吉林大学学报(工学版) ›› 2020, Vol. 50 ›› Issue (1): 84-90.doi: 10.13229/j.cnki.jdxbgxb20181219

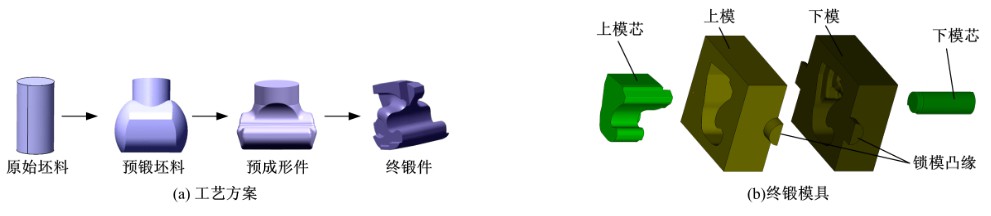

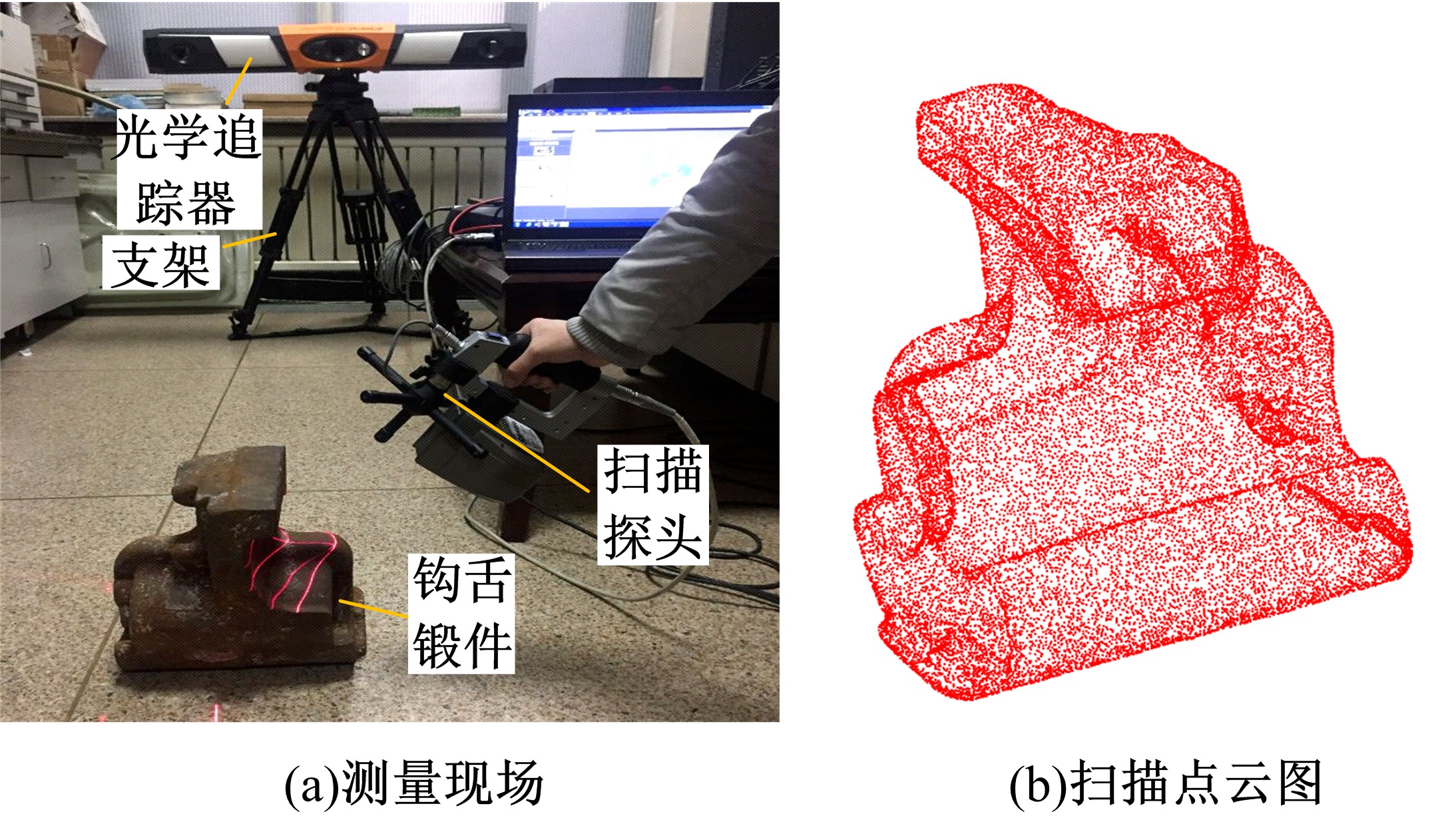

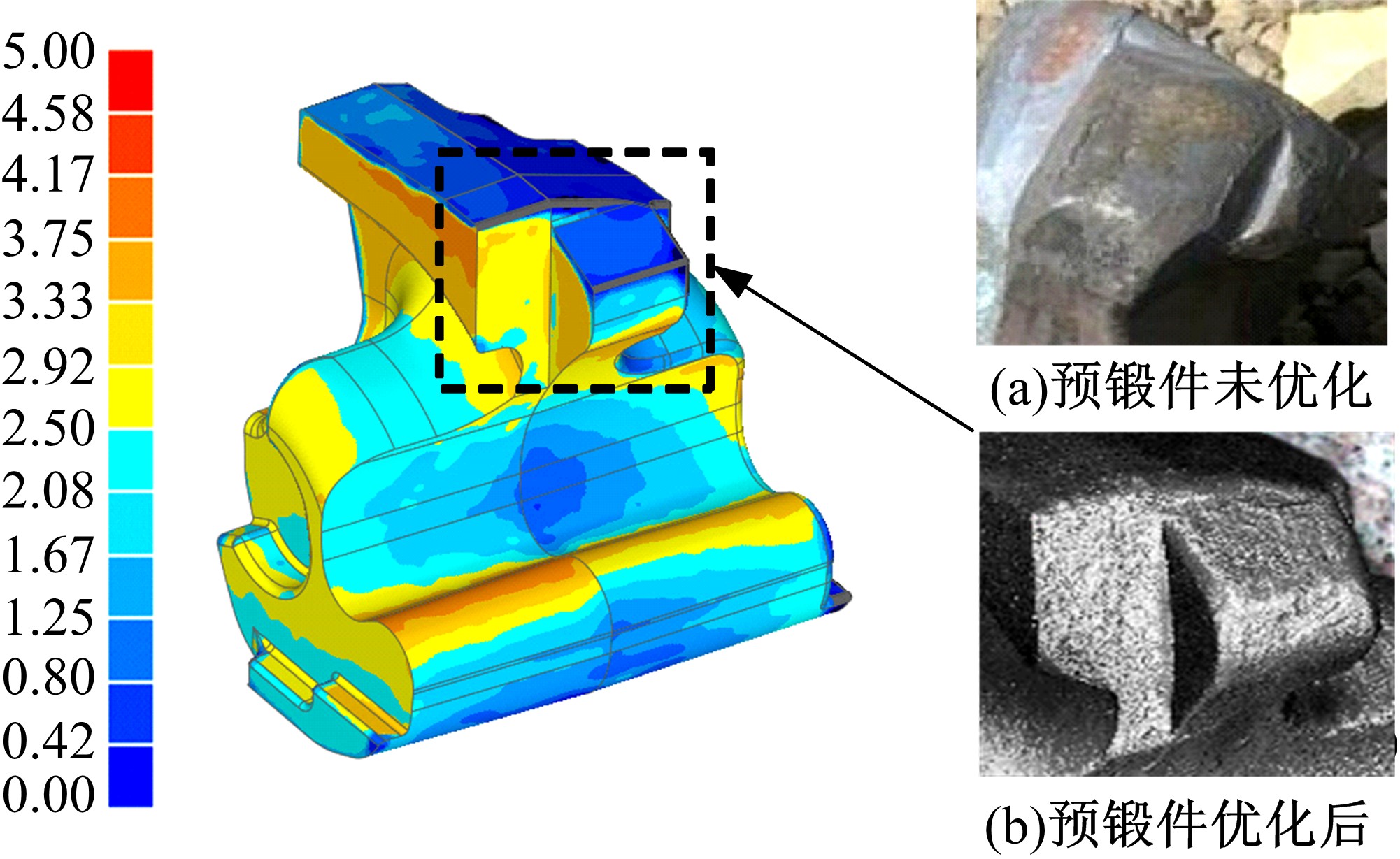

复杂钩舌锻件近净成形的预锻形状优化设计

- 1. 吉林大学 辊锻工艺研究所,长春 130022

2. 吉林大学 材料科学与工程学院 长春 130022

Preform optimization for near-net-shape forming process of complex knuckle forging

Zhong-yi CAI1,2( ),Fan-xiang MENG2,Qing-min CHEN1(

),Fan-xiang MENG2,Qing-min CHEN1( ),Xuan ZHAO2

),Xuan ZHAO2

- 1. Rolling Forging Institute, Jilin University, Changchun 130022, China

2. College of Materials Science and Engineering, Jilin University, Changchun 130022, China

摘要:

