吉林大学学报(工学版) ›› 2020, Vol. 50 ›› Issue (1): 29-35.doi: 10.13229/j.cnki.jdxbgxb20181027

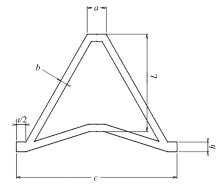

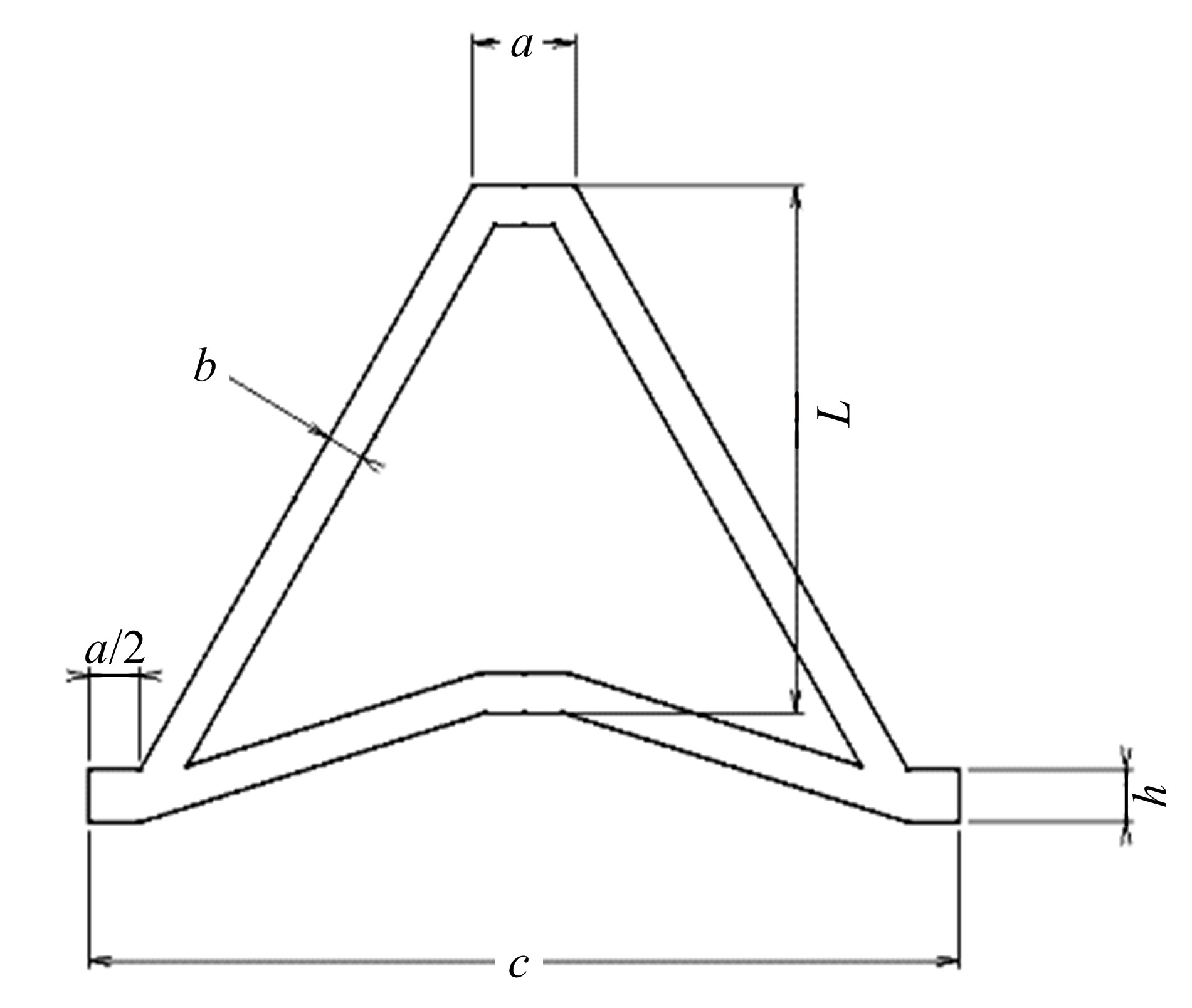

内凹三角形负泊松比结构耐撞性多目标优化设计

- 1. 吉林大学 汽车仿真与控制国家重点实验室, 长春 130022

2. 吉林大学 青岛汽车研究院, 山东 青岛 266000

Multi⁃objective crashworthiness optimization design of concave triangles cell structure with negative Poisson′s ratio

Fang-wu MA1,2( ),Hong-yu LIANG1,2,Ying ZHAO1,Meng YANG1,Yong-feng PU1

),Hong-yu LIANG1,2,Ying ZHAO1,Meng YANG1,Yong-feng PU1

- 1. State Key Laboratory of Automotive Simulation and Control,Jilin University, Changchun 130022,China

2. Qingdao Automobile Research Institute, Jilin University,Qingdao 266000,China

摘要:

