吉林大学学报(工学版) ›› 2021, Vol. 51 ›› Issue (4): 1190-1197.doi: 10.13229/j.cnki.jdxbgxb20200503

• 车辆工程·机械工程 • 上一篇

搅拌摩擦点焊接头拉伸-剪切行为的等效建模

- 吉林大学 汽车仿真与控制国家重点实验室,长春 130022

Equivalent modeling of tensile-shear behavior for friction stir spot welding joints

Xin CHEN( ),Gui-shen YU,Biao ZHANG,Kai-xuan PAN,Li-fei YANG

),Gui-shen YU,Biao ZHANG,Kai-xuan PAN,Li-fei YANG

- State Key Laboratory of Automotive Simulation and Control,Jilin University,Changchun 130022,China

摘要:

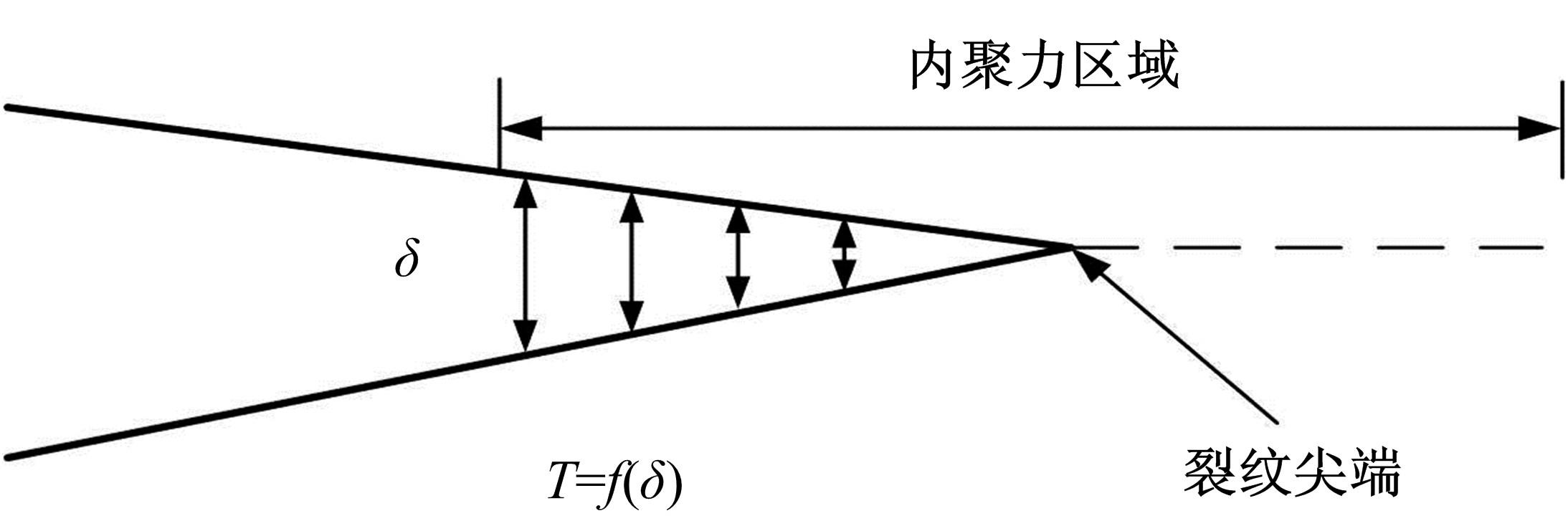

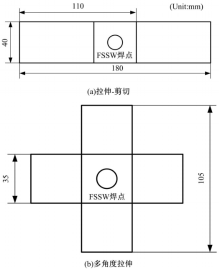

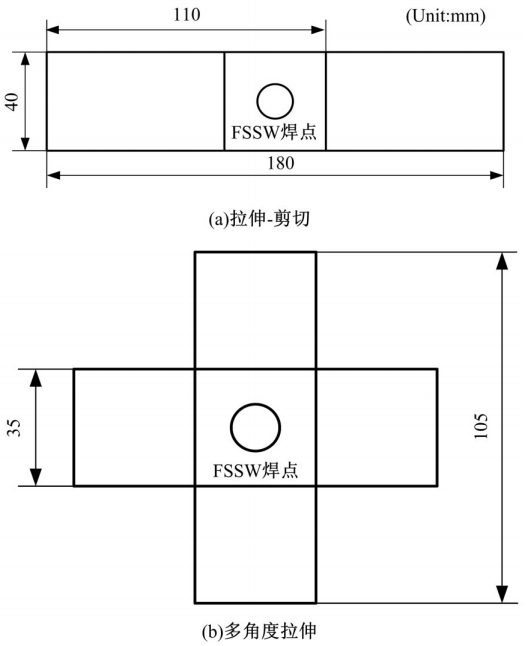

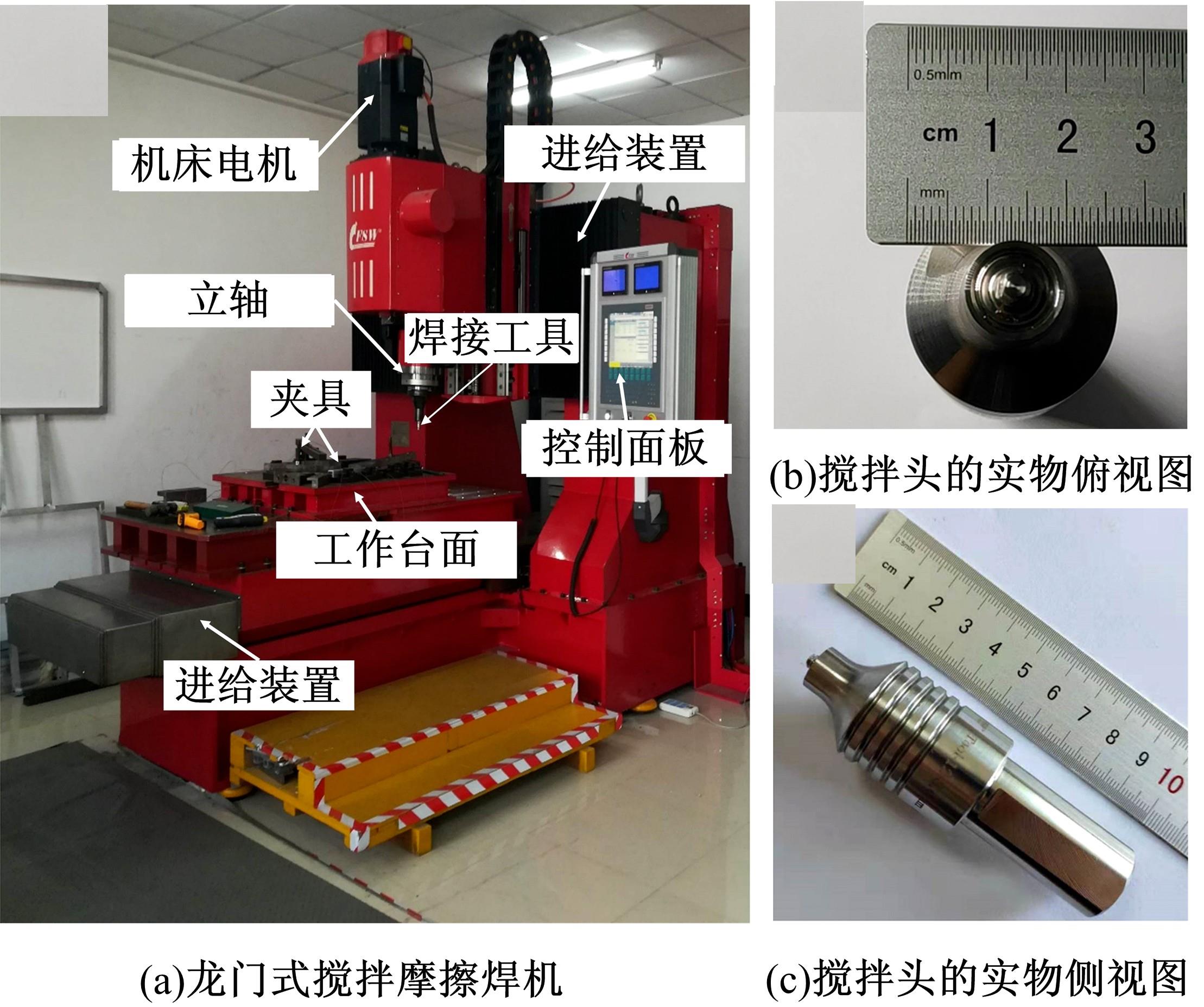

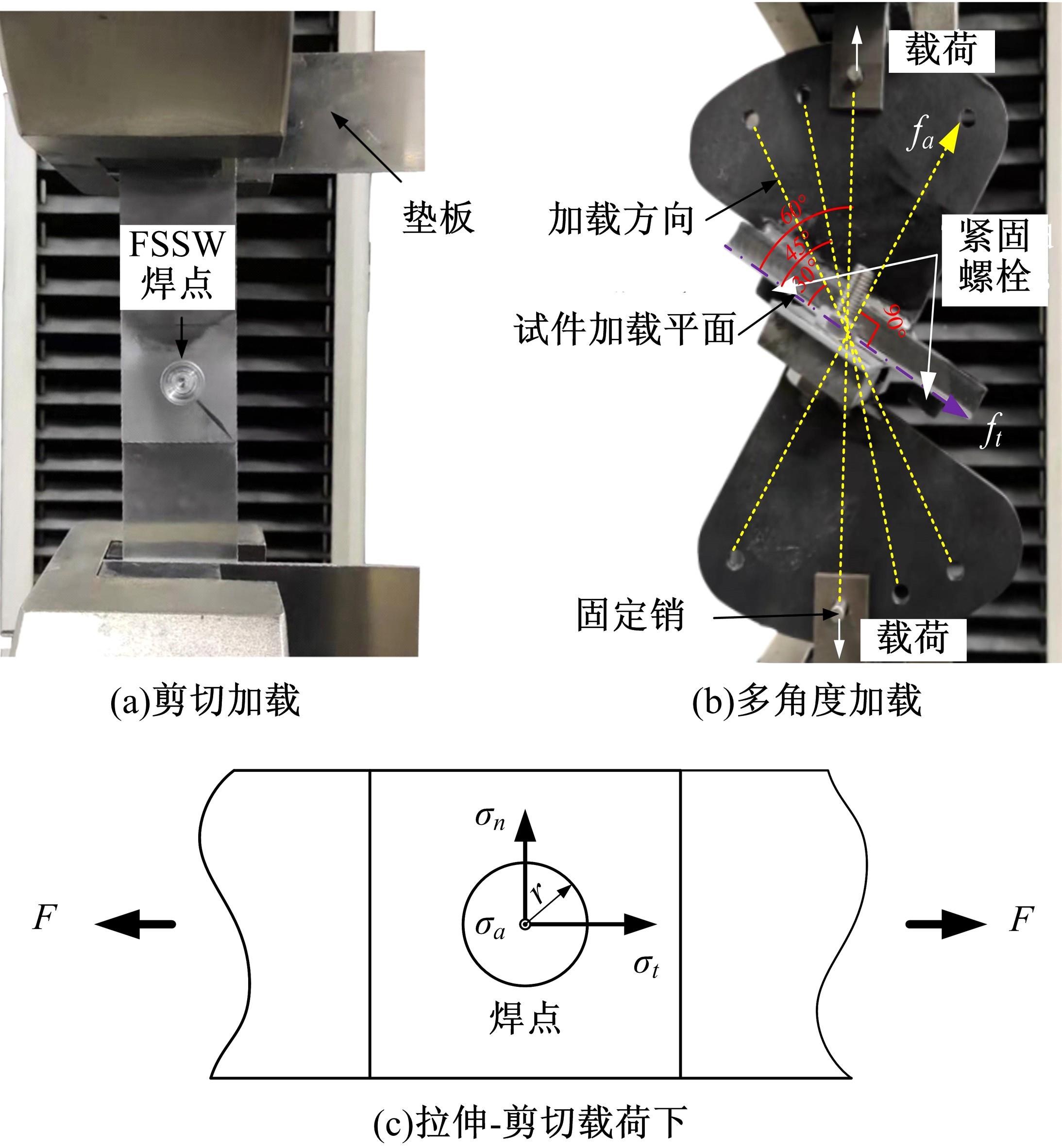

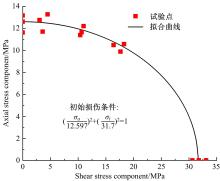

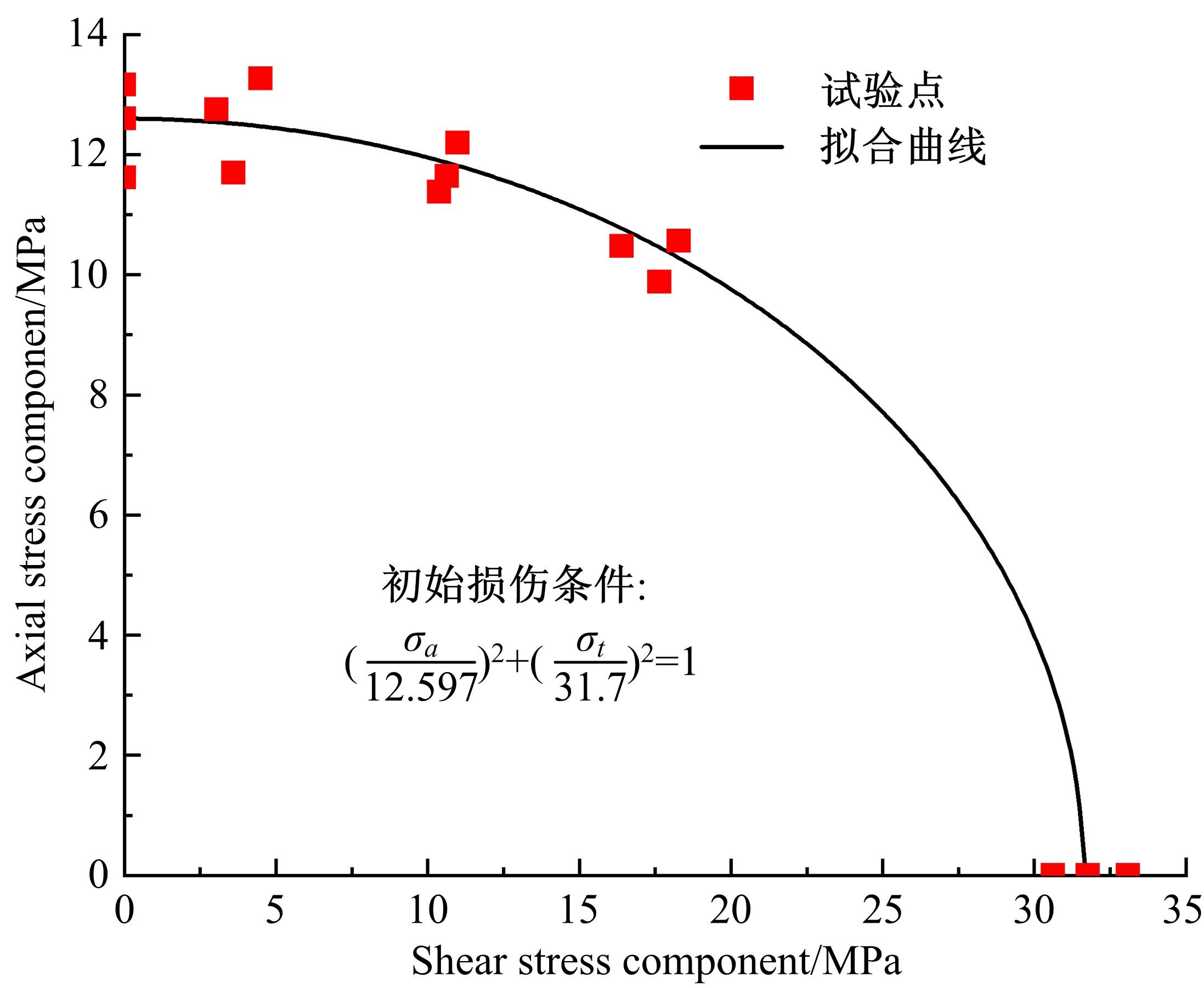

