吉林大学学报(工学版) ›› 2021, Vol. 51 ›› Issue (6): 1959-1966.doi: 10.13229/j.cnki.jdxbgxb20200647

• 车辆工程·机械工程 • 上一篇

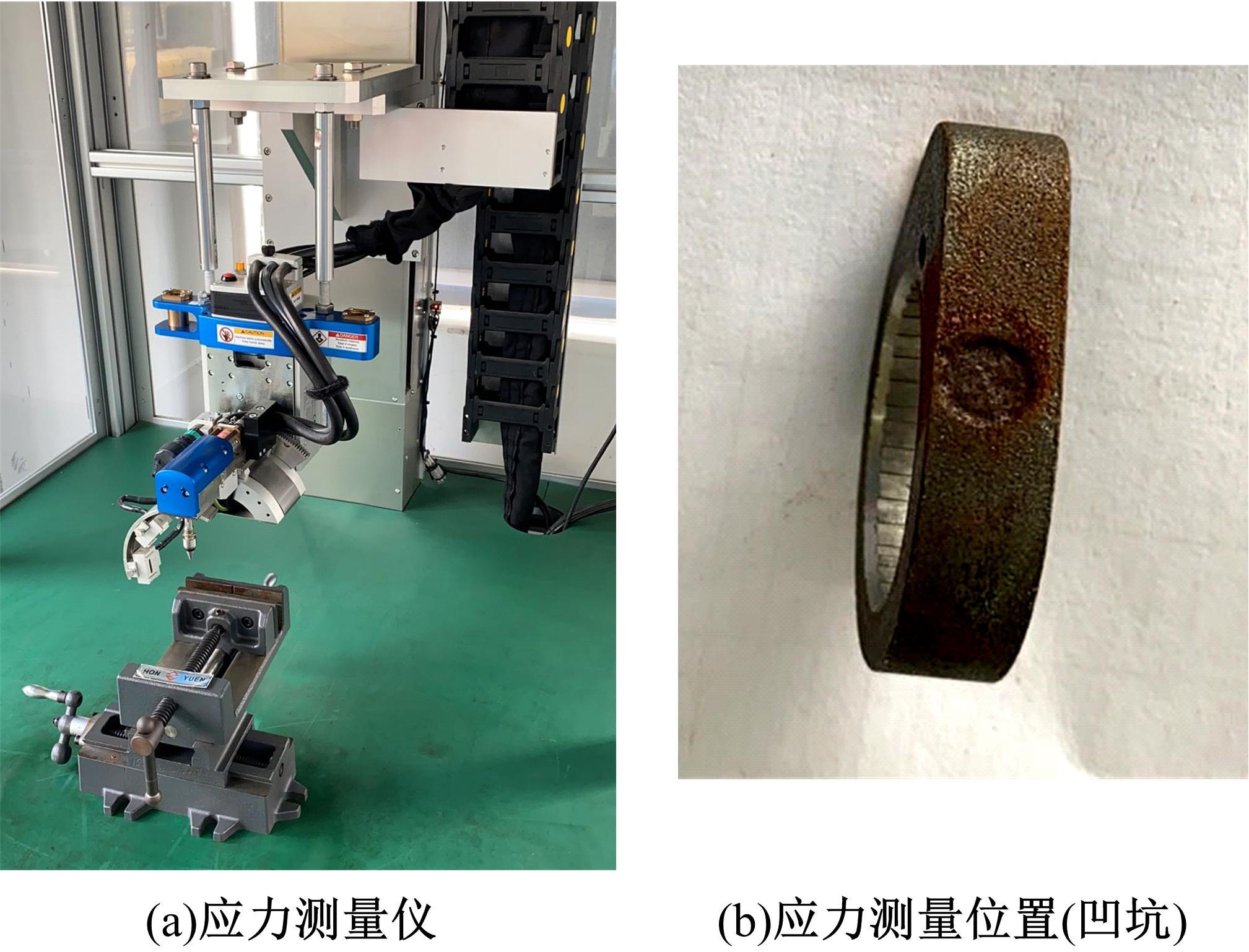

过盈量及滚花方式对装配式凸轮轴压装失效的影响

陈剑斌1,2,3( ),周宋泽3,费峰永2,陈永龙2,凌国平1

),周宋泽3,费峰永2,陈永龙2,凌国平1

- 1.浙江大学 材料科学与工程学院,杭州 310058

2.宁波圣龙(集团)有限公司 圣龙国家级企业技术中心,浙江 宁波 315000

3.宁波大学 机械工程与力学学院,浙江 宁波 315211

Influences of interference fit and knurling connection type on press fitting failure of assembled camshaft

Jian-bin CHEN1,2,3( ),Song-ze ZHOU3,Feng-yong FEI2,Yong-long CHEN2,Guo-ping LING1

),Song-ze ZHOU3,Feng-yong FEI2,Yong-long CHEN2,Guo-ping LING1

- 1.School of Materials Science and Engineering,Zhejiang University,Hangzhou 310058,China

2.SLPT State-level Enterprise Engineering Center,Ningbo Shenglong Group Co. ,Ltd. ,Ningbo 315000,China

3.School of Mechanical Engineering and Mechanics,Ningbo University,Ningbo 315211,China

