吉林大学学报(工学版) ›› 2022, Vol. 52 ›› Issue (3): 703-715.doi: 10.13229/j.cnki.jdxbgxb20200802

• 农业工程·仿生工程 • 上一篇

拖拉机耐久性加速结构试验设计方法

温昌凯1,2( ),谢斌1,2(

),谢斌1,2( ),宋正河1,2,韩建刚3,杨倩雯3

),宋正河1,2,韩建刚3,杨倩雯3

- 1.中国农业大学 工学院,北京 100083

2.中国农业大学 现代农业装备优化设计北京市重点实验室,北京 100083

3.洛阳西苑车辆与动力检验所有限公司,洛阳 471000

Design method of tractor durability accelerated structure test

Chang-kai WEN1,2( ),Bin XIE1,2(

),Bin XIE1,2( ),Zheng-he SONG1,2,Jian-gang HAN3,Qian-wen YANG3

),Zheng-he SONG1,2,Jian-gang HAN3,Qian-wen YANG3

- 1.College of Engineering,China Agricultural University,Beijing 100083,China

2.Beijing Key Laboratory of Optimized Design for Modern Agricultural Equipment,China Agricultural University,Beijing 100083,China

3.Luoyang Xiyuan Vehicle and Power Inspection Institute Co. ,Ltd. ,Luoyang 471000,China

摘要:

