吉林大学学报(工学版) ›› 2021, Vol. 51 ›› Issue (6): 2068-2078.doi: 10.13229/j.cnki.jdxbgxb20200670

• 交通运输工程·土木工程 • 上一篇

悬索桥主索鞍承载力影响因素及结构优化

- 1.西南交通大学 土木工程学院,成都 610031

2.东南大学 土木工程学院,南京 211189

3.中铁大桥勘测设计院集团有限公司,武汉 430050

Influencing factors and structural optimization of main cable saddle bearing capacity of suspension bridge

Chang-jun ZHONG1,2( ),Zhong-bin WANG3(

),Zhong-bin WANG3( ),Chen-yang LIU1

),Chen-yang LIU1

- 1.School of Civil Engineering,Southwest Jiaotong University,Chengdu 610031,China

2.School of Civil Engineering,Southeast University,Nanjing 211189,China

3.China Railway Bridge Survey and Design Institute Group Co. ,Ltd. ,Wuhan 430050,China

摘要:

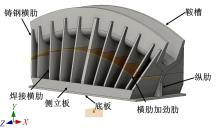

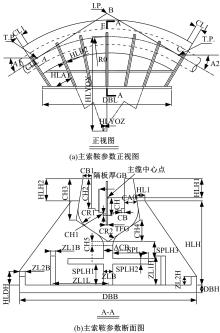

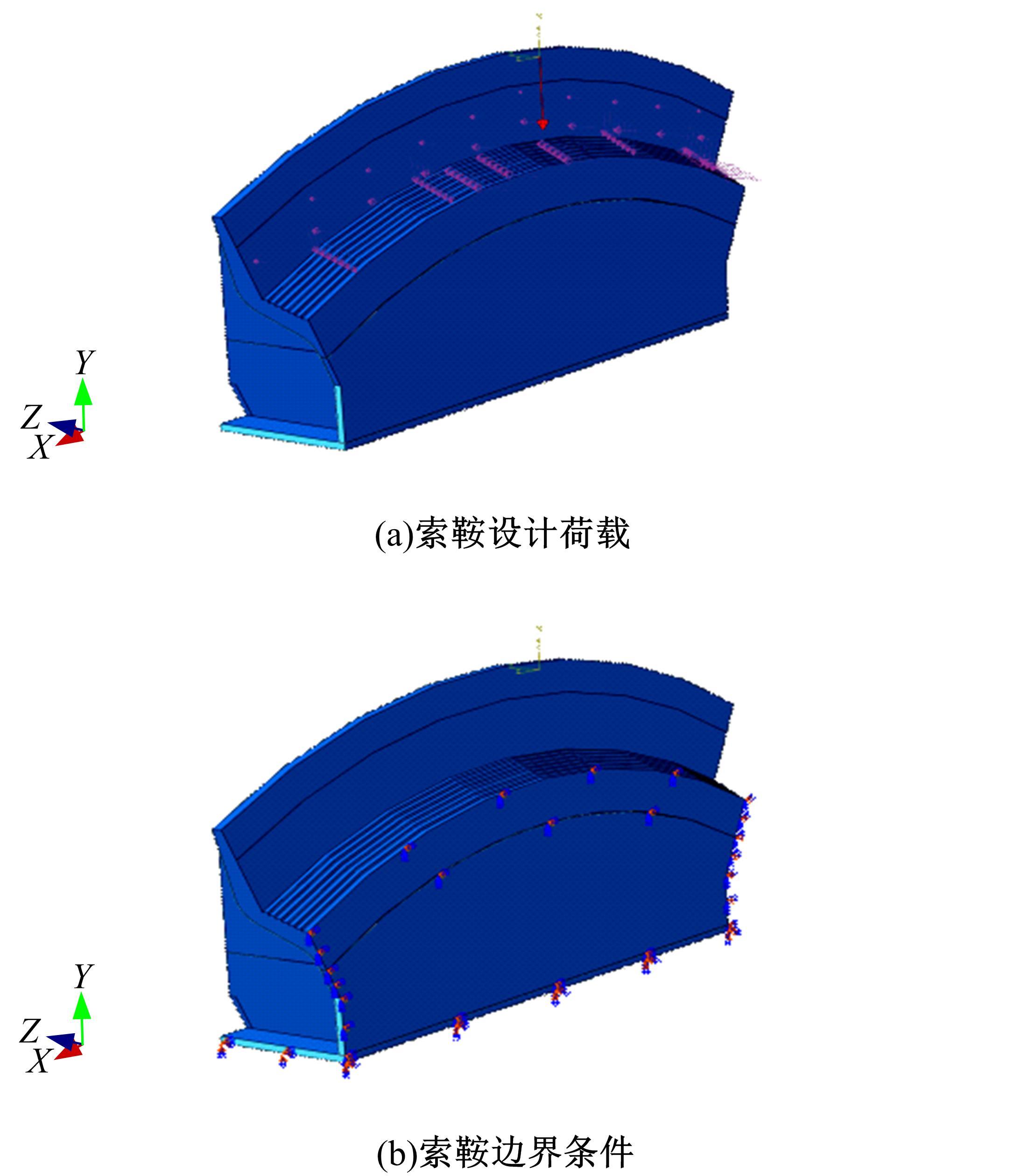

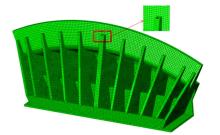

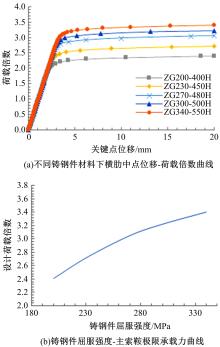

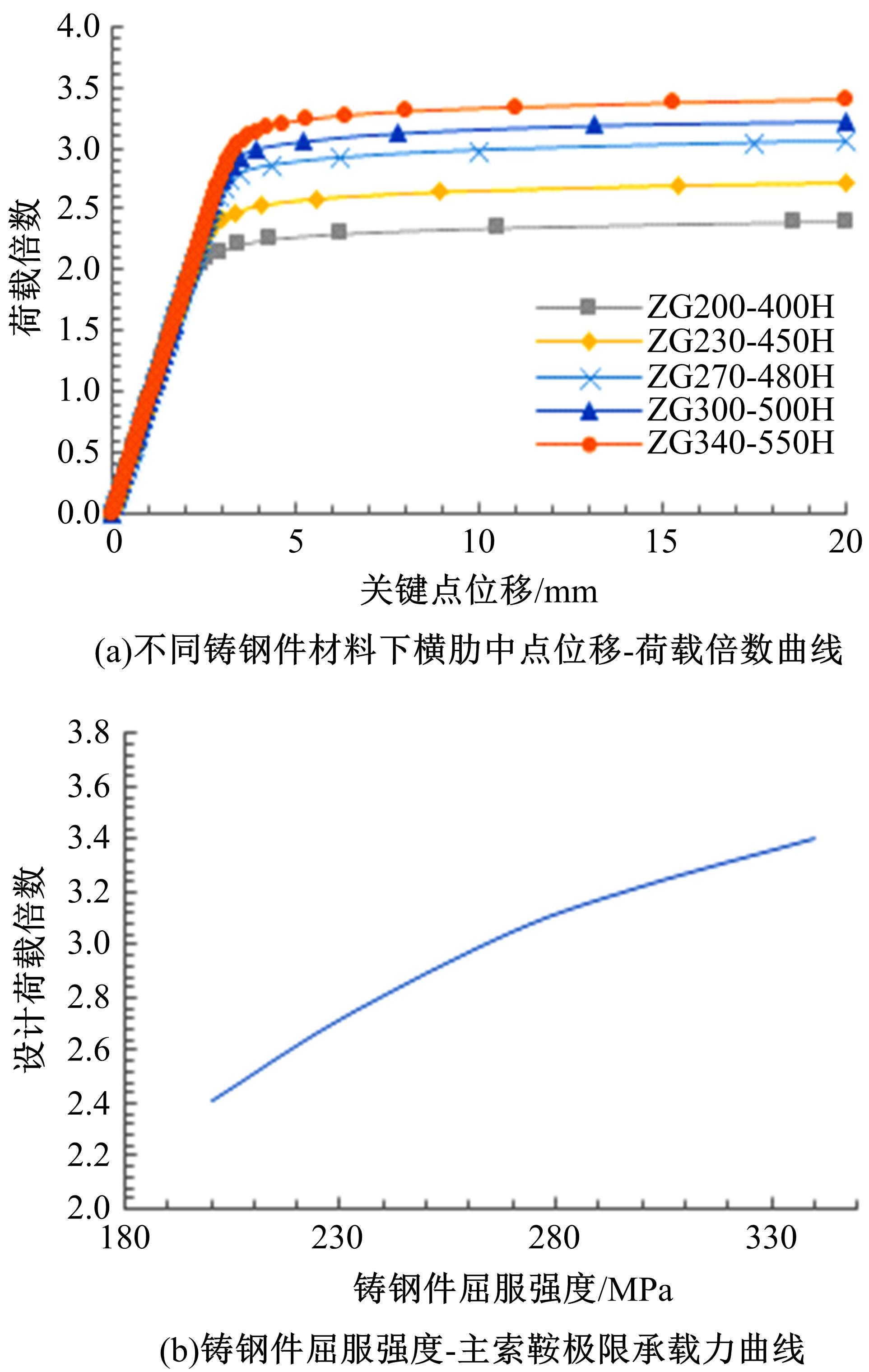

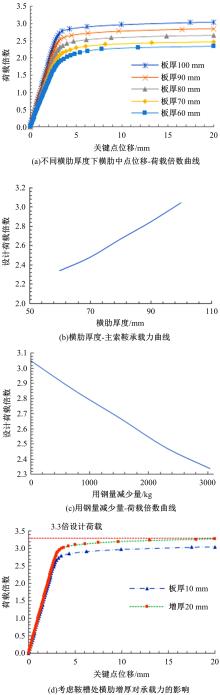

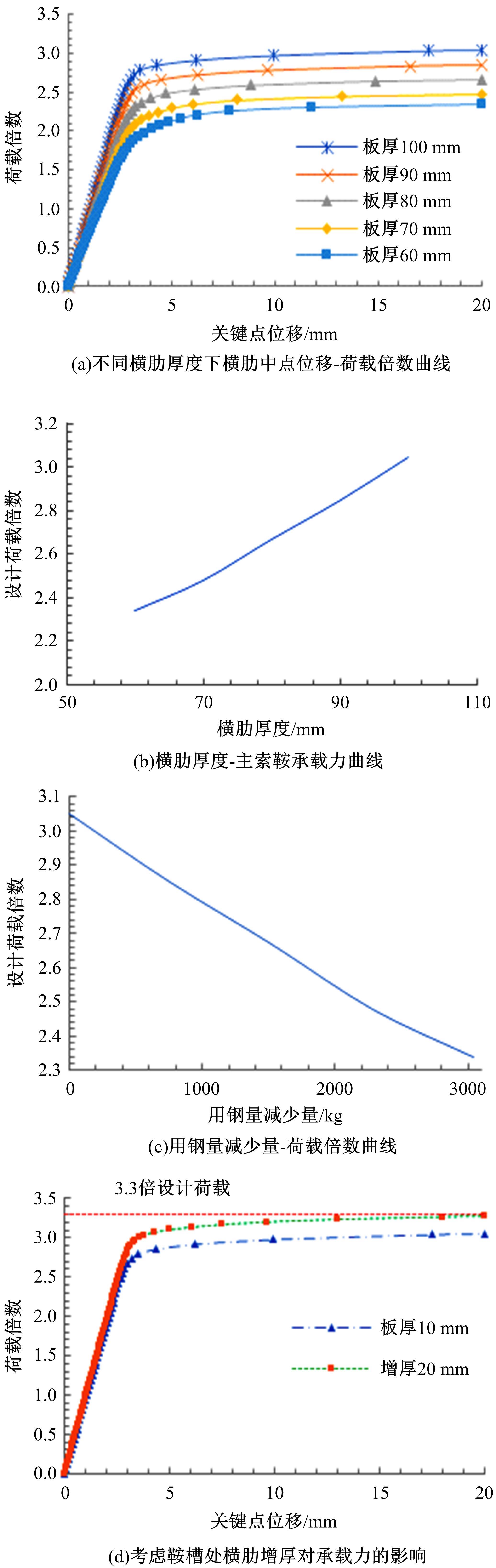

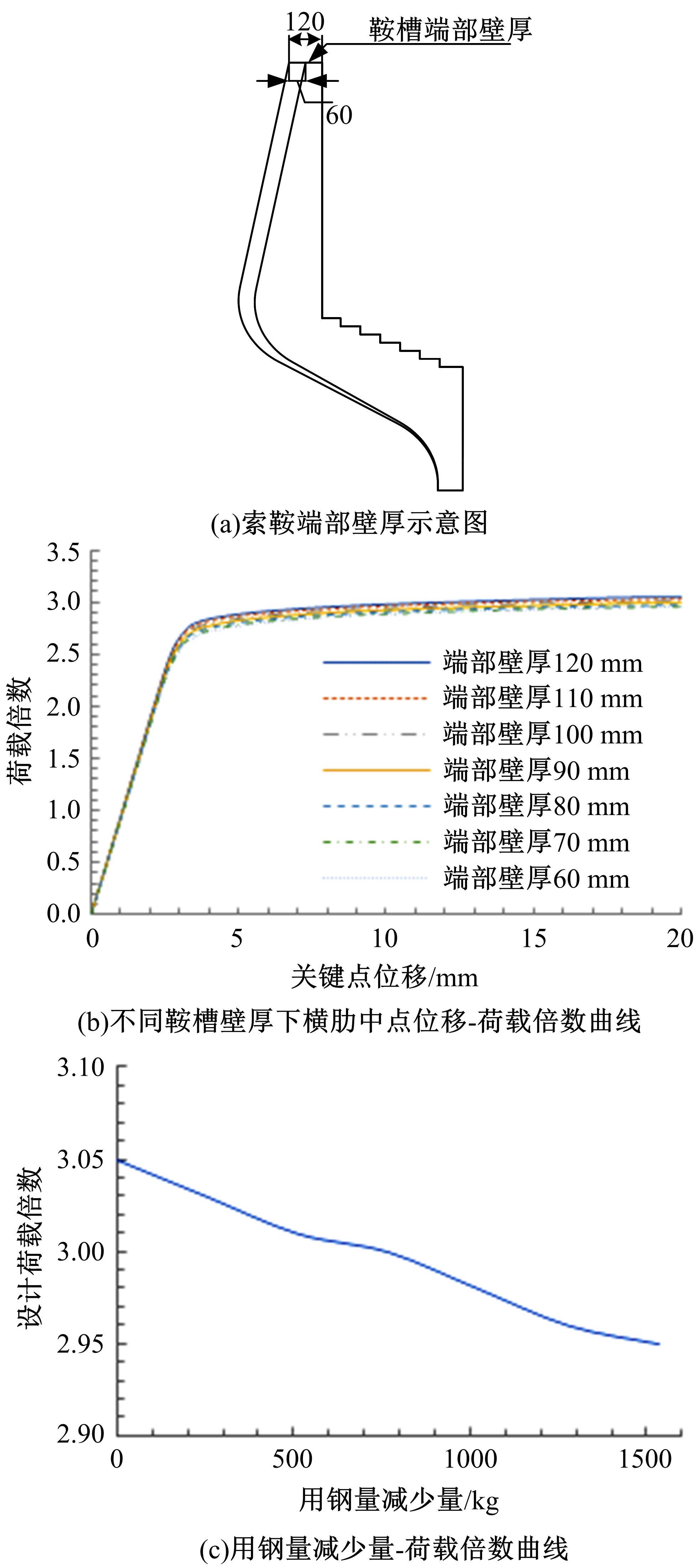

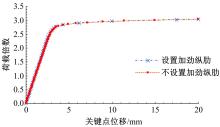

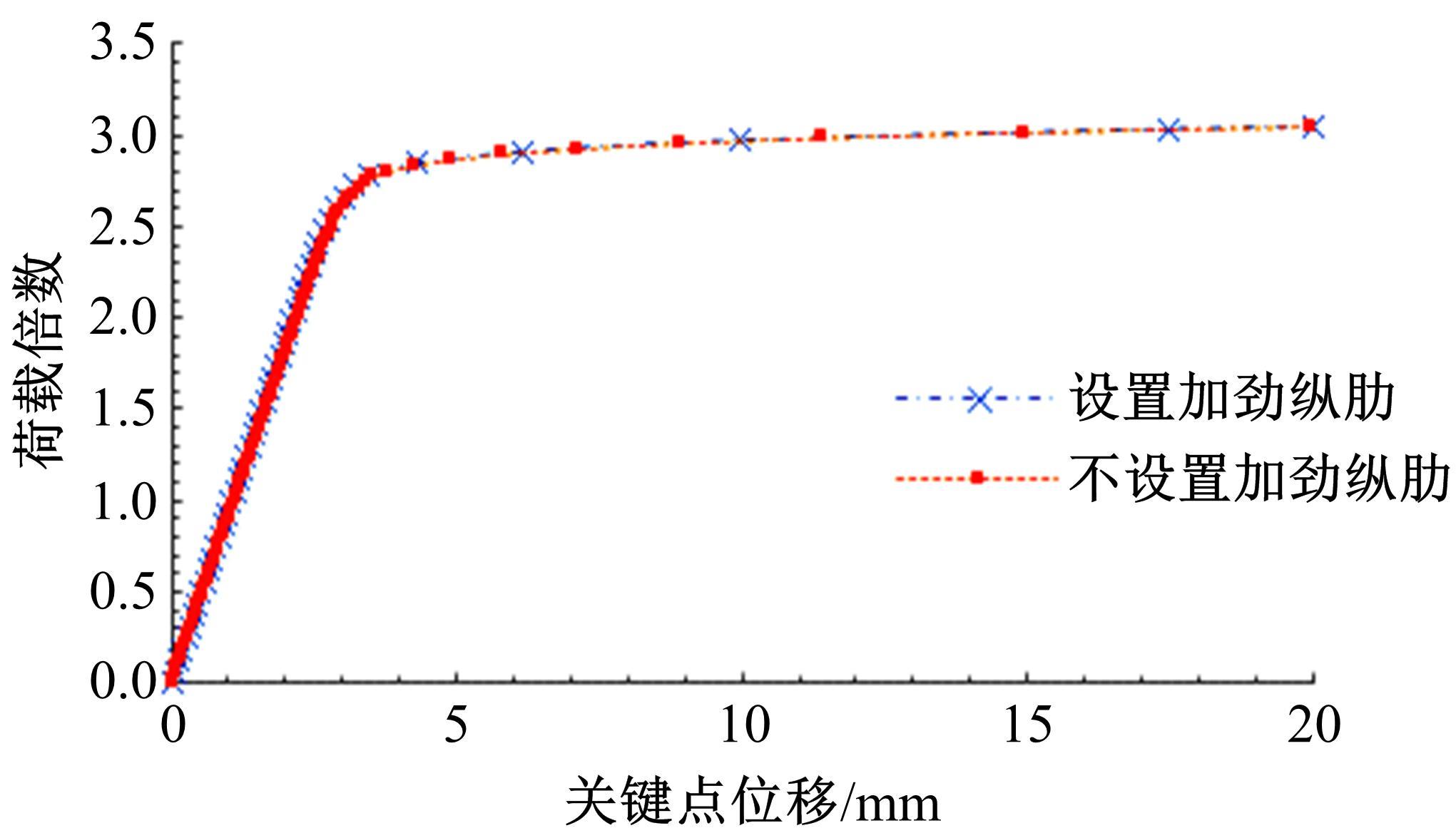

