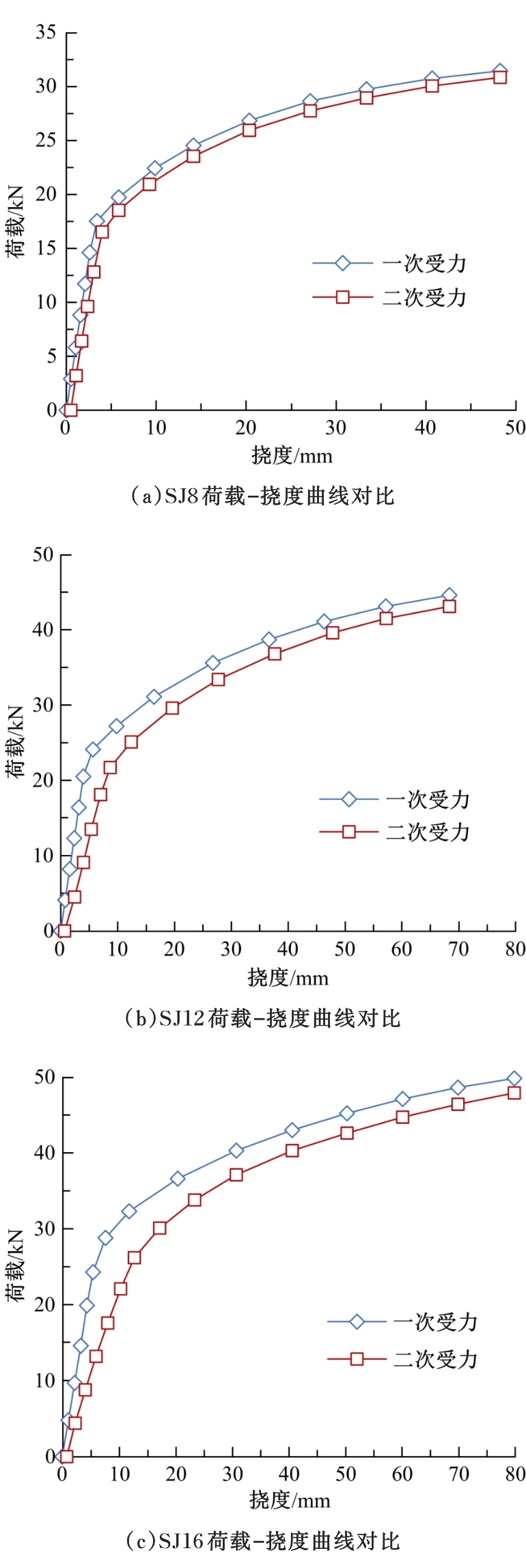

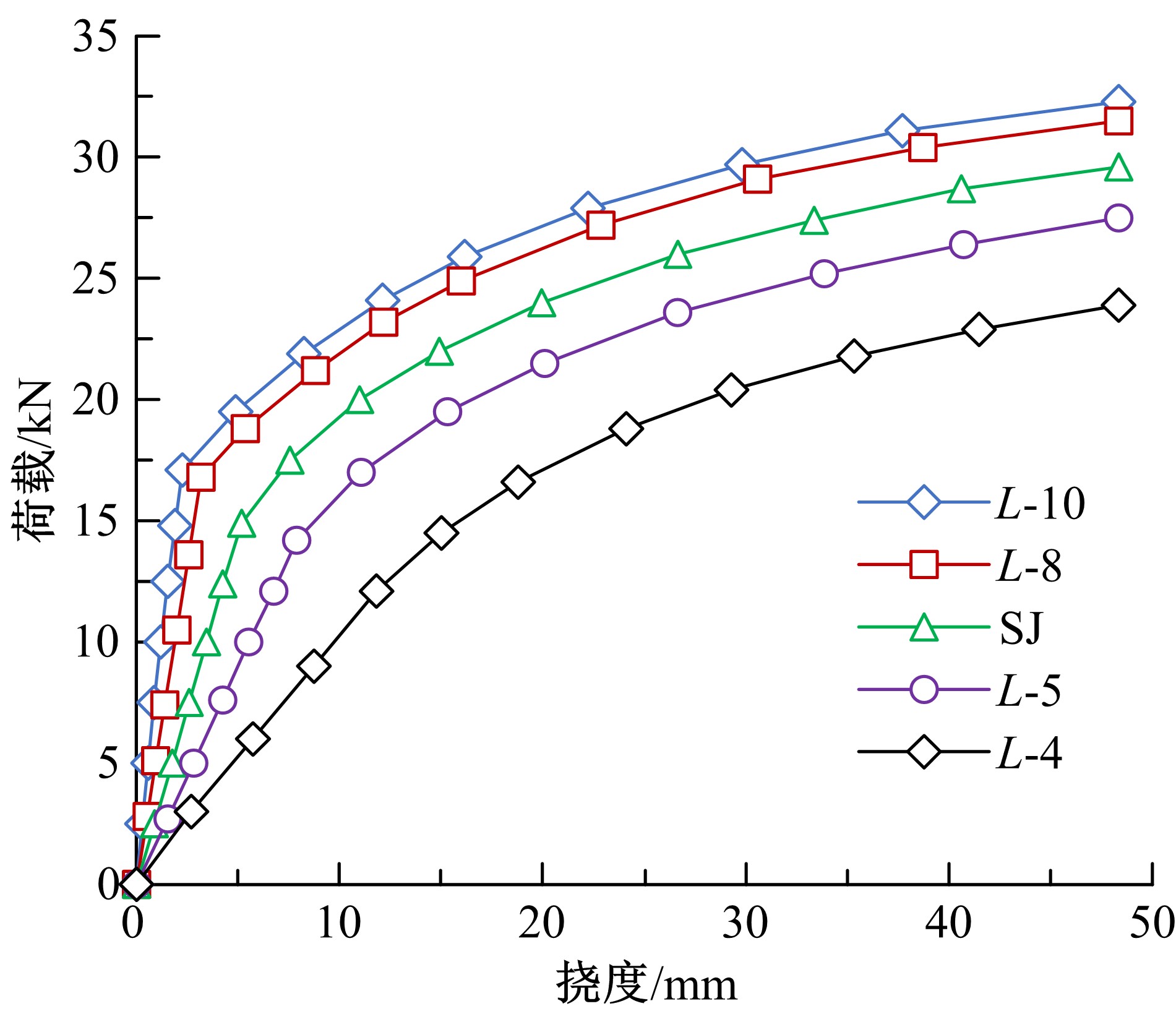

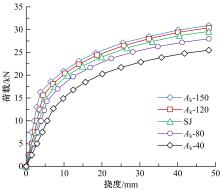

