吉林大学学报(工学版) ›› 2020, Vol. 50 ›› Issue (2): 399-407.doi: 10.13229/j.cnki.jdxbgxb20181118

• 车辆工程·机械工程 • 上一篇

静气动弹性影响下带小翼汽车尾翼的设计与优化

- 1.重庆理工大学 车辆工程学院,重庆 400054

2.日本东北大学 流体科学研究所,日本 仙台 980 ?8577

Design and optimization of a car empennage with winglet under effect of static aeroelasticity

Chen-guang LAI1( ),Qing-yu WANG1,Bo HU1(

),Qing-yu WANG1,Bo HU1( ),Kai-ping WEN2,Yan-yu CHEN2

),Kai-ping WEN2,Yan-yu CHEN2

- 1.College of Vehicle Engineering, Chongqing University of Technology, Chongqing 400054, China

2.Institute of Fluid Science, Tohoku University, Sendai 980? 8577, Japan

摘要:

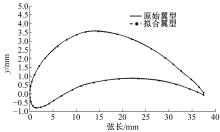

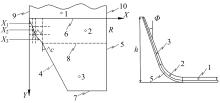

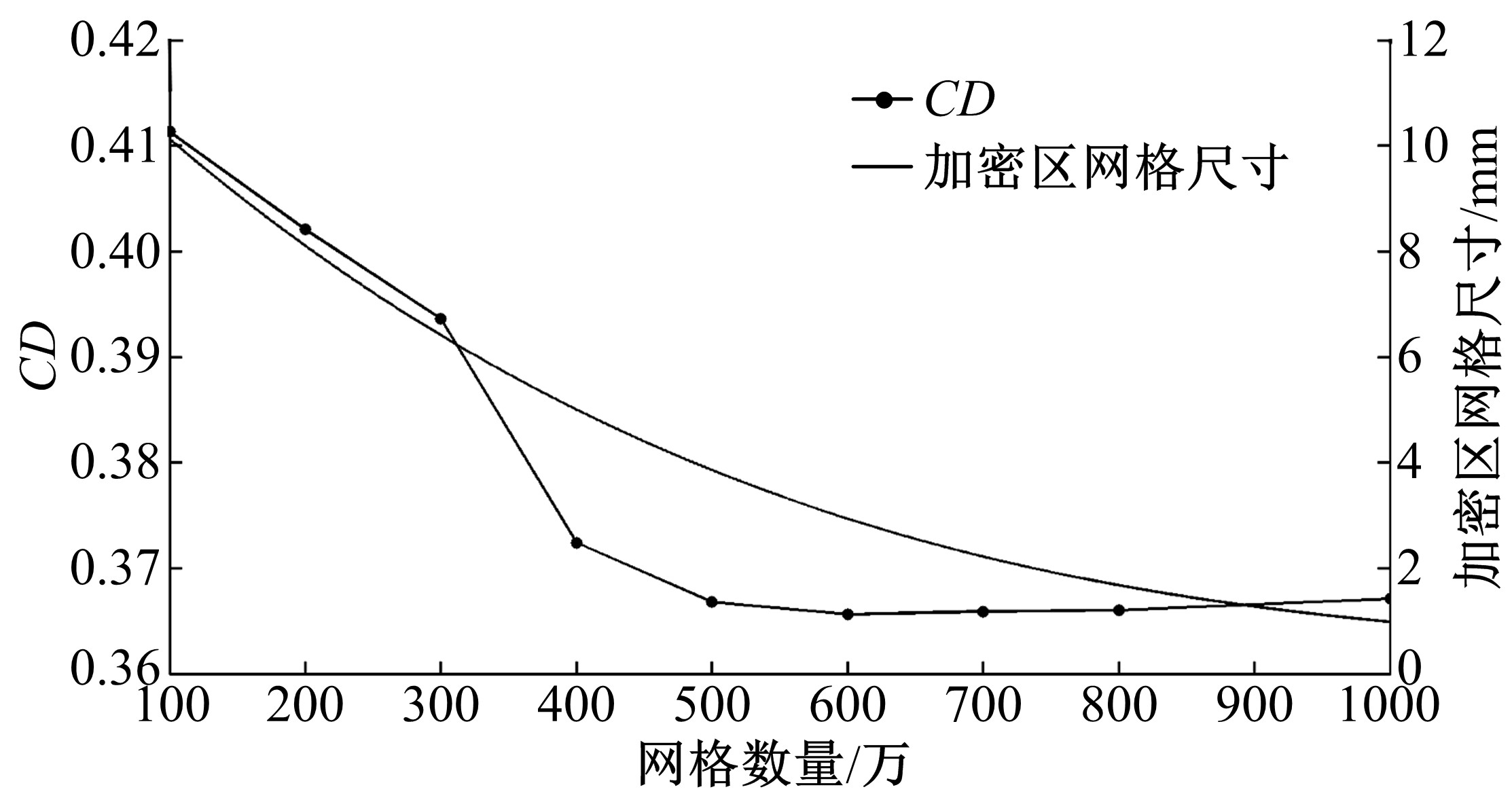

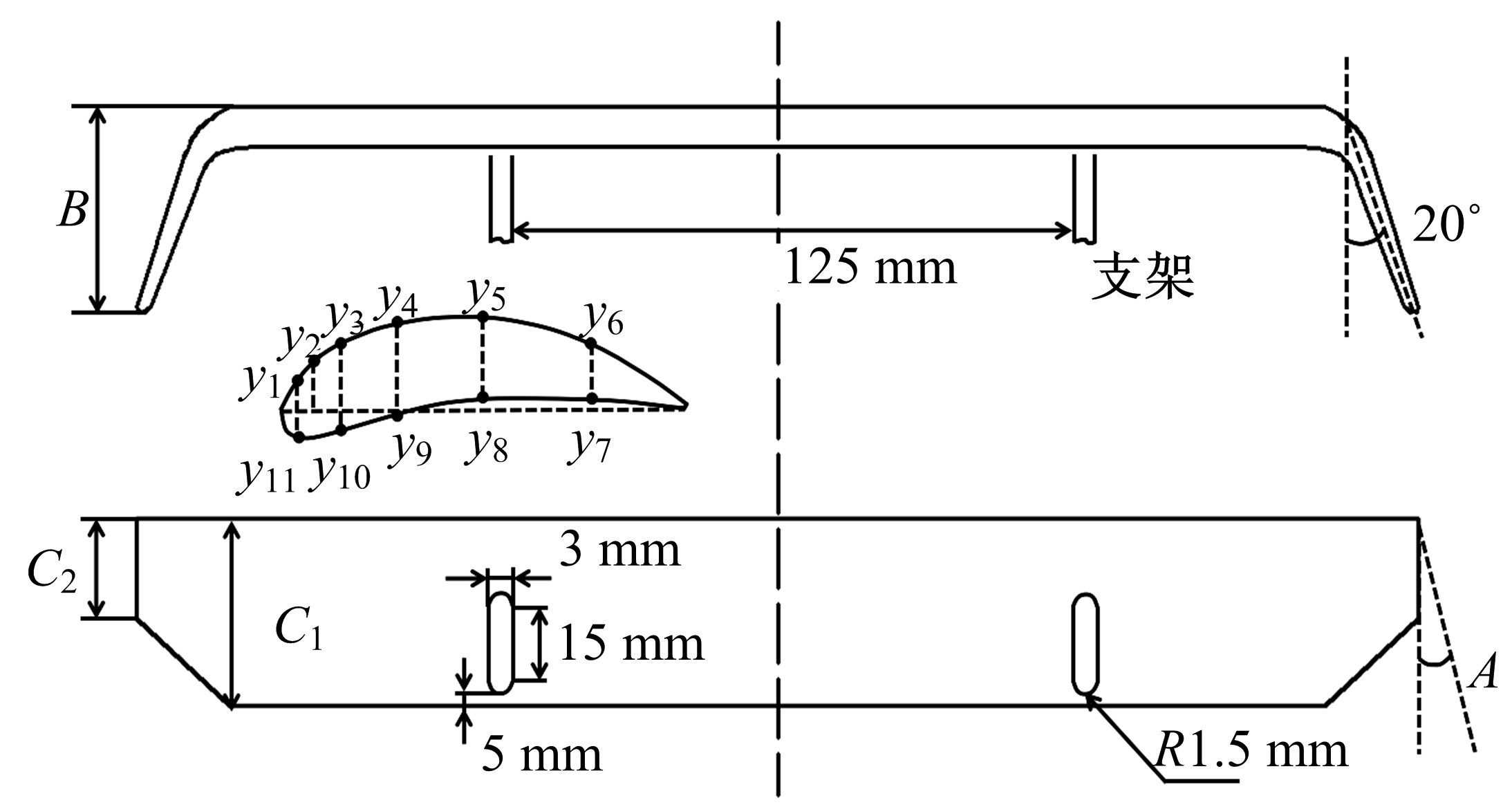

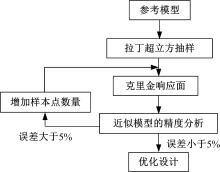

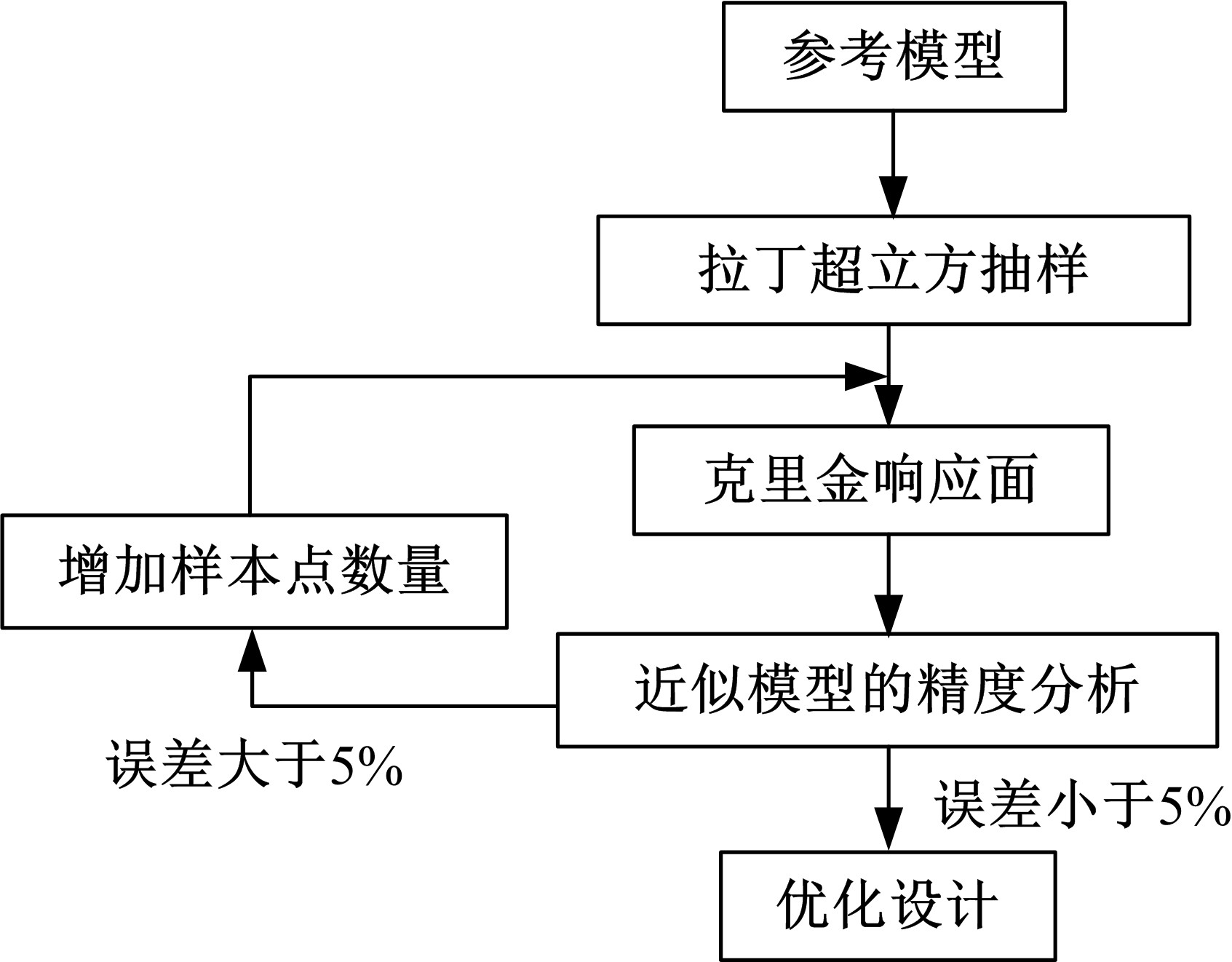

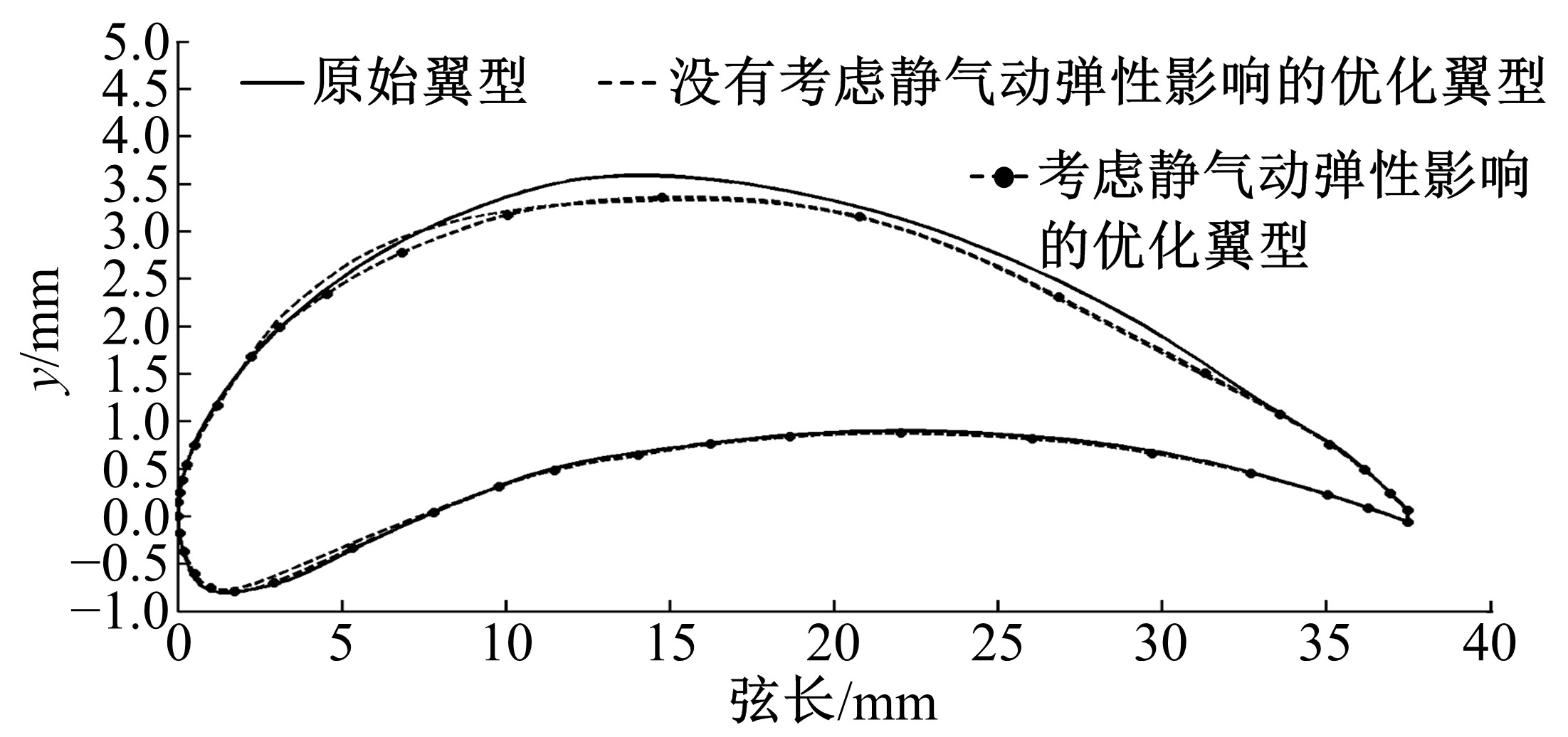

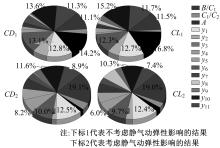

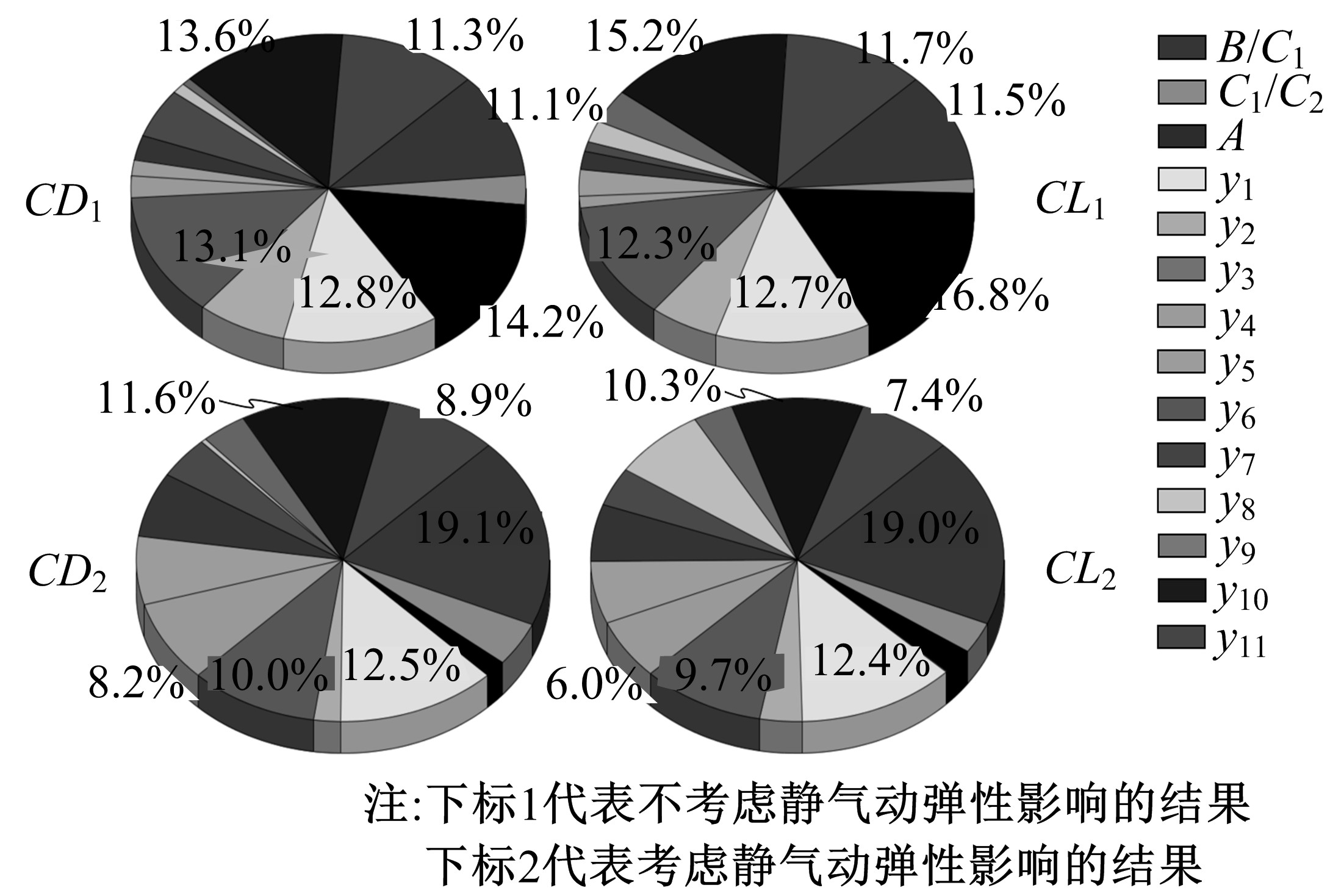

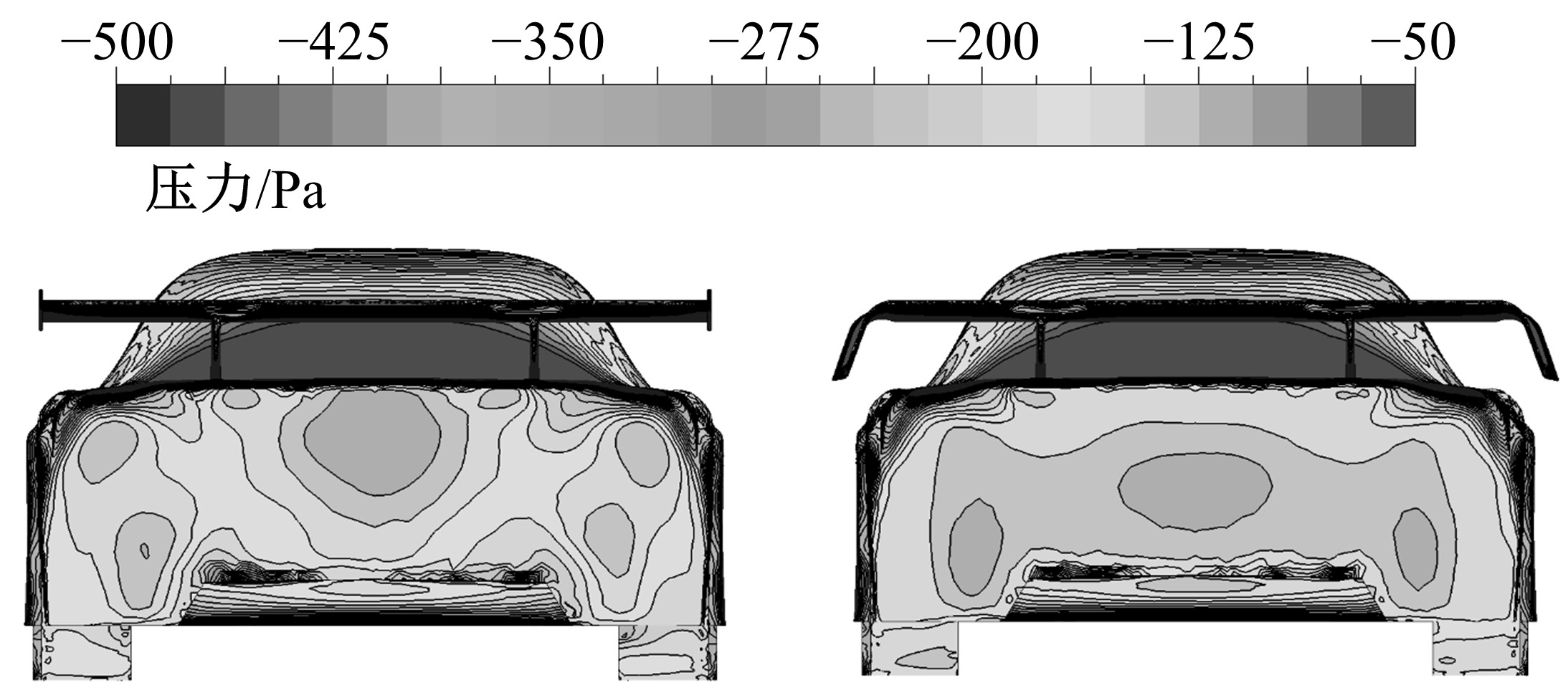

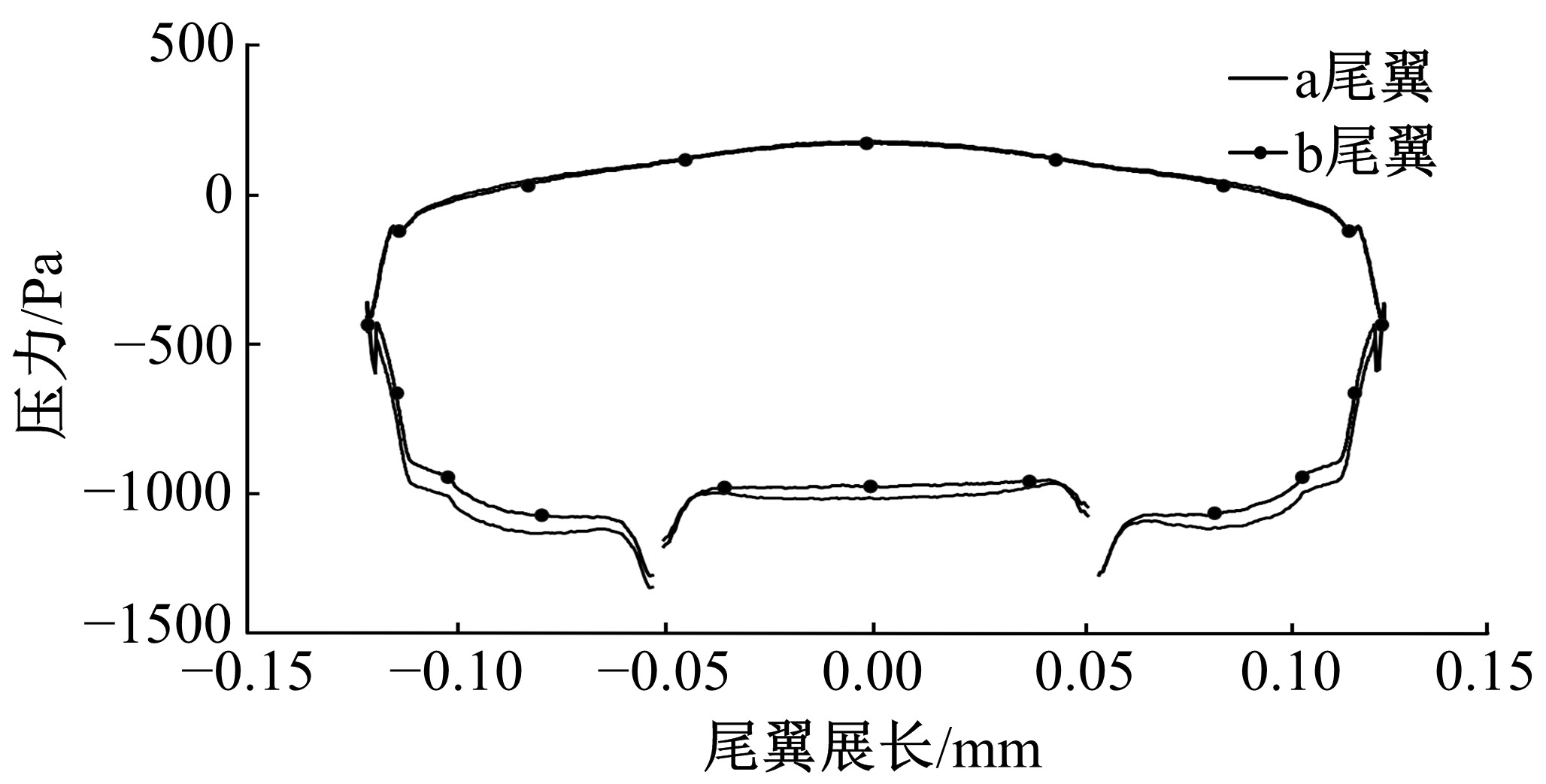

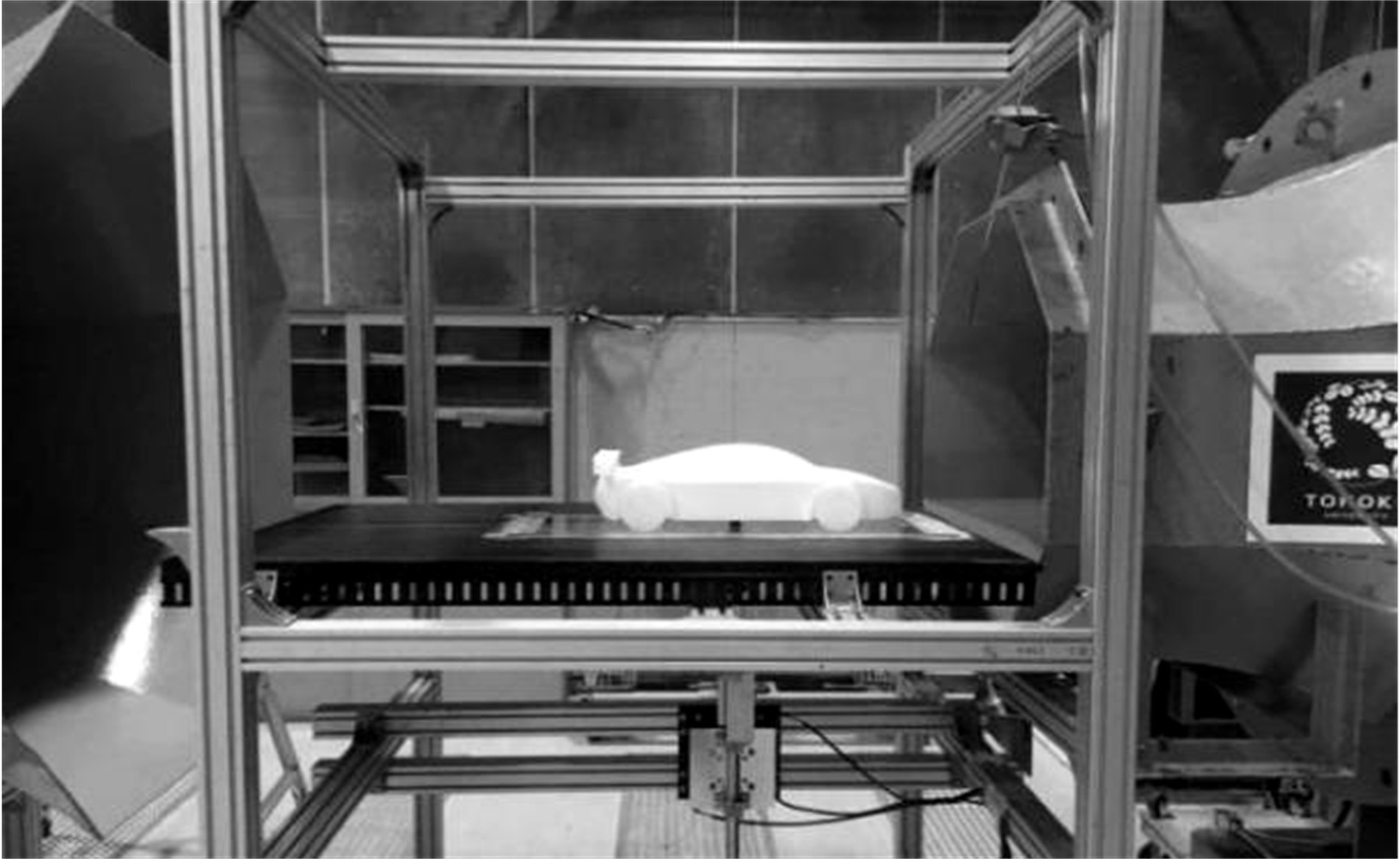

