吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (11): 3175-3183.doi: 10.13229/j.cnki.jdxbgxb.20230621

• 车辆工程·机械工程 • 上一篇

应用于车辆质心测量的改进侧倾法

李任君1( ),赵一兵2,顾莉栋1(

),赵一兵2,顾莉栋1( ),谭洪强1,宋林森1,田岩3

),谭洪强1,宋林森1,田岩3

- 1.长春理工大学 机电工程学院,长春 130022

2.中国人民解放军63850部队,白城 137000

3.华晨宝马汽车有限公司 研发中心,沈阳 110000

Improved tilting method for vehicle mass center measurement

Ren-jun LI1( ),Yi-bing ZHAO2,Li-dong GU1(

),Yi-bing ZHAO2,Li-dong GU1( ),Hong-qiang TAN1,Lin-sen SONG1,Yan TIAN3

),Hong-qiang TAN1,Lin-sen SONG1,Yan TIAN3

- 1.School of Mechanical and Electrical Engineering,Changchun University of Science and Technology,Changchun 130022,China

2.The No. 63850th Troop of PLA,Baicheng 137000,China

3.Research and Development Center,BMW-Brilliance Automotive Ltd. ,Shenyang 110000,China

摘要:

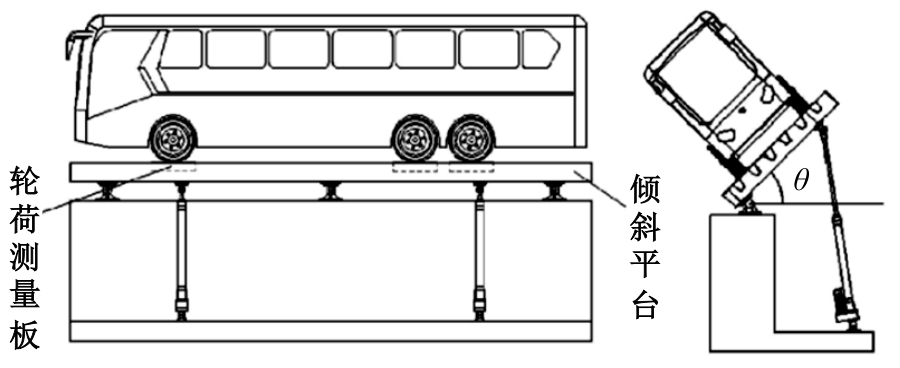

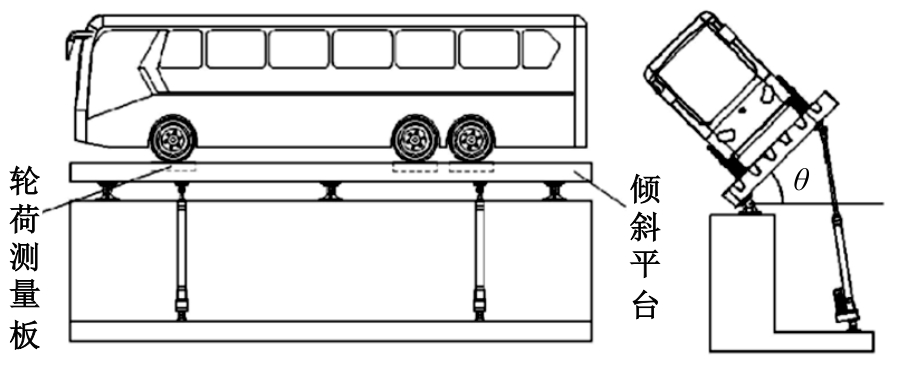

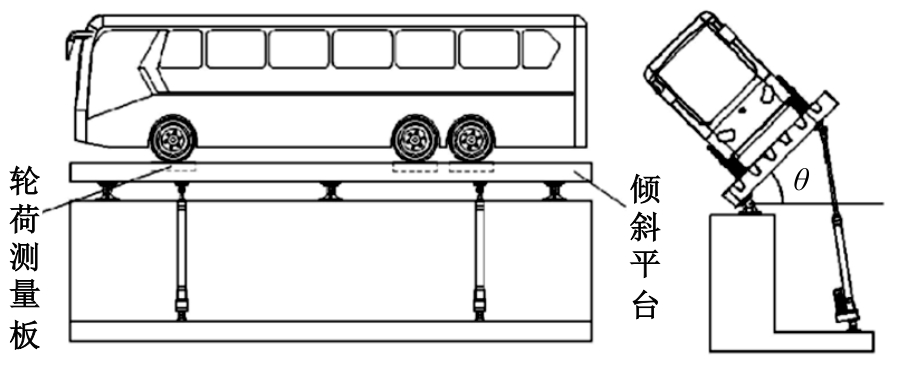

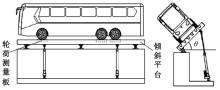

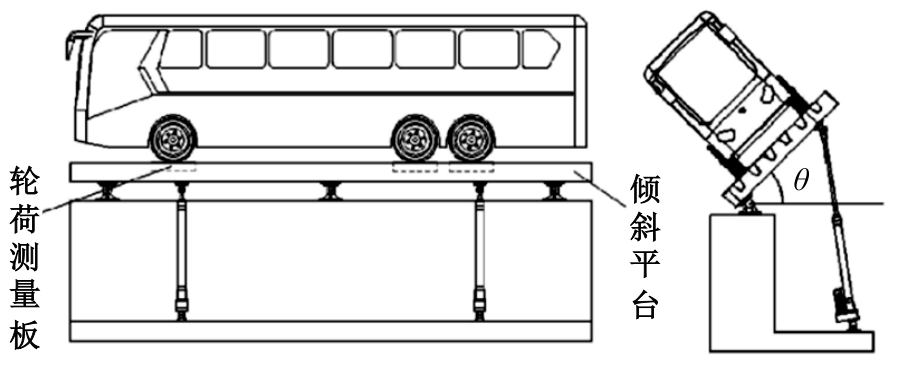

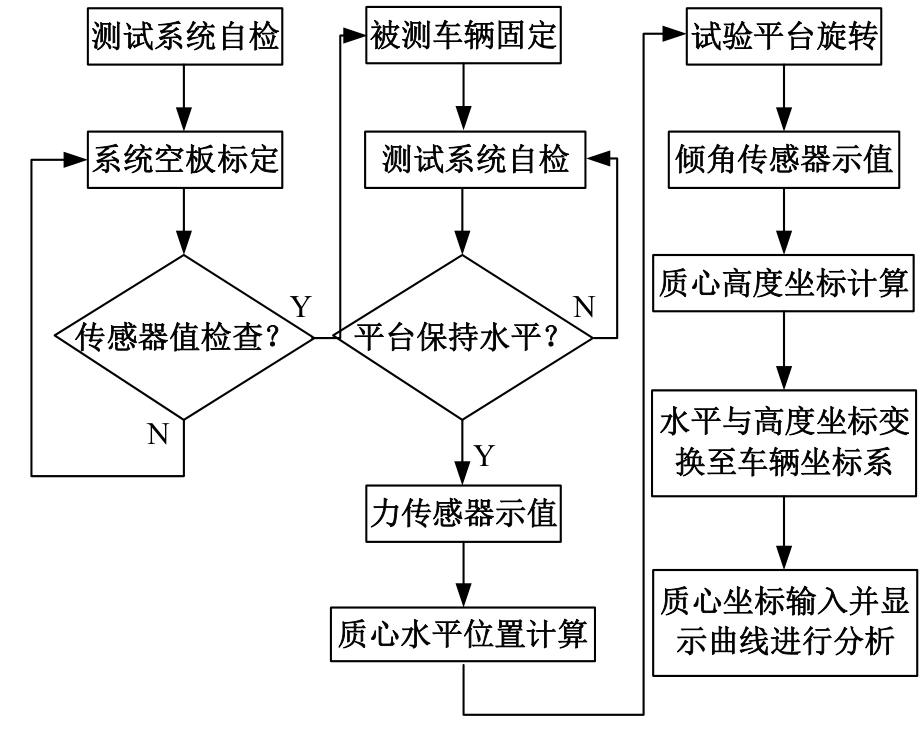

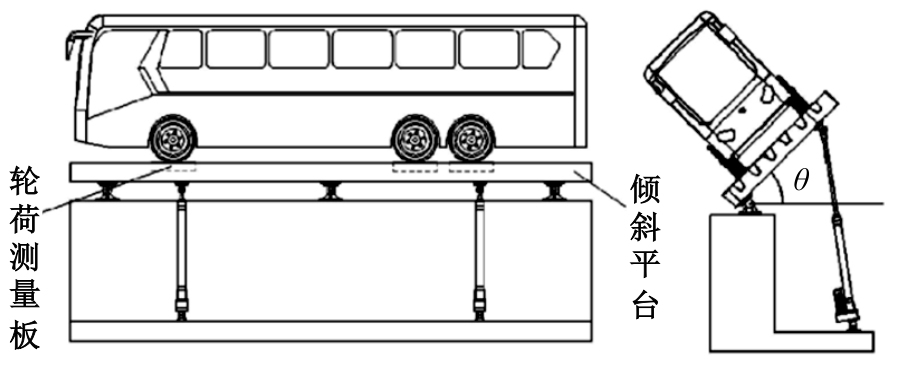

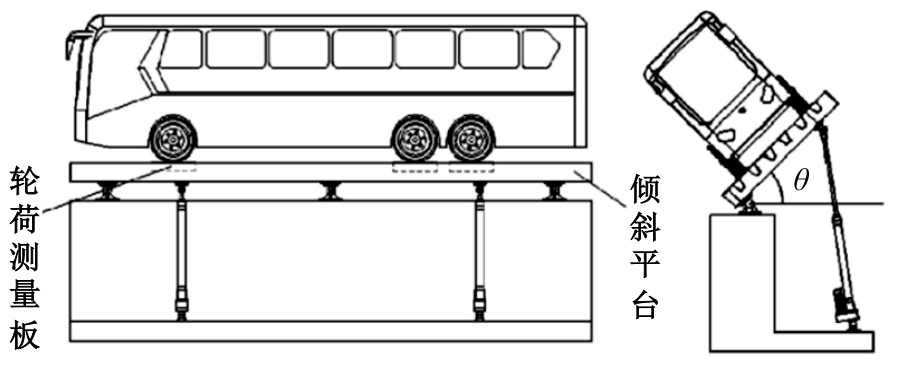

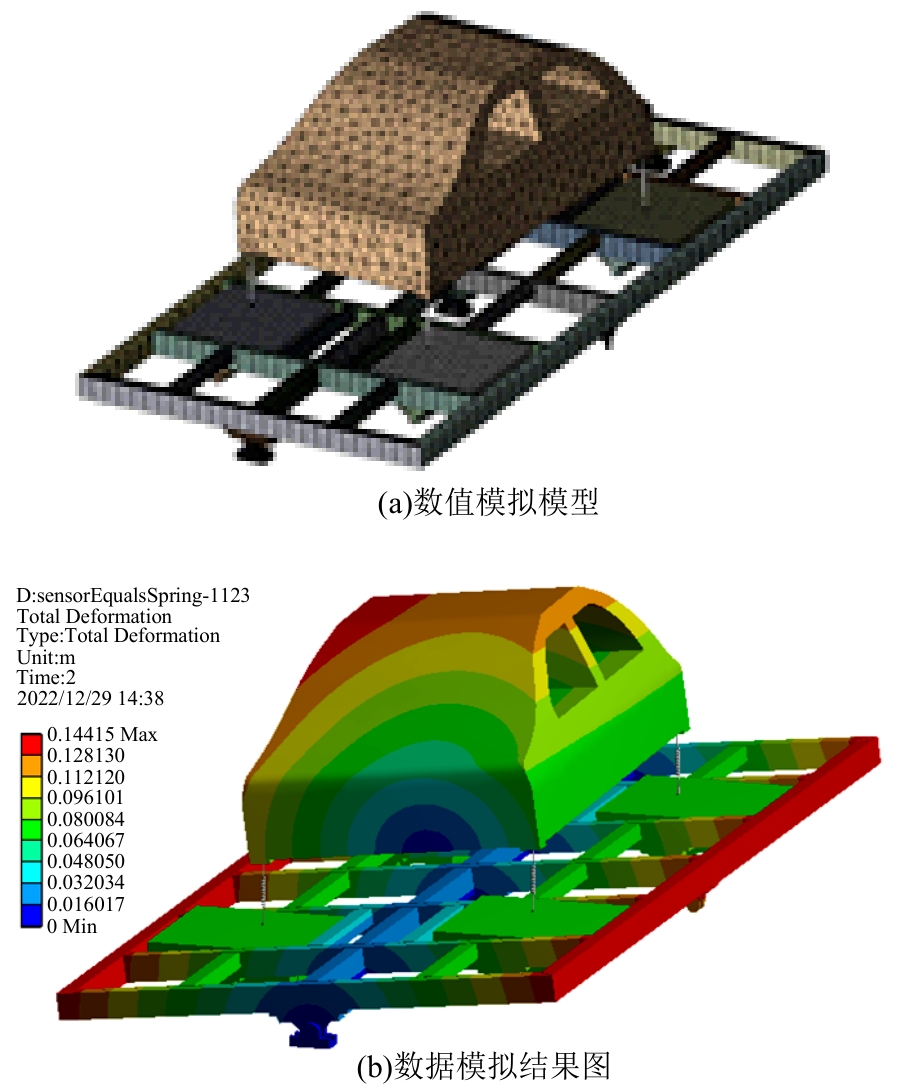