摘要:

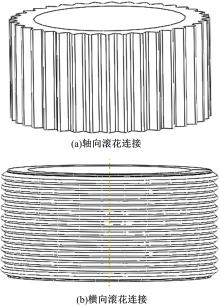

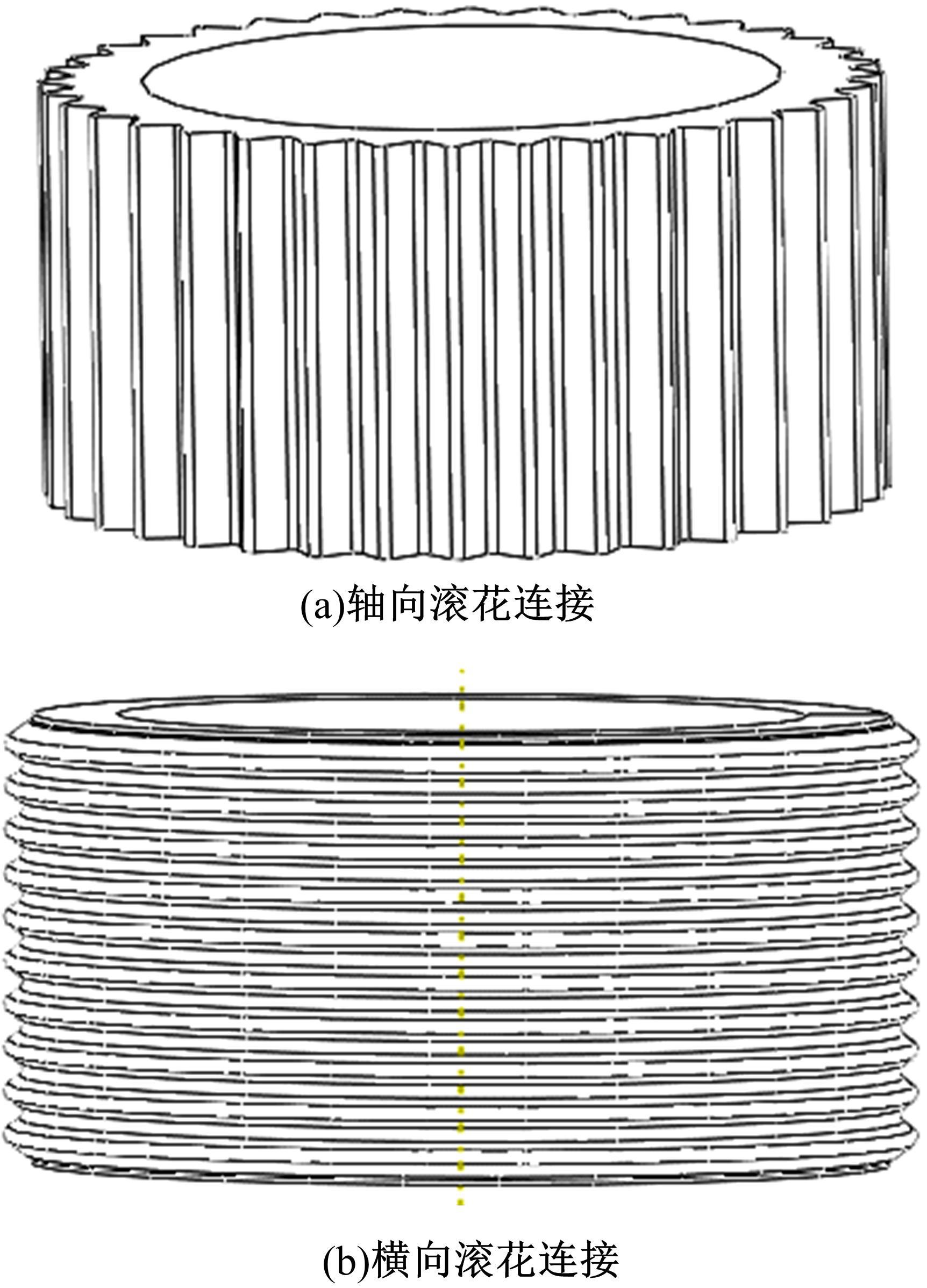

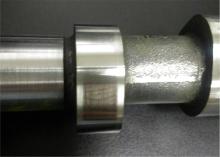

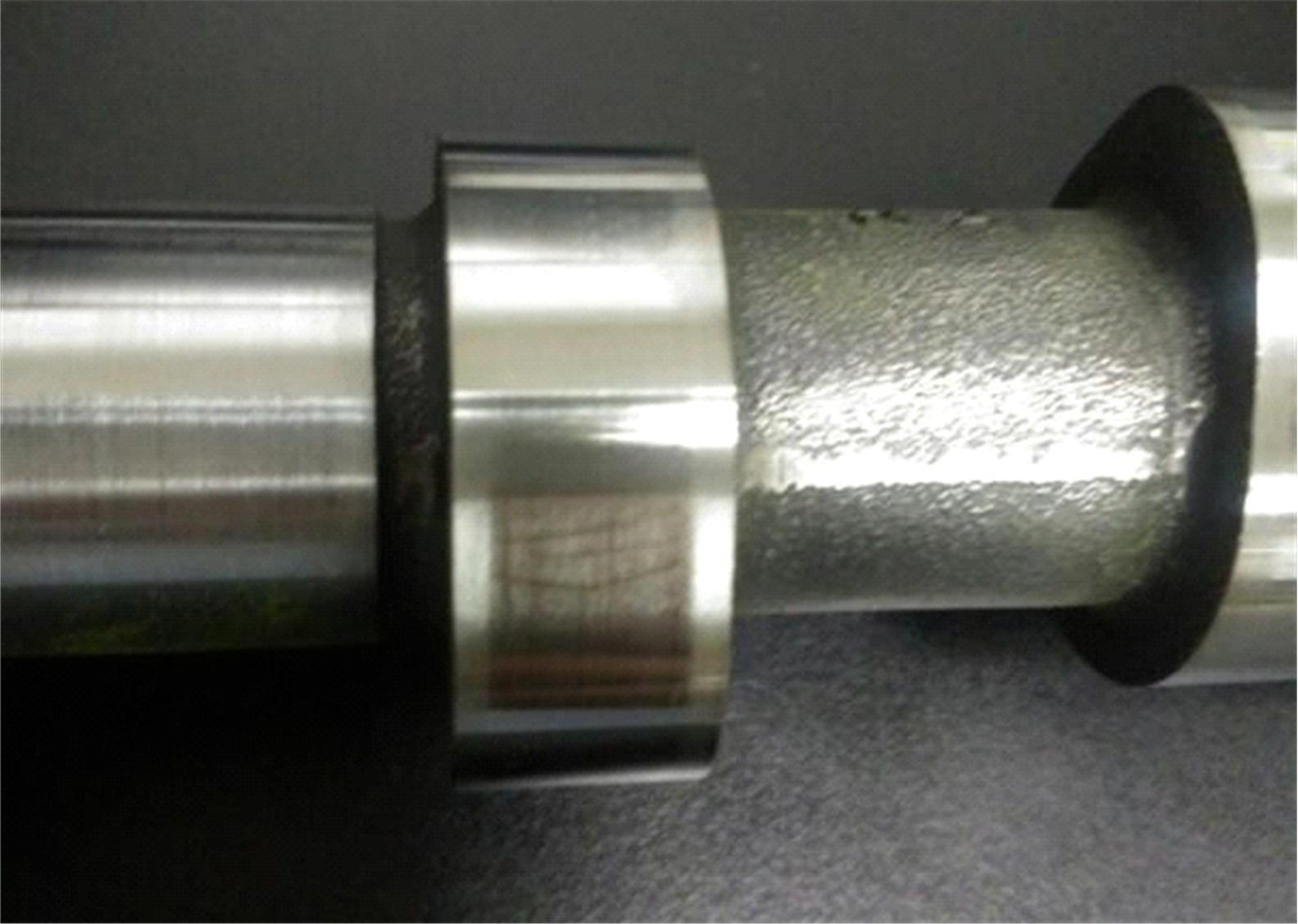

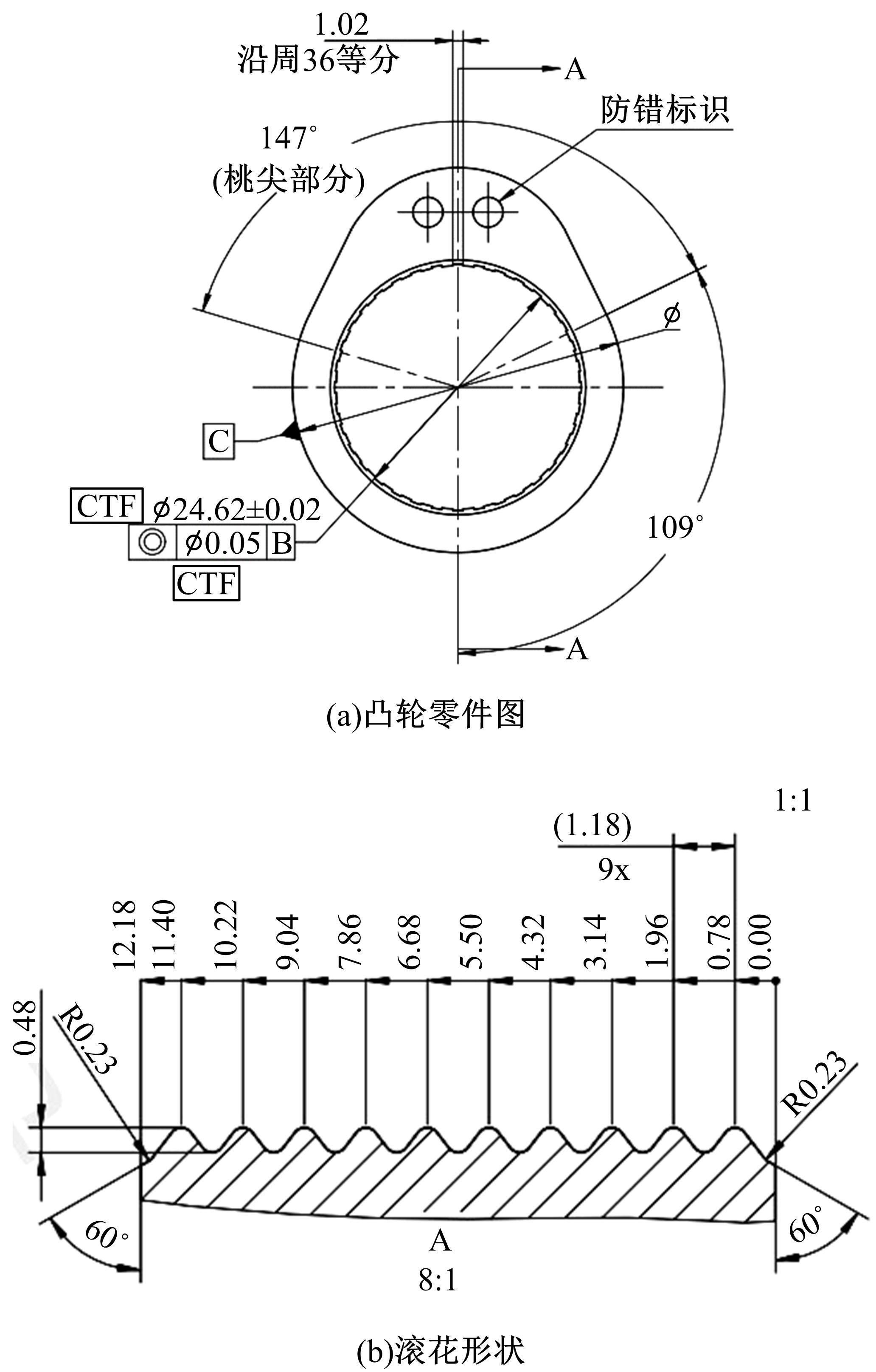

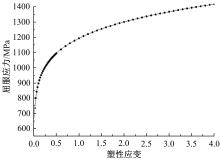

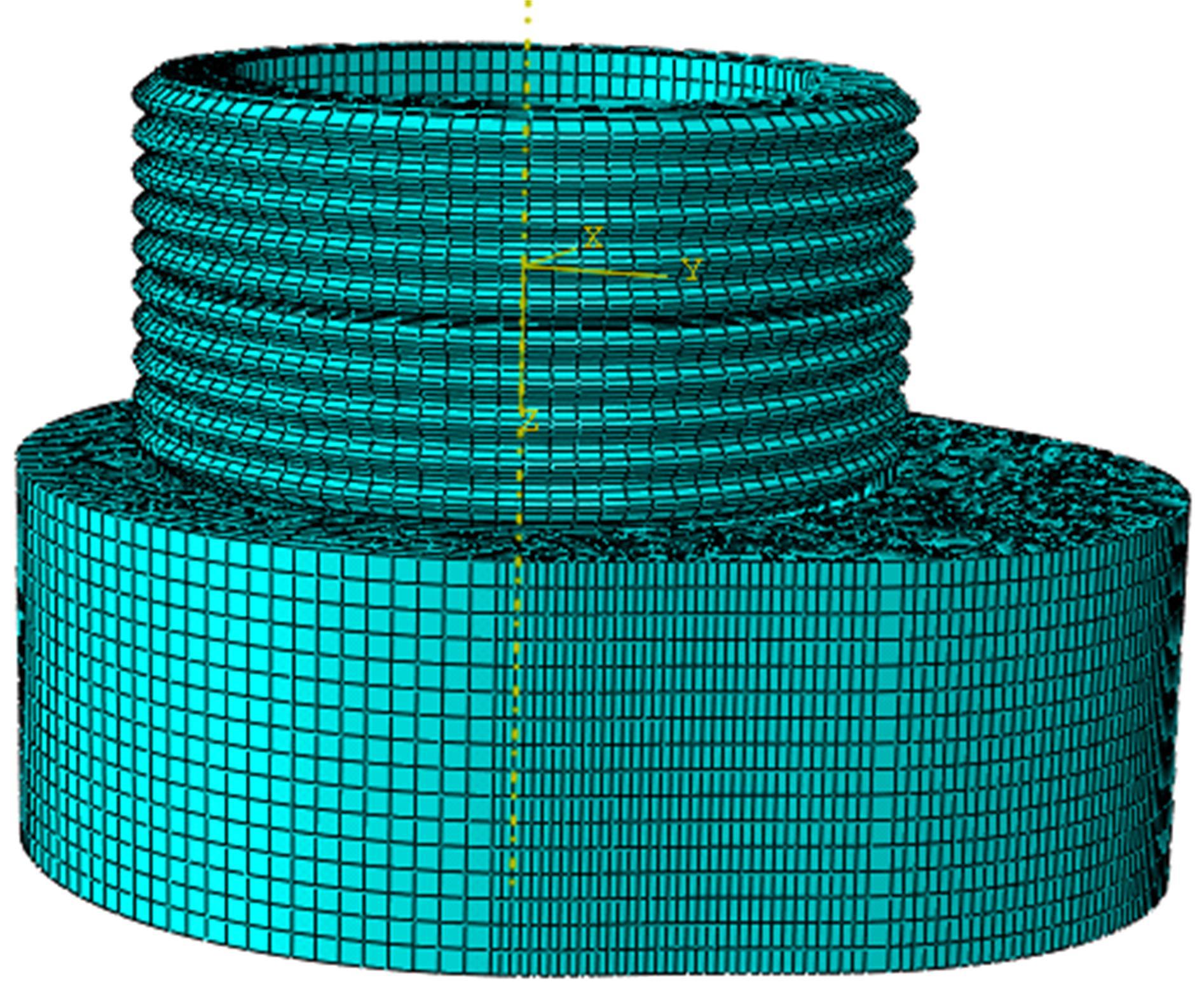

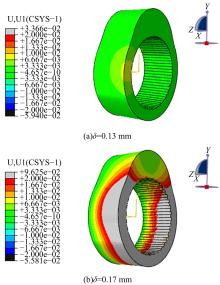

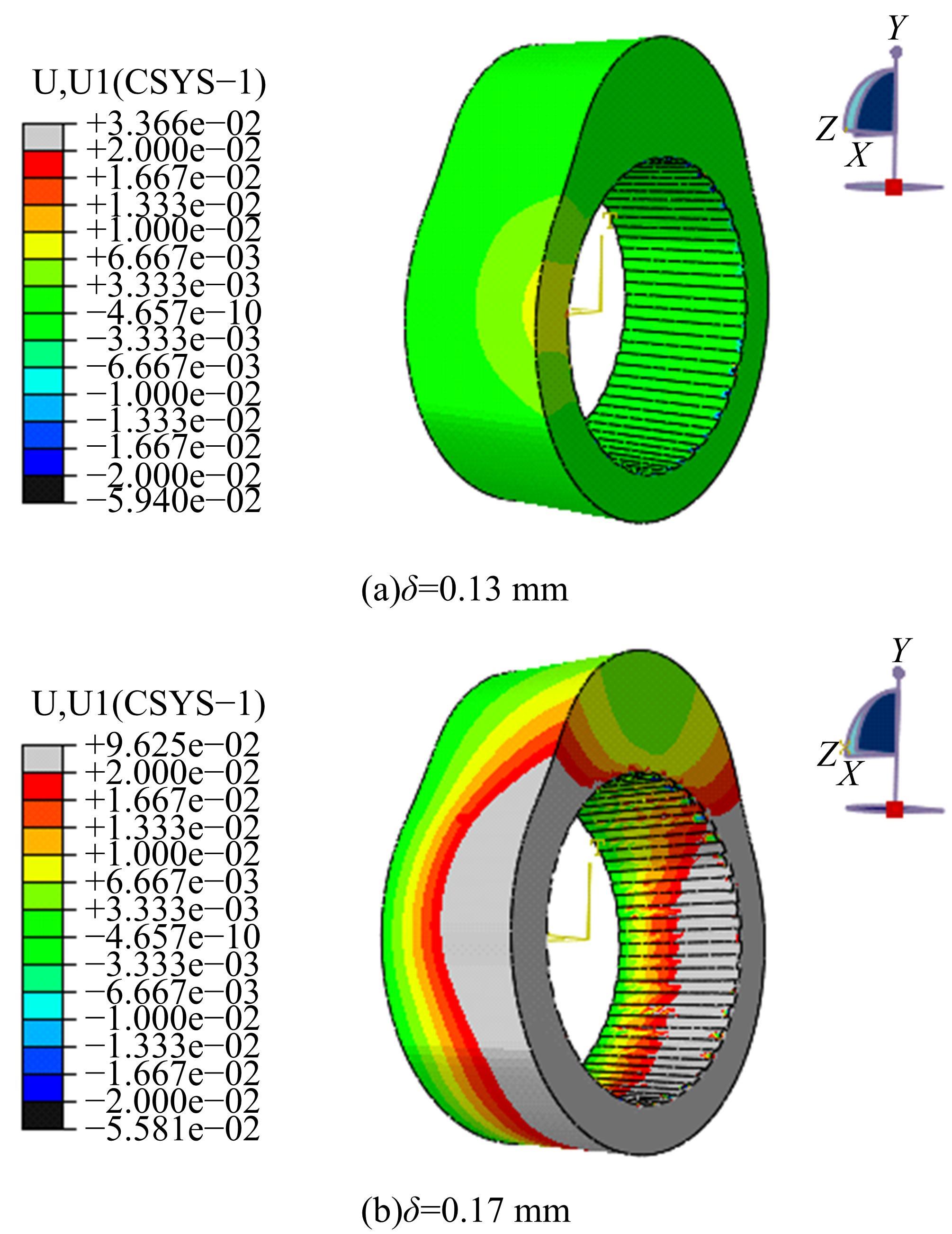

