吉林大学学报(工学版) ›› 2020, Vol. 50 ›› Issue (2): 389-398.doi: 10.13229/j.cnki.jdxbgxb20190172

• 车辆工程·机械工程 •

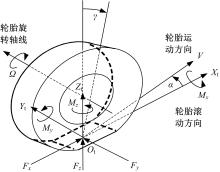

各向异性刚度对轮胎力学特性及车辆操纵性的影响

- 1.吉林大学 汽车仿真与控制国家重点实验室,长春 130022

2.长春孔辉汽车科技股份有限公司,长春 130012

Influence of anisotropic stiffness on tire mechanical properties and vehicle handling characteristics under combined slip situations

Xiao-yu LI1( ),Nan XU1(

),Nan XU1( ),Tao QIU2,Kong-hui GUO1

),Tao QIU2,Kong-hui GUO1

- 1.State Key Laboratory of Automotive Simulation and Control, Jilin University, Changchun 130022, China

2.KH Automotive Technologies Co. Ltd. , Changchun 130012, China

摘要:

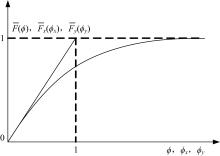

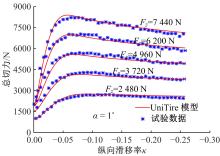

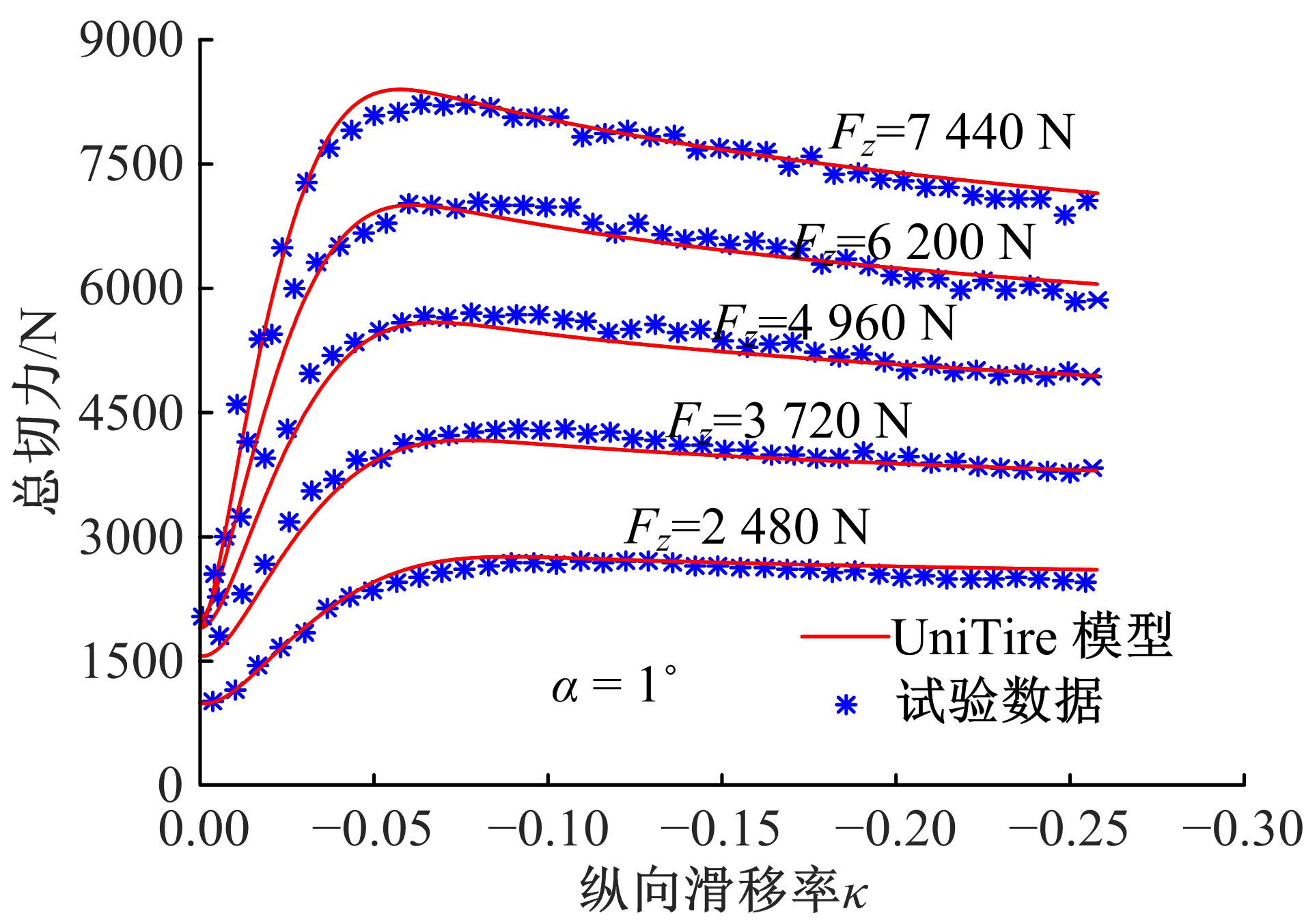

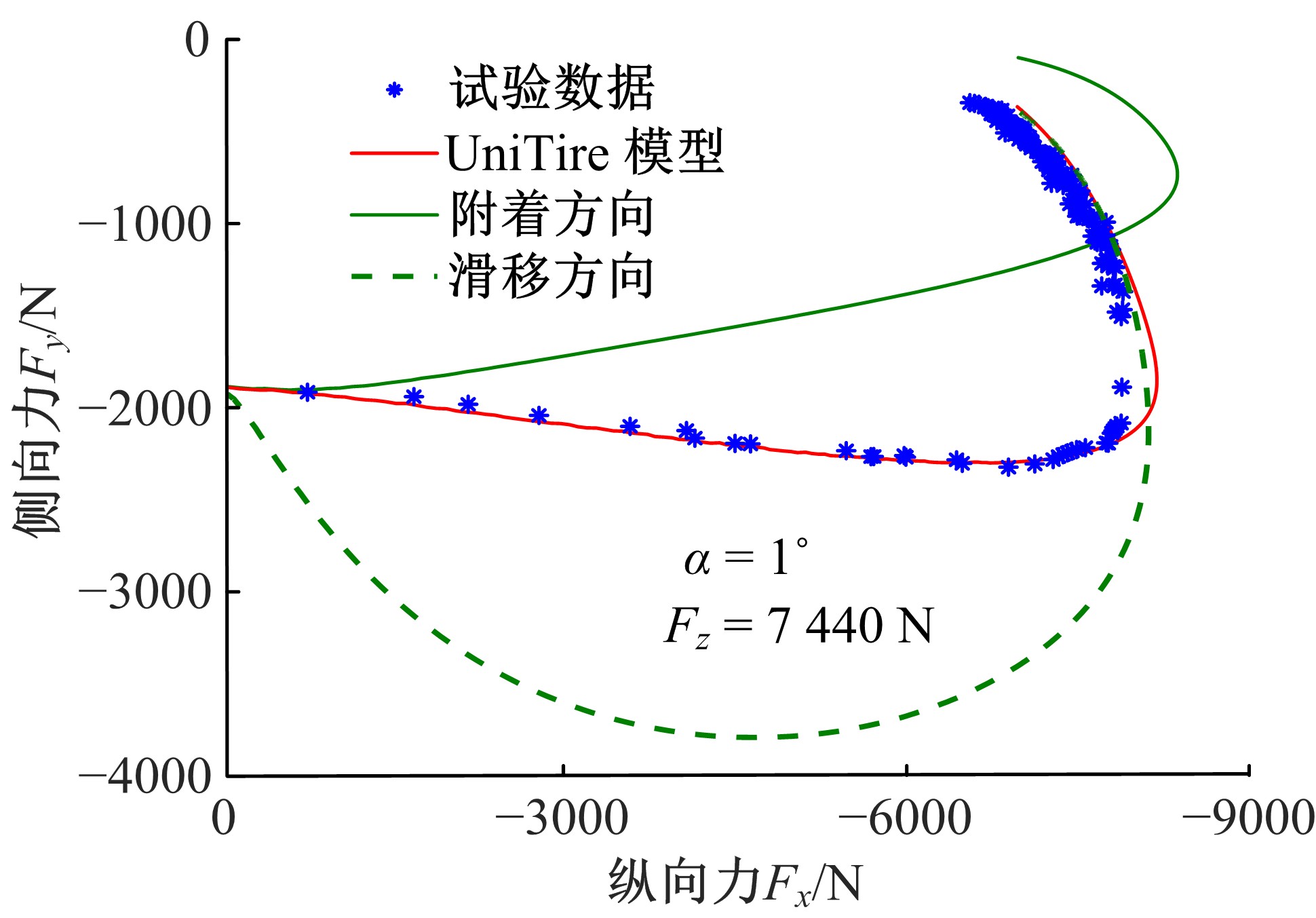

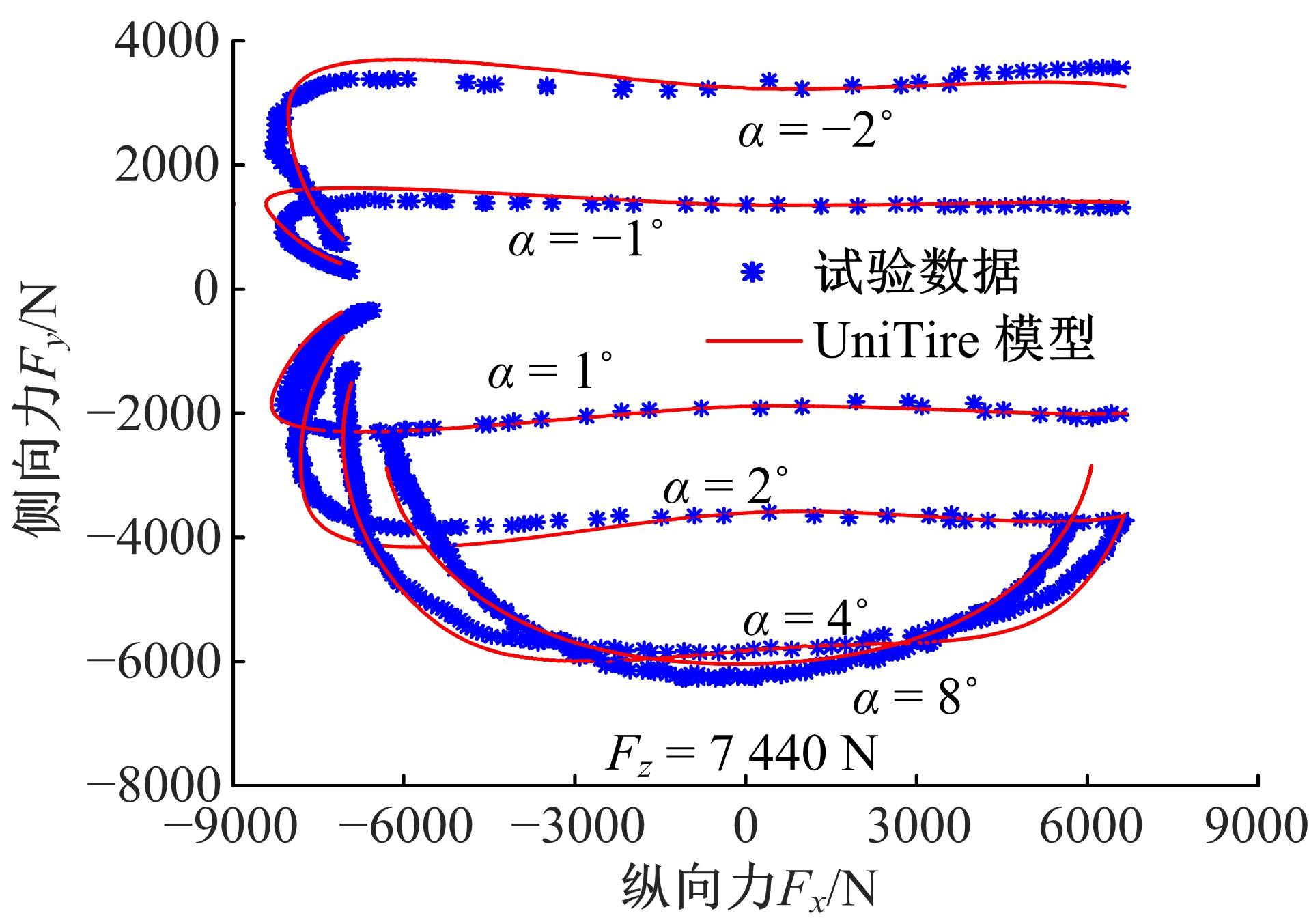

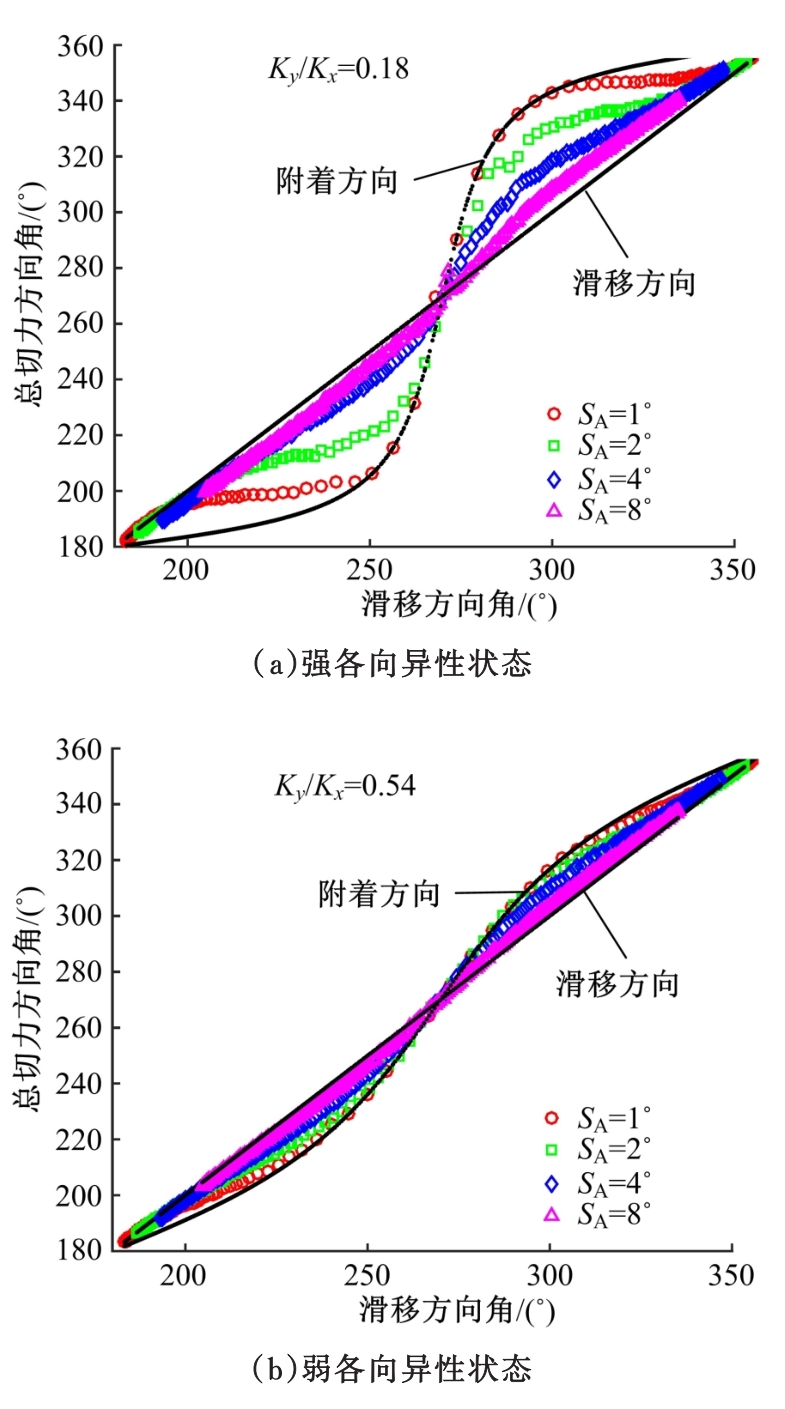