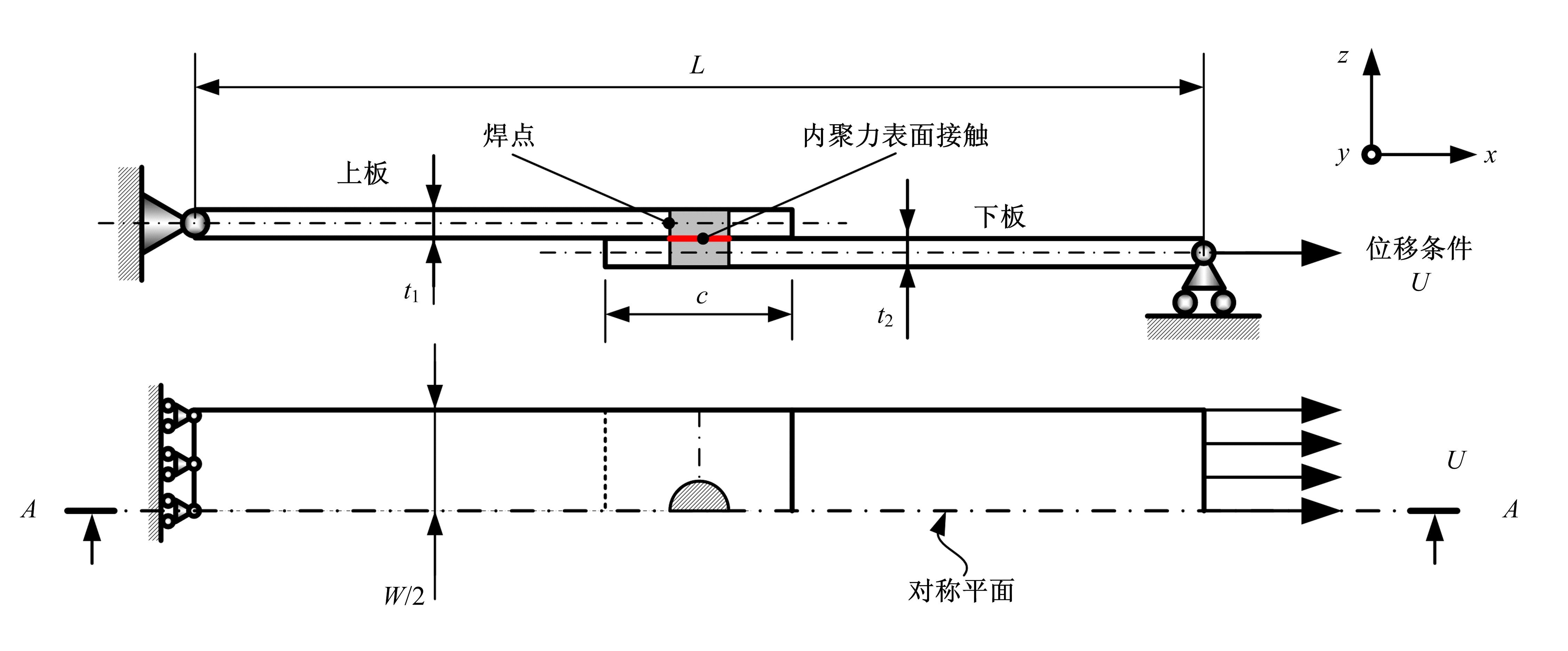

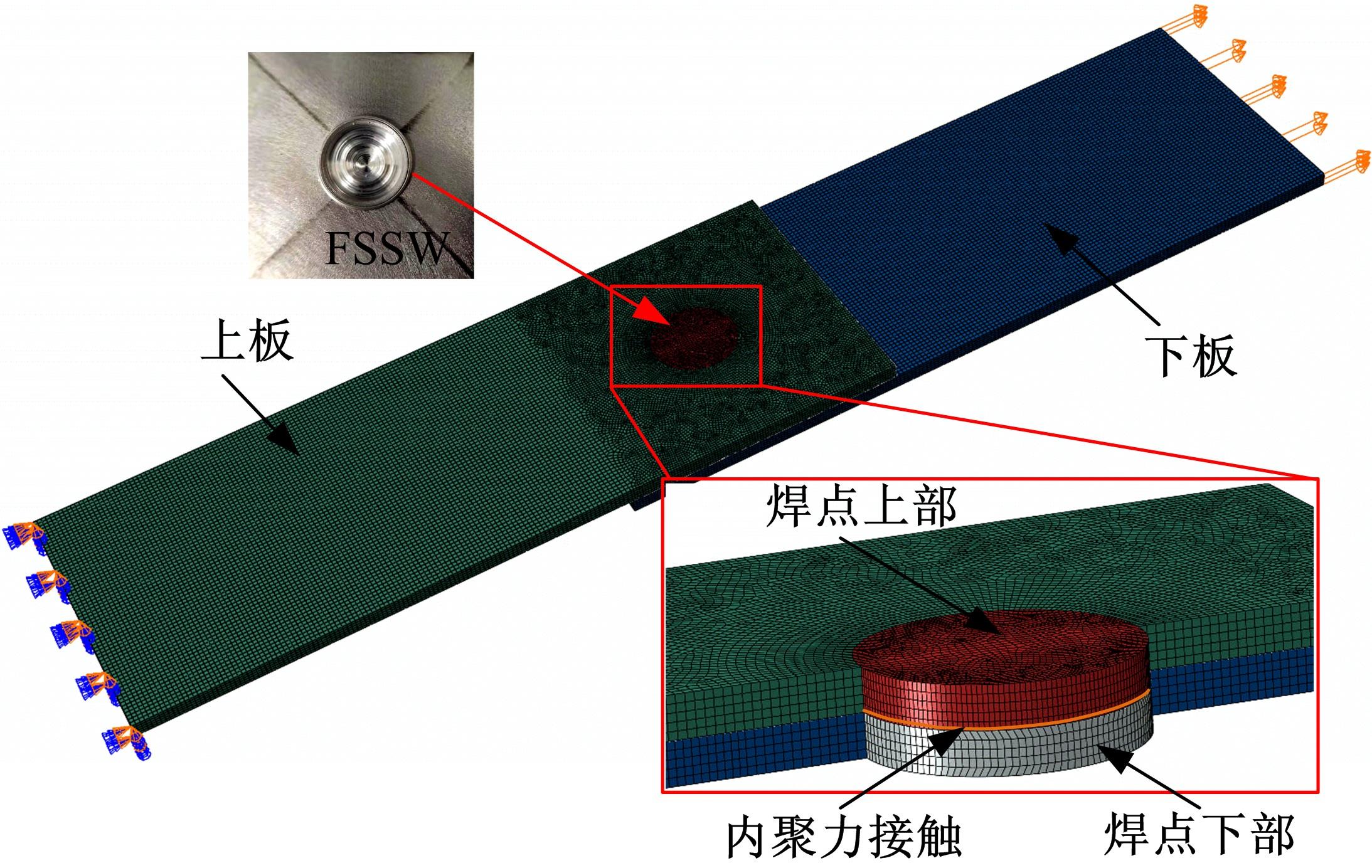

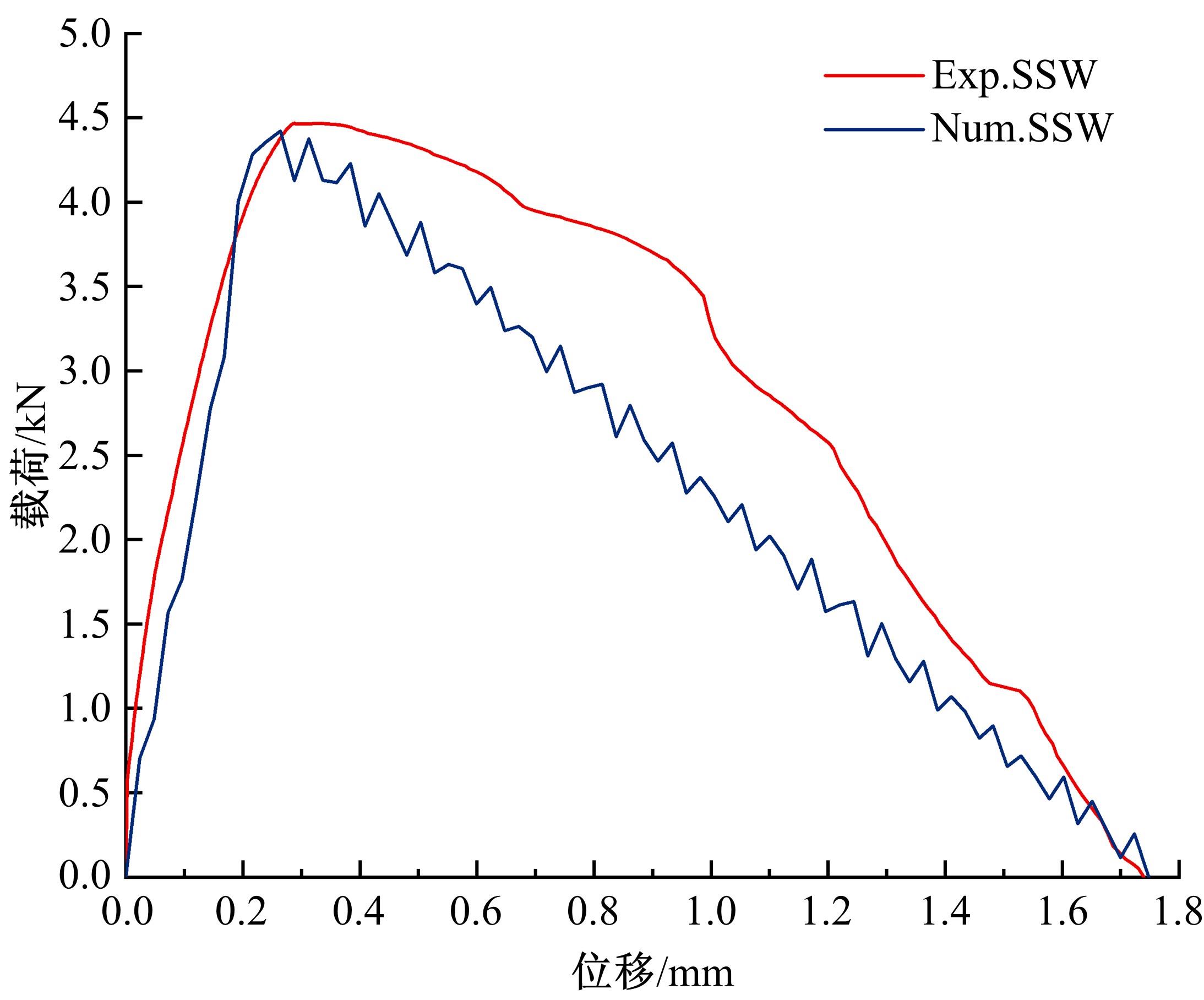

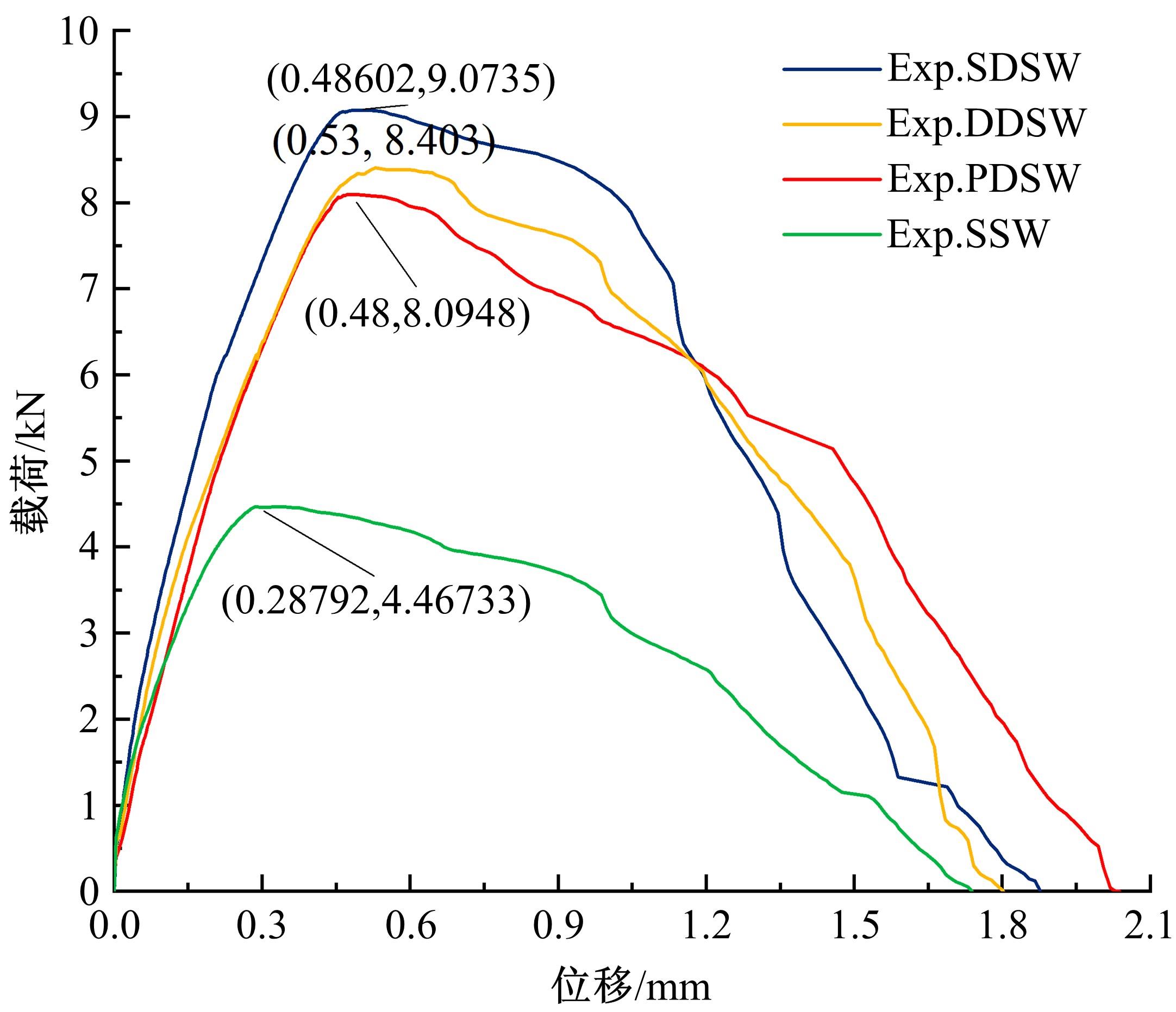

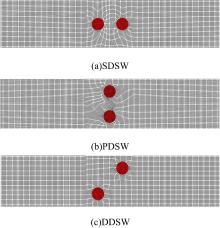

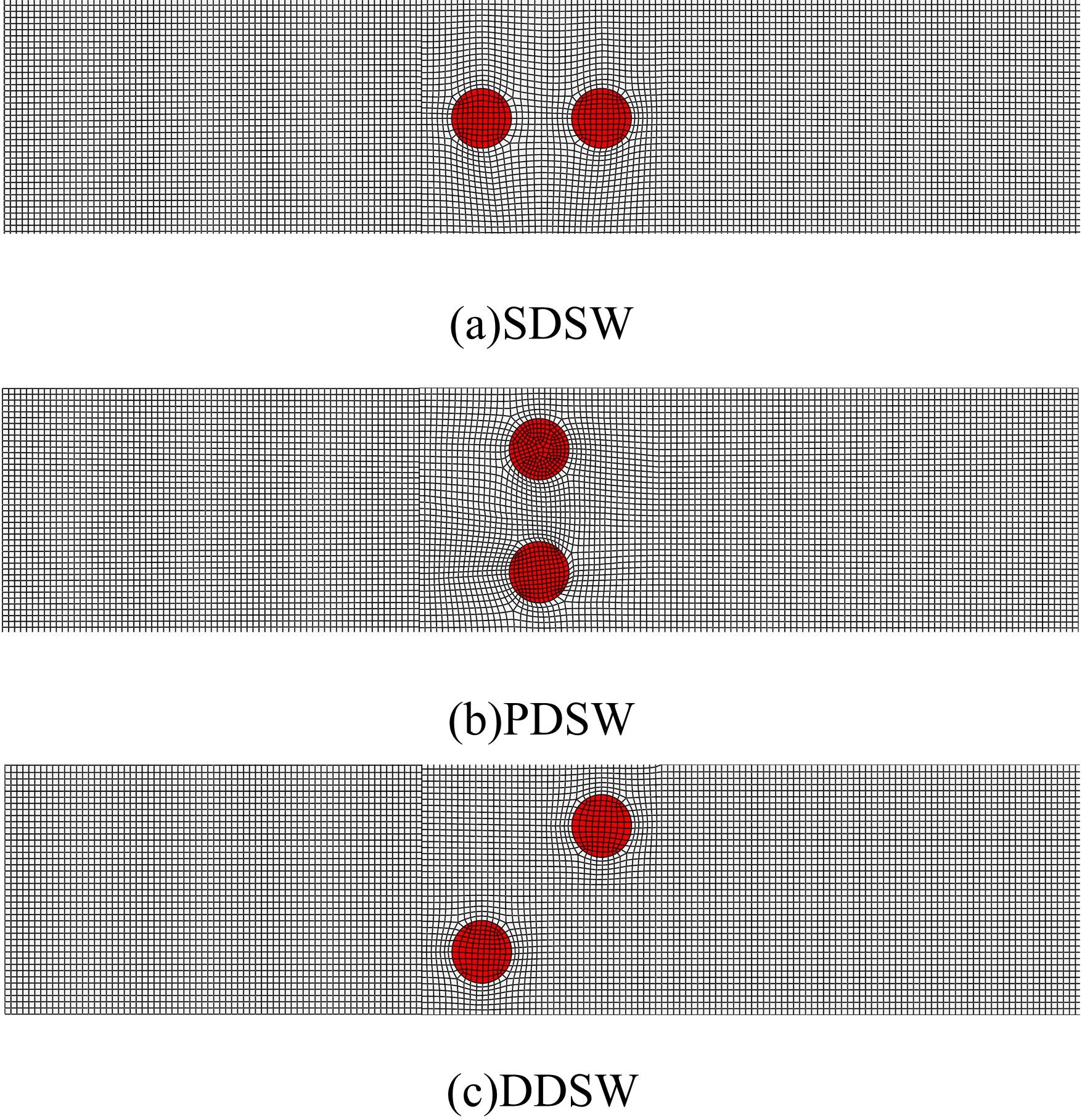

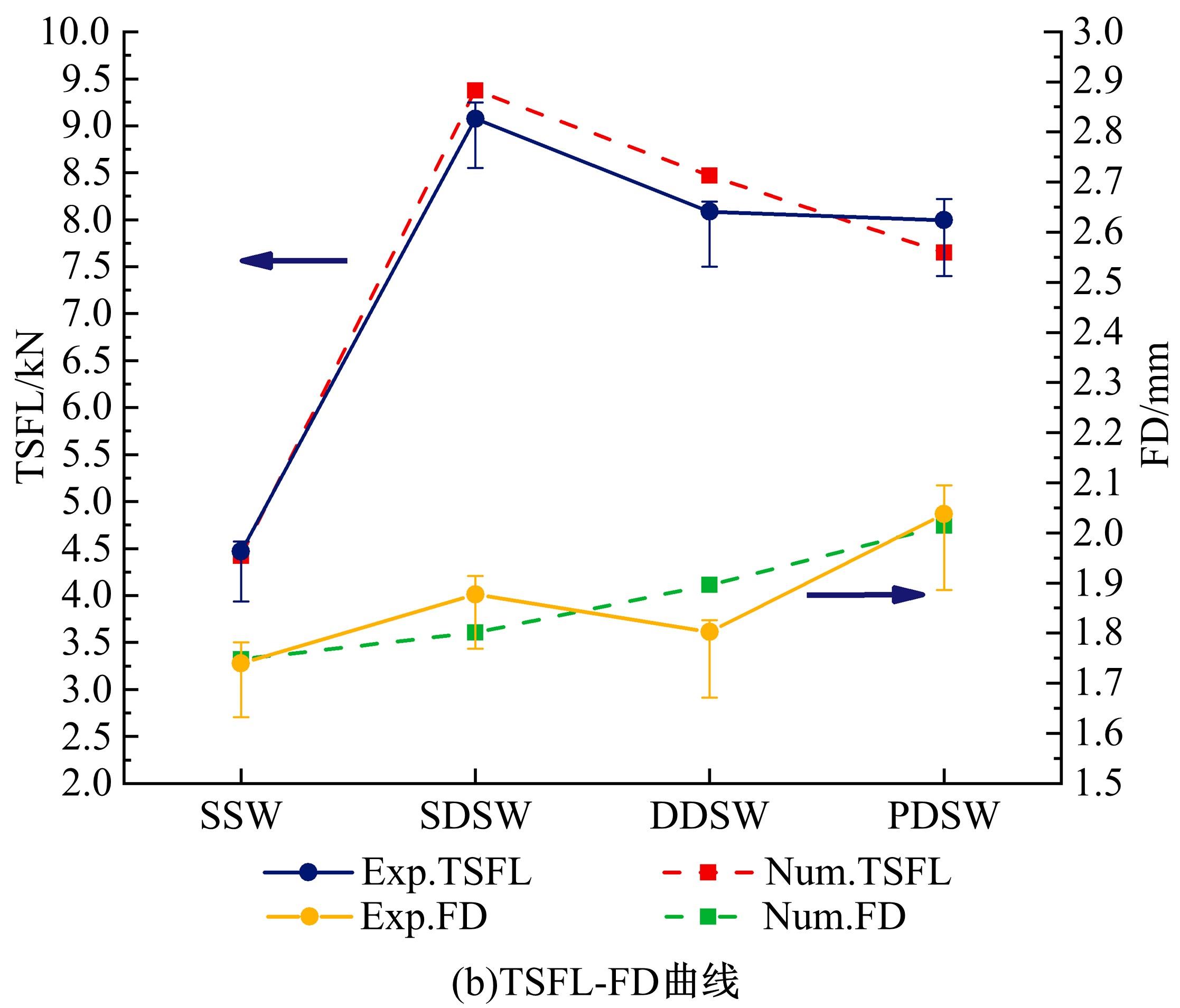

针对车身焊点最主要的拉伸-剪切载荷的仿真,提出了内聚力焊点模型(CZWM)的等效建模方法。通过单焊点接头的剪切和多角度拉伸对焊点的初始损伤和断裂能进行测定,建立接头的等效模型。该模型与单焊点接头的拉伸-剪切过程相吻合。