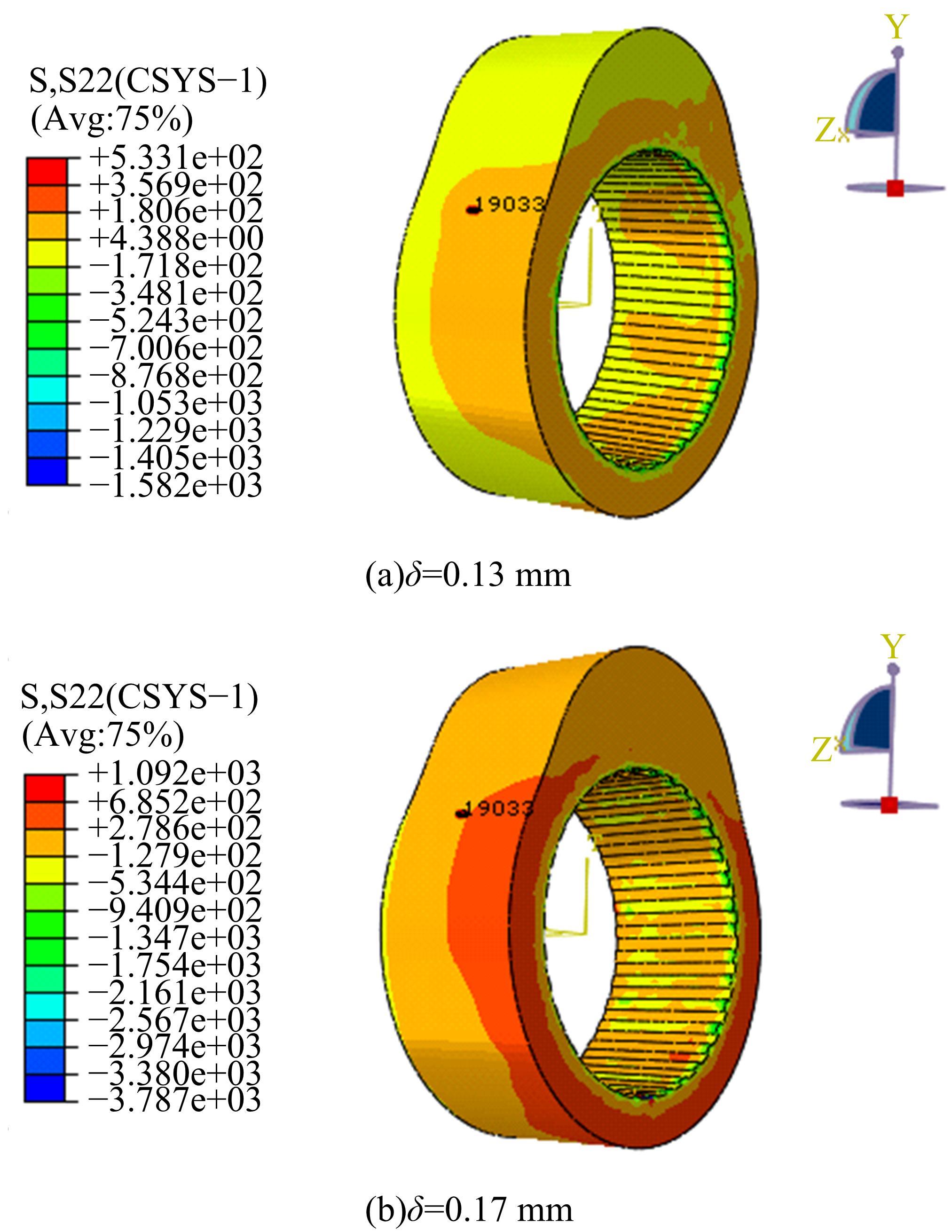

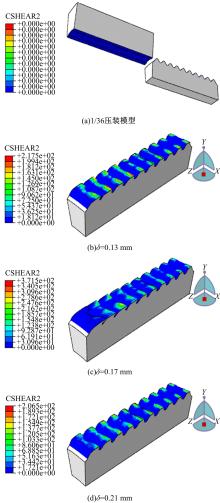

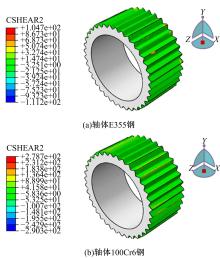

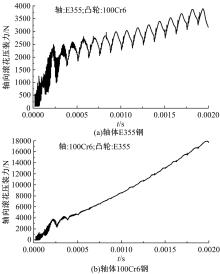

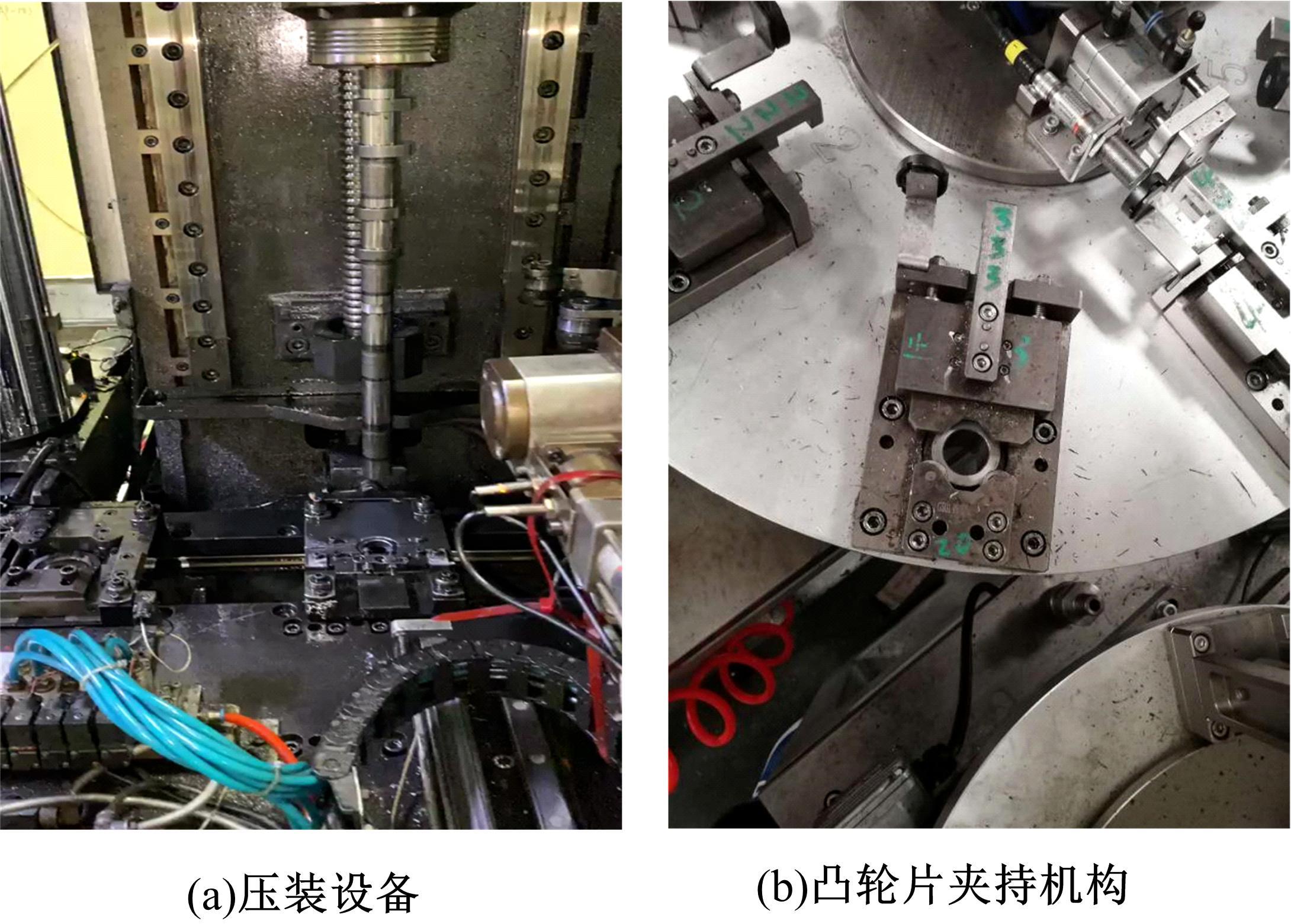

基于有限元仿真方法,研究了过盈量及滚花方式对装配式凸轮轴滚花连接塑性变形及相对滑动等压装失效问题的影响。结果表明:增加连接过盈量能够获得更大的压装力和摩擦剪应力,使连接件配合面越不容易发生相对滑动;另外,过盈量的增加也将导致凸轮轮廓面径向位移数值变大且梯度变化更不均匀,轮廓面过渡区域附近的应力集中明显。