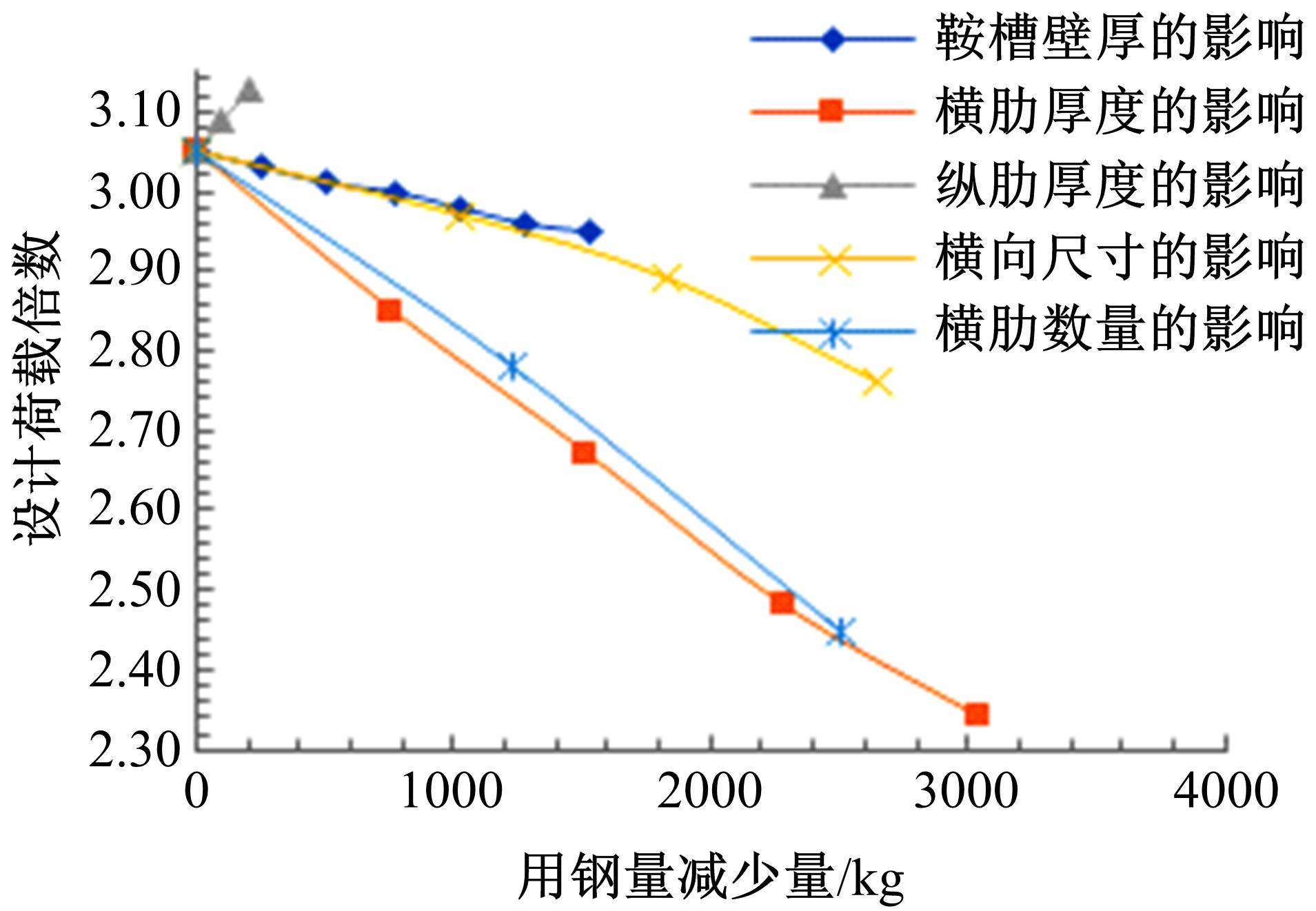

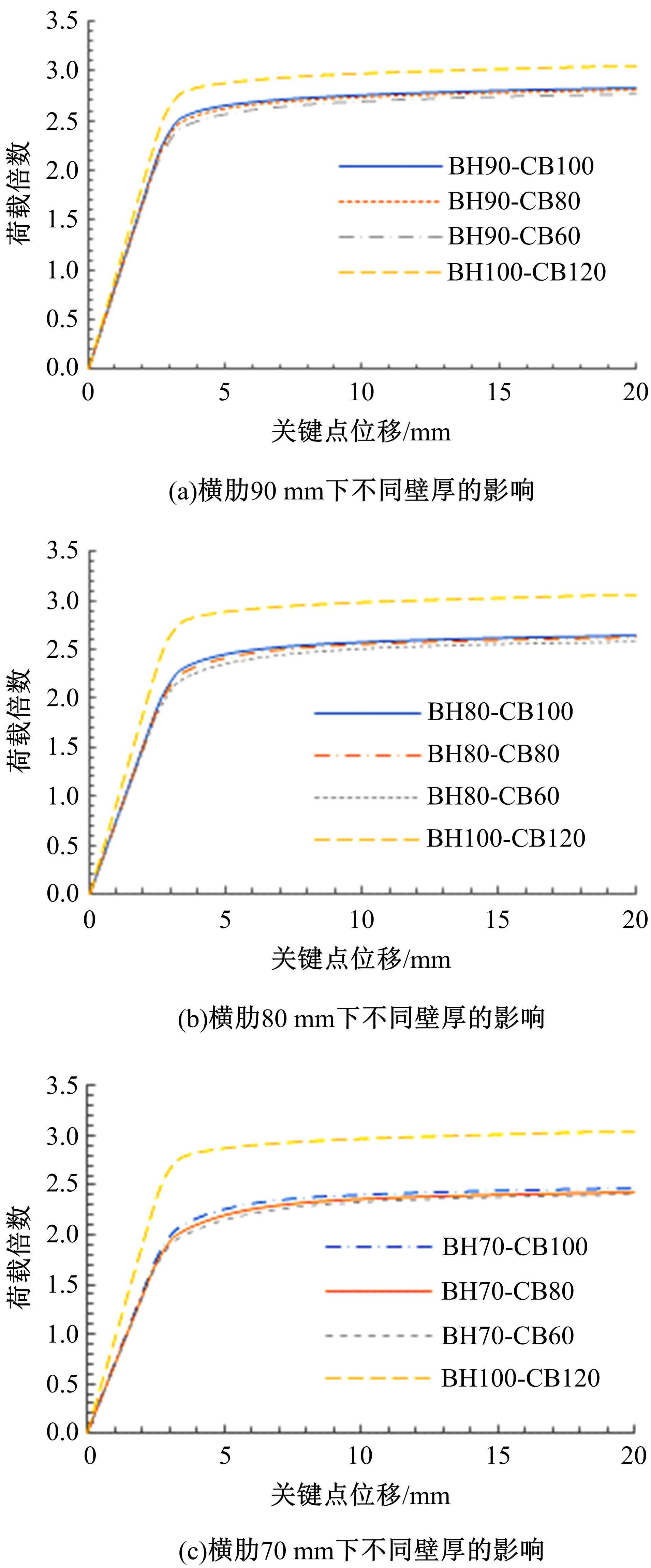

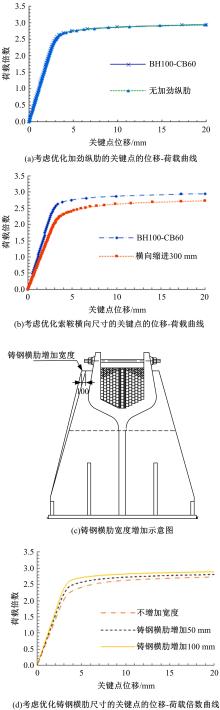

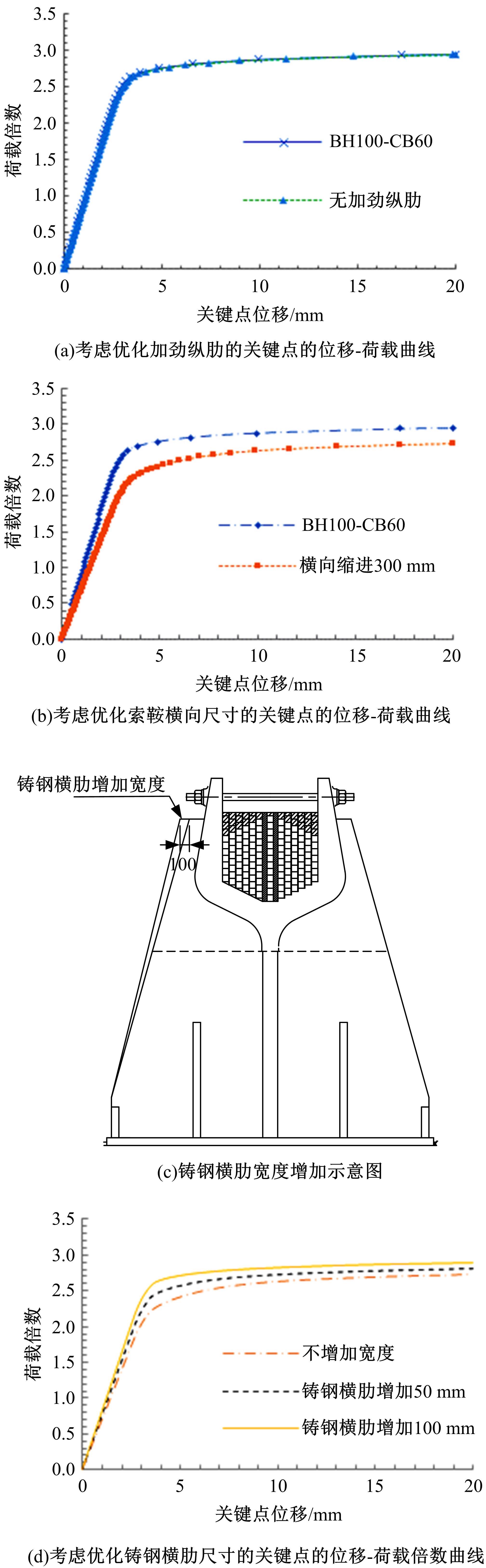

为了解决主索鞍安全性与经济性间的矛盾,对主索鞍极限承载力及其影响因素进行了研究。通过对悬索桥主索鞍结构设计参数进行归纳和总结,利用Autodesk Inventor软件建立了参数化几何模型,导入大型通用有限元软件ABAQUS中进行大量数值模拟,系统研究了主索鞍承载力影响因素及其变化规律,并对结构进行合理优化。结果表明:原设计索鞍的极限承载力为设计荷载的3倍,具有足够的安全储备;铸钢材料强度对主索鞍承载力有很大影响,而容器钢材料强度对主索鞍承载力的影响很小;横肋厚度及数量对索鞍承载力有很大影响,鞍槽侧壁厚度、是否设置横肋的纵向加劲肋以及腹板厚度对索鞍承载力的影响较小;随着索鞍横向尺寸的减小,索鞍横向刚度和极限承载力也随之下降;优化后的索鞍其极限承载力降低了10%,但用钢量降低了20%。

中图分类号:

- U448.25

| 1 | 贾界峰,涂金平,周泳涛,等. 空间索面自锚式悬索桥主索鞍计算方法[J]. 桥梁建设, 2007, 37(5): 38-41. |