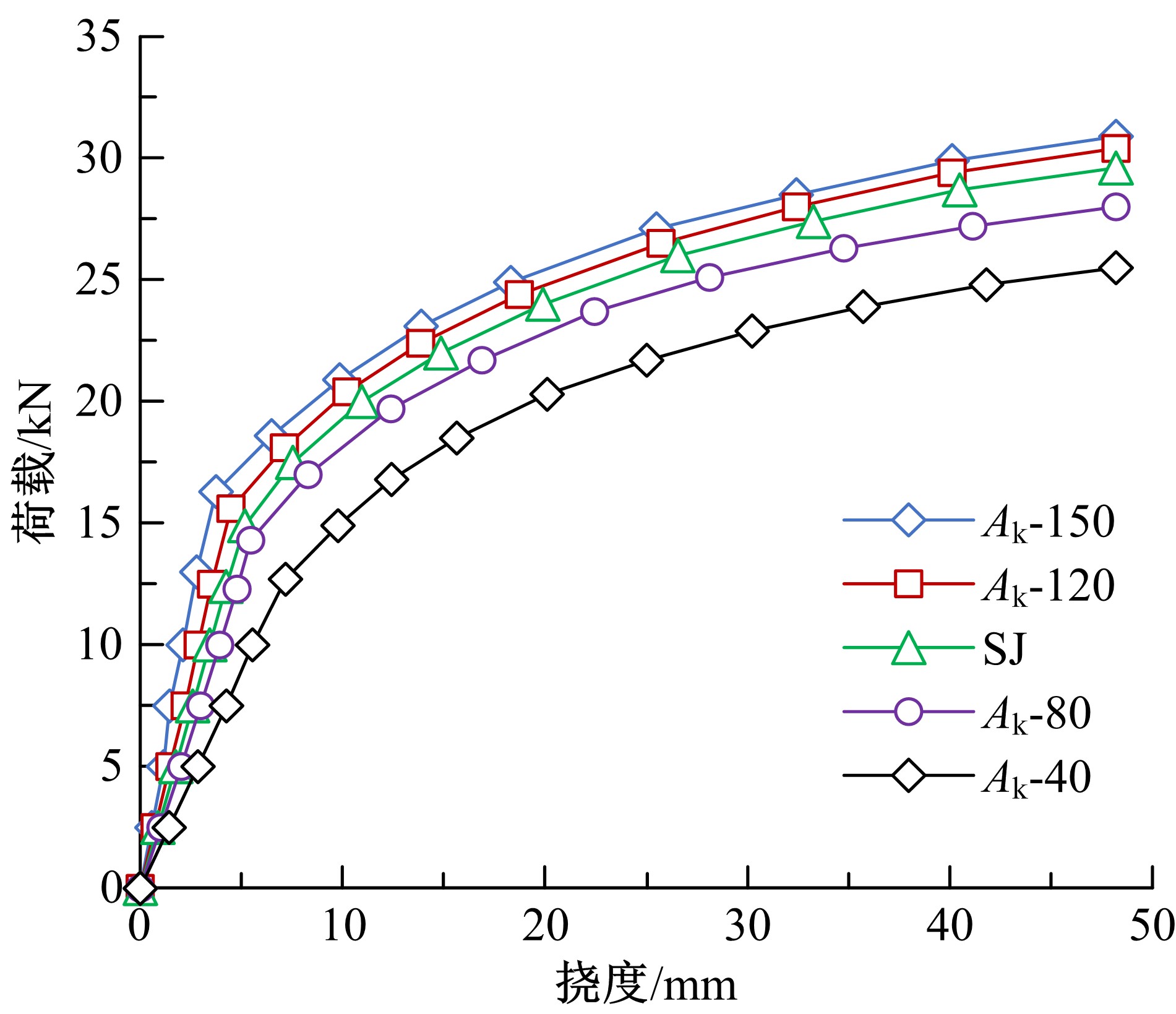

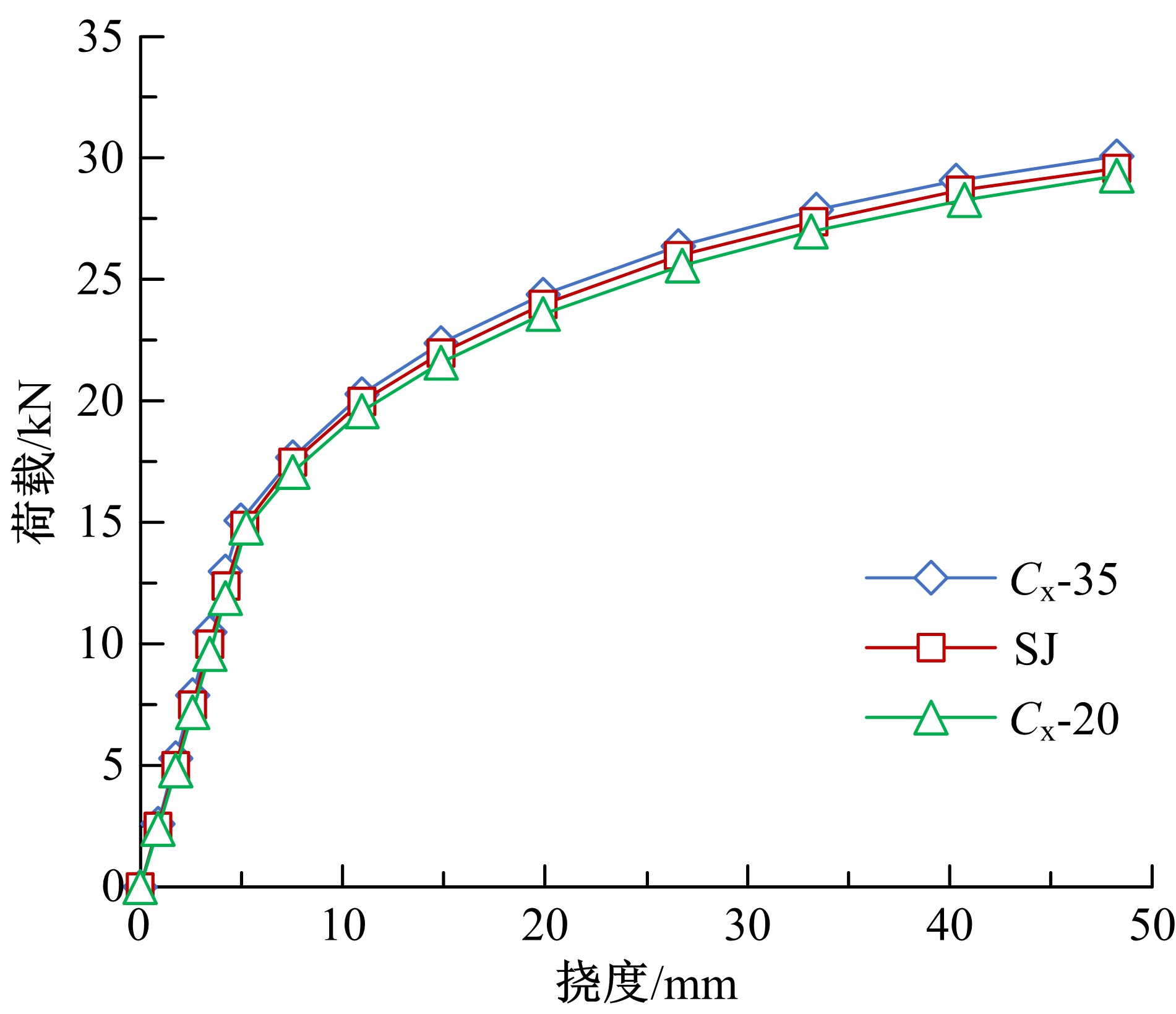

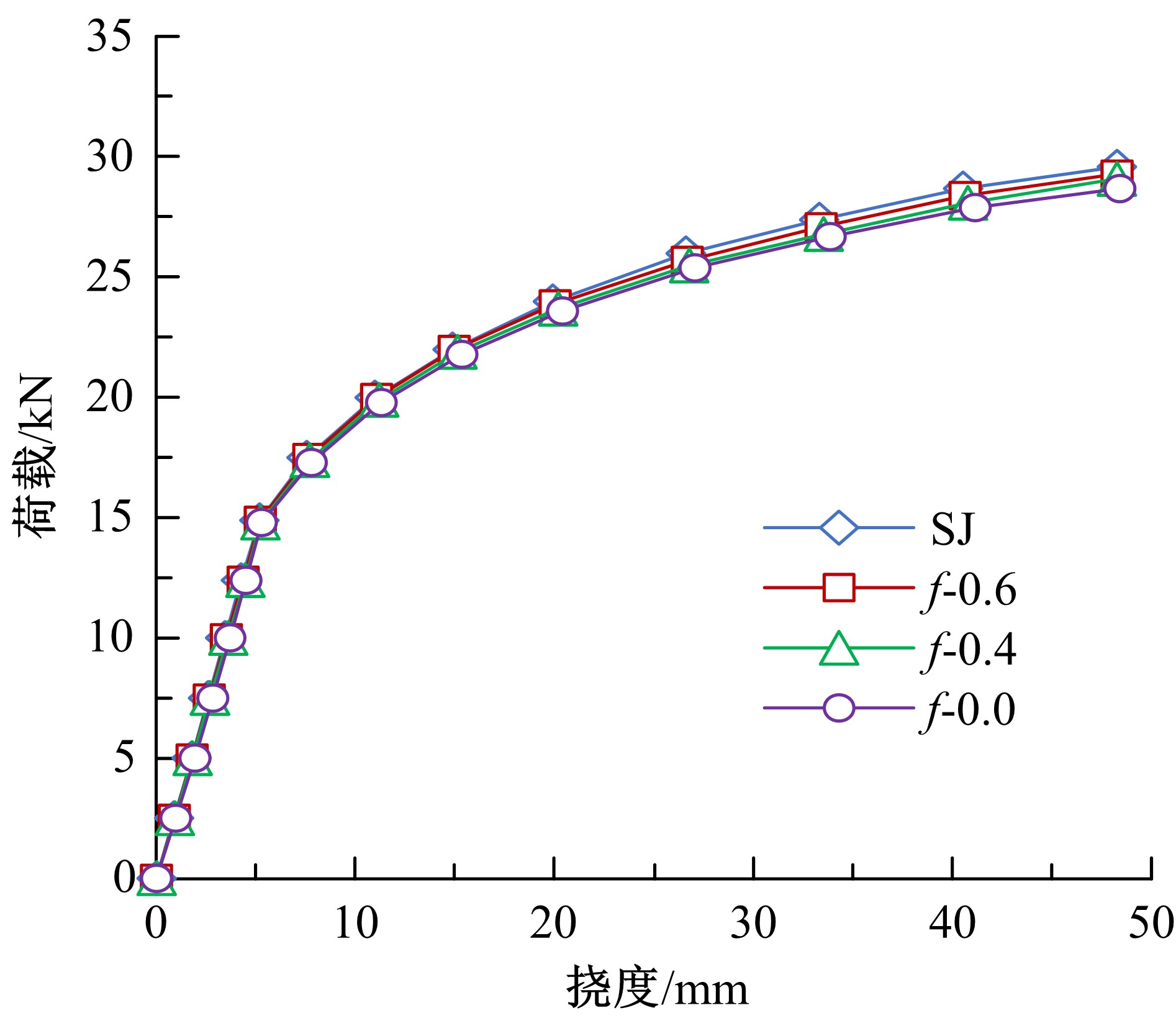

为研究带抗剪键叠合板的受力特性,进行了7块单向板的静力试验,并采用有限元方法补充分析。结果表明:不同形式的抗剪键均能保证叠合板界面连接的可靠性,使其达到与现浇板接近的力学性能;现浇层与预制层混凝土、抗剪键与预制层混凝土结合牢固,整体性好;当跨度小于3.2 m时,两端简支单向带抗剪键叠合板可近似按一次受力构件计算;预制底板和现浇层间采用摩檫接触时,随着抗剪键行数、列数及抗剪键横截面积的增加,叠合板的屈服荷载增加,屈服位移减小,且列数影响更明显,但三者增加到一定程度后,影响不再明显;布置一定数量的抗剪键后,抗剪键混凝土强度等级、现浇层混凝土强度等级及摩擦因数对叠合板的承载力和屈服位移几乎无影响。最后,建立了带抗剪键叠合板的刚度计算式。

中图分类号:

- TU375.2

| 1 | 赵唯坚. 超高强材料与装配式结构[J]. 工程力学, 2012, 29(增刊2): 31-42. |

| Zhao Wei-jian. Ultra-high strength materials and precast concrete structures[J]. Engineering Mechanics, 2012, 29(Sup.2): 31-42. | |

| 2 | 杨联萍, 余少乐, 张其林, 等. 叠合剪力墙结构研究现状和关键问题[J]. 建筑结构, 2017, 47(12): 78-88. |

| Yang Lian-ping, Yu Shao-le, Zhang Qi-lin, et al. Research status quo and key issues in superimposed shear wall structure[J]. Building Structure, 2017, 47(12): 78-88. | |

| 3 | 赵广军. 预制装配式混凝土结构发展现状分析[J]. 工程质量, 2016, 34(7): 16-18. |

| Zhao Guang-jun. The development prospects of the prefabricated concrete structure[J]. Construction Quality, 2016, 34(7): 16-18. | |

| 4 | Vaquero S F, Correa D R, Wolkomirski S F. Precast concrete,steel-braced,hybrid pipe rack structures[J]. PCI Journal, 2013, 58(4): 55-67. |

| 5 | JGJ 1—2014. 装配式混凝土结构技术规程[S]. |

| 6 | 刘香, 倪东阳, 李娟. 预制带肋钢筋桁架叠合板的试验与有限元分析[J]. 沈阳建筑大学学报: 自然科学版, 2018, 34(1): 42-52. |

| Liu Xiang, Ni Dong-yang, Li Juan. Experimental study and finite element analysis of prefabricated ribbed steel truss laminated slabs[J]. Journal of Shenyang Jianzhu University (Natural Science), 2018, 34(1): 42-52. | |

| 7 | Chou C C,Chen J H. Development of floor slab for steel post-tensioned self-centering moment frames[J]. Journal of Constructional Steel Research, 2011, 67(10): 1621-1635. |

| 8 | 李明, 赵唯坚, 孙哲哲. 带抗剪键的混凝土叠合楼板、预制构造和施工方法[P]. 中国: CN201210279952, 2014-09-24. |

| 9 | 肖景平. 预应力高强叠合结构叠合梁生产工艺[J]. 建筑技术, 2014, 45(1): 53-55. |

| Xiao Jing-ping. Production process of prestressed high-strength superimposed beam[J]. Architecture Technology, 2014, 45(1): 53-55. | |

| 10 | GB/T 50152—2012 混凝土结构试验方法标准[S]. 北京: 中国建筑工业出版社, 2012. |

| 11 | GB 50010—2010. 混凝土结构设计规范[S]. |

| 12 | 徐国林, 徐倩, 王祥建, 等. 混凝土单轴弹塑性损伤本构模型及参数确定[J]. 广西大学学报: 自然科学版, 2016, 41(2): 332-338. |

| Xu Guo-lin, Xu Qian, Wang Xiang-jian, et al. Uniaxial elastic-plastic damage constitutive model and parameters of concrete[J]. Journal of Guangxi University (Natural Science Edition), 2016, 41(2): 332-338. | |

| 13 | 戴岩, 聂少锋, 周天华. 带环梁的方钢管约束钢骨混凝土柱-钢梁节点滞回性能有限元分析[J]. 吉林大学学报: 工学版, 2018, 48(5): 1426-1435. |

| Dai Yan, Nie Shao-feng, Zhou Tian-hua. Finite element analysis of hysteretic behavior of square steel tube confined steel reinforced concrete column steel frame ring beam joint[J]. Journal of Jilin University (Engineering and Technology Edition), 2018, 48(5): 1426-1435. | |

| 14 | 陈富强, 田唯, 刘占国, 等. 匹配浇筑混凝土接触面摩擦系数试验研究[J]. 中国港湾建设, 2014(12): 34-38. |

| Chen Fu-qiang, Tian Wei, Liu Zhan-guo, et al. Experiment study on friction coefficient of concrete with matching pouring surface[J]. China Harbor Engineering, 2014(12): 34-38. | |

| 15 | 孙兵, 丁德鑫, 曾晟, 等. 钢筋混凝土叠合结构二次受力过程数值分析[J]. 华中科技大学学报: 城市科学版, 2008, 25(4): 260-263. |