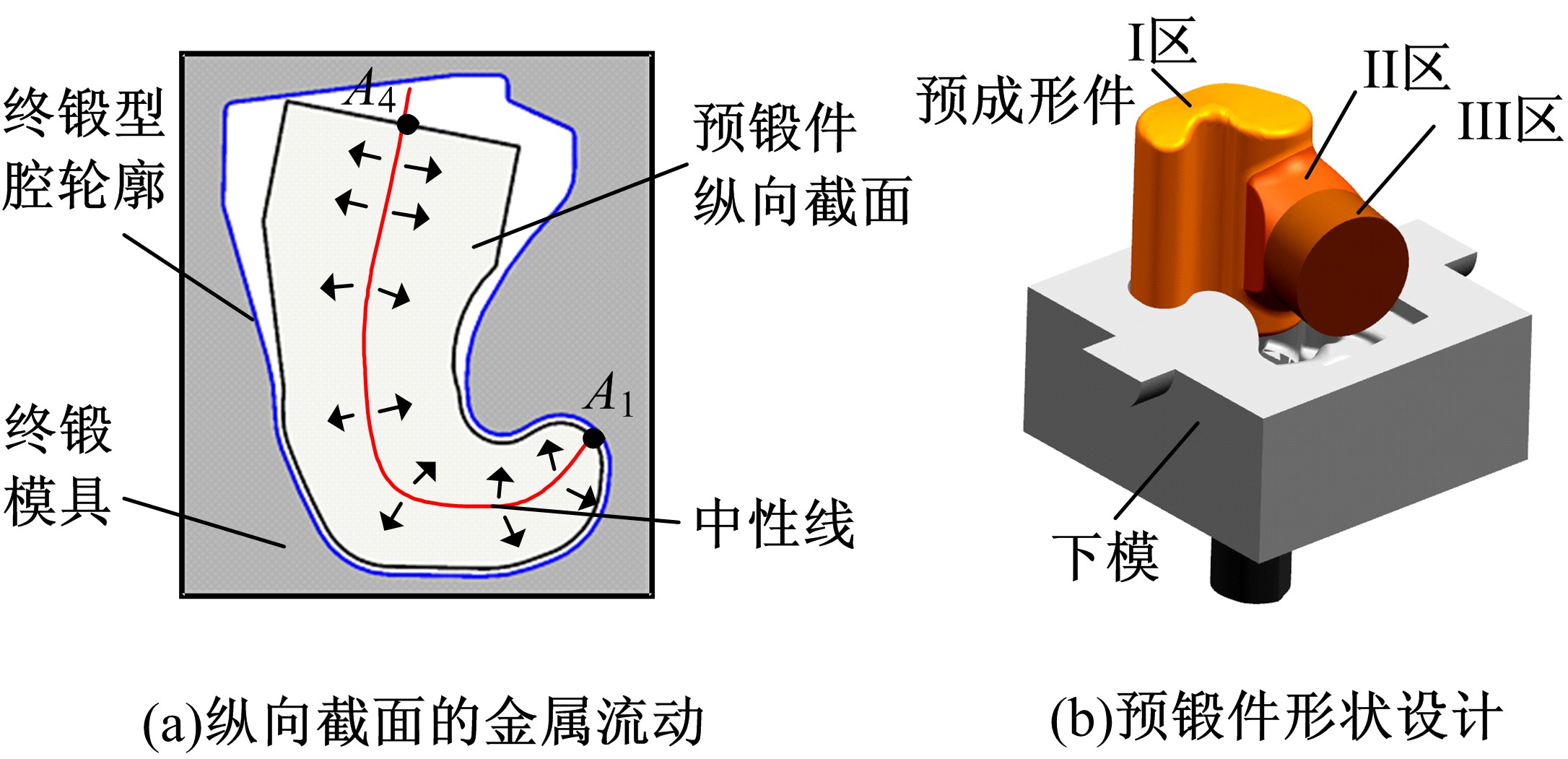

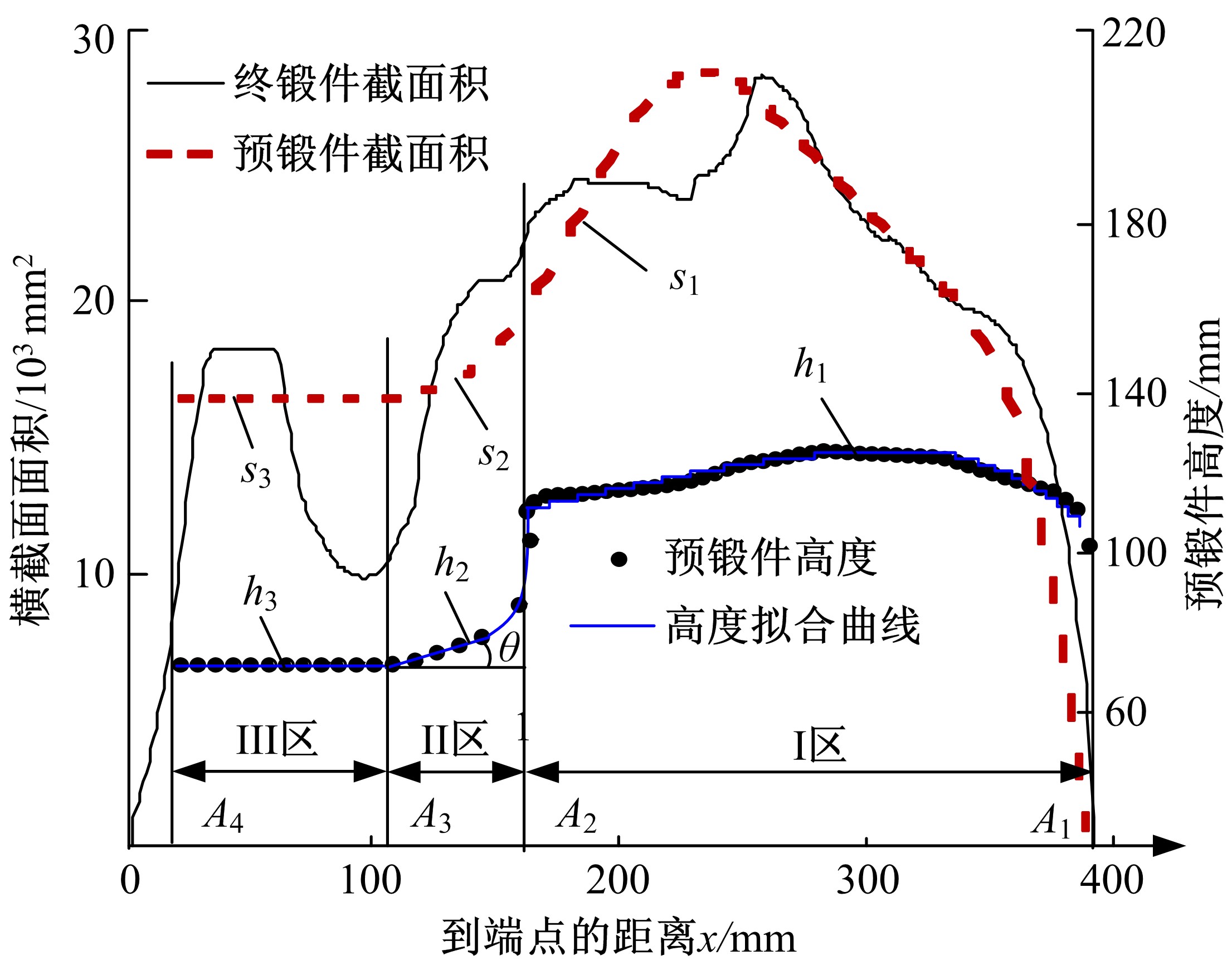

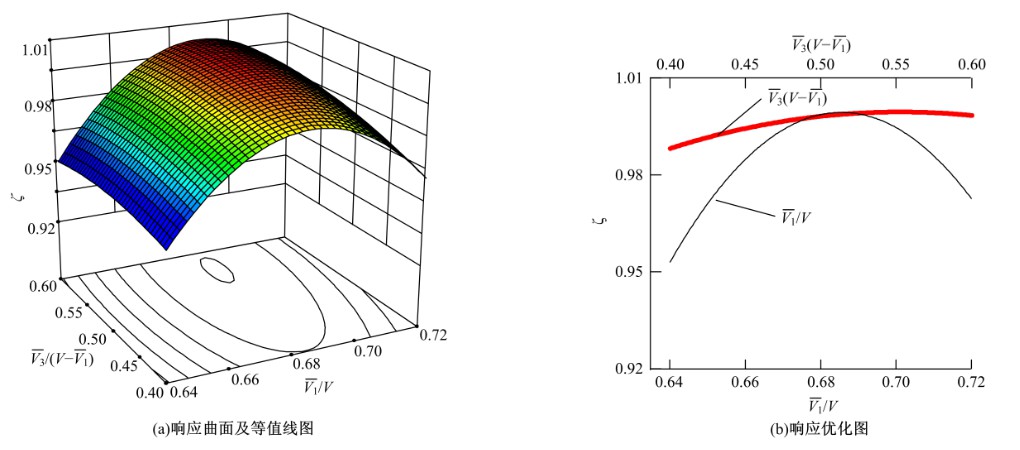

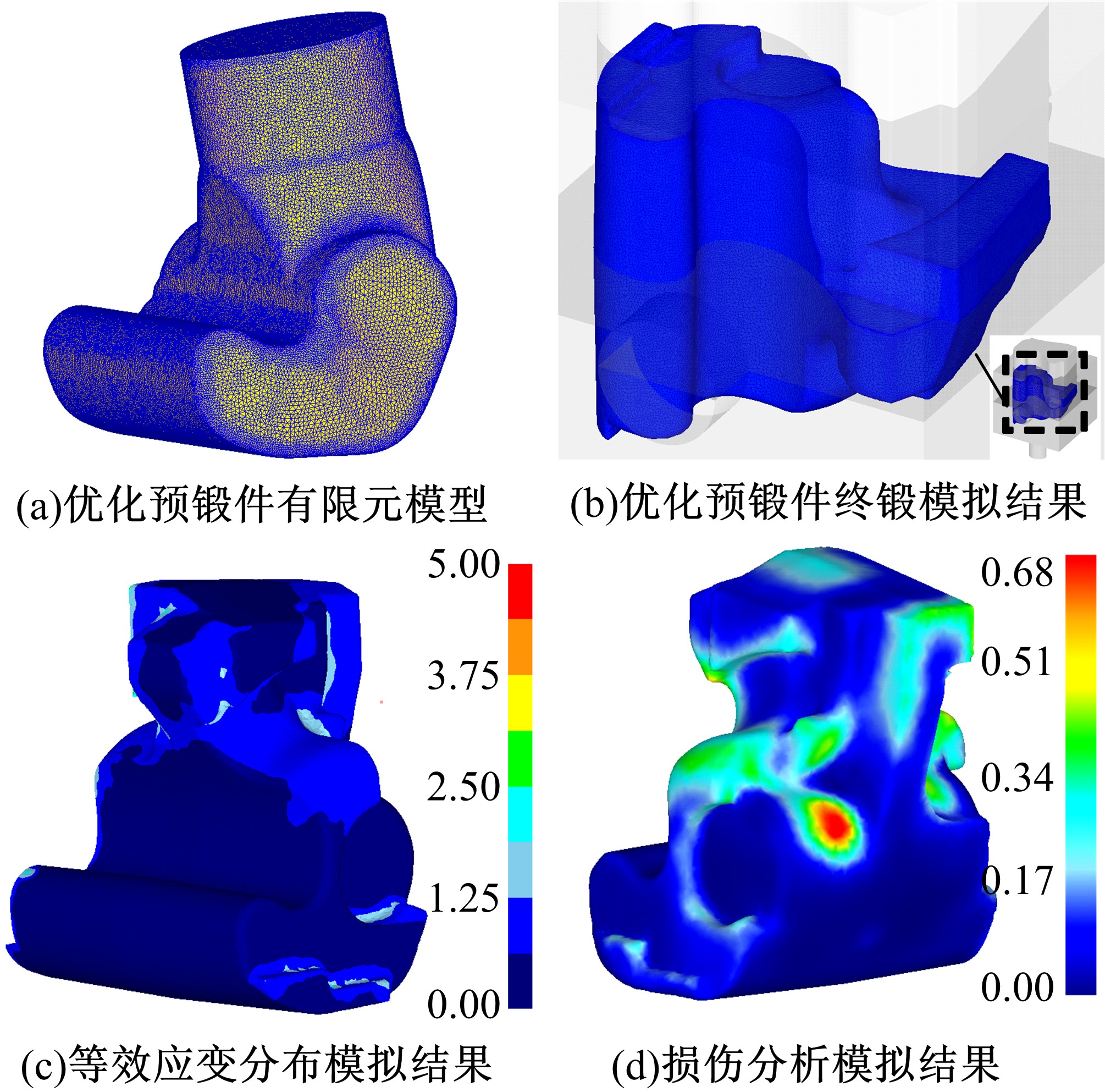

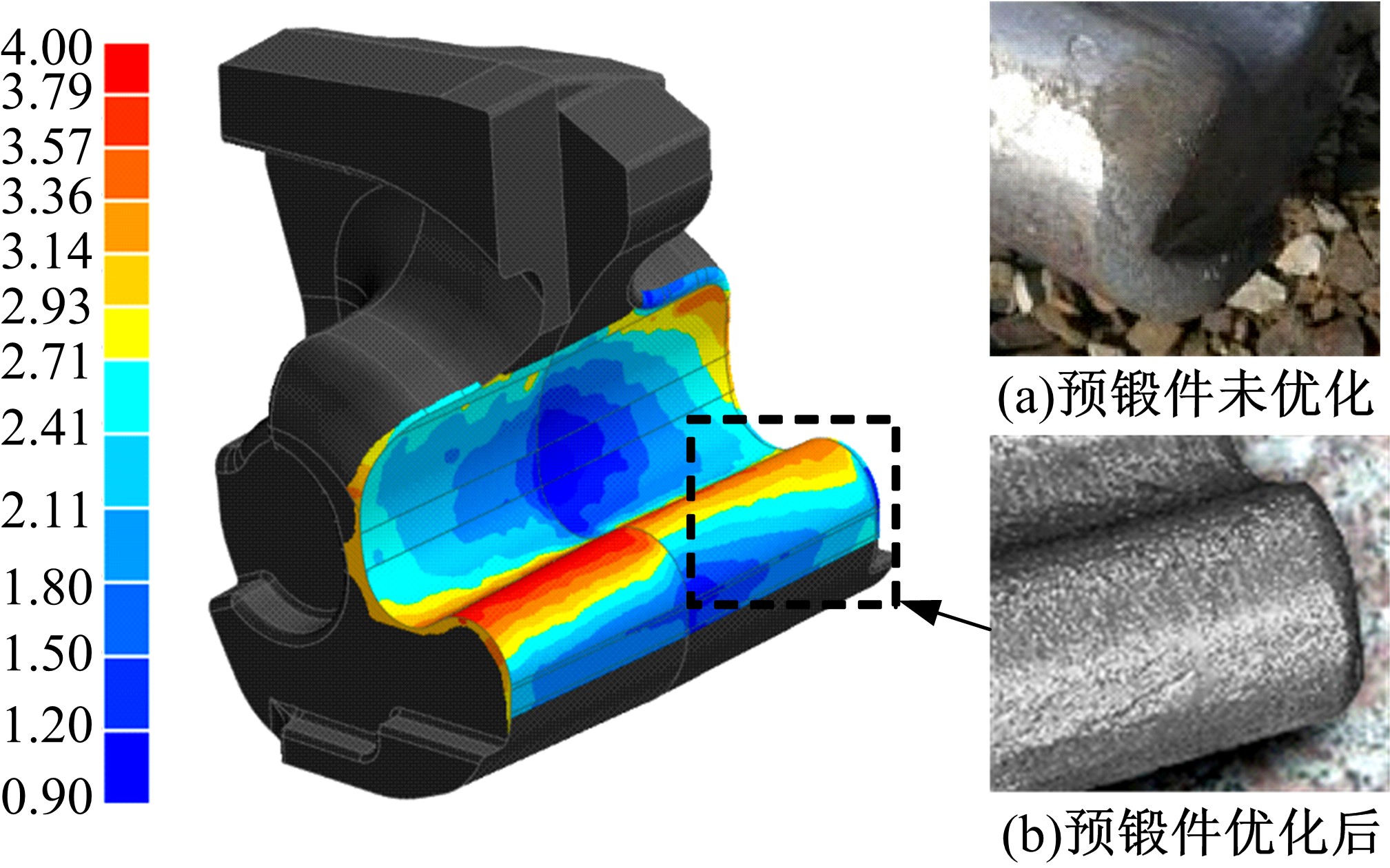

提出了基于闭式模锻的铁路钩舌锻件的近净成形工艺方案,针对近净成形中的预锻成形件设计这一关键技术进行了研究。通过对终锻成形阶段金属流动特点的分析,设计了预锻成形工艺。将多重响应面法与数值模拟相结合,以锻件填充完整、锻件变形均匀性最好以及材料的损伤最小为目标函数对预锻成形件的形状进行了多目标优化,并通过成形试验验证了优化设计的结果。