翼尖小翼能利用机翼翼尖产生的三维绕流为机翼提供额外的升力和前进的推力,其独特的作用机理同样适合用在汽车尾翼上。由于汽车的尾部流场与航空器有较大差别,使传统的航空器翼型很难满足汽车用翼尖小翼的设计需求,同时翼尖小翼的附加会使尾翼翼面因额外的弹性变形而产生新的气动载荷分布,这就需要对车用翼尖小翼进行设计和优化。首先,利用准均匀B样条曲线来拟合翼型,再对拟合的翼型进行小翼的三维参数化建模,最后,使用双向流固耦合的分析方法来考虑静气动弹性对附加了小翼的汽车尾翼的实际影响,并在三维流场中通过数值仿真的手段对小翼翼型及其形状参数进行优化设计。最优样本进行了风洞试验验证和比较,结果说明仿真具有较高的模拟精度,同时风洞试验与数值仿真的结果表明:翼尖小翼通过优化设计能为安装有普通尾翼的汽车带来额外下压力的同时减小其气动阻力;相较于刚性翼,考虑静气动弹性的新型尾翼,其最优解集有使汽车模型的升力系数增加而阻力系数减小的趋势。

中图分类号:

- U463.99

| 1 | 谷正气. 汽车空气动力学[M]. 北京:人民交通出版社, 2006. |

| 2 | 胡兴军, 杨博, 郭鹏, 等. 基于底部隔板的厢式货车的气动减阻[J]. 吉林大学学报: 工学版, 2011, 41(增刊2): 108-113. |

| Hu Xing-jun, Yang Bo, Guo Peng, et al. Aerodynamic drag reduction of van based on underbody skirt[J]. Journal of Jilin University (Engineering and Technology Edition), 2011, 41(Sup.2): 108-113. | |