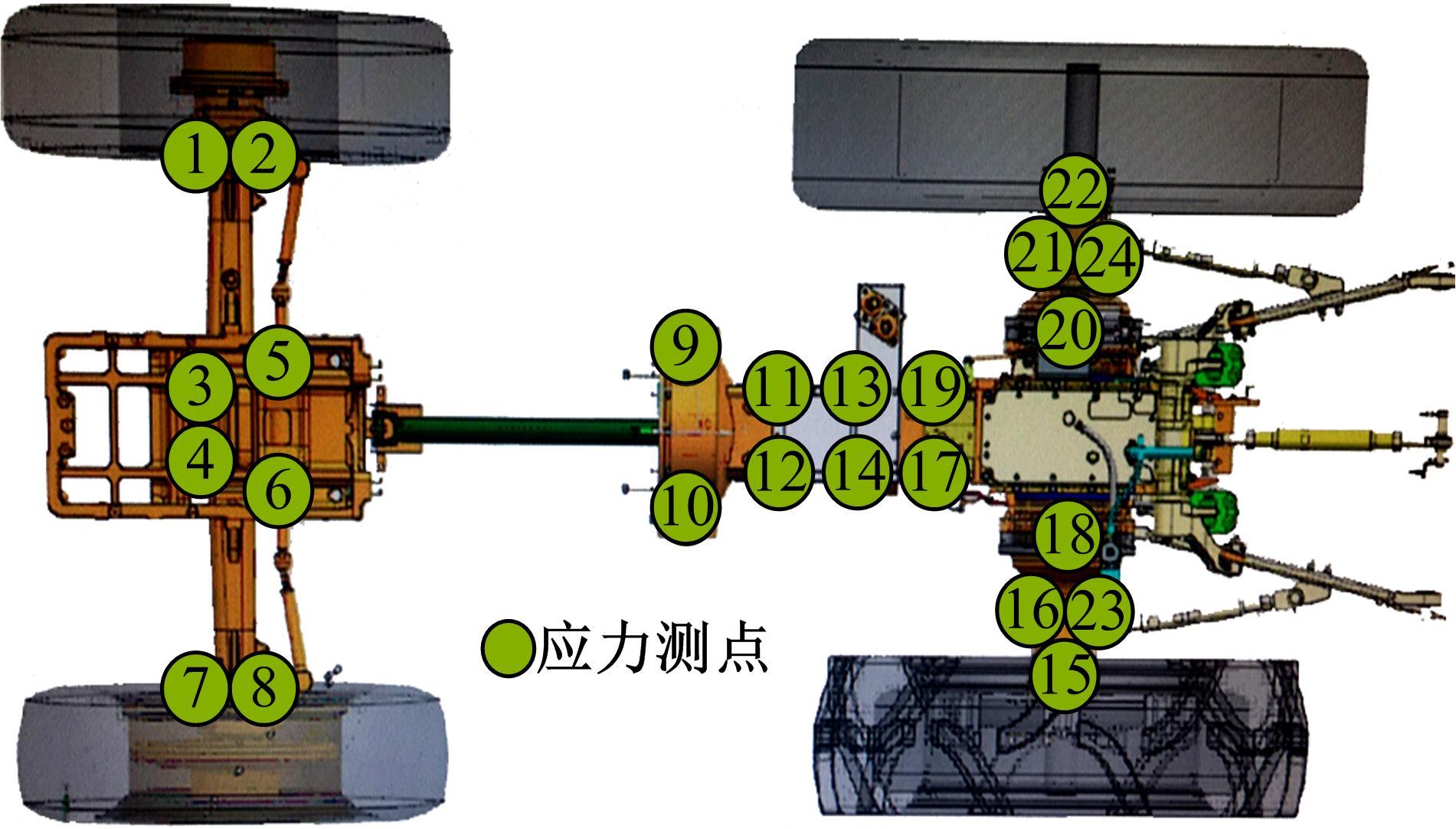

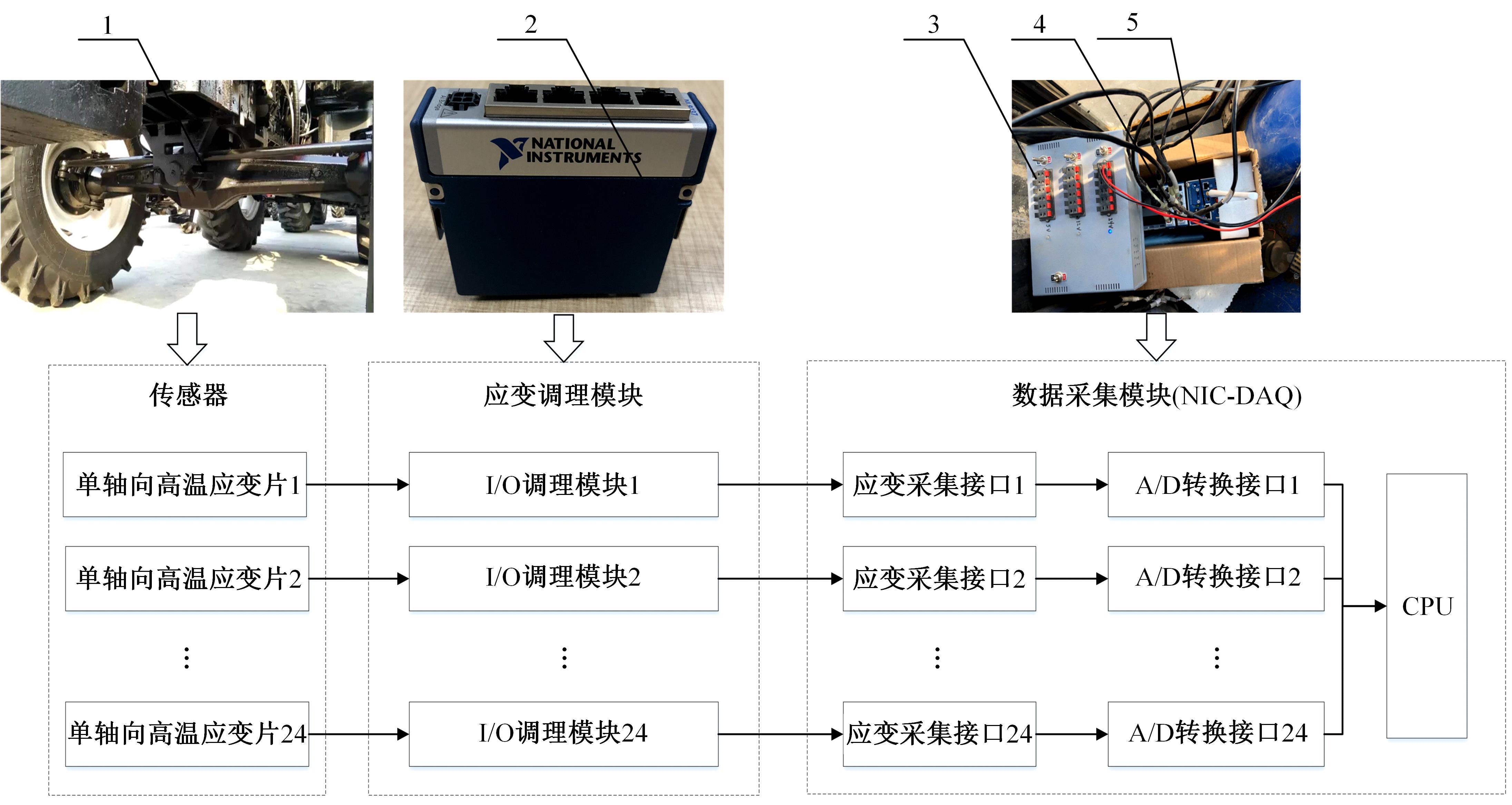

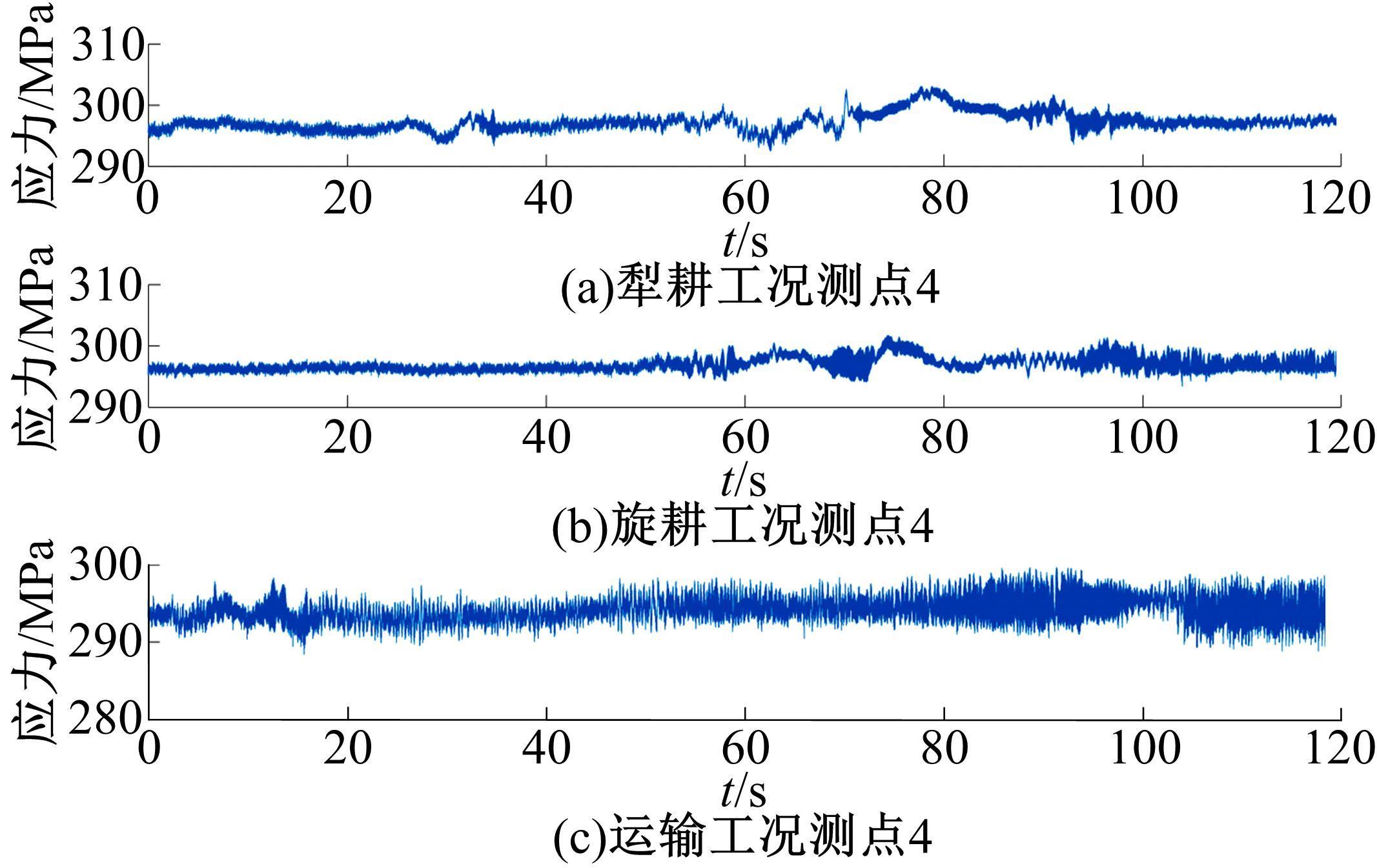

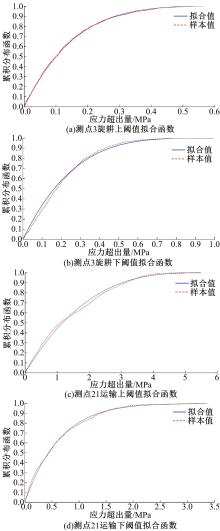

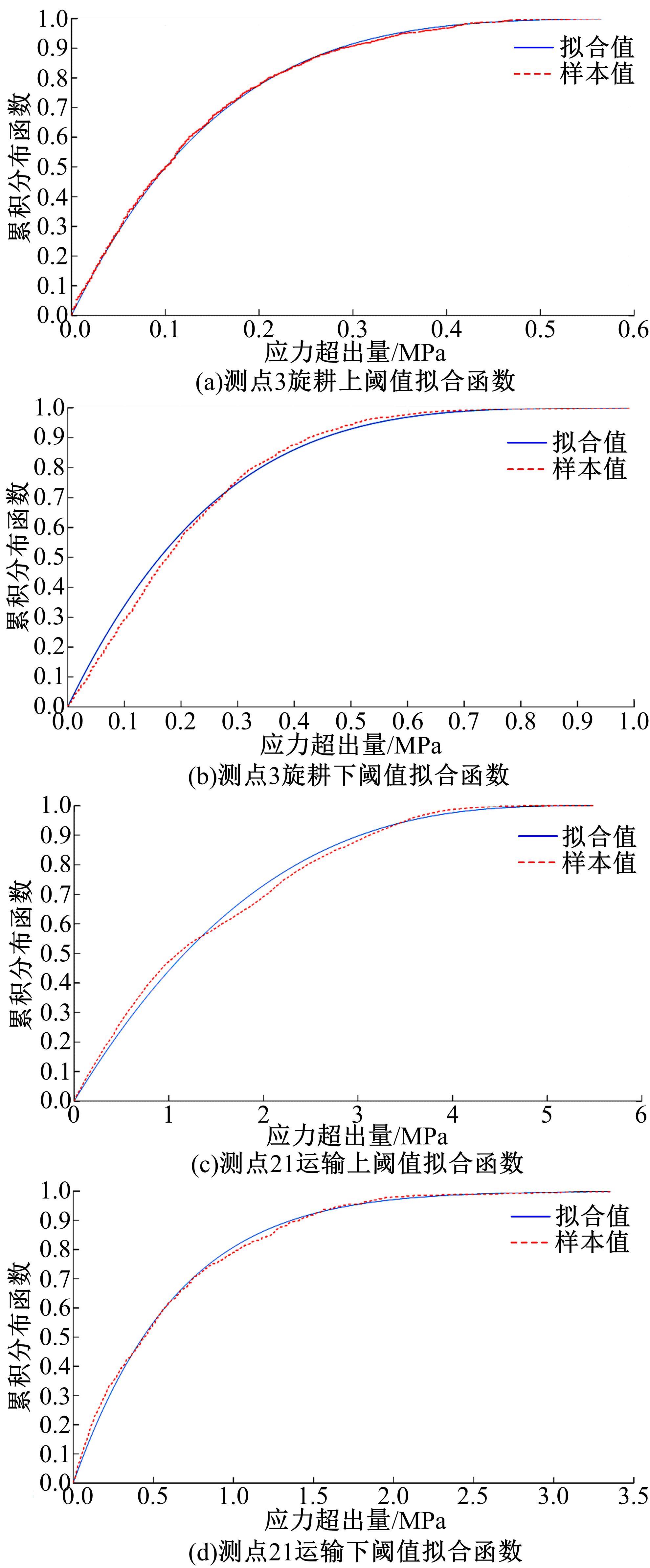

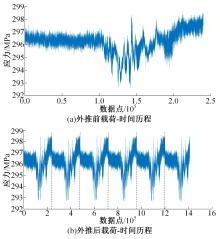

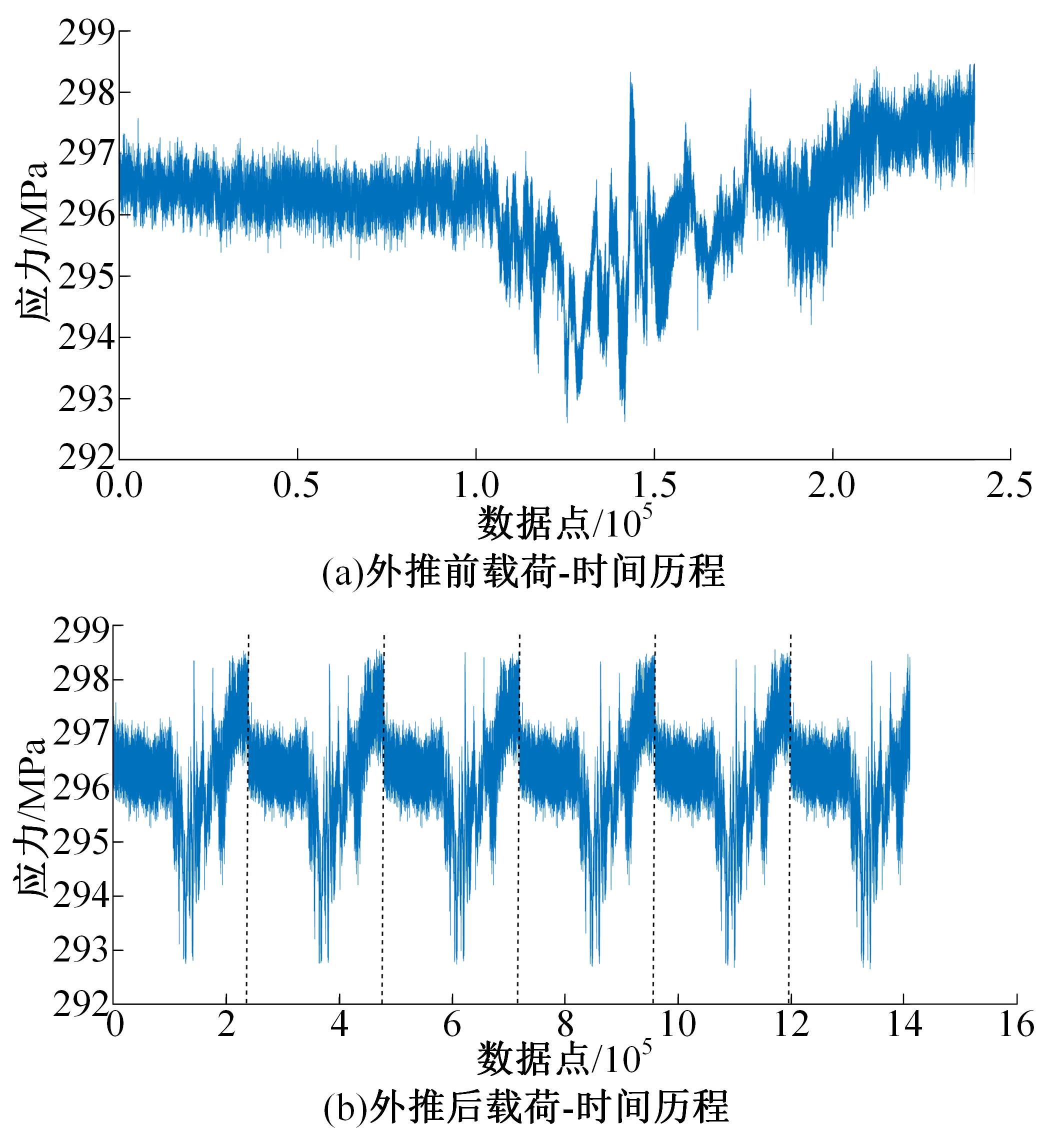

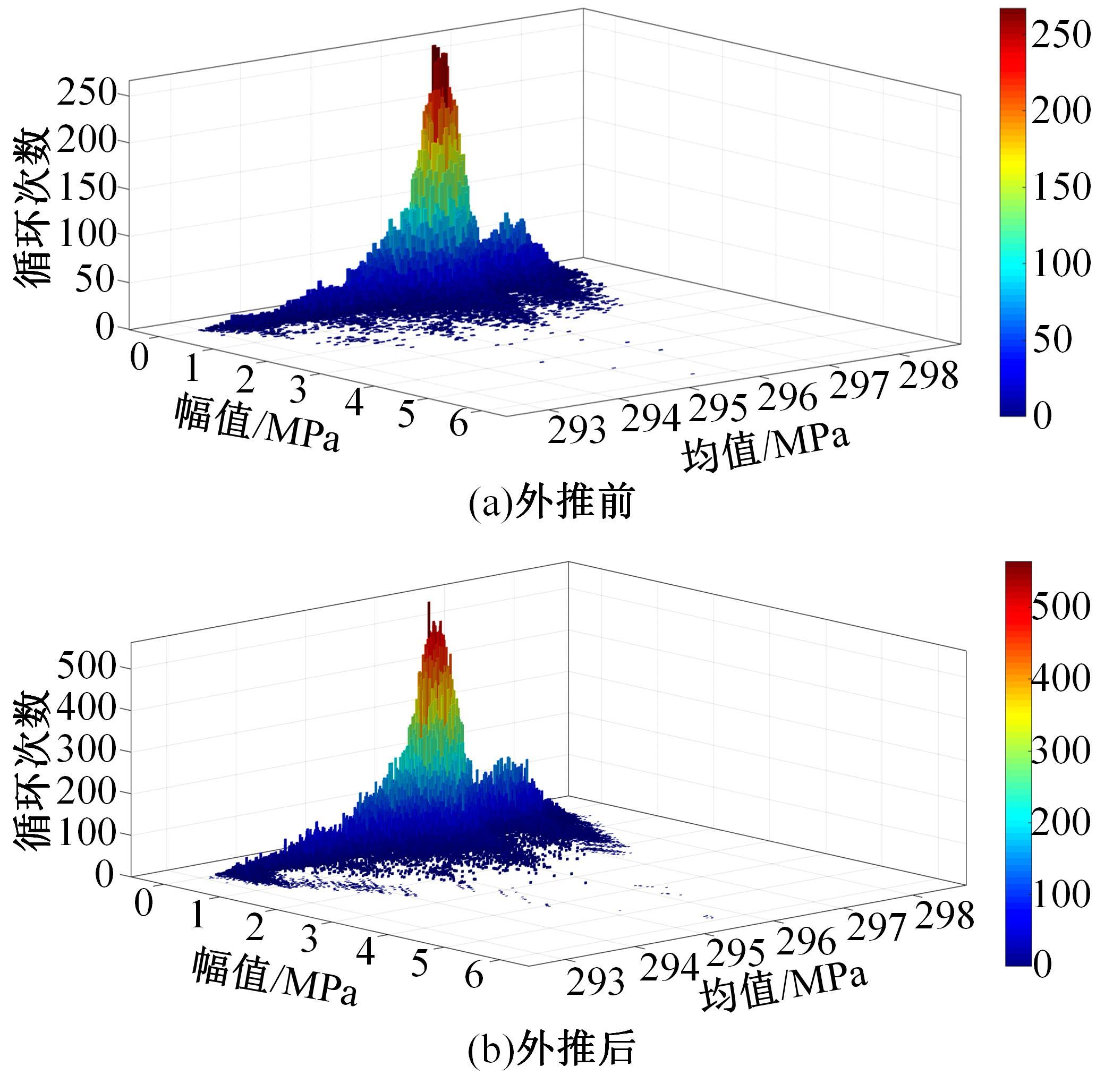

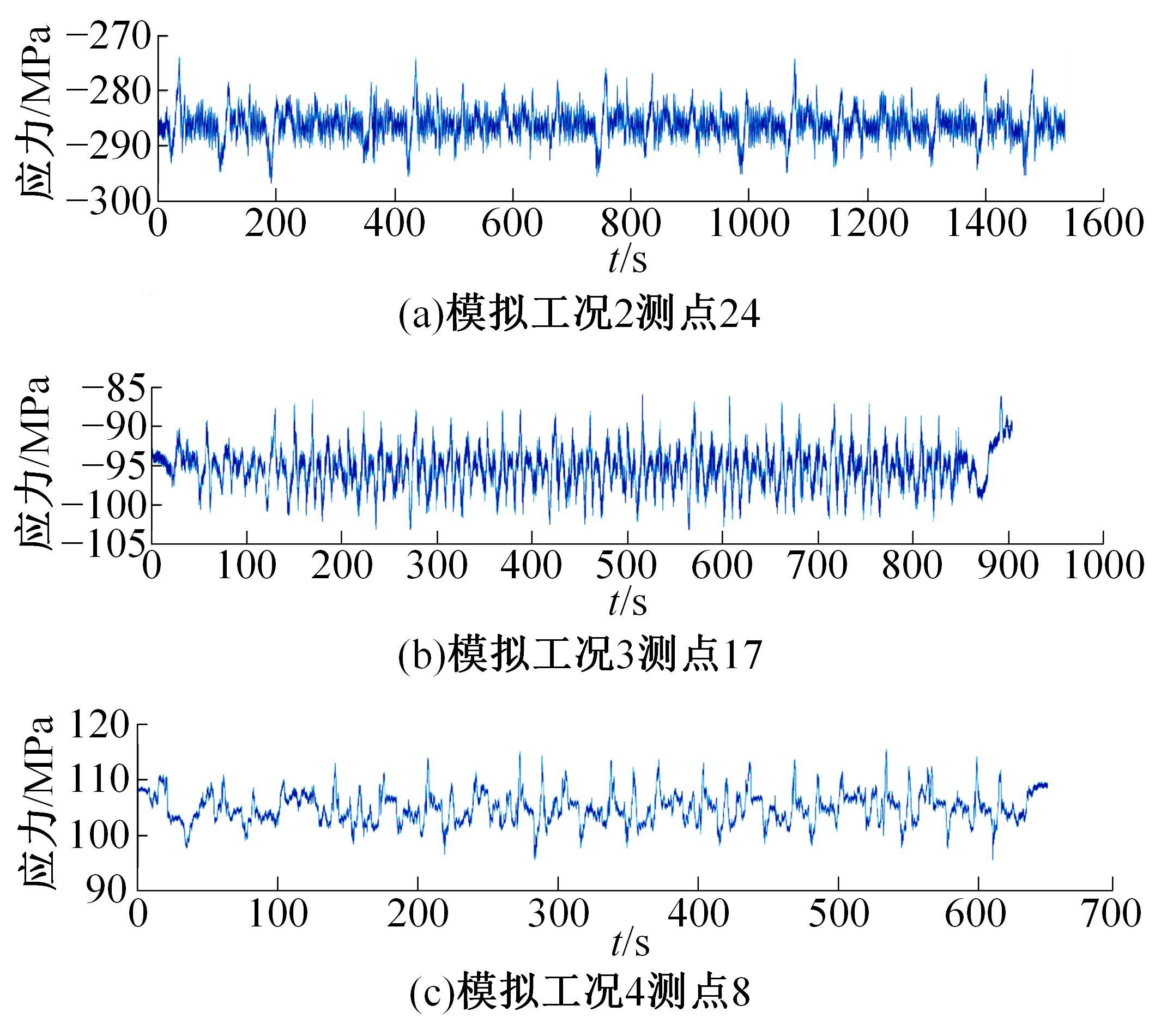

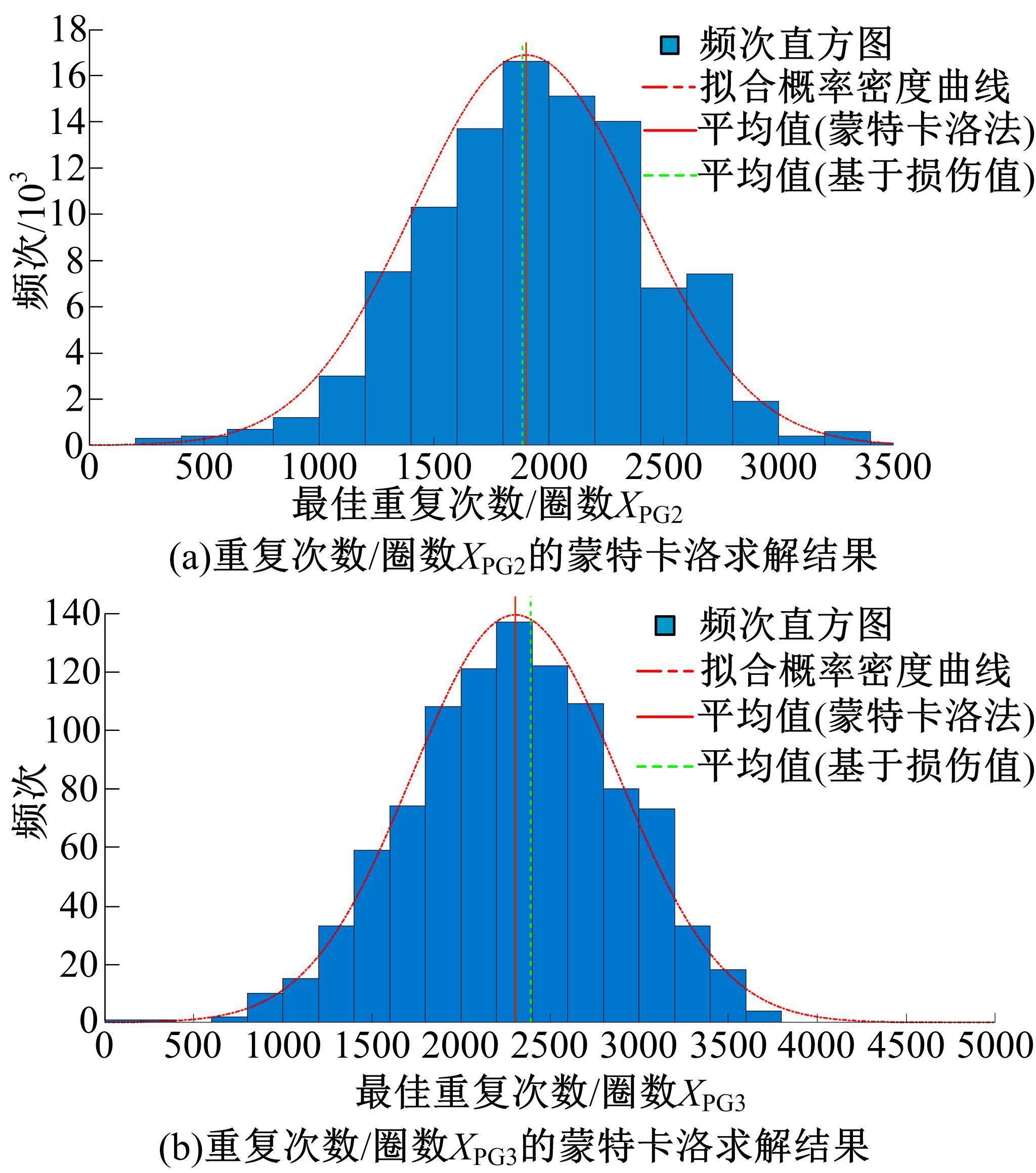