测量与分析结果表明,本文方法可获得优化的预锻件形状,基于本文设计出的预锻件,可得到无成形缺陷且精度好的终锻成形件,实现了钩舌锻件的近净成形。

中图分类号:

- TG316

| 1 | 陈玉清, 李林杰, 王广欣,等 . 新型锻造钩舌复杂曲面误差分析与调整方法[J]. 大连交通大学学报, 2013, 34(2):83-86. |

| Chen Yu-qing , Li Lin-jie , Wang Guang-xin , et al . Error analysis and method of adjusting complex curved surface of new forged coupler knuckle[J]. Journal of Dalian Jiaotong University, 2013, 34(2):83-86. | |

| 2 | 申恩强, 樊自田, 龙威,等 . 车钩钩舌的铸造工艺模拟与优化[J]. 铸造, 2011, 60(8):765-768. |

| Shen En-qiang , Fan Zi-tian , Long Wei , et al . Simulation and optimization of casting process for coupler knuckle[J]. Foundry, 2011, 60(8):765-768. | |

| 5 | Wang Ning , Li Jian , Guan Zhi-jun , et al . Effect of processing parameters on strain distribution during near-isothermal canned forging for molybdenum powder sinter[J]. Journal of Materials Engineering, 2014, 43(23): 123-127. |

| 6 | 赵新海,赵国群,王广春,等 . 锻造过程优化设计目标的研究[J].锻压装备与制造技术,2004, 39(1):48-52. |

| Zhao Xin-hai , Zhao Guo-qun , Wang Guang-chun , et al . Research on the establishment of objective function in forging optimization design[J]. China Metalforming Equipment & Manufacturing Technology, 2004, 39(1): 48-52. | |

| 7 | Mirahmadi S J , Hamedi M , Ajami S . Investigating the effects of cross wedge rolling tool parameters on formability of Nimonic® 80A and Nimonic® 115 superalloys[J]. The International Journal of Advanced Manufacturing Technology, 2014, 74(5-8): 995-1004. |