| Jia Jie-feng, Tu Jin-ping, Zhou Yong-tao, et al. Calculation method of main cable saddle for self-anchored suspension bridge with spatial cable plane[J]. Bridge Construction, 2007, 37(5): 38-41. | |

| 2 | 杜万强. 某悬索桥主索鞍应力试验及数值分析[J]. 铁道建筑, 2013, 18(2): 18-19. |

| Du Wan-qiang. Stress test and numerical analysis of the main saddle of a suspension bridge[J]. Railway Construction, 2013, 18(2): 18-19. | |

| 3 | 方国强,林韬. 岳阳洞庭湖大桥主索鞍受力分析[J]. 市政技术, 2013, 31(3): 56-57, 60. |

| Fang Guo-qiang, Lin Tao. Force analysis of the main cable saddle of Yueyang Dongting lake bridge[J]. Municipal Technology, 2013, 31(3): 56-57, 60. | |

| 4 | 黄奶清,李亚平,黄吉滔. 悬索桥主塔索鞍计算分析研究[J]. 工程与建设, 2014, 28(2): 185-186. |

| Huang Nai-qing, Li Ya-ping, Huang Ji-tao. Calculation and analysis of suspension bridge main tower saddle[J]. Engineering and Construction, 2014, 28(2): 185-186. | |

| 5 | 李俊,卫星,李小珍,等. 大型钢网壳结构铸钢节点复杂受力的试验研究[J]. 土木工程学报, 2005, 38(6): 8-12, 19,53. |

| Li Jun, Wei Xing, Li Xiao-zhen, et al. Experimental study on complex forces of cast steel joints of large steel reticulated shell structure[J]. China Civil Engineering Journal, 2005, 38(6): 8-12, 19,53. | |

