吉林大学学报(工学版) ›› 2023, Vol. 53 ›› Issue (2): 505-514.doi: 10.13229/j.cnki.jdxbgxb20210658

预制预装修模块化建筑连接节点抗震性能

闫清峰1( ),张纪刚1,2(

),张纪刚1,2( ),王涛1,陈德刚3,郁有升1,杨迎春4

),王涛1,陈德刚3,郁有升1,杨迎春4

- 1.青岛理工大学 土木工程学院,山东 青岛 266033

2.山东省高等学校蓝色经济区工程建设与安全协同创新中心,山东 青岛 266033

3.青建集团股份有限公司,山东 青岛 266071

4.荣华(青岛)建设科技有限公司,山东 青岛 266500

Seismic performance of connection joints between prefabricated prefinished volumetric construction

Qing-feng YAN1( ),Ji-gang ZHANG1,2(

),Ji-gang ZHANG1,2( ),Tao WANG1,De-gang CHEN3,You-sheng YU1,Ying-chun YANG4

),Tao WANG1,De-gang CHEN3,You-sheng YU1,Ying-chun YANG4

- 1.School of Civil Engineering,Qingdao University of Technology,Qingdao 266033,China

2.Collaborative Innovation Center for Engineering Construction and Safety of Shandong University Blue Economic Zone,Qingdao 266033,China

3.Qingjian Group Co. ,Ltd. ,Qingdao 266071,China

4.Ronghua (Qingdao) Construction Technology Co. ,Ltd. ,Qingdao 266500,China

摘要:

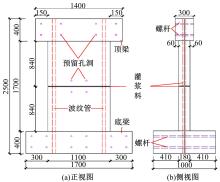

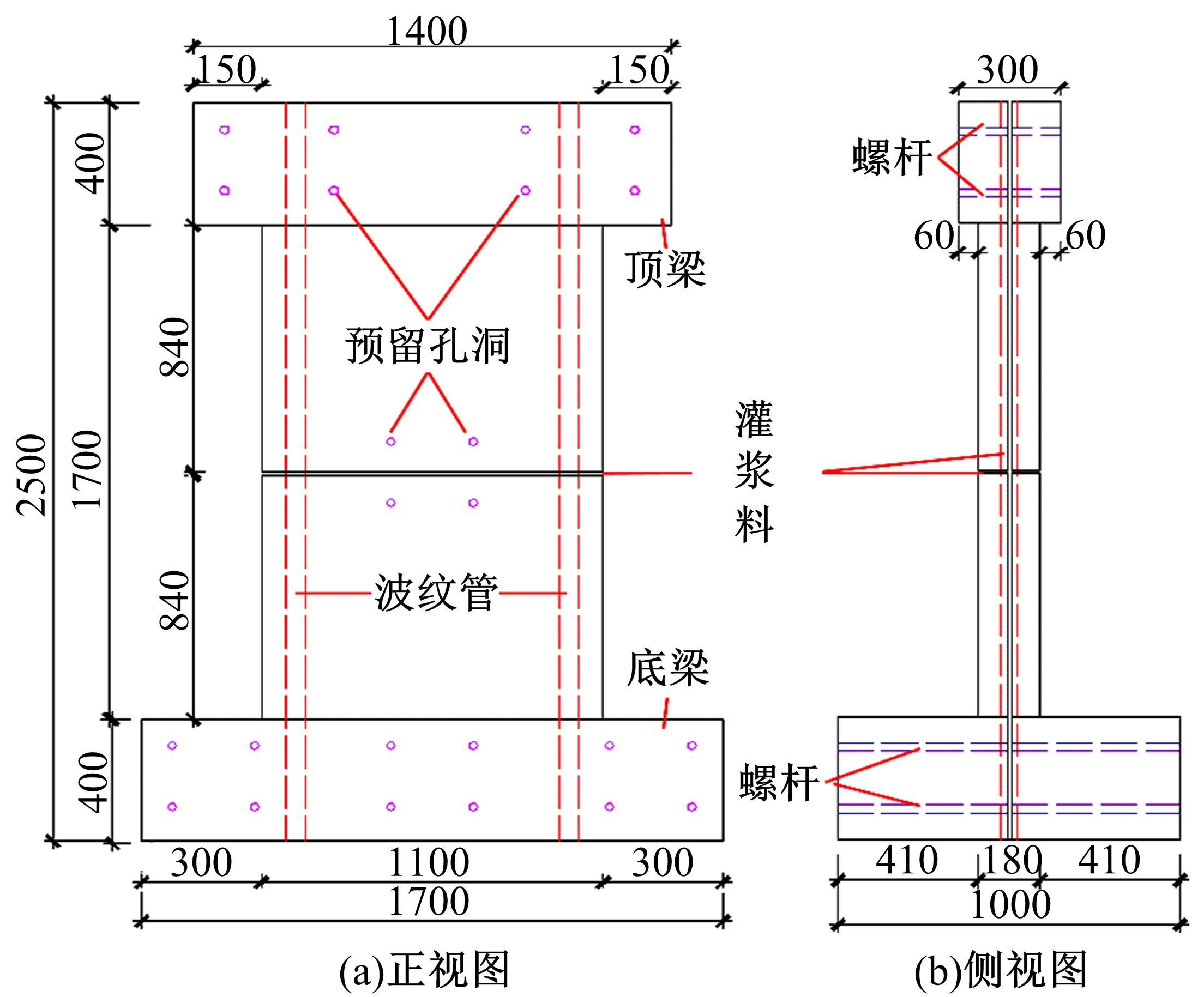

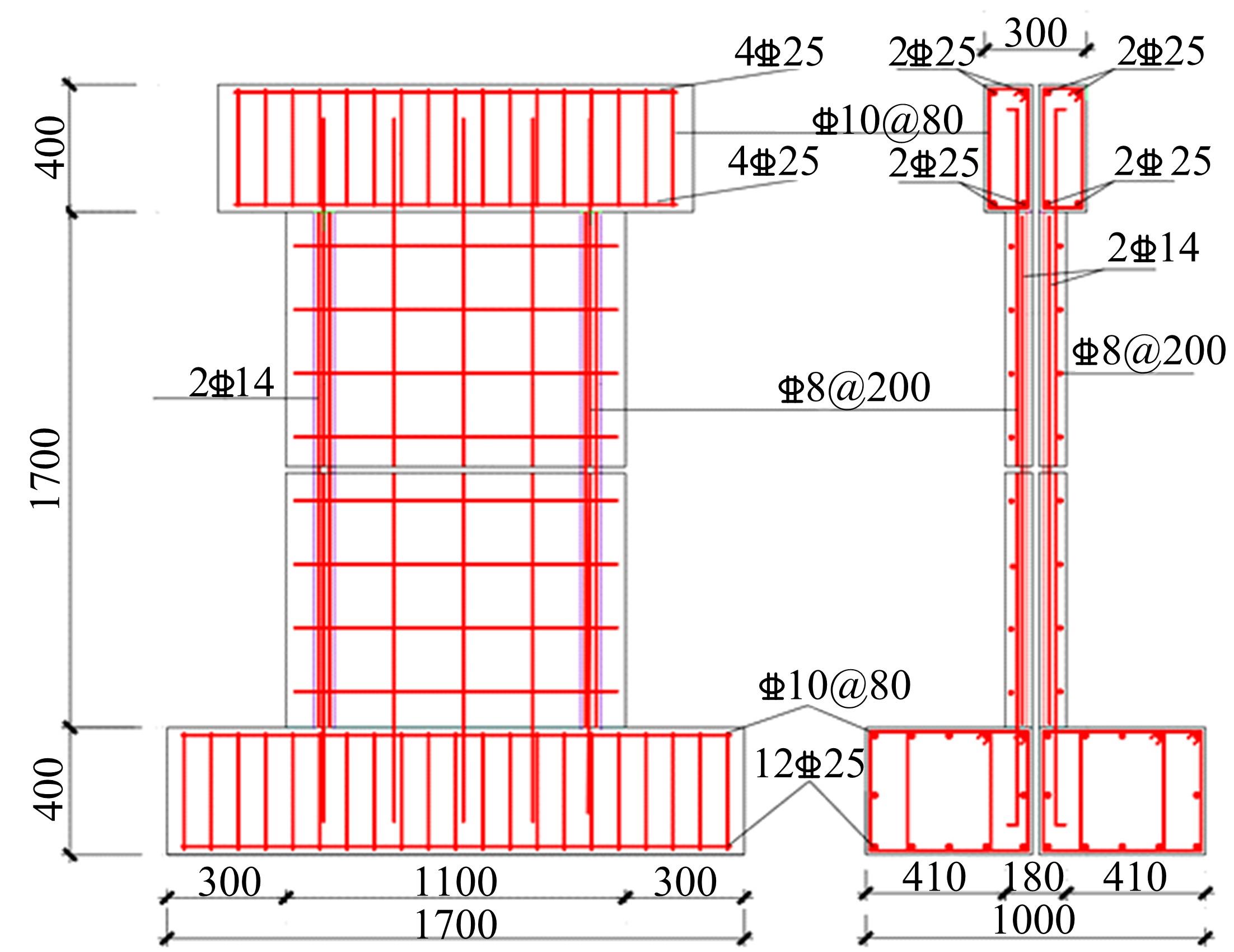

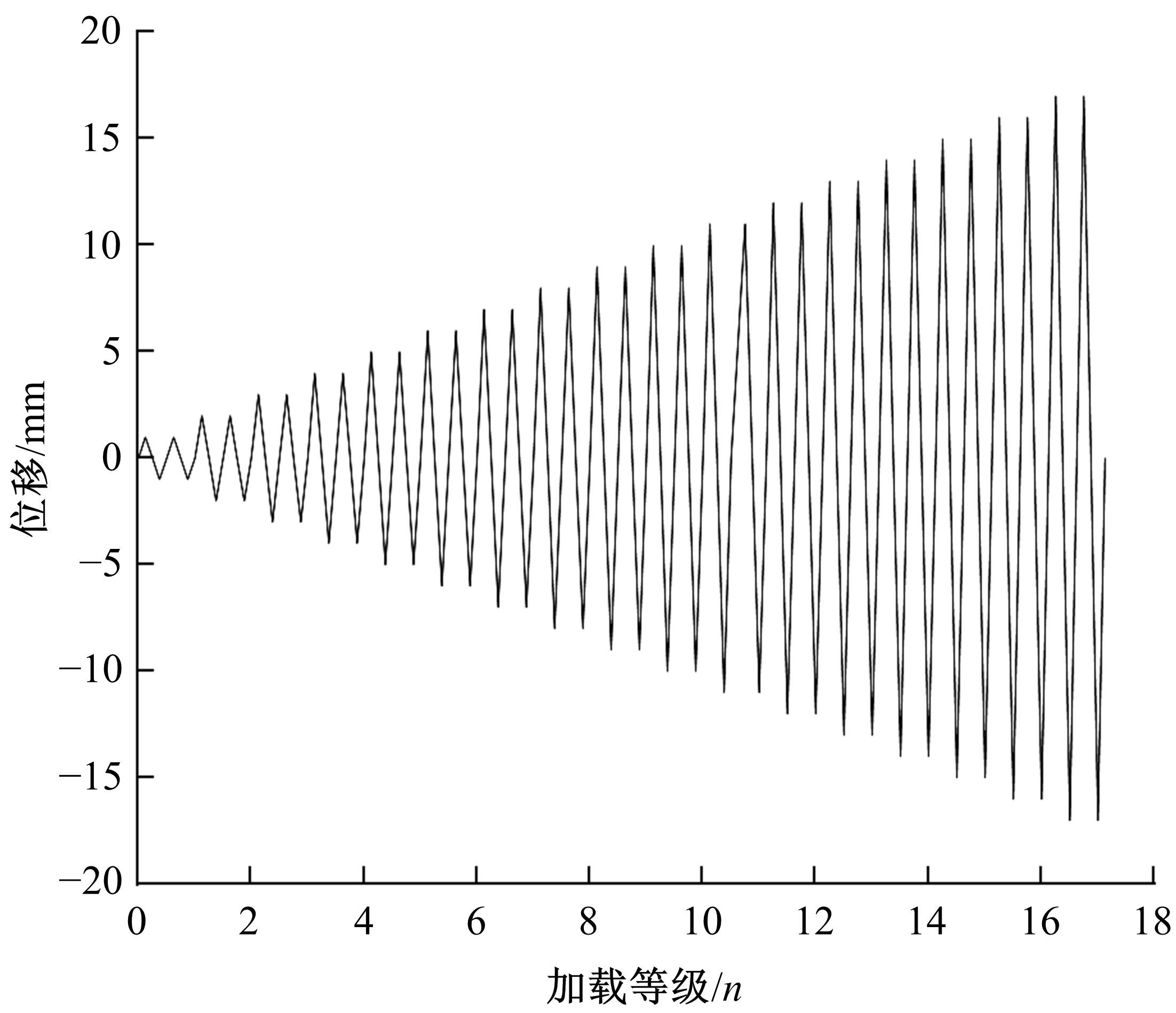

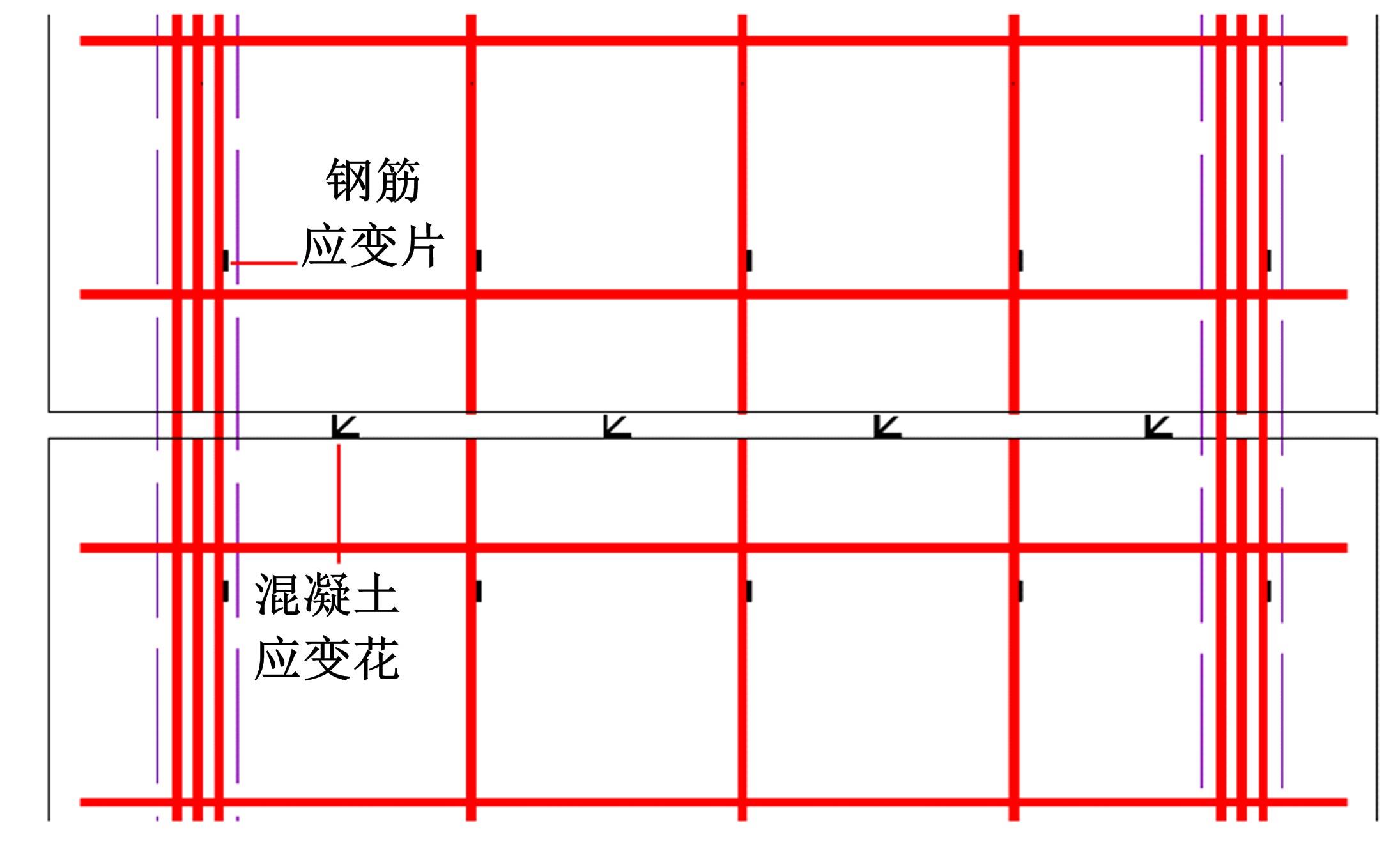

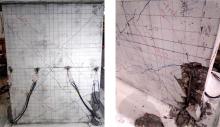

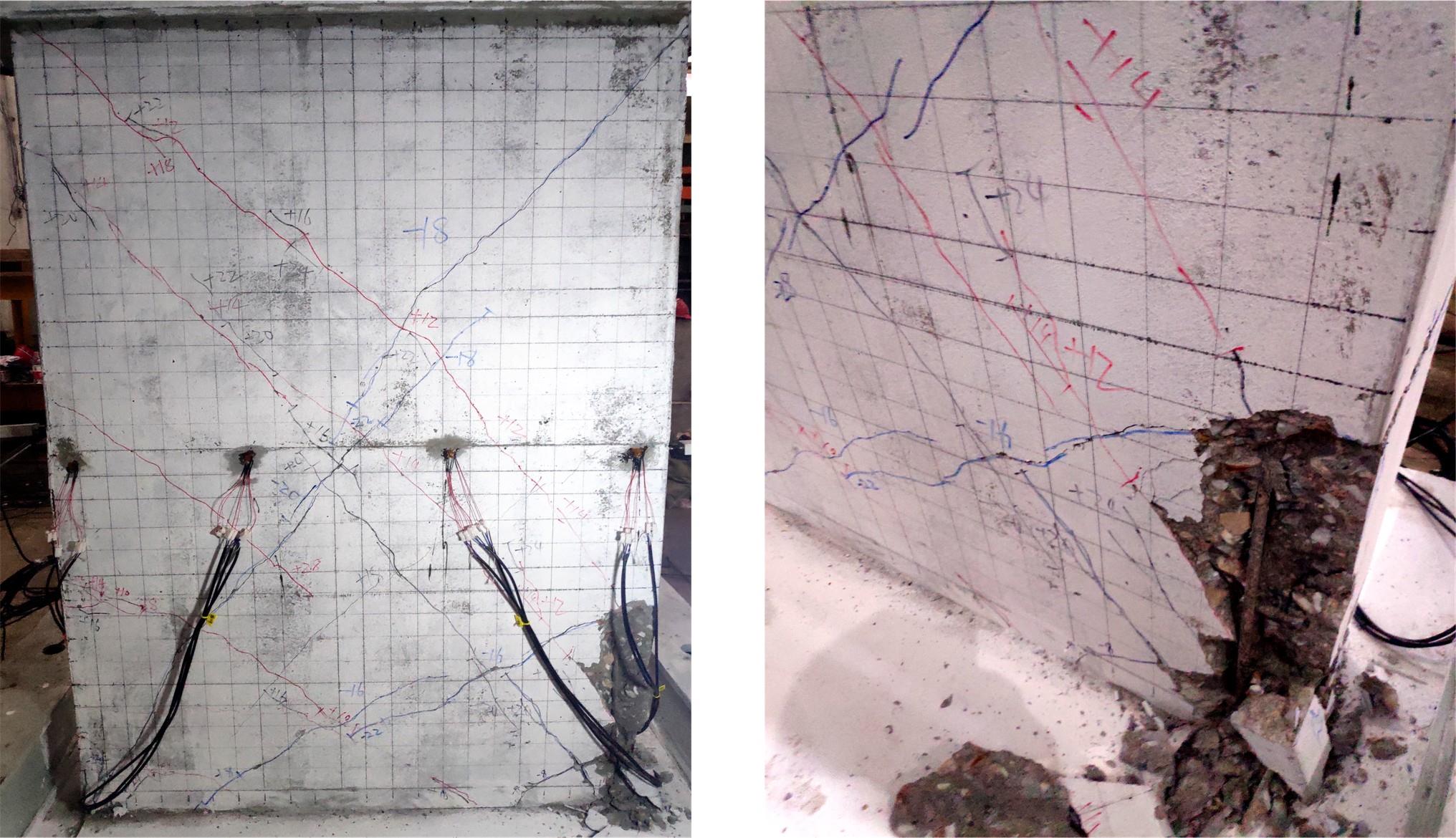

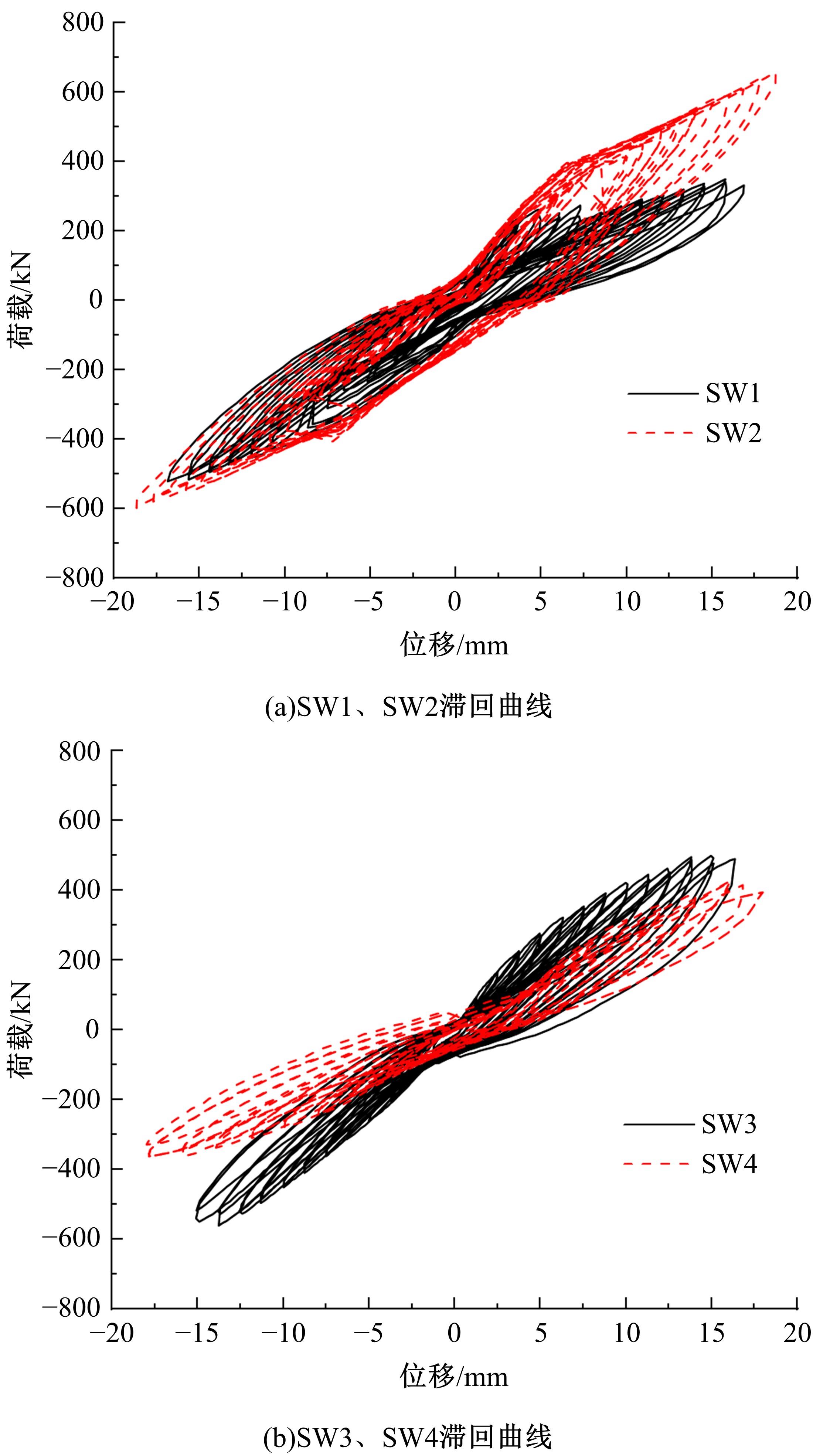

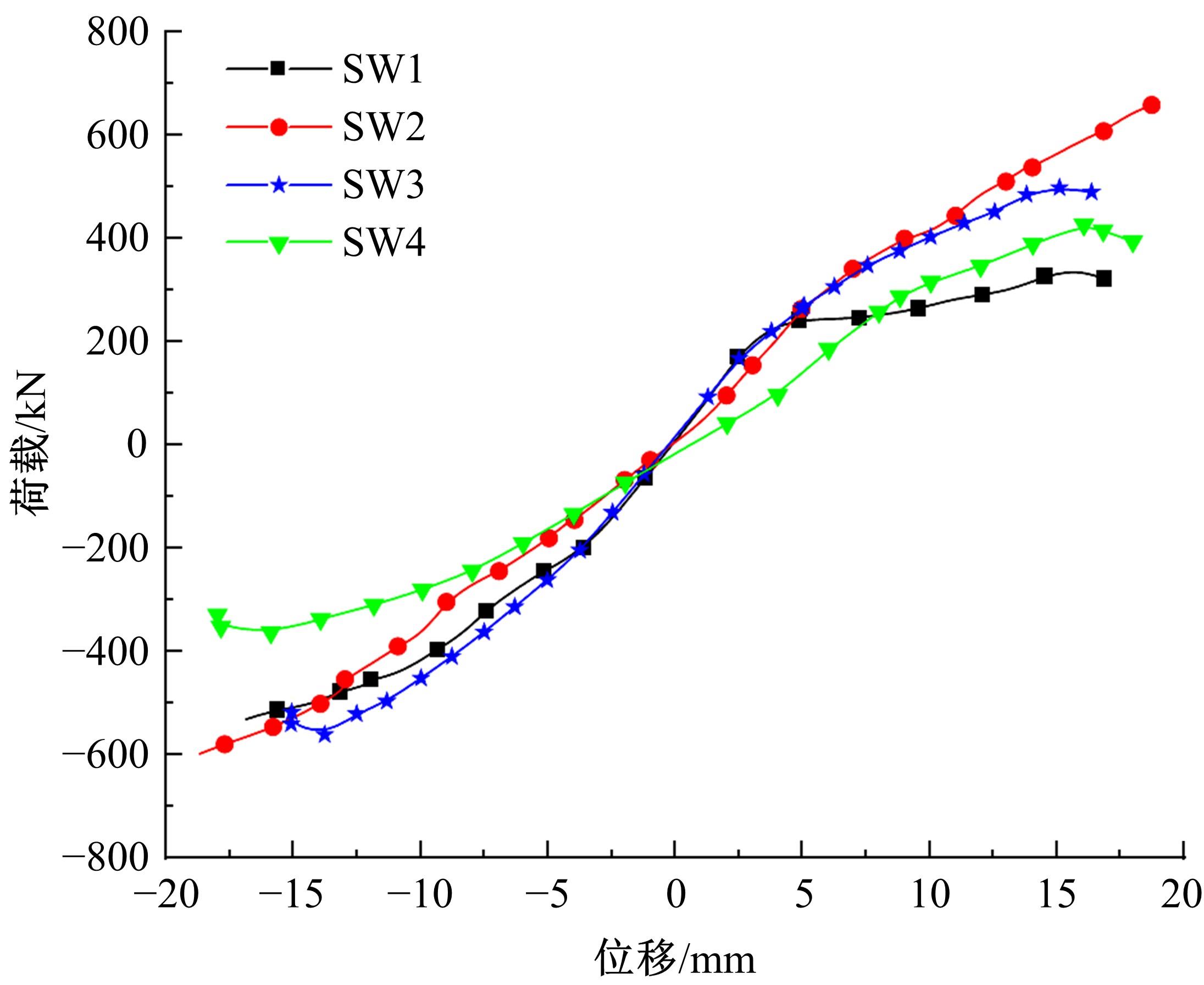

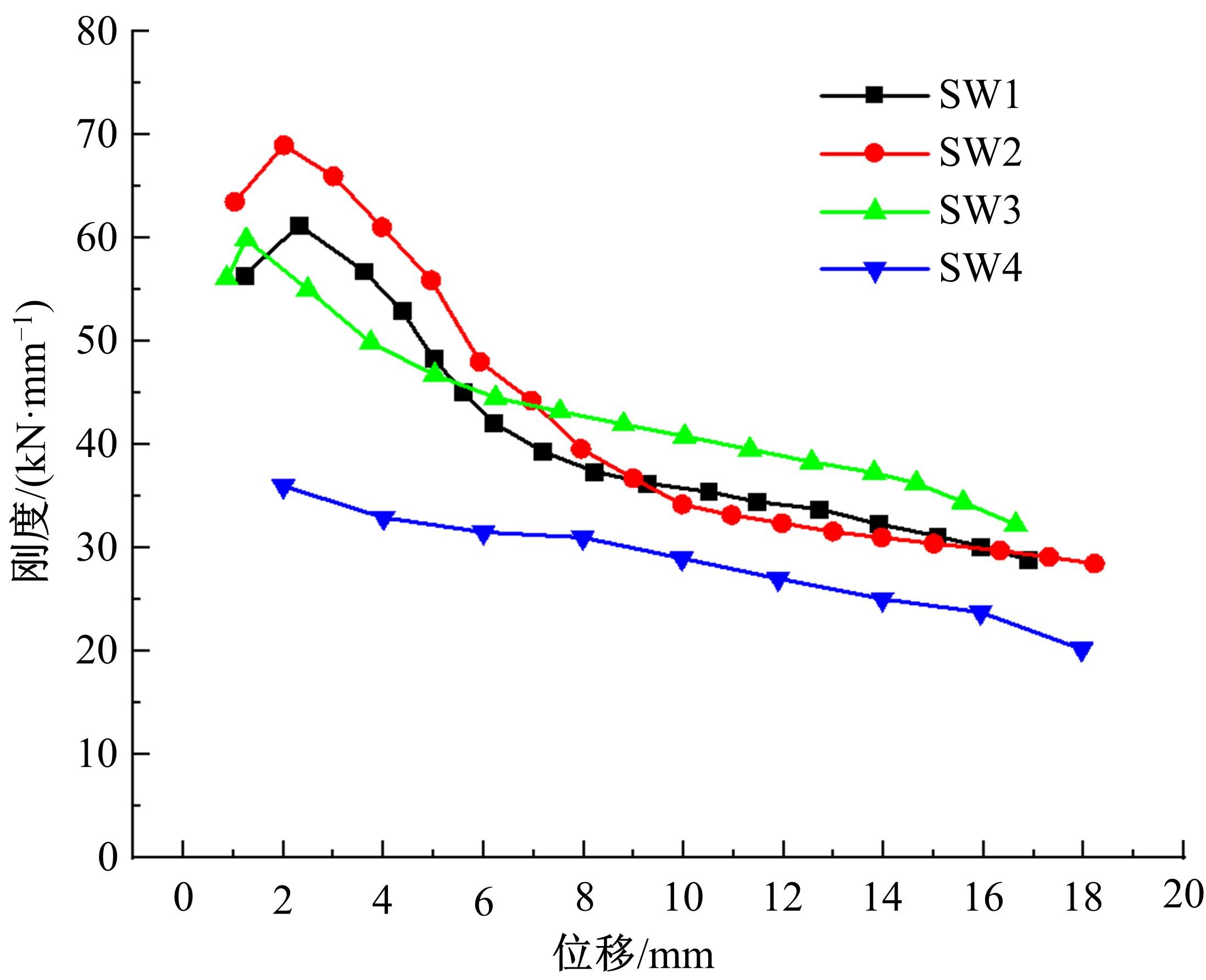