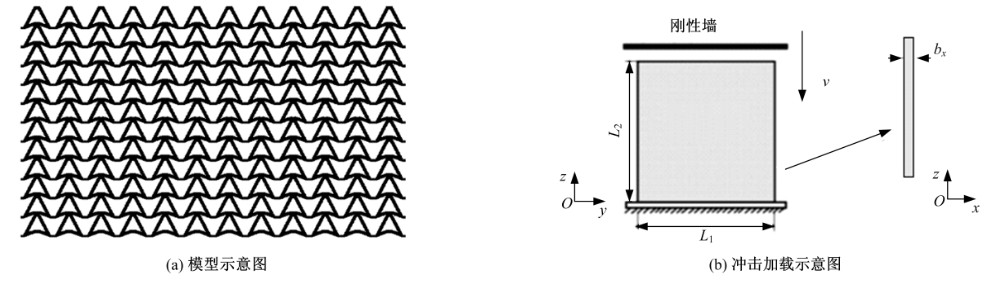

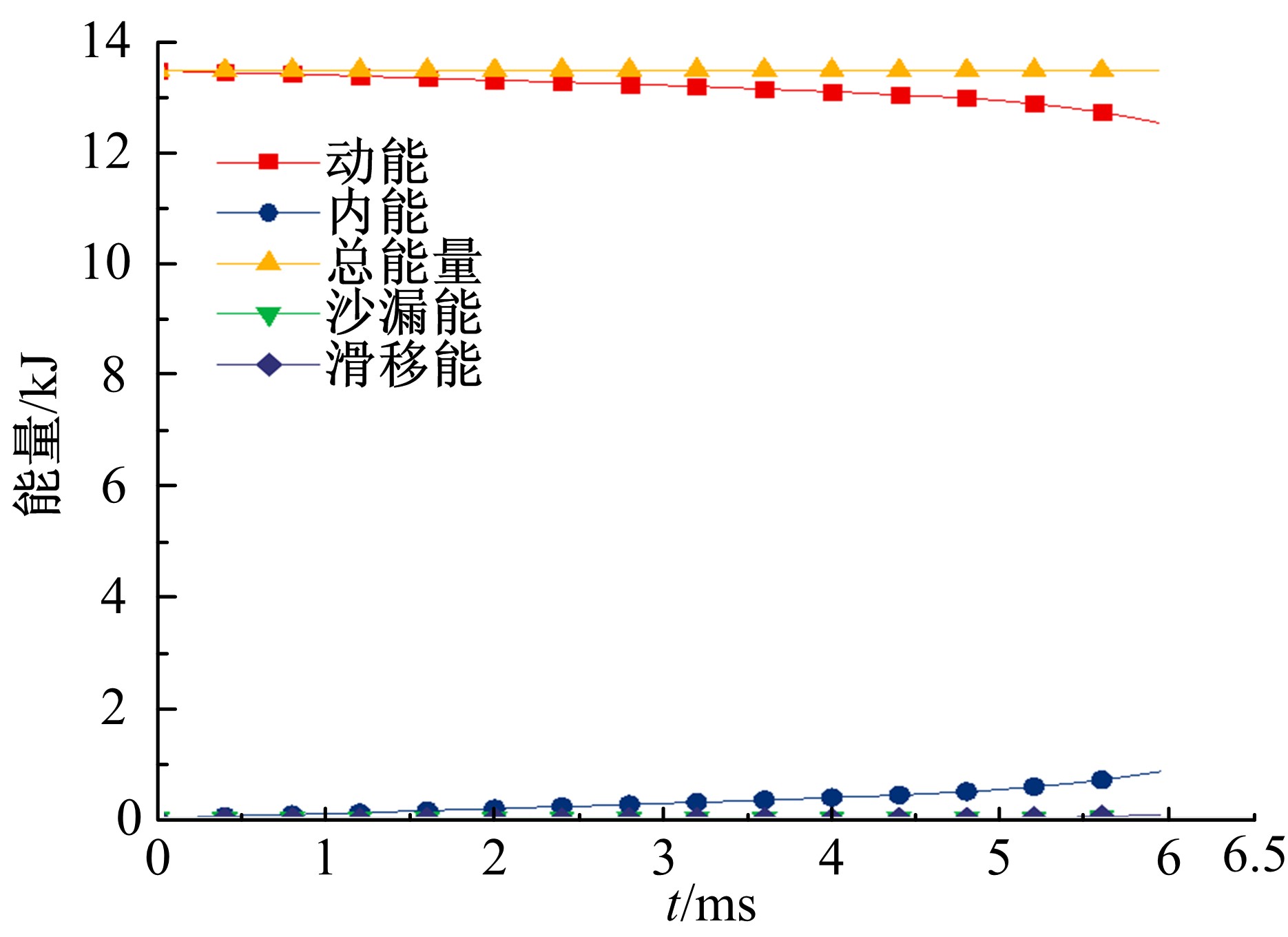

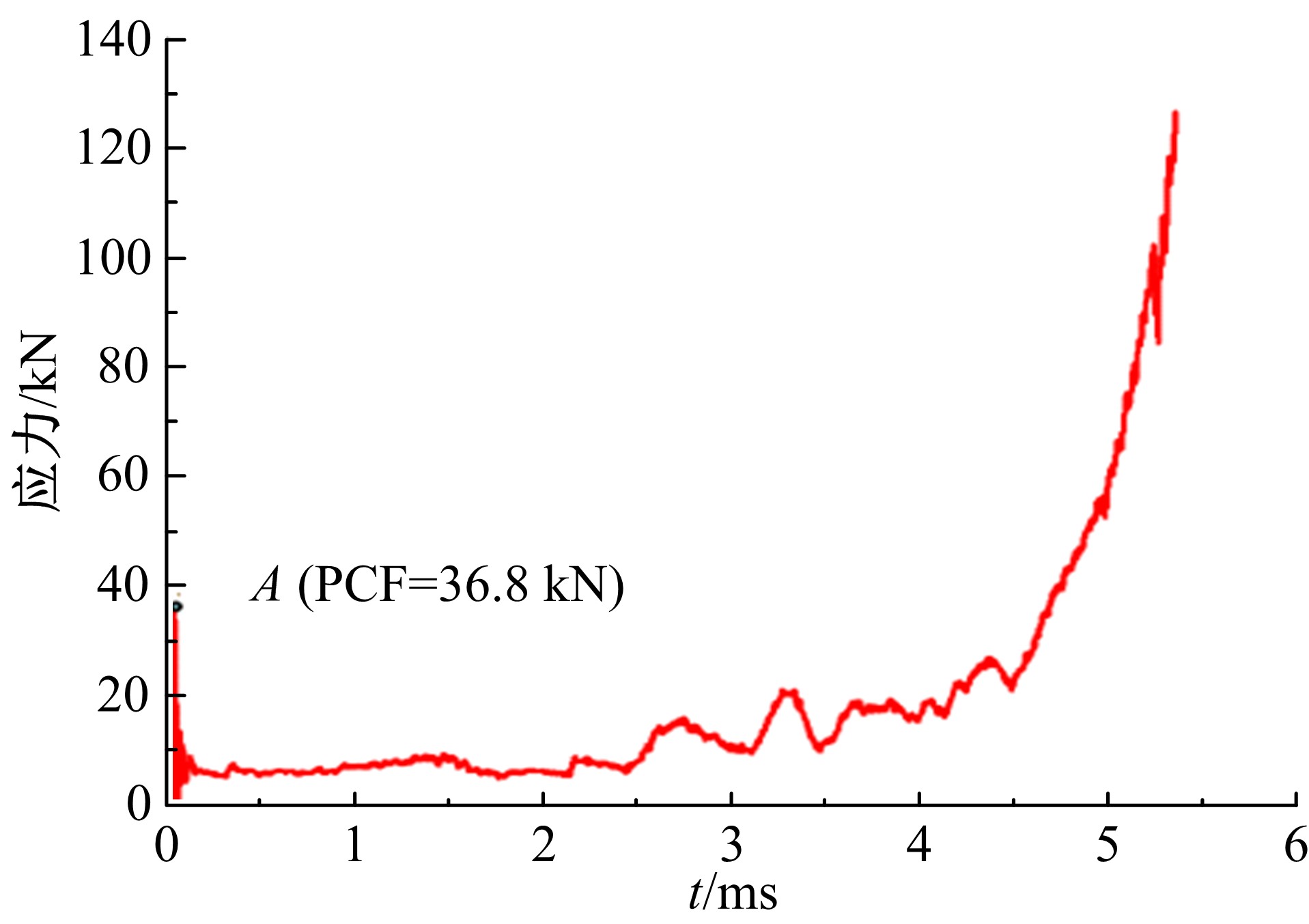

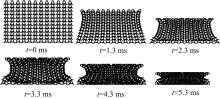

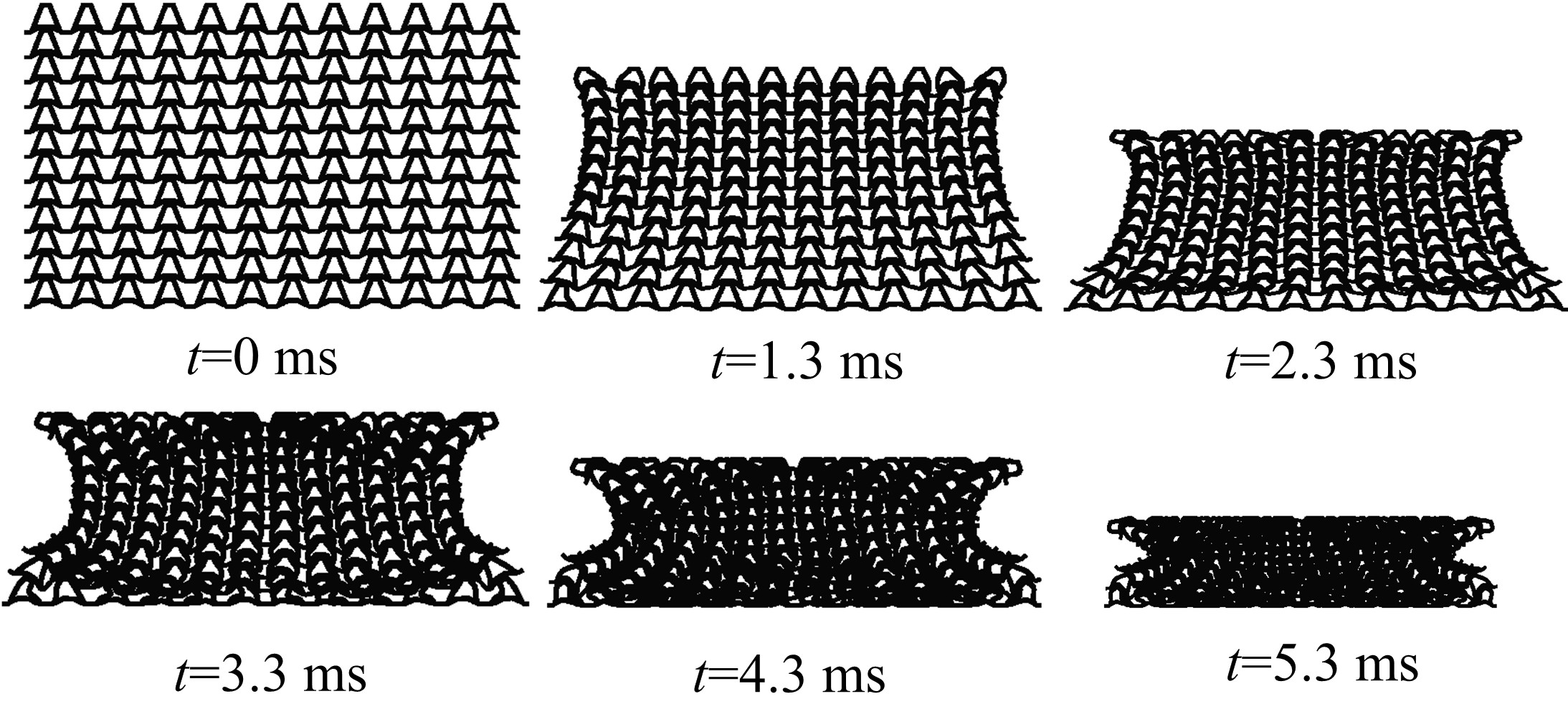

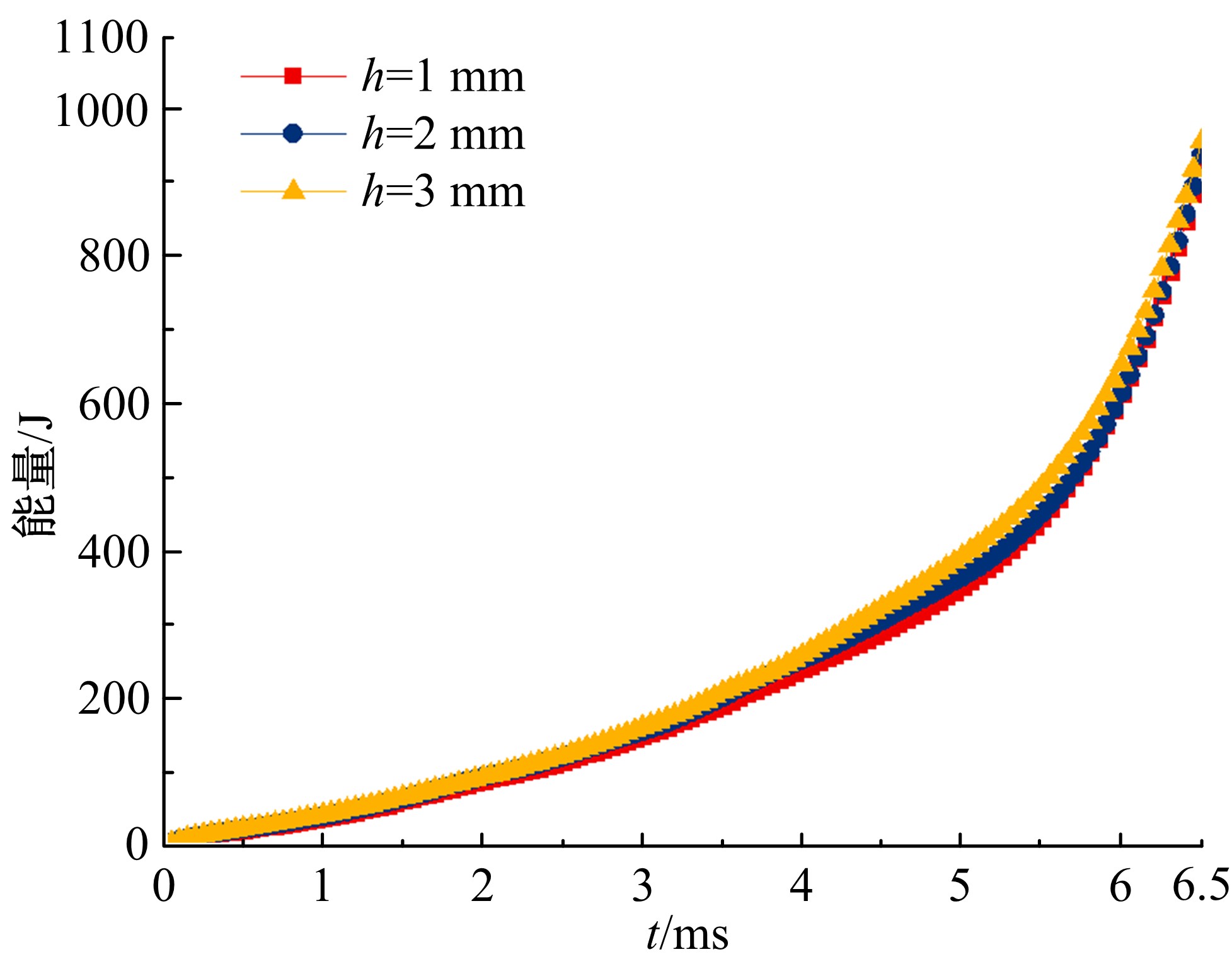

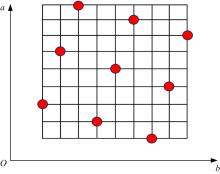

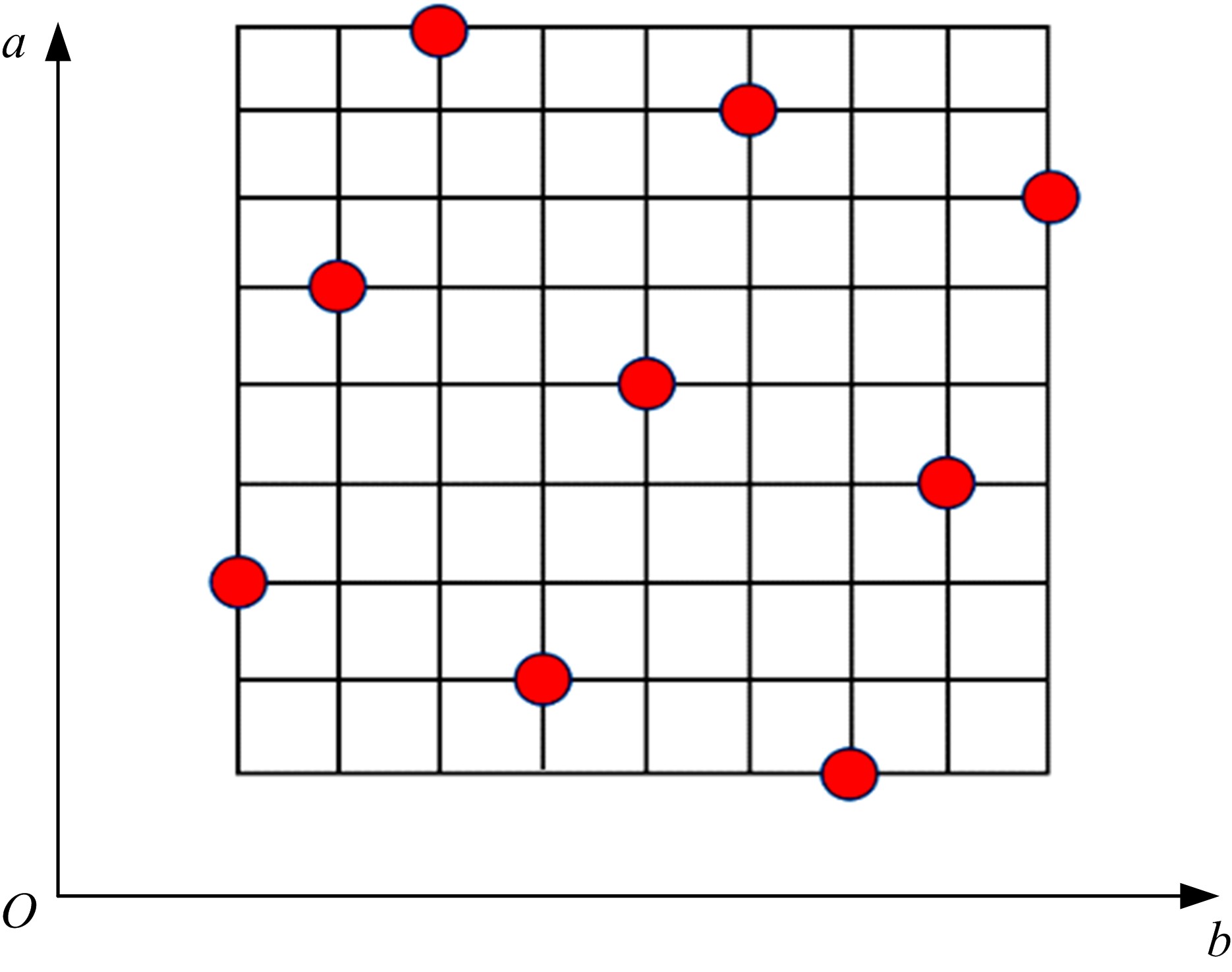

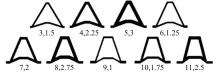

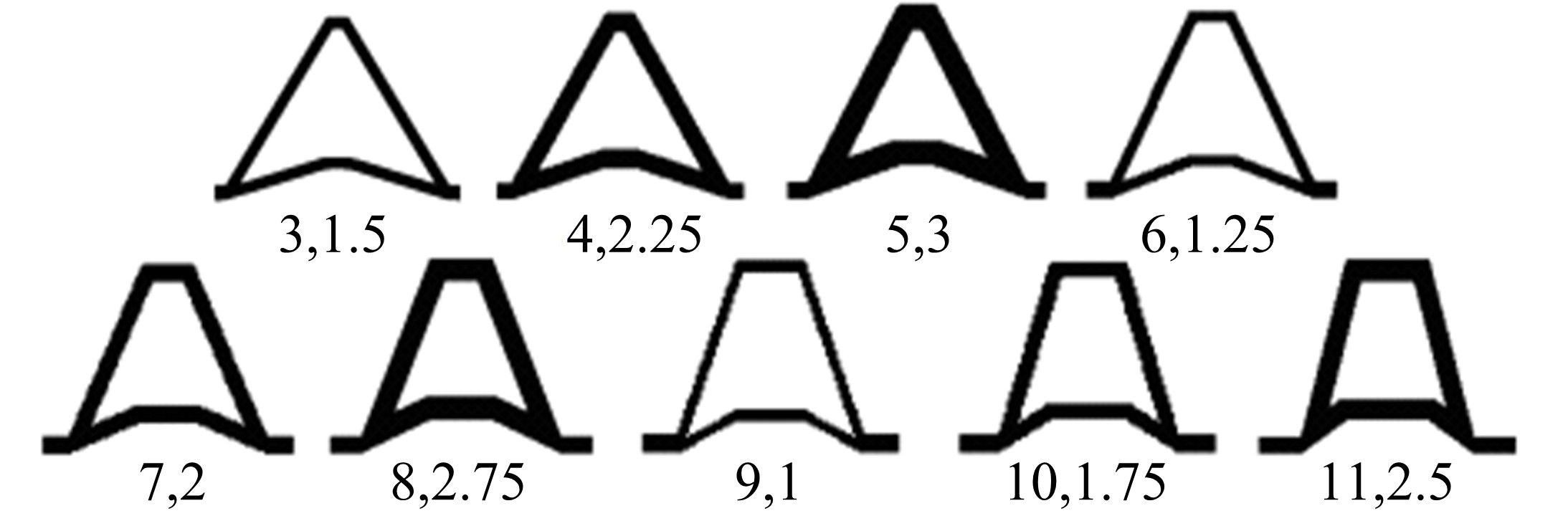

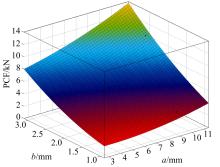

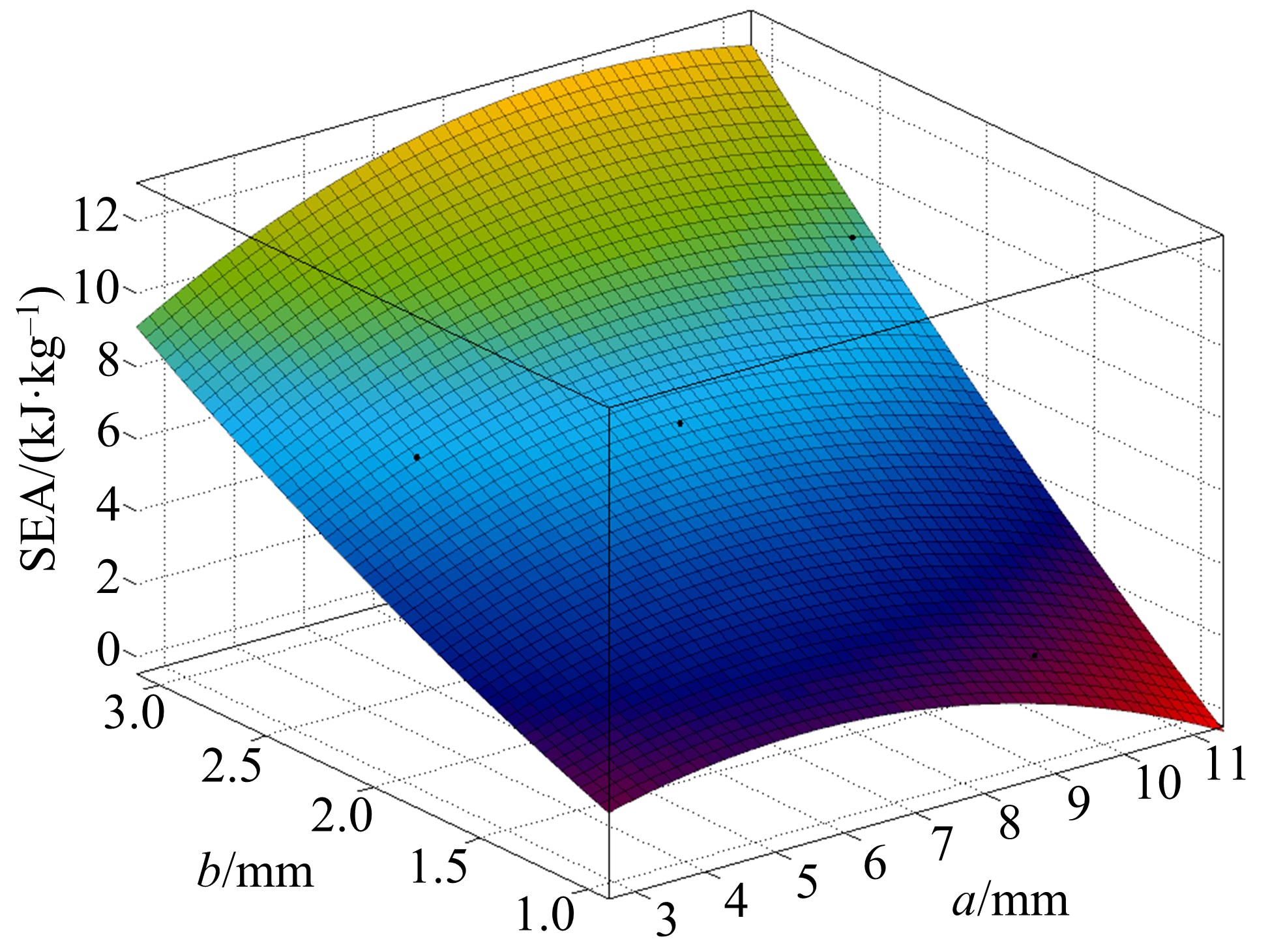

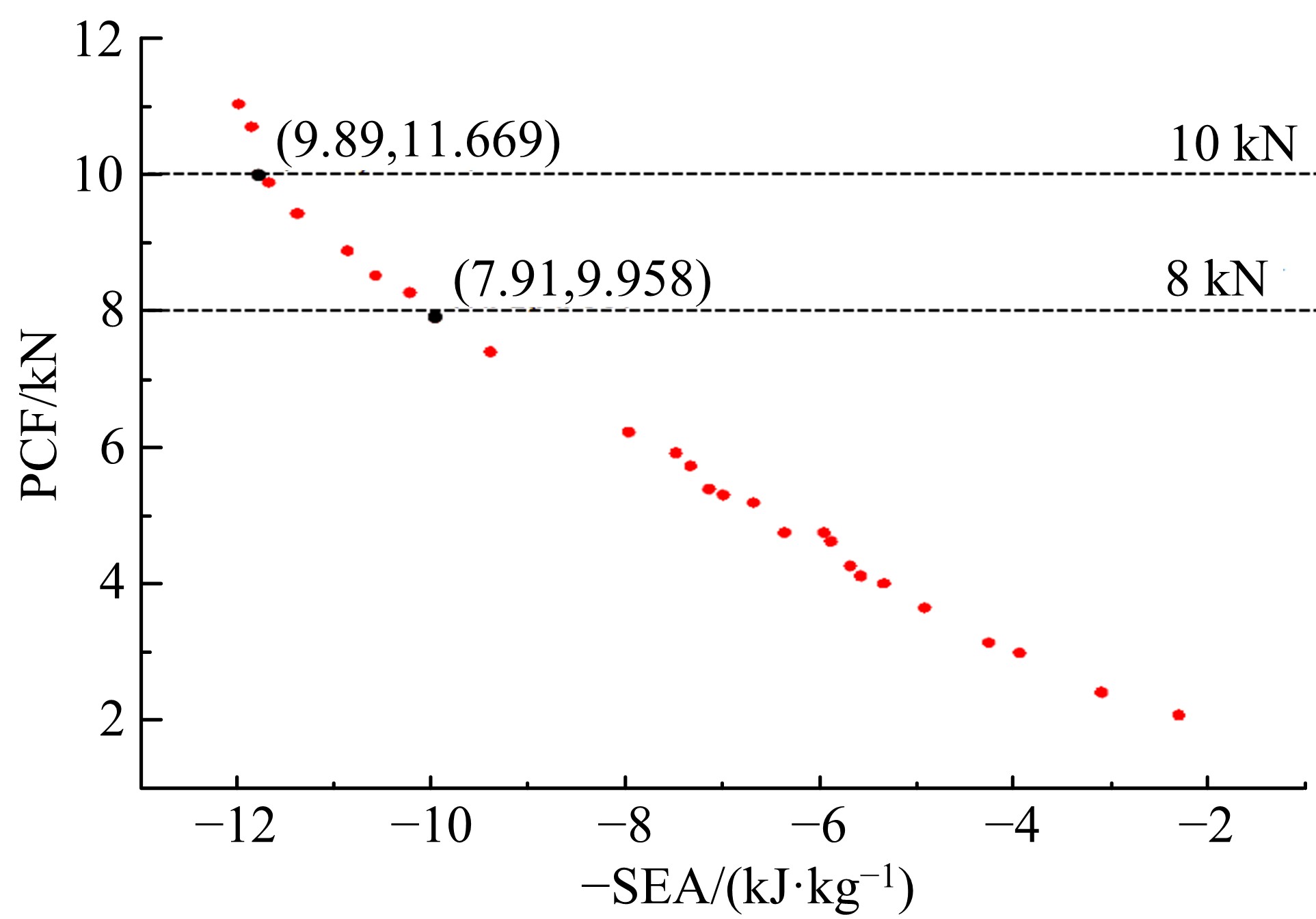