| 3 | Kim I, Chen H, Shulze R C. A rear spoiler of a new type that reduces the aerodynamic forces on a mini-van[J]. SAE Technical Paper, 2006-01-1631. |

| 4 | Katz J. Aerodynamics of race cars[J]. Annual Review of Fluid Mechanics, 2006, 38(1): 27-63. |

| 5 | 张英朝, 韦甘, 张喆. 不同尾翼两厢轿车的气动特性数值模拟[J]. 吉林大学学报: 工学版, 2011, 41(1): 1-5. |

| Zhang Ying-chao, Wei Gan, Zhang Zhe. Aerodynamic numerical simulation of hatch-back car with different spoilers[J]. Journal of Jilin University (Engineering and Technology Edition), 2011, 41(1): 1-5. | |

| 6 | 韩海兰, 李刚, 贾丽娟, 等. 基于驾驶模拟器的FSC赛车操纵稳定性主观评价研究[J]. 农业装备与车辆工程, 2015, 53(1): 5-9. |

| Han Hai-lan, Li Gang, Jia Li-juan, et al. Study on subjective evaluation for handling and stability of FSC racing car based on driving simulator[J]. Agricultural Equipment & Vehicle Engineering, 2015, 53(1): 5-9. | |

| 7 | 汪永泉. 飞机翼梢小翼设计[M]. 北京: 航空工业出版社, 2009. |

| 8 | Castellani M, Cooper J E, Lemmens Y. Nonlinear static aeroelasticity of high-aspect-ratio-wing aircraft by finite element and multibody methods[J]. Journal of Aircraft, 2017, 54(2): 548-560. |