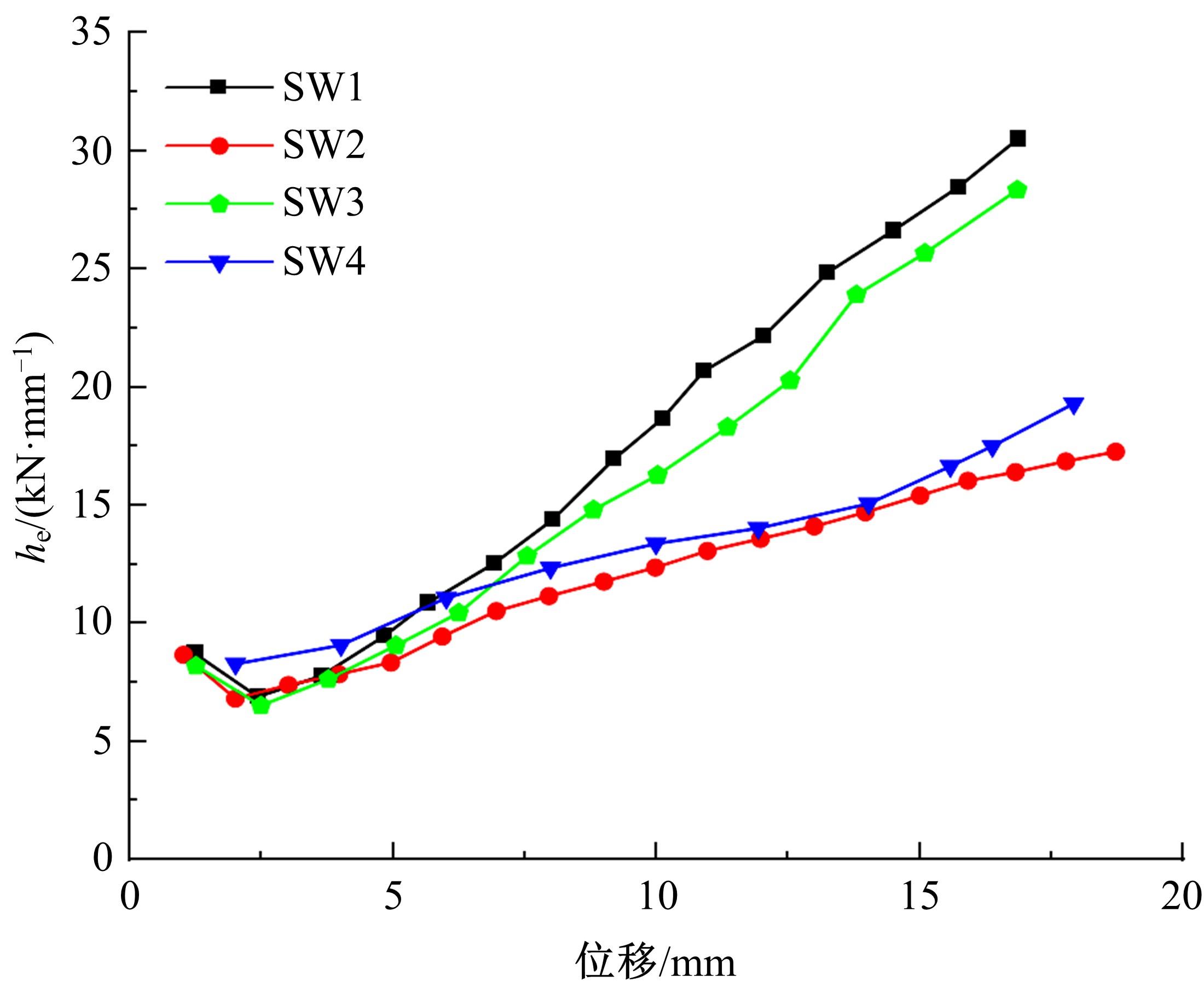

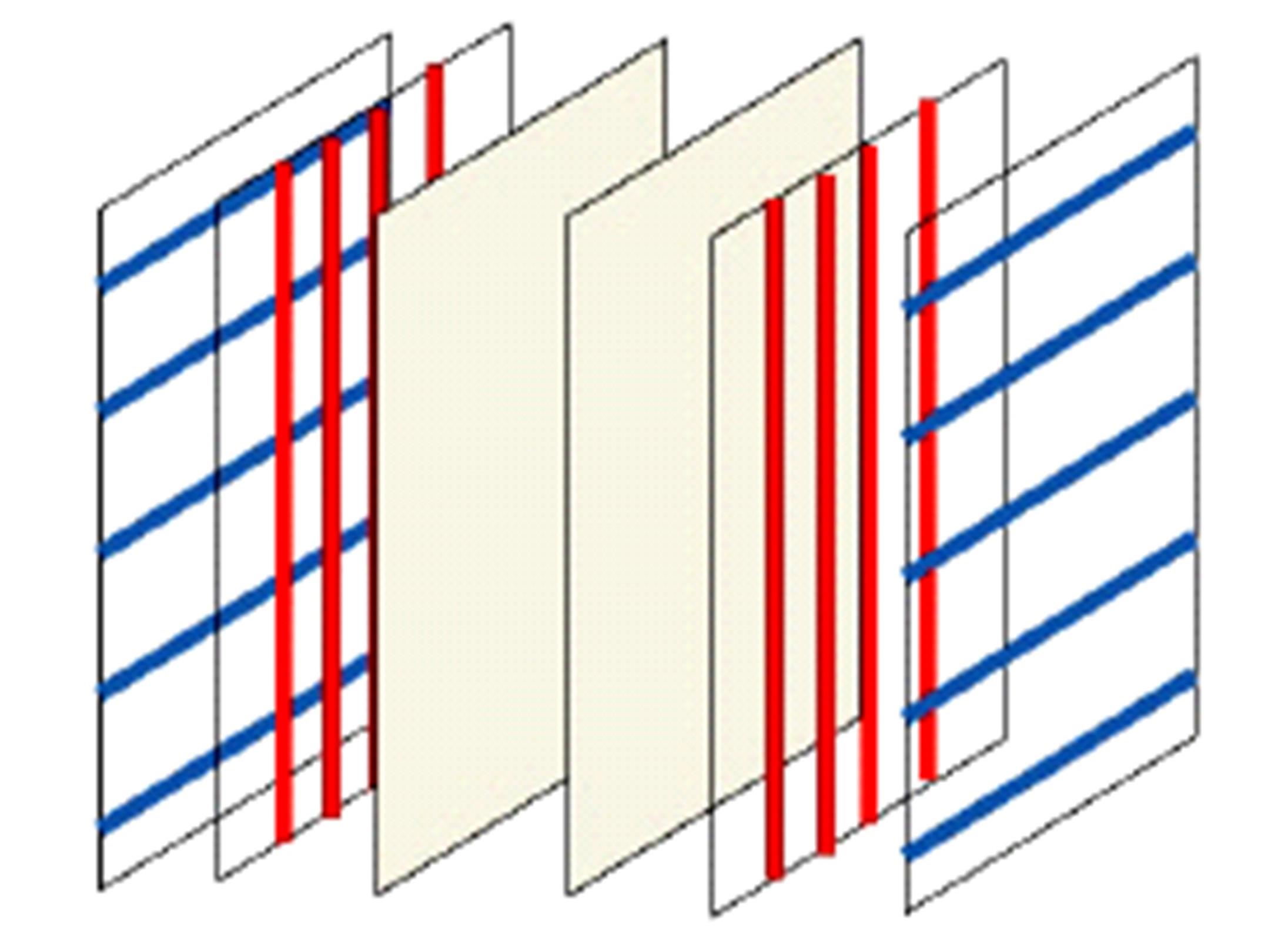

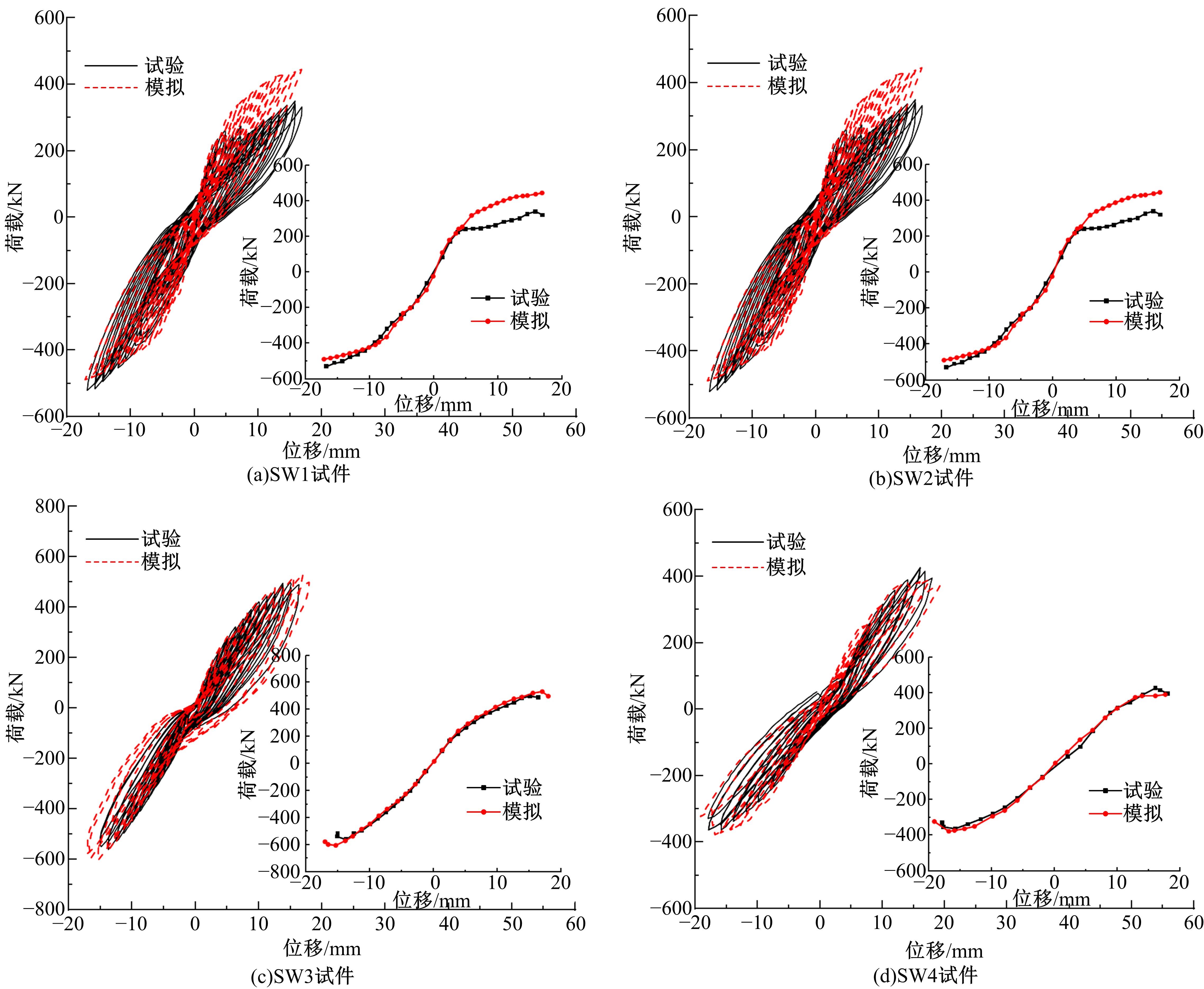

为研究预制预装修模块化建筑连接节点的抗震性能,本文对2组双拼墙连接节点和1组四拼墙连接节点进行了低周往复荷载试验研究,从破坏形态、滞回性能、延性和耗能等方面与现浇剪力墙进行了对比。结果表明:当轴压比为0.4时,双拼墙试件的承载能力提高,但其延性系数仅为现浇剪力墙的58.53%;轴压比0.1时,双拼墙试件的耗能能力、延性与现浇剪力墙相比分别降低了5.5%和3.4%,屈服、极限荷载分别提高了7.9%、5.6%;四拼墙试件由于存在竖向和水平两条灌浆缝,整体性较差,开裂速度快,承载能力较差。

中图分类号:

- TU398

| 1 | Hwang B G, Shan M, Looi K Y. Knowledge-based decision support