为设计出具有良好耐撞性的车辆碰撞吸能结构,以内凹三角形负泊松比多胞结构为研究对象,通过显式动力有限元软件 LS?DYNA建立了此吸能结构的轴向冲击有限元模型。结合最优拉丁超立方设计方法,构建了此吸能结构的峰值冲击力PCF和比吸能SEA关于长胞壁尺寸a与胞壁厚度b的多项式代理模型,采用第二代非劣排序遗传算法(NSGA?II)进行多目标优化设计,并基于适应度函数C获取一妥协解。优化结果表明:胞壁厚度比长胞壁尺寸对此吸能结构耐撞性影响更显著,通过合理匹配壁厚和长胞壁长度,能有效降低峰值冲击力,提高比吸能。

中图分类号:

- U465.9

| 1 | Zhao Y , Ma F , Yang L , et al . Study on engine hood with negative poisson's ratio architected composites based on pedestrian protection[J].SAE International Journal of Engines, 2017, 10(2): 391-404. |

| 2 | Zhang D , Fei Q , Zhang P . In-plane dynamic crushing behavior and energy absorption of honeycombs with a novel type of multi-cells[J]. Thin-walled Structures, 2017, 117: 199-210. |

| 3 | 崔世堂, 王波, 张科 . 负泊松比蜂窝面内动态压缩行为与吸能特性研究[J]. 应用力学学报, 2017, 34(5): 919-924. |

| Cui Shi-tang , Wang Bo , Zhang Ke . Mechanical behavior and energy absorption of honeycomb with negative Poisson′s ratio under in-plane dynamic compression[J].Chinese Journal of Applied Mechanics, 2017, 34(5): 919-924 | |

| 4 | Liu W , Wang N , Luo T , et al . In-plane dynamic crushing of re-entrant auxetic cellular structure[J]. Materials & Design, 2016, 100: 84-91. |