| 9 | 潘秀东. 基于自由曲线建模方法的翼梢小翼优化设计[D]. 上海: 上海交通大学船舶海洋与建筑工程学院, 2011. |

| Pan Xiu-dong. Optimal design of winglet modeled by freestyle curve[D]. Shanghai: School of Naval Architecture, Ocean & Civil Engineering, Shanghai Jiao Tong University, 2011. | |

| 10 | Chattot J J. Low speed design and analysis of wing/winglet combinations including viscous effects[J]. Journal of Aircraft, 2006, 43(2): 386-389. |

| 11 | Panagiotou P, Kaparos P, Yakinthos K. Winglet design and optimization for a MALE UAV using CFD[J]. Aerospace Science & Technology, 2014, 39: 190-205. |

| 12 | Qin N, Vavalle A, Moigne A L, et al. Aerodynamic considerations of blended wing body aircraft[J]. Progress in Aerospace Sciences, 2004, 40(6): 321-343. |

| 13 | 张骥, 朱春钢, 冯仁忠, 等. 一种改进的B样条翼型参数化方法[J]. 图学学报, 2016, 37(3): 342-348. |

| Zhang Ji, Zhu Chun-gang, Feng Ren-zhong, et al. An improved method for airfoil parameterization by B-Spline[J]. Journal of Graphics, 2016, 37(3): 342-348. | |

| 14 | 廖炎平, 刘莉, 龙腾. 几种翼型参数化方法研究[J]. 弹箭与制导学报, 2011, 31(3): 160-164. |

| Liao Yan-ping, Liu Li, Long Teng. The research on some parameterized methods for airfoil[J]. Journal of Projectiles, Missiles and Guidance, 2011, 31(3):160-164. | |