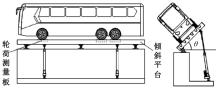

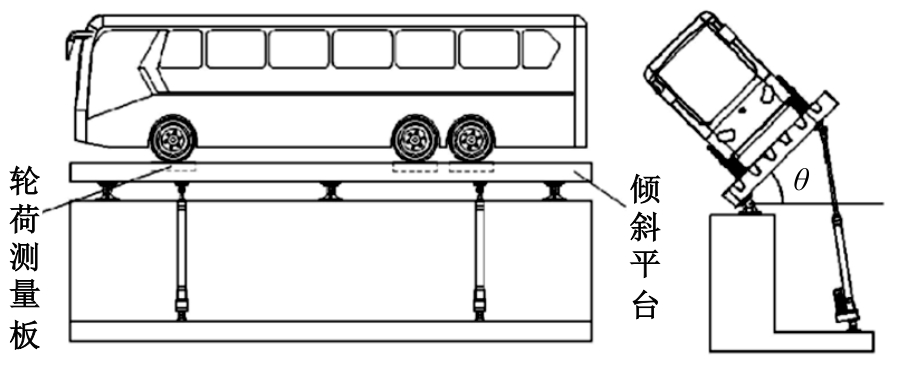

应用侧倾法进行汽车质心位置测量时,会出现轮胎受力点计算不准确、车辆侧倾大等问题,本文提出改进侧倾法。在应用改进侧倾法进行车辆质心位置测量时,轮胎受力方向始终竖直向上,不需额外设计轮荷称重装置,可以减小摩擦力等不利因素的影响。为使改进侧倾法中支承板始终保持水平,采用平行四边形机构对其进行约束。根据静力与力矩平衡,建立改进侧倾法的车辆质心测量计算模型,采用数值模拟手段,对系统关键部件进行校核,并对测量过程进行数值模拟分析。研究表明:改进侧倾法设计的平行四边形机构和测试台框架的刚度和强度可以满足安全性要求;在车辆质心位置确定过程中,改进侧倾法车辆的转动角度会较传统测试方法小,所测质心位置精度高且试验安全性好。

中图分类号:

- TH39

| 1 | 郑德喜. 三轴重型车辆行驶操纵稳定性研究[D]. 秦皇岛: 燕山大学机械工程学院, 2021. |

| Zheng De-xi. Research on driving and handling stability of three-axle heavy vehicle[D]. Qinhuangdao: School of Mechanical Engineering, Yanshan University, 2021 | |

| 2 | 李涛, 卢海波, 林泛业, 等. 质心高度对车辆动力学性能的影响[J]. 汽车实用技术, 2019(3): 110-112. |

| Li Tao, Lu Hai-bo, Lin Fan-ye, et al. Effect of center of mass height on vehicle dynamic performance[J]. Automotive Practical Technology, 2019(3): 110-112. | |

| 3 | Brancati R, Russo R, Savino S. Method and equipment for inertia parameter identification[J]. Mechanical Systems and Signal Processing, 2010, 24(1): 29-40. |

| 4 | 李俊鹏, 顾宇庆, 陈华杰. 稳定摆法在汽车质心高度测量中的应用及不确定评定[J]. 中国检验检测, 2020, 28(2): 42-45. |

| Li Jun-peng, Gu Yu-qing, Chen Hua-jie. Application of stable pendulum method in the height measurement of automobile center of mass and uncertainty evaluation[J]. China Inspection and Testing, 2020, 28(2): 42-45. | |

| 5 | 杨丽君. 基于侧倾法的车辆质心测量台技术研究[D]. 哈尔滨: 哈尔滨理工大学机械动力工程学院, 2015. |

| Yang Li-jun. Technology research of vehicle center of mass measurement table based on roll method[D]. Harbin: School of Mechanical Power Engineering, Harbin University of Science and Technology, 2015. | |

| 6 | 贾晓东, 向飞. 侧倾台测量汽车质心高度的核查方法[J]. 装备制造技术, 2022(4): 95-98. |

| Jia Xiao-dong, Xiang Fei. Verification method for measuring the height of center of mass of automobile by tilting table[J]. Equipment Manufacturing Technology, 2022(4): 95-98. | |

| 7 | 唐平建, 孙泽林, 张畔, 等. 基于三点支承的特种车辆质心测量误差分析[J]. 兵器装备工程学报, 2021, 42(7): 234-238. |

| Tang Ping-jian, Sun Ze-lin, Zhang Pan, et al. Error analysis of centroid measurement of special vehicle based on three-point support[J]. Journal of Ordnance Equipment Engineering, 2021, 42(7): 234-238. | |

| 8 | 钟江, 赵章风, 乔欣, 等. 基于三点支承的质心测量系统及误差分析[J]. 中国机械工程, 2010, 21(12): 1469-1472. |

| Zhong Jiang, Zhao Zhang-feng, Qiao Xin, et al. Center of mass measurement system and error analysis based on three-point support[J]. China Mechanical Engineering, 2010, 21(12): 1469-1472. | |

| 9 | 邱银燕, 熊云, 李剑斌. 基于质量反应法的车辆质心位置测量平台研究[J]. 农业装备与车辆工程, 2018, 56(9): 88-90. |

| Qiu Yin-yan, Xiong Yun, Li Jian-bin. Research on vehicle centroid position measurement platform based on mass response method[J]. Agricultural Equipment and Vehicle Engineering, 2018, 56(9): 88-90. | |

| 10 | Elaal S M A. Empirical equations to predict the tractor center of gravity[J]. Ama Agricultural Mechanization in Asia Africa & Latin America, 2009, 40(3): 64-68. |

| 11 | Fabbri A, Molari G. Static measurement of the centre of gravity height on narrow-track agricultural tractors[J]. Biosystems Engineering, 2004, 87(3): 299-304. |

| 12 | 王德民, 张龙易, 许镇全, 等. 陆行车质心测量机设计与分析[J]. 长春理工大学学报: 自然科学版, 2021, 44(3): 76-82. |

| Wang De-min, Zhang Long-yi, Xu Zhen-quan, et al. Design and analysis of center of mass measuring machine for land vehicle[J]. Journal of Changchun University of Science and Technology (Natural Science Edition), 2021, 44(3): 76-82. | |

| 13 | Zhang Q, Jin X, Zhou K, et al. Novel design method of cog measurement system via supporting reaction method[J]. Journal of Beijing Institute of Technology, 2020, 29(2): 251-259. |

| 14 | Gobbi M, Mastinu G, Previati G. A method for measuring the inertia properties of rigid bodies[J]. Mechanical Systems&Signal Processing, 2011, 25(1): 305-318. |

| 15 | Mastinu G, Gobbi M, Miano C M. The influence of the body inertia tensor on the active safety and ride comfort of road vehicles[J]. Journal of Passenger Car: Mechanical Systems Journal, 2002, 111(6): 1980-1990. |