| 6 | 陈誉, 魏琳. 圆支管-H型钢主管T型节点抗压性能试验研究[J]. 土木工程学报, 2013, 46(12): 25-32. |

| Chen Yu, Wei Lin. Experimental study on compressive performance of circular branch pipe-H-shaped steel main pipe T-joint[J]. China Civil Engineering Journal, 2013, 46(12): 25-32. | |

| 7 | 王朝波,赵宪忠,陈以一,等. 上海铁路南站外柱异形铸钢节点承载性能研究[J]. 土木工程学报, 2008, 41(1): 18-23. |

| Wang Chao-bo, Zhao Xian-zhong, Chen Yi-yi, et al. Research on bearing performance of special-shaped cast steel joints for outer column of Shanghai South Railway Station[J]. China Civil Engineering Journal, 2008, 41(1): 18-23. | |

| 8 | 王萌,石永久,王元清,等. 空间网壳相贯节点受力性能有限元分析[J]. 建筑结构, 2013, 43(21): 9-13, 37. |

| Wang Meng, Shi Yong-jiu, Wang Yuan-qing, et al. Finite element analysis of mechanical performance of intersecting joints of space reticulated shell[J]. Building Structure, 2013, 43(21): 9-13, 37. | |

| 9 | 杨渊. 铸钢件力学性能试验研究及铸钢塔结构分析[D]. 天津:天津大学建筑工程学院, 2017. |

| Yang Yuan. Experimental research on mechanical properties of steel castings and structural analysis of cast steel towers[D]. Tianjin: School of Civil Engineering and Architecture, Tianjin University, 2017. | |