| Sun Bing, Ding De-xin, Zeng Sheng, et al. Numerical analysis of two-stage loading progresses on reinforcement concrete composite structures[J]. Journal of Huazhong University of Science and Technology (Urban Science Edition), 2008, 25(4): 260-263. | |

| 16 | 郭楠, 张平阳, 左熠, 等. 竹板增强胶合木梁受弯性能[J]. 吉林大学学报: 工学版, 2017, 47(3): 778-788. |

| Guo Nan, Zhang Ping-yang, Zuo Yi, et al. Bending performance of glue-lumber beam reinforced by bamboo plyboard[J]. Journal of Jilin University (Engineering and Technology Edition), 2017, 47(3): 778-788. |

| [1] | 修文翠,吴化,韩英,刘云旭. 等温热处理温度对超级贝氏体组织与性能的影响[J]. 吉林大学学报(工学版), 2020, 50(2): 520-525. |

| [2] | 王鹏辉,乔宏霞,冯琼,曹辉,温少勇. 氯氧镁涂层钢筋混凝土两重因素耦合作用下的耐久性模型[J]. 吉林大学学报(工学版), 2020, 50(1): 191-201. |

| [3] | 彭勇,高华,万蕾,刘贵应. 沥青混合料劈裂强度影响因素数值模拟[J]. 吉林大学学报(工学版), 2019, 49(5): 1521-1530. |

| [4] | 佟鑫,张雅娇,黄玉山,胡正正,王庆,张志辉. 选区激光熔化304L不锈钢的组织结构及力学性能分析[J]. 吉林大学学报(工学版), 2019, 49(5): 1615-1621. |

| [5] | 李明,王浩然,赵唯坚. 带抗剪键叠合板的力学性能[J]. 吉林大学学报(工学版), 2019, 49(5): 1509-1520. |

| [6] | 张军,钱诚,郭春燕,钱玉君. 基于多源时空数据的建筑宜居性动态设计[J]. 吉林大学学报(工学版), 2019, 49(4): 1169-1173. |

| [7] | 梁宁慧,缪庆旭,刘新荣,代继飞,钟祖良. 聚丙烯纤维增强混凝土断裂韧度及软化本构曲线确定[J]. 吉林大学学报(工学版), 2019, 49(4): 1144-1152. |

| [8] | 江亮,贺宜. 电动两轮车风险驾驶行为及事故影响因素分析[J]. 吉林大学学报(工学版), 2019, 49(4): 1107-1113. |

| [9] | 张磊,刘保国,储昭飞. 深厚孔隙砂岩含水层疏干排水对盾构斜井的 影响模型试验[J]. 吉林大学学报(工学版), 2019, 49(3): 788-797. |

| [10] | 姜秋月,杨海峰,檀财旺. 22MnB5超高强钢焊接接头强化性能[J]. 吉林大学学报(工学版), 2018, 48(6): 1806-1810. |

| [11] | 庄蔚敏, 赵文增, 解东旋, 李兵. 超高强钢/铝合金热铆连接接头性能[J]. 吉林大学学报(工学版), 2018, 48(4): 1016-1022. |

| [12] | 郑一峰, 赵群, 暴伟, 李壮, 于笑非. 大跨径刚构连续梁桥悬臂施工阶段抗风性能[J]. 吉林大学学报(工学版), 2018, 48(2): 466-472. |

| [13] | 王腾, 周茗如, 马连生, 乔宏霞. 基于断裂理论的湿陷性黄土劈裂注浆裂纹扩展[J]. 吉林大学学报(工学版), 2017, 47(5): 1472-1481. |

| [14] | 郭楠, 张平阳, 左煜, 左宏亮. 竹板增强胶合木梁受弯性能[J]. 吉林大学学报(工学版), 2017, 47(3): 778-788. |

| [15] | 刘晓波, 周德坤, 赵宇光. 不同等温热处理条件下半固态挤压Mg2Si/Al复合材料的组织和性能[J]. 吉林大学学报(工学版), 2016, 46(5): 1577-1582. |

|

||