针对农业机械试验场耐久试验设计不合理和分析不系统的问题,提出了一种适用于拖拉机疲劳耐久评估的加速结构试验设计方法。以构建加速结构试验设计最优化矩阵为核心,融合基于峰值超阈值(POT)模型的时域外推方法、求解最优矩阵的增广拉格朗日乘子法以及用于灵敏度分析的蒙特卡洛方法,并以标准试验场为例进行方法验证。结果表明:4种模拟工况求解的最优重复次数/圈数分别为0、1885、2392和241,组合试验总时长仅为134 h,加速系数达到3.2,损伤相对误差的平均值仅为23.14%,各项指标均优于传统的疲劳耐久性试验;与蒙特卡洛方法计算结果进行对比,模拟工况最优重复次数的误差均小于5%,验证了拖拉机耐久性加速结构试验设计方法的准确性、合理性和有效性。

中图分类号:

- S219

| 1 | 谢斌, 武仲斌, 毛恩荣. 农业拖拉机关键技术发展现状与展望[J]. 农业机械学报, 2018, 49(8):1-17. |

| Xie Bin, Wu Zhong-bin, Mao En-rong. Development and prospect of key technologies on agricultural tractor[J]. Transactions of the Chinese Society for Agricultural Machinery, 2018, 49(8):1-17. | |

| 2 | 吴思航. 农用万向节传动轴的载荷特点与快速模拟试验方法的探讨[J]. 农业机械学报, 1984(4):55-63. |

| Wu Si-hang. The research on the load characteristics of agricultural universal joint transmission shaft and rapid analog test program[J]. Transactions of the Chinese Society for Agricultural Machinery, 1984(4):55-63. | |

| 3 | 苏佳, 敖长林, 焦杨. 基于模糊神经网络的拖拉机使用可靠性评价[J].东北农业大学学报, 2008, 39(12): 99-103. |