| 8 | Quan G , Wang F , Liu Y , et al . Evaluation of varying ductile fracture criterion for 7075 aluminum alloy[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(3): 749-755. |

| 9 | 陈学文,王进,陈军,等 .热锻成形过程数值模拟与多目标设计优化技术研究[J].塑性工程学报,2005(4):80-84. |

| Chen Xue-wen , Wang Jin , Chen Jun , et al . Research on multiple-objective design optimization and numerical simulation of hot forging process[J]. Journal of Plasticity Engineering,2005(4):80-84. | |

| 10 | Stebunov Sergey , Vlasov Andrey , Biba Nikolai . Prediction of fracture in cold forging with modified Cockcroft-Latham criterion[J]. Procedia Manufacturing,2018(15):519-526. |

| [1] | 庄蔚敏,施宏达,解东旋,杨冠男. 钢铝异质无铆钉粘铆复合连接胶层厚度分布[J]. 吉林大学学报(工学版), 2020, 50(1): 100-106. |

| [2] | 马芳武,梁鸿宇,赵颖,杨猛,蒲永锋. 内凹三角形负泊松比结构耐撞性多目标优化设计[J]. 吉林大学学报(工学版), 2020, 50(1): 29-35. |

| [3] | 关庆丰,姚欣雯,杨洋,张凌燕,刘迪,李晨,吕鹏. 强流脉冲电子束作用下TC4钛合金表面Cr合金层制备及性能[J]. 吉林大学学报(工学版), 2019, 49(6): 2002-2009. |

| [4] | 贾富淳,孟宪皆,雷雨龙. 基于多目标遗传算法的二自由度动力吸振器优化设计[J]. 吉林大学学报(工学版), 2019, 49(6): 1969-1976. |

| [5] | 石舟,寇淑清. 36MnVS4裂解连杆性能分析及轻量化设计[J]. 吉林大学学报(工学版), 2019, 49(6): 1992-2001. |

| [6] | 依卓,付文智,李明哲. 双层剖分式超高压模具数值模拟及实验[J]. 吉林大学学报(工学版), 2019, 49(5): 1593-1599. |

| [7] | 谷晓燕,刘东锋,刘婧,孙大千,马会峰. 焊接能量对Cu/Al超声波焊接接头组织与性能的影响[J]. 吉林大学学报(工学版), 2019, 49(5): 1600-1607. |

| [8] | 李欣,孙延朋,王丹,陈军绪,谷诤巍,徐虹. 汽车前地板成形有限元数值模拟[J]. 吉林大学学报(工学版), 2019, 49(5): 1608-1614. |

| [9] | 王家序,蒋倩倩,李俊阳,韩彦峰,张雷,唐挺. 双圆弧谐波传动柔轮齿形参数多目标优化设计[J]. 吉林大学学报(工学版), 2019, 49(4): 1194-1202. |

| [10] | 李欣,王丹,陈军绪,孙延朋,谷诤巍,徐虹. 手刹固定板冲压成形数值模拟[J]. 吉林大学学报(工学版), 2019, 49(4): 1258-1265. |

| [11] | 刘文权,盈亮,荣海,胡平. 基于损伤修正M⁃K模型的高强度钢成形极限预测[J]. 吉林大学学报(工学版), 2019, 49(4): 1266-1271. |

| [12] | 张学广,贾明萌,刘纯国,何广忠. 基于增量控制的型材拉弯轨迹设计及有限元仿真[J]. 吉林大学学报(工学版), 2019, 49(4): 1272-1279. |

| [13] | 姜秋月,杨海峰,檀财旺. 22MnB5超高强钢焊接接头强化性能[J]. 吉林大学学报(工学版), 2018, 48(6): 1806-1810. |

| [14] | 胡志清, 颜庭旭, 李洪杰, 吕振华, 廖伟, 刘庚. 深冷处理对铝合金薄板冲剪成形性能的影响[J]. 吉林大学学报(工学版), 2018, 48(5): 1524-1530. |

| [15] | 邱小明, 王银雪, 姚汉伟, 房雪晴, 邢飞. 基于灰色关联的DP1180/DP590异质点焊接头工艺参数优化[J]. 吉林大学学报(工学版), 2018, 48(4): 1147-1152. |

|

||