system for prefabricated prefinished volumetric construction[J]. Au tomation in Construction, 2018, 94: 168-178. |

| 2 | Hwang B G, Shan M, Looi K Y. Key constraints and mitigation strategies for prefabricated prefinished volumetric construction[J]. Journal of Cleaner Production, 2018, 183: 183-193. |

| 3 | Matthew G, Yang M G. Lean production theory-based simulation of modular construction processes[J]. Automation in Construction, 2019, 101(1): 227-244. |

| 4 | Chua Y S, Richard L J Y, Pang S D. Modelling of connections and lateral behavior of high-rise modular steel buildings[J]. Journal of Constructional Steel Research, 2020, 166: 105901. |

| 5 | Lv Y F, Li G Q, Cao K, et al. Behavior of splice connection during transfer of vertical load in full-scale corner-supported modular building[J]. Engineering Structures, 2021, 230: 111698. |

| 6 | Chen Z H, Niu X Y, Liu J D, et al. Seismic study on an innovative fully-bolted beam-column joint in prefabricated modular steel buildings[J]. Engineering Structures, 2021, 234: 111875. |

| 7 | Sukhi V S, David P T, Perera N, et al. Seismic mitigation of steel modular building structures through innovative inter-modular connections[J]. Heliyon, 2019, 5(11): 02751. |

| 8 | 向沛国. 装配式模块化建筑节点试验研究[D]. 哈尔滨: 哈尔滨工业大学土木工程学院, 2017. |

| Xiang Pei-guo. Experimental research on joint of fabricated modular buildings[D]. Harbin: School of Civil Engineering, Harbin Institute of Technology, 2017. | |

| 9 | 刘学春, 任旭, 詹欣欣, 等. 一种盒子式模块化装配式钢结构房屋梁柱节点受力性能分析[J]. 工业建筑,2018, 48(5): 62-69. |

| Liu Xue-chun, Ren Xu, Zhan Xin-xin, et al. Mechanical property analysis of beam-to-column connection in a box-type modular prefabricated steel structure building[J]. Industrial Construction, 2018, 48(5): 62-69. | |