| 15 | 张珅榕, 蔡卫军, 杨春武, 等. 基于复合映射法及B样条的翼型参数化方法[J]. 鱼雷技术, 2015, 23(3): 161-165. |

| Zhang Shen-rong, Cai Wei-jun, Yang Chun-wu, et al. A parameterization method for airfoil based on composite mapping method and B-Spline[J]. Torpedo Technology, 2015, 23(3): 161-165. | |

| 16 | 孙勤, 张俊彦, 邹汝红. 三种翼型参数化方法的研究[J]. 湘潭大学自然科学学报, 2013, 35(3): 34-39. |

| Sun Qin, Zhang Jun-yan, Zou Ru-hong. The research on three parameterized methods for airfoil[J]. Natural Science Journal of Xiangtan University, 2013, 35(3): 34-39. | |

| 17 | Gratzer L B. Blended Winglet[P]. United States: 5348253, 1994. |

| 18 | Inc ANSYS. Ansys Fluent Theory Guide[M]. Canonsburg, USA: ANSYS Inc, 2017. |

| 19 | 田内科斯H, 兰姆利J L. 湍流初级教程: A First Course in Turbulence[M]. 施红辉, 林培锋, 译. 北京: 科学出版社, 2015. |

| 20 | 范锐军, 冯朝辉, 周洲. 大展弦比无人机的静气弹问题计算及分析[J]. 力学季刊, 2009, 30(4): 548-554. |

| Fan Rui-jun, Feng Zhao-hui, Zhou Zhou. Static aeroelastic investigation of large aspect ratio UAV[J]. Chinese Quarterly of Mechanics, 2009, 30(4): 548-554. | |

| 21 | Jung Y S, Yu D O, Kwon O J. Aeroelastic analysis of high-aspect-ratio wings using a coupled CFD-CSD method[J]. Transactions of the Japan Society for Aeronautical & Spaceences, 2016, 59(3): 123-133. |

| 22 | Gerrard J H. The mechanics of the formation region of vortices behind bluff bodies[J]. Journal of Fluid Mechanics, 1966, 25(2): 401-413. |

| 23 | Tsubokura M, Nakashima T, Kitayama M, et al. Large eddy simulation on the unsteady aerodynamic response of a road vehicle in transient crosswinds[J]. International Journal of Heat & Fluid Flow, 2010, 31(6): 1075-1086. |

| [1] | 李小雨,许男,仇韬,郭孔辉. 各向异性刚度对轮胎力学特性及车辆操纵性的影响[J]. 吉林大学学报(工学版), 2020, 50(2): 389-398. |

| [2] | 蔡中义,孟凡响,陈庆敏,赵轩. 复杂钩舌锻件近净成形的预锻形状优化设计[J]. 吉林大学学报(工学版), 2020, 50(1): 84-90. |

| [3] | 刘毅,肖玲玲,王改静,张武军. 基于联合优化的D2D资源分配算法[J]. 吉林大学学报(工学版), 2020, 50(1): 306-314. |

| [4] | 王芳,李晓光,郭慧,胡佳. 基于驾驶员视觉兴趣区的沙漠草原公路曲线间直线段线形指标优化[J]. 吉林大学学报(工学版), 2020, 50(1): 114-120. |

| [5] | 马芳武,梁鸿宇,赵颖,杨猛,蒲永锋. 内凹三角形负泊松比结构耐撞性多目标优化设计[J]. 吉林大学学报(工学版), 2020, 50(1): 29-35. |

| [6] | 郭孔辉,黄世庆,吴海东. 适用于高频激励的面内轮胎动态模型[J]. 吉林大学学报(工学版), 2020, 50(1): 19-28. |

| [7] | 王哲,谢怡,臧鹏飞,王耀. 基于极小值原理的燃料电池客车能量管理策略[J]. 吉林大学学报(工学版), 2020, 50(1): 36-43. |

| [8] | 毛艳,成凯. 基于Hopfield神经网络的单缸插销式伸缩臂伸缩路径优化[J]. 吉林大学学报(工学版), 2020, 50(1): 53-65. |

| [9] | 金顺福,郄修尘,武海星,霍占强. 基于新型休眠模式的云虚拟机分簇调度策略及性能优化[J]. 吉林大学学报(工学版), 2020, 50(1): 237-246. |

| [10] | 史文库,陈龙,张贵辉,陈志勇. 多级刚度双质量飞轮扭转特性建模与试验验证[J]. 吉林大学学报(工学版), 2020, 50(1): 44-52. |

| [11] | 管欣,金号,段春光,卢萍萍. 汽车行驶道路侧向坡度估计[J]. 吉林大学学报(工学版), 2019, 49(6): 1802-1809. |

| [12] | 陈鑫,阮新建,李铭,王宁,王佳宁,潘凯旋. 基于大涡模拟的离散格式改进方法及应用[J]. 吉林大学学报(工学版), 2019, 49(6): 1756-1763. |

| [13] | 马芳武,倪利伟,吴量,聂家弘,徐广健. 轮腿式全地形移动机器人位姿闭环控制[J]. 吉林大学学报(工学版), 2019, 49(6): 1745-1755. |

| [14] | 靳立强, 田端洋, 田浩, 刘蒙蒙. 汽车电子稳定系统制动增力辅助技术[J]. 吉林大学学报(工学版), 2019, 49(6): 1764-1776. |

| [15] | 王杨,宋占帅,郭孔辉,庄晔. 转动惯量试验台的惯性参数测量[J]. 吉林大学学报(工学版), 2019, 49(6): 1795-1801. |

|

||