| 5 | 卢子兴, 李康 . 手性和反手性蜂窝材料的面内冲击性能研究[J]. 振动与冲击, 2017, 36(21): 16-22, 39. |

| Lu Zi-xing , Li Kang . In-plane dynamic crushing of chiral and anti-chiral honeycombs[J]. Journal of Vibration and Shock,2017, 36(21): 16-22, 39 | |

| 6 | 樊喜刚, 尹西岳 . 梯度蜂窝面外动态压缩力学行为与吸能特性研究[J]. 固体力学学报, 2015, 36(2): 114-122. |

| Fan Xi-gang , Yin Xi-yue . Mechanical behavior and energy absorption of graded honeycomb materials under out-of-plane dynamic compression[J]. Chinese Journal of Solid Mechanics, 2015, 36(2): 114-122. | |

| 7 | Wang Z , Lu Z , Yao S , et al . Deformation mode evolutional mechanism of honeycomb structure when undergoing a shallow inclined load[J]. Composite Structures, 2016, 147: 211-219. |

| 8 | Gao D , Zhang C . Theoretical and numerical investigation on in-plane impact performance of chiral honeycomb core structure[J]. Journal of Structural Integrity and Maintenance, 2018, 3(2): 95-105. |

| 9 | 韩会龙, 张新春 . 星形节点周期性蜂窝结构的面内动力学响应特性研究[J]. 振动与冲击, 2017, 36(23): 223-231. |

| Han Hui-long , Zhang Xin-chun . In-plane dynamic impact response characteristics of periodic 4-pointstar-shaped honeycomb structures[J]. Journal of Vibration and Shock, 2017, 36(23): 223-231. | |

| 10 | 邓小林, 刘旺玉 . 一种负泊松比正弦曲线蜂窝结构的面内冲击动力学分析[J]. 振动与冲击, 2017, 36(13): 103-109. |

| Deng Xiao-lin , Liu Wang-yu . In-plane impact dynamics analysis of sinusoidal honeycomb structure with negative poisson's ratio[J]. Journal of Vibration and Shock,2017, 36(13): 103-109. | |

| 11 | 王登峰, 张帅, 汪勇 . 基于疲劳和13°冲击性能的组装式车轮优化设计[J]. 吉林大学学报:工学版, 2018,48(1): 44-56. |

| Wang Deng-feng , Zhang Shuai , Wang Yong . Optimization design of assembled wheel based on performance of fatigue and 13° impact[J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(1): 44-56. | |