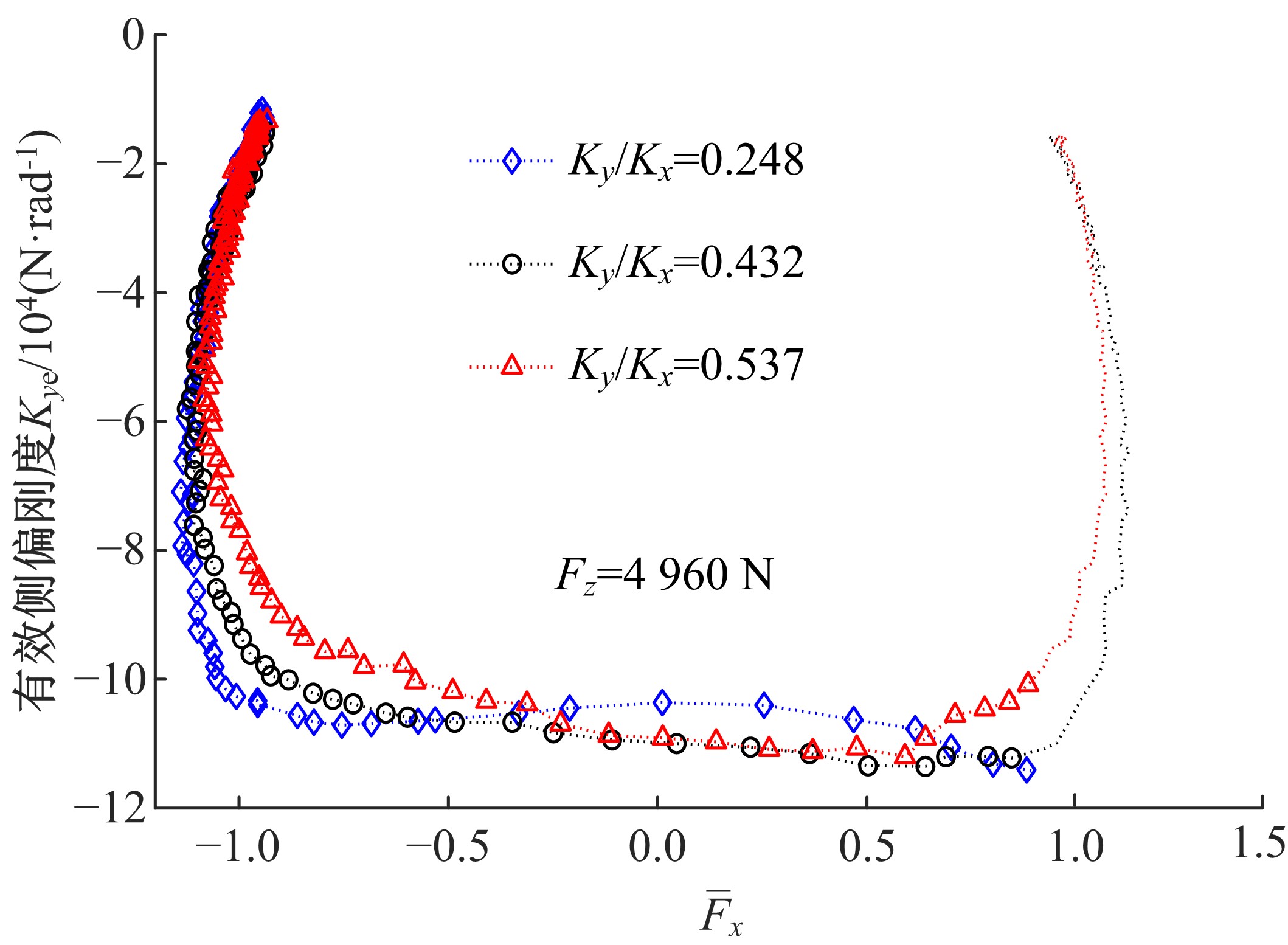

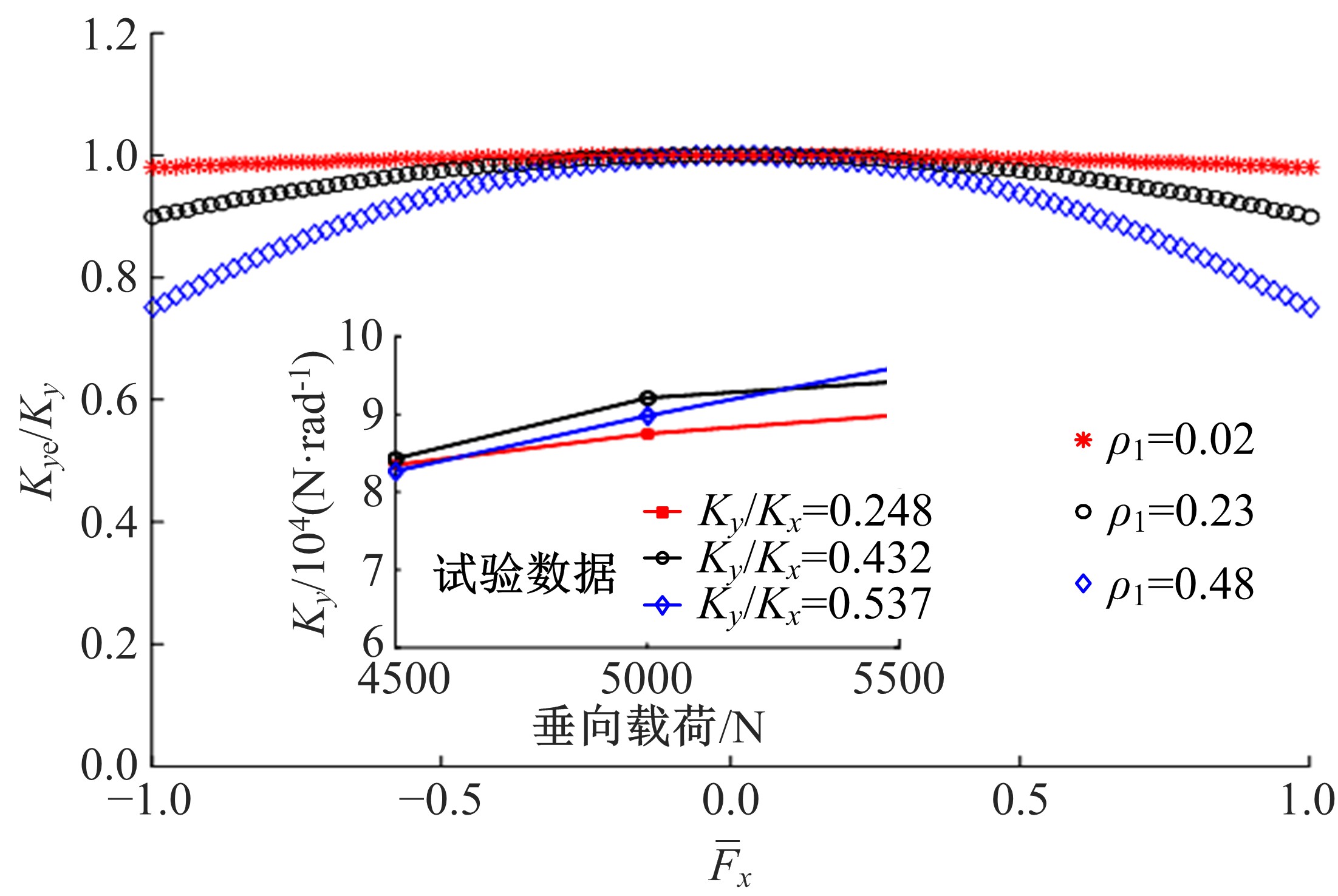

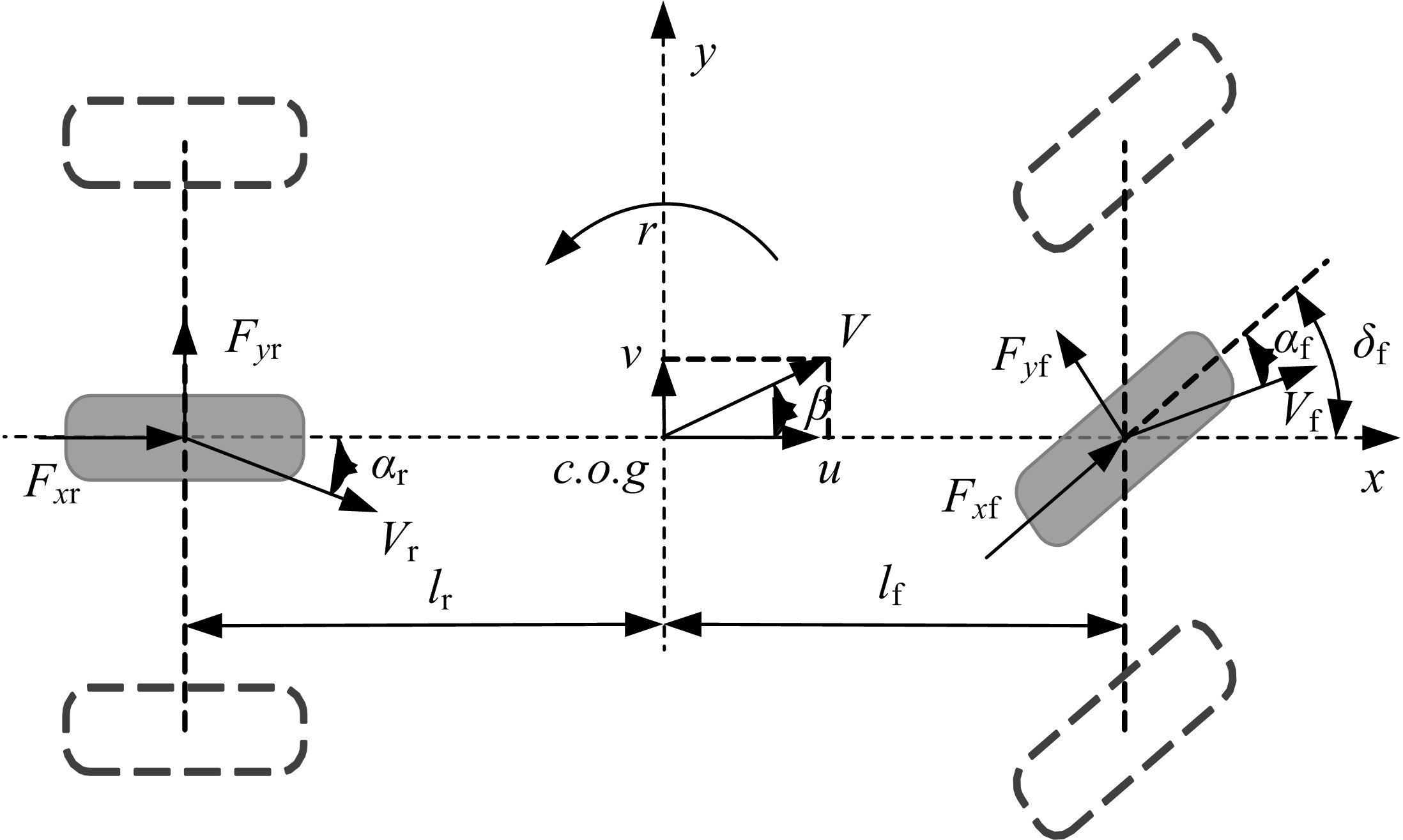

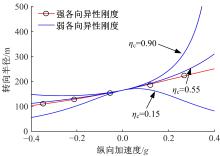

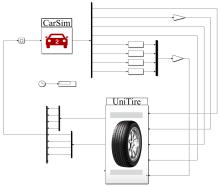