| 10 | 刘学春,浦双辉,徐阿新,等.模块化装配式多高层钢结构全螺栓连接节点静力及抗震性能试验研究[J]. 建筑结构学报, 2015, 36(12): 43-51. |

| Liu Xue-chun, Pu Shuang-hui, Xu A-xin, et al. Experimental study on static and seismic performance of bolted joint in modularized multi-layer and high-rise prefabricated steel structures[J]. Journal of Building Structures, 2015, 36(12): 43-51. | |

| 11 | 刘学春,徐阿新,倪真,等.模块化装配式钢结构梁柱节点极限承载力分析与抗震性能研究[J].工业建筑, 2014, 44(8): 23-26, 60. |

| Liu Xue-chun, Xu A-xin, Ni Zhen, et al. Analysis of the limit bearing capacity and seismic performance of typical joint of truss-beam and column in fabricated high-rise steel structure[J]. Industrial Construction, 2014, 44(8): 23-26, 60. | |

| 12 | 熊枫,黄炎生,周靖,等.装配式内置双钢套管混凝土组合剪力墙的抗震性能试验研究[J]. 土木工程学报, 2021, 54(4): 8-17, 94. |

| Xiong Feng, Huang Yan-sheng, Zhou Jing,et al.Experimental study on seismic performance of precast concrete composite shear walls embedded with high-strength concrete-filled double steel tube[J]. China Civil Engineering Journal, 2021, 54(4): 8-17, 94. | |

| 13 | 龚永智,况锦华,柯福隆,等.UHPC连接的装配式剪力墙节点抗震性能试验[J].吉林大学学报:工学版, 2022, 52(10): 2367-2375. |

| Gong Yong-zhi, Kuang Jin-hua, Ke Fu-long, et al. Experiment on seismic behavior of assembled shear wall joints connected by ultra high performance concrete[J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(10): 2367-2375. | |

| 14 | 陈俊,王韶纤,胥卉,等.负弯矩作用下可拆卸预制装配式组合梁力学性能试验[J].吉林大学学报:工学版, 2022, 52(3): 604-614. |

| Chen Jun, Wang Shao-xian, Xu Hui, et al. Experiment on mechanical properties of detachable prefabricated composite beams subjected to negative bending moment[J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(3): 604-614. | |

| 15 | 范亮,徐英铭,谭阳. 集束群钉式装配组合梁界面滑移计算理论研究[J/OL]. [2022-02-07]. |

| 16 | . 建筑抗震试验规程 [S]. |

| 17 | . 混凝土物理力学性能试验方法标准 [S]. |

| 18 | . 金属材料 拉伸试验 第1部分:室温试验方法 [S]. |

| 19 | Lu X Z, Xie L L, Guan H, et al. A shear wall element for nonlinear seismic analysis of super-tall buildings using OpenSees[J]. Finite Elements in Analysis & Design, 2015, 98: 14-25. |

| 20 | 曹徐阳,冯德成,王谆,等.基于OpenSEES的装配式混凝土框架节点数值模拟方法研究[J].土木工程学报, 2019, 52(4): 13-27. |

| Cao Xu-yang, Feng De-cheng, Wang Zhun, et al. Investigation on modelling approaches for prefabricated concrete beam-to-column connections using openSEES[J].China Civil Engineering Journal, 2019, 52(4): 13-27. |

| [1] | 陈伟宏,陈艳,洪秋榕,崔双双,颜学渊. BRBs加固震损装配式混凝土框架结构抗震性能试验[J]. 吉林大学学报(工学版), 2022, 52(8): 1817-1825. |

| [2] | 何兆益,李金凤,周文,官志桃. 多孔沥青混合料的动态模量及其预估模型[J]. 吉林大学学报(工学版), 2022, 52(6): 1375-1385. |

| [3] | 龚永智,况锦华,柯福隆,周泉,罗小勇. UHPC连接的装配式剪力墙节点抗震性能试验[J]. 吉林大学学报(工学版), 2022, 52(10): 2367-2375. |

| [4] | 谷拴成,聂红宾. 极温冻融-荷载作用下碳纤维复合材料修复试件损伤分析[J]. 吉林大学学报(工学版), 2021, 51(6): 2108-2120. |

| [5] | 周靖,黎亚军,赵卫锋,罗宗健,补国斌. 胶合竹板-钢管约束收尘石粉混凝土柱的偏压性能[J]. 吉林大学学报(工学版), 2021, 51(6): 2096-2107. |

| [6] | 刁延松,郭荡,屠康,焦圣伦,刘芸,刘秀丽. 新型异形钢管混凝土柱⁃钢梁节点抗震性能试验[J]. 吉林大学学报(工学版), 2021, 51(5): 1724-1733. |

| [7] | 张广泰,张路杨,邢国华,曹银龙,易宝. 钢-聚丙烯混杂纤维混凝土剪力墙抗震性能[J]. 吉林大学学报(工学版), 2021, 51(3): 946-955. |

| [8] | 许卫晓,程扬,杨伟松,鞠佳昌,于德湖. RC框架⁃抗震墙并联结构体系拟静力试验[J]. 吉林大学学报(工学版), 2021, 51(1): 268-277. |

| [9] | 单德山,张潇,顾晓宇,李乔. 斜拉索悬链线构形的伸长量解析计算方法[J]. 吉林大学学报(工学版), 2021, 51(1): 217-224. |

| [10] | 刘柳,冯卫星. 基于NNBR模型的隧道盾构施工地表沉降实测与计算分析[J]. 吉林大学学报(工学版), 2021, 51(1): 245-251. |

| [11] | 薛素铎,鲁建,李雄彦,刘人杰. 跳格布置对环形交叉索桁结构静动力性能的影响[J]. 吉林大学学报(工学版), 2020, 50(5): 1687-1697. |

| [12] | 王勃,董元正,董丽欣. 基于短期风速资料的基本风压计算方法[J]. 吉林大学学报(工学版), 2020, 50(5): 1739-1746. |

| [13] | 李明,王浩然,赵唯坚. 单向带抗剪键叠合板的受力性能试验[J]. 吉林大学学报(工学版), 2020, 50(2): 654-667. |

| [14] | 王鹏辉,乔宏霞,冯琼,曹辉,温少勇. 氯氧镁涂层钢筋混凝土两重因素耦合作用下的耐久性模型[J]. 吉林大学学报(工学版), 2020, 50(1): 191-201. |

| [15] | 李明,王浩然,赵唯坚. 带抗剪键叠合板的力学性能[J]. 吉林大学学报(工学版), 2019, 49(5): 1509-1520. |

|