为保证配合面不发生打滑,当轴体相对凸轮片较硬时,宜选用轴向滚花连接;反之,则采用横向滚花连接。横向滚花压装试验测得的压装力数据验证了1/36等分压装模型和完整压装模型的合理性。

中图分类号:

- U466

| 1 | 乔健, 寇淑清, 卢清华,等. 材料力学性能对装配式凸轮轴球体扩径连接性能的影响[J]. 锻压技术, 2018, 43(8):144-149. |

| Qiao Jian, Kou Shu-qing, Lu Qing-hua, et al. Influence of material mechanical properties on ball expanding and connection performance for assembled camshaft[J]. Forging & Stamping Technology, 2018, 43(8): 144-149. | |

| 2 | 黄进杰, 杨连发, 马建平. 基于液压胀形的三叶等距型面装配式凸轮轴的接触有限元分析[J]. 锻压技术, 2020, 45(3):101-108. |

| Huang Jin-jie, Yang Lian-fa, Ma Jian-ping. Contact finite element analysis on assembled camshaft with isometric-trilateral sectional profiles based on hydraulic expansion[J]. Forging & Stamping Technology, 2020, 45(3):101-108. | |

| 3 | Cecchel S, Ferrario D, Mondini C, et al. Application of laser metal deposition for a new model of assembled camshaft[J]. Journal of Materials Engineering and Performance, 2019, 28(5):7756-7767. |

| 4 | Zhang P, Kou S Q, Li C, et al. Joint mechanism and prediction of strength for a radial knurling connection of assembled camshaft using a subsequent modeling approach[J]. SAE International Journal of Engines, 2018, 11(3): 301-310. |

| 5 | 齐红敏. 粉末冶金复合凸轮过盈装配的应力研究[D]. 北京:北京有色金属研究总院, 2016. |

| Qi Hong-min. research on the interference assembly stress of powder metallurgy cam with composite layered structure[D]. Beijing: General Research Institute for Nonferrous Metals, 2016. | |

| 6 | 张驰, 徐沛娟, 何东野, 等. 凸轮轴横向滚花连接的压装扭转数值模拟分析[J]. 吉林大学学报: 工学版, 2012, 42():216-220. |