同时,通过3种双焊点接头对CZWM的有效性进行了验证。结果表明:CZWM在拉伸-剪切失效载荷(TSFL)和失效位移(FD)的最大偏差分别为9.3%和7.1%;双焊点接头的焊点分布与外载荷方向平行时接头承载最强,垂直时承载最差,斜交居中。该模型为车身FSSW焊点力学行为的数值模拟提供了一种选择。

中图分类号:

- U41

| 1 | Shen Z, Ding Y, Gerlich A P. Advances in friction stir spot welding[J]. Critical Reviews in Solid State and Materials Sciences, 2020,45(6):457-534. |

| 2 | Kayode O, Akinlabi E T. An overview on joining of aluminium and magnesium alloys using friction stir welding (FSW) for automotive lightweight applications[J]. Materials Research Express, 2019, 6(11):190. |

| 3 | Ma Z Y, Feng A H, Chen D, et al. Recent advances in friction stir welding/processing of aluminum alloys: microstructural evolution and mechanical properties[J]. Critical Reviews in Solid State and Materials Sciences, 2018, 43(4): 269-333. |

| 4 | Ojo O O, Taban E, Kaluc E. Friction stir spot welding of aluminum alloys: a recent review[J]. Materials Testing, 2015, 57(7/8): 609-627. |

| 5 | Bagheri B, Abbasi M, Givi M. Effects of vibration on microstructure and thermal properties of friction stir spot welded (FSSW) aluminum alloy (Al5083)[J]. International Journal of Precision Engineering and Manufacturing, 2019, 20(7): 1219-1227. |

| 6 | Bagheri B, Rizi A A M, Abbasi M, et al. Friction stir spot vibration welding: improving the microstructure and mechanical properties of Al5083 joint[J]. Metallography Microstructure and Analysis, 2019, 8(5): 713-725. |

| 7 | Lacki P, Adamus K, Winowiecka J. The numerical simulation of aviation structure joined by FSW[J]. Archives of Metallurgy and Materials, 2019, 64(1): 387-392. |