| Su Jia, Ao Chang-lin, Jiao Yang. Evaluation of tractor reliability based on fuzzy neural network[J]. Journal of Northeast Agricultural University, 2008, 39(12): 99-103. | |

| 4 | 虞明, 赵济海, 邬惠乐. 随机不平路面上的汽车强化试验研究[J]. 汽车工程, 1993, 15(1):42-53. |

| Yu Ming, Zhao Ji-hai, Wu Hui-le. Automotive strenuous test on testing track of random surface irregularities[J]. Automotive Engineering, 1993, 15(1):42-53. | |

| 5 | 郭虎, 陈文华, 樊晓燕, 等. 汽车试验场可靠性强化试验强化系数的研究[J]. 机械工程学报, 2004, 40(10): 73-76, 81. |

| Guo Hu, Chen Wen-hua, Fan Xiao-yan, et al. Research of enhancement coefficient of automobile reliability enhancement test on proving ground[J]. Chinese Journal of Mechanical Engineering, 2004, 40(10):73-76, 81. | |

| 6 | 吴建国, 周鋐, 陈栋华, 等. 目标用户道路谱与试验场道路谱的载荷当量等效模拟研究[J]. 汽车技术, 2007(7):21-24. |

| Wu Jian-guo, Zhou Hong, Chen Dong-hua, et al. Study on road equivalent simulation based on loading spectrums in customer road and proving ground[J]. Automobile Technology, 2007(7):21-24. | |