| Zhang Chi, Xu Pei-juan, He Dong-ye, et al. Research on the transverse knurling connection mechanism of assembled camshaft and numerical simulation analysis on the press mounting and torsion process[J]. Journal of Jilin University(Engineering and Technology Edition), 2012, 42(Sup.1):216-220. | |

| 7 | 寇淑清, 石舟, 朱欢, 等. 滚花联接凸轮轴装配过程数值仿真及影响因素分析[J]. 精密成形工程, 2019, 11(1):63-69. |

| Kou Shu-qing, Shi Zhou, Zhu Huan, et al. Simulation analysis on knurling connection process and influencing factors of assembled camshaft[J]. Journal of Netshape Forming Engineering, 2019, 11(1):63-69. | |

| 8 | Zhang P, Kou S, Lin B, et al. Optimization for radial knurling connection process of assembled camshaft using response surface method[J]. International Journal of Advanced Manufacturing Technology, 2015, 77(1-4): 653-661. |

| 9 | 郭爱贵, 范为民, 孙伟, 等. 基于有限元法的过盈配合接触特性分析[J]. 成组技术与生产现代化, 2009, 26(4):4-7. |

| Guo Ai-gui, Fan Wei-min, Sun Wei, et al. Contact characteristics analysis of interference fit based on finite element method[J]. Group Technology & Production Modernization, 2009, 26(4):4-7. | |

| 10 | 袁靖, 赵蛟, 姚进, 等. 不同材料对圆柱滚花过盈联接连接强度的影响[J]. 陕西理工大学学报:自然科学版, 2020, 36(1):8-13, 48. |

| Yuan Jing, Zhao Jiao, Yao Jin, et al. Influence of different materials on connection strength in knurling connection[J]. Journal of Shaanxi University of Technology(Natural Science Edition), 2020, 36(1):8-13, 48. |

| [1] | 胡兴军,张靖龙,罗雨霏,辛俐,李胜,胡金蕊,兰巍. 冷却管结构及进气方向对空冷中冷器性能的影响[J]. 吉林大学学报(工学版), 2021, 51(6): 1933-1942. |

| [2] | 罗勇,韦永恒,黄欢,肖人杰,任淋,崔环宇. 驾驶员意图识别的P2.5插混构型双离合器起步控制[J]. 吉林大学学报(工学版), 2021, 51(5): 1575-1582. |

| [3] | 曾小华,宋美洁,宋大凤,王越. 基于车联网信息的公交客车行驶工况数据处理方法[J]. 吉林大学学报(工学版), 2021, 51(5): 1692-1699. |

| [4] | 马超,高云凯,刘哲,段月星,田林雳. 骨架式车身多材料及梁截面形状和尺寸优化[J]. 吉林大学学报(工学版), 2021, 51(5): 1583-1592. |

| [5] | 兰凤崇,李继文,陈吉清. 面向动态场景复合深度学习与并行计算的DG-SLAM算法[J]. 吉林大学学报(工学版), 2021, 51(4): 1437-1446. |

| [6] | 杨建,夏琦,周海超,王国林. 修正胎体弦轮廓载重子午线轮胎的降噪机理[J]. 吉林大学学报(工学版), 2021, 51(4): 1198-1203. |

| [7] | 龙江启,向锦涛,俞平,王骏骋. 适用于非线性主动悬架滑模控制的线性干扰观测器[J]. 吉林大学学报(工学版), 2021, 51(4): 1230-1240. |

| [8] | 陈鑫,于贵申,张彪,潘凯旋,杨立飞. 搅拌摩擦点焊接头拉伸-剪切行为的等效建模[J]. 吉林大学学报(工学版), 2021, 51(4): 1190-1197. |

| [9] | 宋大凤,杨丽丽,曾小华,王星琦,梁伟智,杨南南. 基于行驶工况合成的混合动力汽车电池寿命优化[J]. 吉林大学学报(工学版), 2021, 51(3): 781-791. |

| [10] | 张家旭,王欣志,赵健,施正堂. 汽车高速换道避让路径规划及离散滑模跟踪控制[J]. 吉林大学学报(工学版), 2021, 51(3): 1081-1090. |

| [11] | 何仁,赵晓聪,杨奕彬,王建强. 基于驾驶人风险响应机制的人机共驾模型[J]. 吉林大学学报(工学版), 2021, 51(3): 799-809. |

| [12] | 王波,何洋扬,聂冰冰,许述财,张金换. 底部爆炸条件下车内乘员的腹部损伤[J]. 吉林大学学报(工学版), 2021, 51(3): 792-798. |

| [13] | 庄蔚敏,王鹏跃,高瑞娟,解东旋. 温热成形对AA5754铝合金静态力学性能的影响[J]. 吉林大学学报(工学版), 2021, 51(3): 847-854. |

| [14] | 宋强,孙丹婷,章伟. 纯电动车机械式自动变速器换挡非线性建模及控制[J]. 吉林大学学报(工学版), 2021, 51(3): 810-819. |

| [15] | 李寿涛,王蕊,徐靖淳,王德军,田彦涛,于丁力. 一种基于模型预测复合控制的车辆避碰控制方法[J]. 吉林大学学报(工学版), 2021, 51(2): 738-746. |

|

||