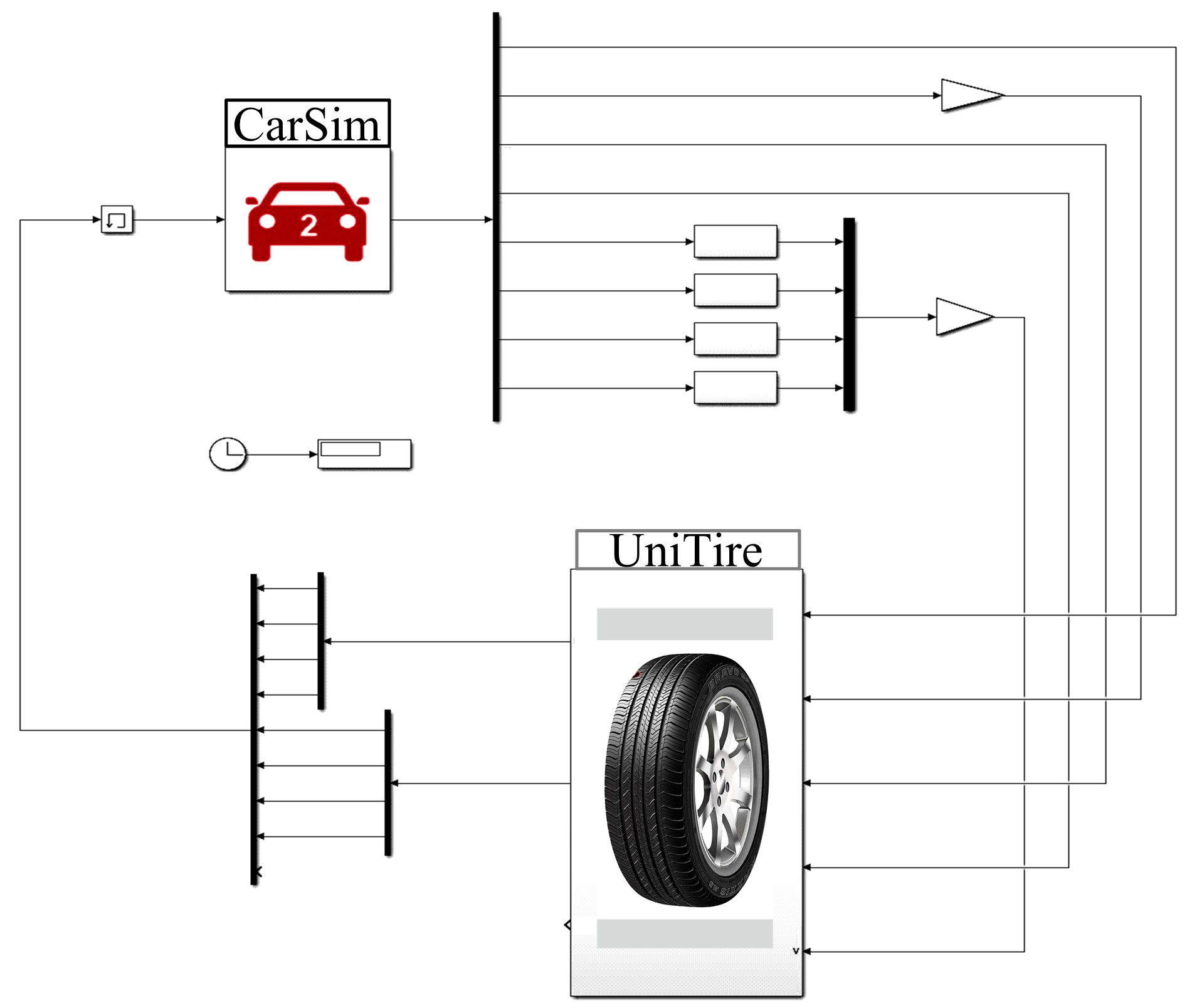

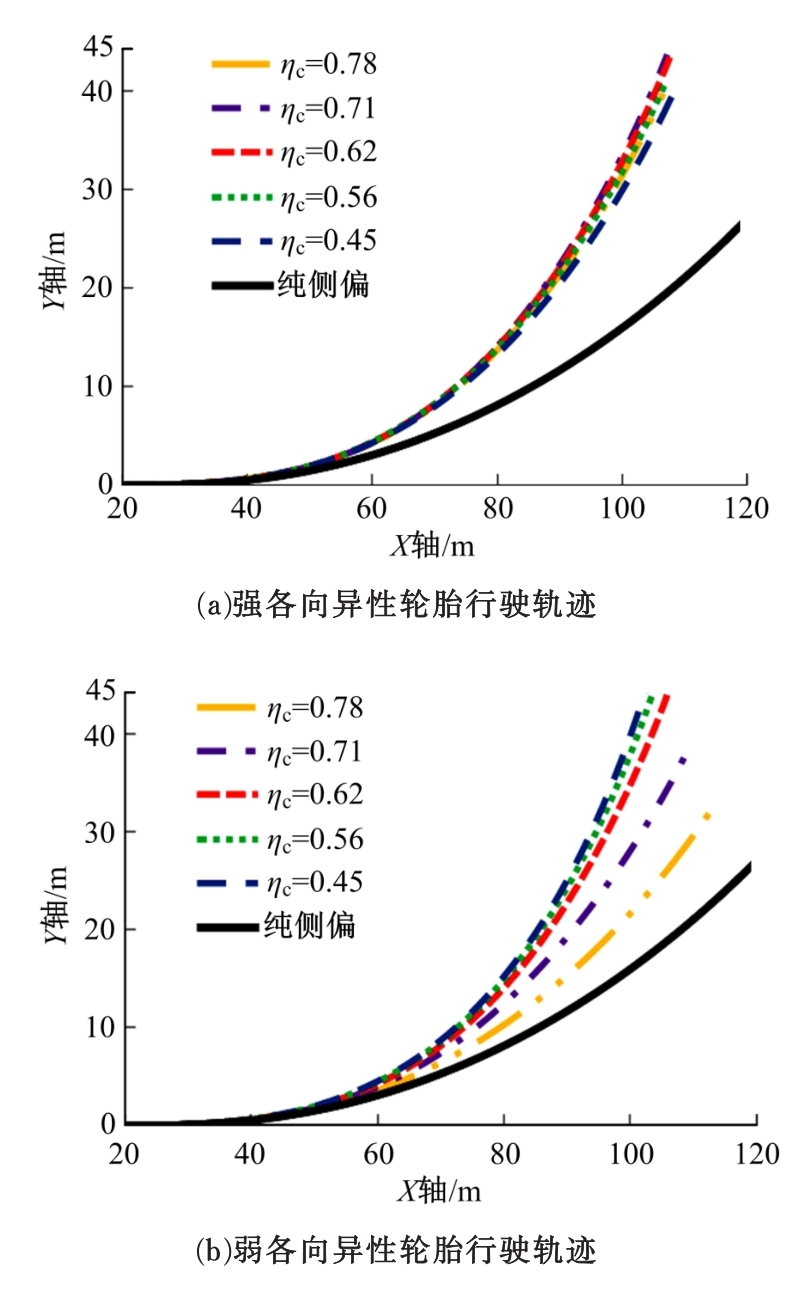

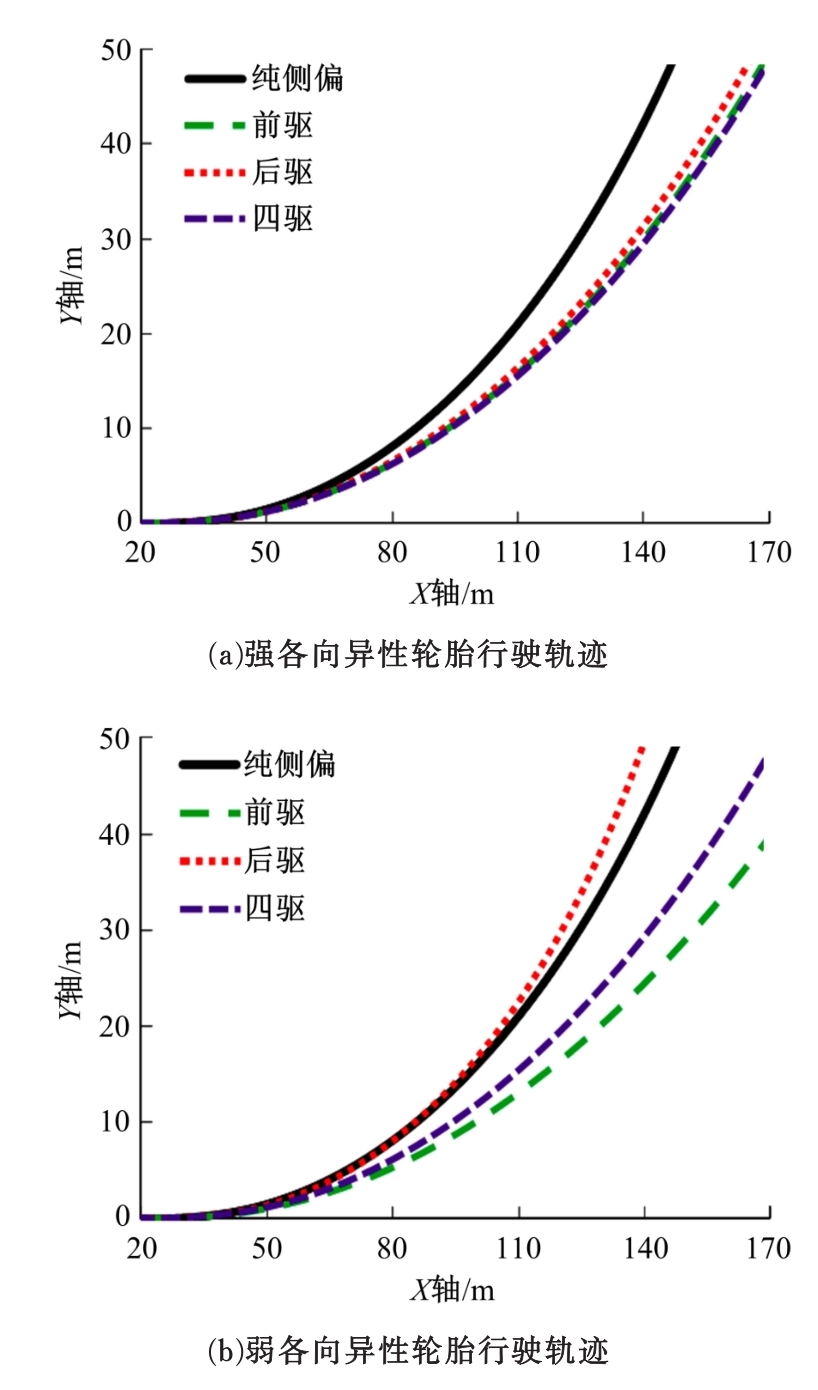

为揭示各向异性刚度值与轮胎力学特性的关系以及对复合工况车辆操纵性的影响规律,首先,通过引入方向因子描述复合工况总切力方向,提高了UniTire对复合工况轮胎力的建模精度;然后,根据轮胎试验数据分析了不同各向异性刚度值下轮胎力学特性变化规律,建立了考虑轮胎各向异性刚度值影响的有效侧偏刚度表达式;之后,建立了考虑轮胎各向异性刚度值影响的复合工况车辆操纵性分析模型,分析了轮胎处于不同各向异性刚度值时纵向加速度对车辆操纵性的影响;最后,通过CarSim软件平台对分析结果进行了仿真验证。结果表明:当轮胎各向异性刚度强时,复合工况下不同的制动/驱动模式对车辆的操纵性影响很小;当轮胎各向异性刚度弱时,复合工况下不同的制动/驱动模式会使车辆呈现出不同的操纵性。

中图分类号:

- U461.1

| 1 | 郭孔辉. 汽车操纵动力学原理[M]. 南京: 江苏科学技术出版社, 2011: 58- 60. |

| 2 | Rafei M, Ghoreishy M H R, Naderi G. Thermo-mechanical coupled finite element simulation of tire cornering characteristics—effect of complex material models and friction law[J]. Mathematics and Computers in Simulation, 2018, 144: 35- 51. |

| 3 | Calabrese F, Baecker M, Galbally C, et al. A detailed thermo-mechanical tire model for advanced handling applications[J]. SAE International Journal of Passenger Cars-Mechanical Systems, 2015, 8( 2): 501- 511. |

| 4 | Bibin S, Pandey A K. A hybrid approach to model the temperature effect in tire forces and moments[J]. SAE International Journal of Passenger Cars-Mechanical Systems, 2017, 10( 1): 25- 37. |

| 5 | 马彬, 许洪国, 刘宏飞. 路面分形和橡胶特性对轮胎滑动摩擦因数的影响[J]. 吉林大学学报: 工学版, 2013, 43( 2): 317- 322. |

| Ma Bin, Xu Hong-guo, Liu Hong-fei. Effects of road surface fractal and rubber characteristics on tire sliding friction factor[J]. Journal of Jilin University (Engineering and Technology Edition), 2013, 43( 2): 317- 322. | |

| 6 | 卢荡, 郭孔辉. 轮胎侧偏力学特性的胎压影响分析及预测[J]. 吉林大学学报: 工学版, 2011, 41( 4): 915- 920. |

| Lu Dang, Guo Kong-hui. Analysis and prediction of tire cornering property for different inflation pressure[J]. Journal of Jilin University (Engineering and Technology Edition), 2011, 41( 4): 915- 920. | |

| 7 | Höpping K, Augsburg K, Büchner F. Extending the HSRI tyre model for large inflation pressure changes[C]∥ 59th Ilmenau Scientific Colloquium, Technische Universität Ilmenau,Ilmenau, 2017: 11- 15. |

| 8 | Kasprzak E M, Lewis K, Milliken D. Tire asymmetries and pressure variations in the Radt/Milliken nondimensional tire model[C]∥SAE Technical Paper, 2006-01-1968. |

| 9 | Mizuno M, Sakai H, Oyma K, et al. Development of a tyre force model incorporating the influence of the tyre surface temperature[J]. Vehicle System Dynamics, 2005, 43( Sup.1): 395- 402. |

| 10 | Gil G, Park J. Physical handling tire model incorporating temperature and inflation pressure change effect[C]∥SAE Technical Paper, 2018-01-1338. |

| 11 | 许男. 复合工况下轮胎稳态模型研究[D]. 长春: 吉林大学汽车工程学院, 2012. |

| Xu Nan. Study on the steady state tire model under combined conditions[D]. Changchun: College of Automotive Engineering, Jilin University, 2012. | |

| 12 | Reiter M, Wagner J. Automated automotive tire inflation system-effect of tire pressure on vehicle handling[J]. IFAC Proceedings, 2010, 43( 7): 638- 643. |

| 13 | Alexander V. Influence of tyre inflation pressure on fuel consumption, vehicle handling and ride quality-modelling and simulation[D]. Sweden: Chalmers University of Technology, 2013. |

| 14 | Abe M. Vehicle Handling Dynamics[M]. Amsterdam, Netherlands: Elsevier, 2009: 171- 182. |

| [1] | 马芳武,梁鸿宇,赵颖,杨猛,蒲永锋. 内凹三角形负泊松比结构耐撞性多目标优化设计[J]. 吉林大学学报(工学版), 2020, 50(1): 29-35. |

| [2] | 郭孔辉,黄世庆,吴海东. 适用于高频激励的面内轮胎动态模型[J]. 吉林大学学报(工学版), 2020, 50(1): 19-28. |

| [3] | 王哲,谢怡,臧鹏飞,王耀. 基于极小值原理的燃料电池客车能量管理策略[J]. 吉林大学学报(工学版), 2020, 50(1): 36-43. |

| [4] | 史文库,陈龙,张贵辉,陈志勇. 多级刚度双质量飞轮扭转特性建模与试验验证[J]. 吉林大学学报(工学版), 2020, 50(1): 44-52. |

| [5] | 管欣,金号,段春光,卢萍萍. 汽车行驶道路侧向坡度估计[J]. 吉林大学学报(工学版), 2019, 49(6): 1802-1809. |

| [6] | 陈鑫,阮新建,李铭,王宁,王佳宁,潘凯旋. 基于大涡模拟的离散格式改进方法及应用[J]. 吉林大学学报(工学版), 2019, 49(6): 1756-1763. |

| [7] | 马芳武,倪利伟,吴量,聂家弘,徐广健. 轮腿式全地形移动机器人位姿闭环控制[J]. 吉林大学学报(工学版), 2019, 49(6): 1745-1755. |

| [8] | 靳立强, 田端洋, 田浩, 刘蒙蒙. 汽车电子稳定系统制动增力辅助技术[J]. 吉林大学学报(工学版), 2019, 49(6): 1764-1776. |

| [9] | 王杨,宋占帅,郭孔辉,庄晔. 转动惯量试验台的惯性参数测量[J]. 吉林大学学报(工学版), 2019, 49(6): 1795-1801. |

| [10] | 庄蔚敏,刘洋,王鹏跃,施宏达,徐纪栓. 钢铝异质自冲铆接头剥离失效仿真[J]. 吉林大学学报(工学版), 2019, 49(6): 1826-1835. |

| [11] | 李杰, 郭文翠, 赵旗, 谷盛丰. 基于车辆响应的路面不平度识别方法[J]. 吉林大学学报(工学版), 2019, 49(6): 1810-1817. |

| [12] | 陈百超,邹猛,党兆龙,黄晗,贾阳,石睿杨,李建桥. CE-3月球车筛网轮月面沉陷行为试验[J]. 吉林大学学报(工学版), 2019, 49(6): 1836-1843. |

| [13] | 何仁,涂琨. 基于温度补偿气隙宽度的电磁制动器[J]. 吉林大学学报(工学版), 2019, 49(6): 1777-1785. |

| [14] | 刘巧斌,史文库,陈志勇,骆联盟,苏志勇,黄开军. 混合可靠性模型参数的核密度和引力搜索估计[J]. 吉林大学学报(工学版), 2019, 49(6): 1818-1825. |

| [15] | 高振海,孙天骏,何磊. 汽车纵向自动驾驶的因果推理型决策[J]. 吉林大学学报(工学版), 2019, 49(5): 1392-1404. |

|

||