| 7 | 于海波, 李幼德, 门玉琢. 一种和用户数据相关的汽车加速疲劳试验新技术[J]. 机械强度, 2008, 30(3):461-466. |

| Yu Hai-bo, Li You-de, Yu-zhuo Men. New technique for automobile accelerated fatigue test correlated with customer data[J]. Journal of Mechanical Strength, 2008, 30(3):461-466. | |

| 8 | 张新宇. 车辆结构试验场疲劳耐久试验规范及台架试验研究[D]. 北京:清华大学汽车工程学院, 2014. |

| Zhang Xin-yu. Research on proving ground testing standard and rig testing of durability performance of vehicle structure[D]. Beijing: Department of Automotive Engineering, Tsinghua University, 2014. | |

| 9 | 张禄. 大型营运客车用户关联试验场可靠性理论分析及试验研究[D]. 北京: 中国农业大学工学院, 2015. |

| Zhang Lu. Reliability theory analysis and test on proving ground correlated with customers usage of big operation vehicle[D]. Beijing: College of Engineering, China Agricultural University, 2015. | |

| 10 | 王世英. 基于车辆损伤贡献分析的试验场耐久性试验方法研究[D]. 长春:吉林大学汽车工程学院, 2019. |

| Wang Shi-ying. The study of DG durability test method based on vehicle damage contribution analysis[D]. Changchun:College of Automotive Engineering, Jilin University, 2019. | |

| 11 | Michele M, Giovanni M, Enrico S. Methodology for the realisation of accelerated structural tests on tractors[J]. Biosystems Engineering, 2012, 113(3):266-271. |

| 12 | Paraforos D S, Griepentrog H W, Vougioukas S G, et al. Fatigue life assessment of a four-rotor swather based on rainflow cycle counting[J]. Biosystems Engineering, 2014, 127: 1-10. |

| 13 | Mattetti M, Molari G, Andrea Vertua. New methodology for accelerating the four-post testing of tractors using wheel hub displacements[J]. Biosystems Engineering, 129: 307-314. |

| 14 | Paraforos D S, Griepentrog H W, Vougioukas S G. Methodology for designing accelerated structural durability tests on agricultural machinery[J]. Biosystems Engineering, 149: 24-37. |

| 15 | László G, Péter K. A comparative study of destructive effects resulting from road profile acting on off-road towed vehicles[J]. Journal of Terramechanics, 2019, 81: 57-65. |

| 16 | . 农林拖拉机和机械-串行控制和通信数据网络 [S]. |

| 17 | Wen Chang-kai, Xie Bin, Song Zheng-he, et al. Methodology for designing tractor accelerated structure tests for an indoor drum-type test bench[J]. Biosystems Engineering, 2021, 205:1-26. |

| 18 | 杨子涵, 宋正河, 尹宜勇, 等. 基于POT模型的大功率拖拉机传动轴载荷时域外推方法[J]. 农业工程学报, 2019, 35(15):40-47. |

| Yang Zi-han, Song Zheng-he, Yin Yi-yong, et al. Time domain extrapolation method for load of drive shaft of high-power tractor based on POT model[J]. Transactions of the CSAE, 2019, 35(15):40-47. | |

| 19 | 林志强, 苏万华. 基于LaGrange-SUMT方法的全电控柴油引燃天然气发动机MAP优化标定技术[J]. 内燃机学报, 2004, 22(5):385-390. |

| Lin Zhi-qiang, Su Wan-hua. A mapping technique based on the LaGrange-SUMT method for a pilot ignited CNG engine[J]. Transactions of CSICE, 2004,22(5):385-390. | |

| 20 | 林巨广, 杨兰和, 刘明周, 等. 基于工序能力指数的零件选配优化模型[J]. 农业机械学报, 2007, 38(4): 130-134, 117. |

| Lin Ju-guang, Yang Lan-he, Liu Ming-zhou, et al. Study on optimization model of matching parts assembly based on the process capability index[J]. Transactions of the Chinese Society for Agricultural Machinery, 2007, 38(4): 130-134, 117. | |

| 21 | 宗钟凌, 郭小明. 基于接触协同作用结构非线性屈曲分析[J]. 工程力学, 2011, 28(6):40-44. |

| Zong Zhong-ling, Guo Xiao-ming. Nonlinear buckling analysis of structure based on contact synergy[J]. Engineering Mechanics, 2011, 28(6):40-44. | |

| 22 | Jiang Yan, Li Xu-yong, Huang Chong-chao, et al. An augmented Lagrangian multiplier method based on a CHKS smoothing function for solving nonlinear bilevel programming problems[J]. Knowledge-Based Systems, 2014, 55:9-14. |

| 23 | 高翔, 王林军, 杜义贤. 采用增广乘子法和模拟退火法的结构可靠性分析[J]. 西安交通大学学报, 2019, 53(7):144-152. |

| Gao Xiang, Wang Lin-jun, Du Yi-xian. Structure reliability analysis by combining augmented multiplier method and simulated annealing algorithm[J]. Journal of Xi'an Jiaotong University, 2019, 53(7):144-152. | |

| 24 | 张将伟, 卢文喜, 曲延光, 等. 基于Monte Carlo方法的地表水地下水耦合模拟模型不确定分析[J]. 水利学报, 2018, 49(10):1254-1264. |

| Zhang Jiang-wei, Lu Wen-xi, Qu Yan-gaung, et al. Uncertainty analysis of surface water and groundwater coupling simulation model based on Monte Carlo method[J]. Journal of Hydraulic Engineering, 2018, 49(10):1254-1264. | |

| 25 | 陈浩然, 崔利杰, 任博, 等. 不确定条件下航空不安全事件灵敏度分析的Monte-Carlo方法[J]. 北京航空航天大学学报, 2020, 46(2):414-421. |

| Chen Hao-ran, Cui Li-jie, Ren Bo, et al. Sensitivity analysis for aviation insecure event using Monte-Carlo method under uncertain condition[J]. Journal of Beijing University of Aeronautics and Astronautics, 2020, 46(2):414-421. | |