| 12 | 宋康, 陈潇凯, 林逸 . 汽车行驶动力学性能的多目标优化[J]. 吉林大学学报:工学版, 2015, 45(2): 352-357. |

| Song Kang , Chen Xiao-kai , Lin Yi . Multi-objective optimization of vehicle ride dynamic behaviors[J]. Journal of Jilin University(Engineering and Technology Edition), 2015, 45(2): 352-357. | |

| 13 | 胡云峰, 王长勇, 于树友 . 缸内直喷汽油机共轨系统结构参数优化[J]. 吉林大学学报:工学版, 2018, 48(1): 236-244. |

| Hu Yun-feng , Wang Chang-yong , Yu Shu-you . Structure parameters optimization of common rail system for gasoline direct injection engine[J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(1): 236-244. | |

| 14 | Fazilati J , Alisadeghi M . Multiobjective crashworthiness optimization of multi-layer honeycomb energy absorber panels under axial impact[J]. Thin-Walled Structures, 2016, 107: 197-206. |

| 15 | Zhou G , Ma Z D , Li G , et al . Design optimization of a novel NPR crash box based on multi-objective genetic algorithm[J]. Structural & Multidisciplinary Optimization, 2016, 54(3): 673-684. |

| 16 | Santosa S P , Wierzbicki T , Hanssenb A G , et al . Experimental and numerical studies of foam-filled sections[J]. International Journal of Impact Engineering, 2000, 24(5): 509-534. |

| 17 | Ruan D , Lu G , Wang B , et al . In-plane dynamic crushing of honeycombs―a finite element study[J]. International Journal of Impact Engineering, 2003, 28(2): 161-182. |

| 18 | 文桂林, 孔祥正, 尹汉锋 . 泡沫填充夹芯墙多胞结构的耐撞性多目标优化设计[J]. 振动与冲击, 2015, 34(5): 115-121. |

| Wen Gui-lin , Kong Xiang-zheng , Yin Han-feng . Multi-objective crashworthiness optimization design of foam-filled sandwich wall multi-cell structures[J]. Journal of Vibration and Shock, 2015, 34(5): 115-121. | |

| 19 | Zhang P , Wang Z , Zhao L . Dynamic crushing behavior of open-cell aluminum foam with negative Poisson’s ratio[J]. Applied Physics A, 2017, 123(5): No.321. |

| [1] | 郭孔辉,黄世庆,吴海东. 适用于高频激励的面内轮胎动态模型[J]. 吉林大学学报(工学版), 2020, 50(1): 19-28. |

| [2] | 陈鑫,阮新建,李铭,王宁,王佳宁,潘凯旋. 基于大涡模拟的离散格式改进方法及应用[J]. 吉林大学学报(工学版), 2019, 49(6): 1756-1763. |

| [3] | 马芳武,倪利伟,吴量,聂家弘,徐广健. 轮腿式全地形移动机器人位姿闭环控制[J]. 吉林大学学报(工学版), 2019, 49(6): 1745-1755. |

| [4] | 靳立强, 田端洋, 田浩, 刘蒙蒙. 汽车电子稳定系统制动增力辅助技术[J]. 吉林大学学报(工学版), 2019, 49(6): 1764-1776. |

| [5] | 王杨,宋占帅,郭孔辉,庄晔. 转动惯量试验台的惯性参数测量[J]. 吉林大学学报(工学版), 2019, 49(6): 1795-1801. |

| [6] | 庄蔚敏,刘洋,王鹏跃,施宏达,徐纪栓. 钢铝异质自冲铆接头剥离失效仿真[J]. 吉林大学学报(工学版), 2019, 49(6): 1826-1835. |

| [7] | 李杰, 郭文翠, 赵旗, 谷盛丰. 基于车辆响应的路面不平度识别方法[J]. 吉林大学学报(工学版), 2019, 49(6): 1810-1817. |

| [8] | 陈百超,邹猛,党兆龙,黄晗,贾阳,石睿杨,李建桥. CE-3月球车筛网轮月面沉陷行为试验[J]. 吉林大学学报(工学版), 2019, 49(6): 1836-1843. |

| [9] | 贾富淳,孟宪皆,雷雨龙. 基于多目标遗传算法的二自由度动力吸振器优化设计[J]. 吉林大学学报(工学版), 2019, 49(6): 1969-1976. |

| [10] | 何仁,涂琨. 基于温度补偿气隙宽度的电磁制动器[J]. 吉林大学学报(工学版), 2019, 49(6): 1777-1785. |

| [11] | 刘巧斌,史文库,陈志勇,骆联盟,苏志勇,黄开军. 混合可靠性模型参数的核密度和引力搜索估计[J]. 吉林大学学报(工学版), 2019, 49(6): 1818-1825. |

| [12] | 管欣,金号,段春光,卢萍萍. 汽车行驶道路侧向坡度估计[J]. 吉林大学学报(工学版), 2019, 49(6): 1802-1809. |

| [13] | 鄢挺,杨林,陈亮. AMT换挡执行机构自适应智能控制策略[J]. 吉林大学学报(工学版), 2019, 49(5): 1441-1450. |

| [14] | 马芳武,韩露,周阳,王世英,蒲永锋. 采用聚乳酸复合材料的汽车零件多材料优化设计[J]. 吉林大学学报(工学版), 2019, 49(5): 1385-1391. |

| [15] | 张博,张建伟,郭孔辉,丁海涛,褚洪庆. 路感模拟用永磁同步电机电流控制[J]. 吉林大学学报(工学版), 2019, 49(5): 1405-1413. |

|

||