| 8 | Chu Q, Yang X, Li W, et al. Numerical analysis of material flow in the probeless friction stir spot welding based on coupled Eulerian-Lagrangian approach[J]. Journal of Manufacturing Processes, 2018, 36: 181-187. |

| 9 | Eskandari M, Aval H J, Jamaati R. The study of thermomechanical and microstructural issues in dissimilar FSW of AA6061 wrought and A390 cast alloys[J]. Journal of Manufacturing Processes, 2019, 41: 168-176. |

| 10 | Li Z, Yue Y, Ji S, et al. Optimal design of thread geometry and its performance in friction stir spot welding[J]. Materials & Design, 2016, 94: 368-376. |

| 11 | Zhang B, Chen X, Pan K, et al. Thermo-mechanical simulation using microstructure-based modeling of friction stir spot welded AA6061-T6[J]. Journal of Manufacturing Processes, 2019, 37: 71-81. |

| 12 | Park K, Choi H, Paulino G H. Assessment of cohesive traction-separation relationships in ABAQUS: a comparative study[J]. Mechanics Research Communications, 2016, 78(B): 71-78. |

| 13 | Silva L D, Rodrigues T, Figueiredo M, et al. Effect of adhesive type and thickness on the lap shear strength[J]. The Journal of Adhesion, 2006, 82(11): 1091-1115. |

| 14 | Sadigh M. Enhanced failure load bearing in adhesively bonded strap repairs: numerical analysis and experimental results[J]. Journal of Failure Analysis and Prevention, 2019, 19(1): 182-192. |

| 15 | Bozzi S, Helbert-Etter A L, Baudin T, et al. Influence of FSSW parameters on fracture mechanisms of 5182 aluminium welds[J]. Journal of Materials Processing Technology, 2010, 210(11): 1429-1435. |

| 16 | Garg A, Bhattacharya A. On lap shear strength of friction stir spot welded AA6061 alloy[J]. Journal of Manufacturing Processes, 2017, 26: 203-215. |

| 17 | 马轶男, 陶汪, 陈彦宾, 等. 焊点排布方式对激光点焊-胶接复合接头断裂过程的影响[J]. 中国激光, 2013, 40(10):83-90. |

| Ma Yi-nan, Tao Wang, Chen Yan-bin, et al. Influence of spot arrangements on laser spot weld bonded joint fracture process[J]. China Laser, 2013, 40(10): 83-90. | |

| 18 | 马轶男. 激光点焊-胶接复合连接特性及接头断裂机制研究[D]. 哈尔滨: 哈尔滨工业大学先进焊接与连接国家重点实验室, 2015. |

| Ma Yi-nan. Laser spot welding-glue composite connection characteristics and joint fracture mechanism research[D]. Harbin: Advanced Welding and Connection of the National Key Laboratory,Harbin University of Technology,2015. |

| [1] | 宋大凤,杨丽丽,曾小华,王星琦,梁伟智,杨南南. 基于行驶工况合成的混合动力汽车电池寿命优化[J]. 吉林大学学报(工学版), 2021, 51(3): 781-791. |

| [2] | 张家旭,王欣志,赵健,施正堂. 汽车高速换道避让路径规划及离散滑模跟踪控制[J]. 吉林大学学报(工学版), 2021, 51(3): 1081-1090. |

| [3] | 何仁,赵晓聪,杨奕彬,王建强. 基于驾驶人风险响应机制的人机共驾模型[J]. 吉林大学学报(工学版), 2021, 51(3): 799-809. |

| [4] | 宋强,孙丹婷,章伟. 纯电动车机械式自动变速器换挡非线性建模及控制[J]. 吉林大学学报(工学版), 2021, 51(3): 810-819. |

| [5] | 王波,何洋扬,聂冰冰,许述财,张金换. 底部爆炸条件下车内乘员的腹部损伤[J]. 吉林大学学报(工学版), 2021, 51(3): 792-798. |

| [6] | 庄蔚敏,王鹏跃,高瑞娟,解东旋. 温热成形对AA5754铝合金静态力学性能的影响[J]. 吉林大学学报(工学版), 2021, 51(3): 847-854. |

| [7] | 李寿涛,王蕊,徐靖淳,王德军,田彦涛,于丁力. 一种基于模型预测复合控制的车辆避碰控制方法[J]. 吉林大学学报(工学版), 2021, 51(2): 738-746. |

| [8] | 王伟达,武燕杰,史家磊,李亮. 基于驾驶员意图识别的电子液压制动助力系统控制策略[J]. 吉林大学学报(工学版), 2021, 51(2): 406-413. |

| [9] | 陈国迎,姚军,王鹏,夏其坤. 适用于后轮轮毂驱动车辆的稳定性控制策略[J]. 吉林大学学报(工学版), 2021, 51(2): 397-405. |

| [10] | 马芳武,梁鸿宇,王强,蒲永锋. 双材料负泊松比结构的面内冲击动力学性能[J]. 吉林大学学报(工学版), 2021, 51(1): 114-121. |

| [11] | 吴岛,张立斌,张云翔,单洪颖,单红梅. 基于滑移率辨识的汽车制动时序视觉检测方法[J]. 吉林大学学报(工学版), 2021, 51(1): 206-216. |

| [12] | 张恩慧,何仁,苏卫东. 不同挡板结构对油箱内油液晃动特性的数值分析[J]. 吉林大学学报(工学版), 2021, 51(1): 83-95. |

| [13] | 熊璐,魏琰超,高乐天. 基于惯性测量单元/轮速融合的车辆零速检测方法[J]. 吉林大学学报(工学版), 2021, 51(1): 134-138. |

| [14] | 陈吉清,蓝庆生,兰凤崇,刘照麟. 基于轮胎力预判与拟合的轨迹跟踪控制[J]. 吉林大学学报(工学版), 2020, 50(5): 1565-1573. |

| [15] | 杨志刚,范亚军,夏超,储世俊,单希壮. 基于双稳态尾迹的方背Ahmed模型减阻[J]. 吉林大学学报(工学版), 2020, 50(5): 1635-1644. |

|

||