| 26 | 李园园, 陈国平, 孙东阳, 等. 柔性关节机械臂不确定性及灵敏度分析[J]. 振动·测试与诊断, 2017, 37(6):1141-1148, 1278. |

| Li Yuan-yuan, Chen Guo-ping, Sun Dong-yang, et al. Uncertainty and sensitivity of flexible-joint manipulator[J]. Journal of Vibration, Measurement & Diagnosis, 2017, 37(6): 1141-1148, 1278. | |

| 27 | 谢斌, 温昌凯, 杨子涵, 等. 基于实测载荷的蔬菜田间动力机械车架结构优化[J]. 农业机械学报, 2018, 49():463-469. |

| Xie Bin, Wen Chang-kai, Yang Zi-han, et al. Structure optimization of frame for field vegetable power machinery based on measured load data[J]. Transactions of the Chinese Society for Agricultural Machinery, 2018, 49(Sup.1):463-469. | |

| 28 | 温昌凯, 谢斌, 杨子涵, 等. 基于功率密度的大功率拖拉机变速箱壳体疲劳分析[J]. 农业机械学报, 2019, 50(6):389-396, 404. |

| Wen Chang-kai, Xie Bin, Yang Zi-han, et al. Fatigue analysis of gearbox shell of high horsepower tractor based on power density[J]. Transactions of the Chinese Society for Agricultural Machinery, 2019, 50(6):389-396, 404. | |

| 29 | Wen Chang-kai, Xie Bin, Li Zhen, et al. Power density based fatigue load spectrum editing for accelerated durability testing for tractor front axles[J]. Biosystems Engineering, 2020, 200: 73-88. |

| 30 | 秦嘉浩, 李臻, 光岡宗司, 等. 基于模型实验的拖拉机配置对稳定性的影响差异[J]. 吉林大学学报:工学版, 2019, 49(4):1236-1245. |

| Qin Jia-hao, Li Zhen, Mitsuoka M, et al. Significance variation of factorial effects on tractor stability employing scale-model-based experimental approach[J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4):1236-1245. | |

| 31 | 彭贺, 马文星, 王忠山, 等. 丘陵山地拖拉机车身调平控制仿真分析与试验[J]. 吉林大学学报:工学版,2019,49(1):157-165. |

| Peng He, Ma Wen-xing, Wang Zhong-shan, et al. Control system of self-leveling in hilly tractor body through simulation and experiment [J]. Journal of Jilin University (Engineering and Technology Edition),2019,49(1):157-165. | |

| 32 | . 球墨铸铁-分类 [S]. |

| [1] | 耿端阳,孙延成,牟孝栋,张国栋,姜慧新,朱俊科. 基于差速辊的青贮玉米籽粒破碎仿真试验及优化[J]. 吉林大学学报(工学版), 2022, 52(3): 693-702. |

| [2] | 梁方,王德成,尤泳,王光辉,王宇兵,张晓明,冯金奎. 草地切根施肥补播复式改良机设计与试验[J]. 吉林大学学报(工学版), 2022, 52(1): 231-241. |

| [3] | 王国伟,朱庆辉,于海业,黄东岩. 基于数字化农机装备的青贮饲料可追溯系统[J]. 吉林大学学报(工学版), 2022, 52(1): 242-252. |

| [4] | 耿端阳,牟孝栋,张国栋,王宗源,朱俊科,徐海刚. 小麦联合收获机清选机理分析与优化试验[J]. 吉林大学学报(工学版), 2022, 52(1): 219-230. |

| [5] | 王新彦,江泉,吕峰,易政洋. 基于参数化模型的零转弯半径割草机侧翻稳定性[J]. 吉林大学学报(工学版), 2021, 51(5): 1908-1918. |

| [6] | 钱震杰,金诚谦,袁文胜,倪有亮,张光跃. 柔性脱粒齿杆与谷物含摩擦打击动力学模型[J]. 吉林大学学报(工学版), 2021, 51(3): 1121-1130. |

| [7] | 程超,付君,陈志,任露泉. 玉米籽粒收获机清选筛堵塞规律及脱附试验[J]. 吉林大学学报(工学版), 2021, 51(2): 761-771. |

| [8] | 丛茜,徐金,马博帅,张晓超,陈廷坤. 基于虚拟仿真的拖拉机后悬挂检测装置设计与实验[J]. 吉林大学学报(工学版), 2021, 51(2): 754-760. |

| [9] | 陈学深,黄柱健,马旭,齐龙,方贵进. 水稻机械除草避苗控制系统设计与试验[J]. 吉林大学学报(工学版), 2021, 51(1): 386-396. |

| [10] | 耿端阳,谭德蕾,于兴瑞,苏国粱,王骞,鹿秀凤,金诚谦. 玉米柔性脱粒滚筒脱粒元件设计与试验[J]. 吉林大学学报(工学版), 2020, 50(5): 1923-1933. |

| [11] | 高锐涛,单建,杨洲,文晟,兰玉彬,张泉勇,汪洋. 植保无人机变量喷雾处方图实时解译系统的设计与试验[J]. 吉林大学学报(工学版), 2020, 50(1): 361-374. |

| [12] | 刘恩泽,吴文福. 基于综合指标品质评价算法的单色水果生长状态检测互联网架构[J]. 吉林大学学报(工学版), 2019, 49(6): 2019-2026. |

| [13] | 秦嘉浩,李臻,光岡宗司,井上英二,宋正河,朱忠祥. 基于模型实验的拖拉机配置对稳定性的影响差异[J]. 吉林大学学报(工学版), 2019, 49(4): 1236-1245. |

| [14] | 梁方,尤泳,王德成,王光辉,贺长彬,李帅. 运动参数对草地切根刀具与土壤作用关系的影响[J]. 吉林大学学报(工学版), 2019, 49(3): 903-911. |

| [15] | 王扬, 王晓梅, 陈泽仁, 于建群. 基于离散元法的玉米籽粒建模[J]. 吉林大学学报(工学版), 2018, 48(5): 1537-1547. |

|

||