| 10 | 秦蓬军. 铸钢柱脚的性能研究[D]. 西安:西安建筑科技大学土木工程学院, 2005. |

| Qin Peng-jun. Research on the performance of cast steel column foot[D]. Xi'an: School of Civil Engineering, Xi'an University of Architecture and Technology, 2005. | |

| 11 | 张达明. 复杂钢结构局部壳体屈曲及铸钢节点受力分析[D]. 杭州:浙江大学建筑工程学院, 2007. |

| Zhang Da-ming. Analysis of local shell buckling and cast steel joint forces of complex steel structures[D]. Hangzhou:School of Civil Engineering and Architecture, Zhejiang University, 2007. | |

| 12 | 孙鹏,王元清,石永久. 考虑倒角系数的T型铸钢节点轴向承载力非线性分析[J]. 空间结构, 2006, 12(2): 39-43. |

| Sun Peng, Wang Yuan-qing, Shi Yong-jiu. Nonlinear analysis of axial bearing capacity of T-type cast steel joints considering chamfer coefficient[J]. Space Structure, 2006, 12(2): 39-43. | |

| 13 | 刘宇航. 基于BIM的悬索桥缆索系统参数化设计研究[D]. 成都:西南交通大学土木工程学院, 2019. |

| Liu Yu-hang. Research on parametric design of suspension bridge cable system based on BIM[D]. Chendu: School of Civil Engineering, Southwest Jiaotong University, 2019. | |

| 14 | . 公路悬索桥设计规范[S]. |

| 15 | . 公路桥涵设计通用规范[S]. |

| [1] | 陈巍,万田保,王忠彬,厉萱,沈锐利. 悬索桥主缆除湿的内部送气管道设计与性能[J]. 吉林大学学报(工学版), 2021, 51(5): 1749-1755. |

| [2] | 郭殊伦,钟铁毅,闫志刚. 大跨度斜拉桥拉索的抖振响应计算方法[J]. 吉林大学学报(工学版), 2021, 51(5): 1756-1762. |

| [3] | 高凯,刘纲. 全局临界强度分枝-约界法的有效强度改进[J]. 吉林大学学报(工学版), 2021, 51(2): 597-603. |

| [4] | 宫亚峰,宋加祥,谭国金,毕海鹏,刘洋,单承新. 多车桥梁动态称重算法[J]. 吉林大学学报(工学版), 2021, 51(2): 583-596. |

| [5] | 孔庆雯,谭国金,王龙林,王勇,魏志刚,刘寒冰. 基于有限元方法的裂缝箱梁桥自振特性分析[J]. 吉林大学学报(工学版), 2021, 51(1): 225-232. |

| [6] | 陈华,陈耀嘉,谢斌,王鹏凯,邓朗妮. CFRP筋粘结式锚固体系界面失效演化机制及粘结强度计算[J]. 吉林大学学报(工学版), 2020, 50(5): 1698-1708. |

| [7] | 宫亚峰,宋加祥,毕海鹏,谭国金,胡国海,林思远. 装配式箱涵结构缩尺模型静载试验及有限元分析[J]. 吉林大学学报(工学版), 2020, 50(5): 1728-1738. |

| [8] | 高昊,王君杰,刘慧杰,王剑明. 连续梁桥地震行为可控设计准则及实用装置[J]. 吉林大学学报(工学版), 2020, 50(5): 1718-1727. |

| [9] | 蒲黔辉,刘静文,赵刚云,严猛,李晓斌. 高性能树脂混凝土加固混凝土偏压柱承载力理论分析[J]. 吉林大学学报(工学版), 2020, 50(2): 606-612. |

| [10] | 张云龙,郭阳阳,王静,梁东. 钢-混凝土组合梁的固有频率及其振型[J]. 吉林大学学报(工学版), 2020, 50(2): 581-588. |

| [11] | 王伯昕,杨海涛,王清,高欣,陈小旭. 基于补充改进集合经验模态分析法⁃多尺度排列熵分析桥梁振动信号优化滤波方法[J]. 吉林大学学报(工学版), 2020, 50(1): 216-226. |

| [12] | 张淼,钱永久,张方,朱守芹. 基于增大截面法的混凝土加固石拱桥空间受力性能试验分析[J]. 吉林大学学报(工学版), 2020, 50(1): 210-215. |

| [13] | 杨德磊,童乐为. 支管受轴向受拉工况下CHS-CFSHS T型节点应力集中系数计算公式[J]. 吉林大学学报(工学版), 2019, 49(6): 1891-1899. |

| [14] | 贾毅,赵人达,王永宝,李福海. 多跨长联连续梁桥粘滞阻尼器参数敏感性分析[J]. 吉林大学学报(工学版), 2019, 49(6): 1871-1883. |

| [15] | 钟春玲,梁东,张云龙,王静. 体外预应力加固简支梁自振频率计算[J]. 吉林大学学报(工学版), 2019, 49(6): 1884-1890. |

|

||