| 16 | 秦剑文, 李波辉. 两种测量质心高度方法的研究[J]. 装备制造技术, 2020(12): 95-96. |

| Qin Jian-wen, Li Bo-hui. Research on two methods for measuring the height of the center of mass[J]. Equipment Manufacturing Technology, 2020(12): 95-96. | |

| 17 | 丁伟, 高浩, 张坤, 等. 多轴车辆轮荷计算方法研究[J]. 汽车技术, 2014, 469(10): 18-21. |

| Ding Wei, Gao Hao, Zhang Kun, et al. Research on calculation method of wheel load for multi-axle vehicle[J]. Automotive Technology, 2014, 469(10): 18-21. |

| [1] | 朱冰,范天昕,赵文博,李伟男,张培兴. 自动驾驶汽车连续测试场景复杂度评估方法[J]. 吉林大学学报(工学版), 2025, 55(2): 456-467. |

| [2] | 高天洋,胡大伟,姜瑞森,吴雪,刘慧甜. 基于模块化车辆的区域灵活接驳公交线路优化[J]. 吉林大学学报(工学版), 2025, 55(2): 537-545. |

| [3] | 刘建辉,王琼. 基于多目标蚁群算法的多配送中心应急物资配送车辆调度优化方法[J]. 吉林大学学报(工学版), 2025, 55(2): 631-638. |

| [4] | 曲俊龙,史文库,玄圣夷,陈志勇. 面向汽车传动系统多挡共振的多级吸振器参数设计方法[J]. 吉林大学学报(工学版), 2025, 55(2): 444-455. |

| [5] | 陈鑫,张祥源,武子涛,于贵申,杨立飞. 工艺顺序对车用铝薄板胶-PFSSW接头拉剪性能的影响[J]. 吉林大学学报(工学版), 2025, 55(2): 468-475. |

| [6] | 郑利民,陈双,李刚. YOLOv5网络算法下交通监控视频违章车辆多目标检测[J]. 吉林大学学报(工学版), 2025, 55(2): 693-699. |

| [7] | 胡宏宇,张争光,曲优,蔡沐雨,高菲,高镇海. 基于双分支和可变形卷积网络的驾驶员行为识别方法[J]. 吉林大学学报(工学版), 2025, 55(1): 93-104. |

| [8] | 王军年,曹宇靖,罗智仁,李凯旋,赵文伯,孟盈邑. 基于双目视觉的道路水深在线检测算法[J]. 吉林大学学报(工学版), 2025, 55(1): 175-184. |

| [9] | 谭草,任浩鑫,葛文庆,宋亚东,陆佳瑜. 直驱阀控液压振动平台改进自抗扰控制[J]. 吉林大学学报(工学版), 2025, 55(1): 84-92. |

| [10] | 李寿涛,杨路,屈如意,孙鹏鹏,于丁力. 基于模型预测控制的滑移率控制方法[J]. 吉林大学学报(工学版), 2024, 54(9): 2687-2696. |

| [11] | 吴金星,马宇翔,肖嘉邦,徐耀,李松歌. H型翅片椭圆管壁面磨损特性的数值模拟[J]. 吉林大学学报(工学版), 2024, 54(9): 2495-2501. |

| [12] | 吴量,顾义凡,邢彪,马芳武,倪利伟,贾微微. 基于线性二次型调节器的四轮转向与分布式集成控制方法[J]. 吉林大学学报(工学版), 2024, 54(9): 2414-2422. |

| [13] | 党兆龙,邹猛,宋家锋,陈百超,申彦,齐迎春. 模拟火壤结壳及其力学性能试验[J]. 吉林大学学报(工学版), 2024, 54(8): 2393-2400. |

| [14] | 张辉,温鑫,陈海宇,黄世淳. 基于激光测距传感器的车辆轨迹全息感知方法[J]. 吉林大学学报(工学版), 2024, 54(8): 2378-2384. |

| [15] | 王玉海,李晓之,李兴坤. 面向高速工况的混合动力卡车预见性节能算法[J]. 吉林大学学报(工学版), 2024, 54(8): 2121-2129. |

|

||