吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (9): 2495-2501.doi: 10.13229/j.cnki.jdxbgxb.20230458

• 材料科学与工程 • 上一篇

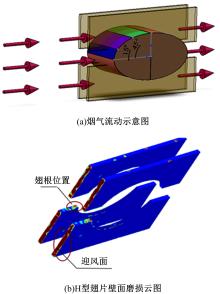

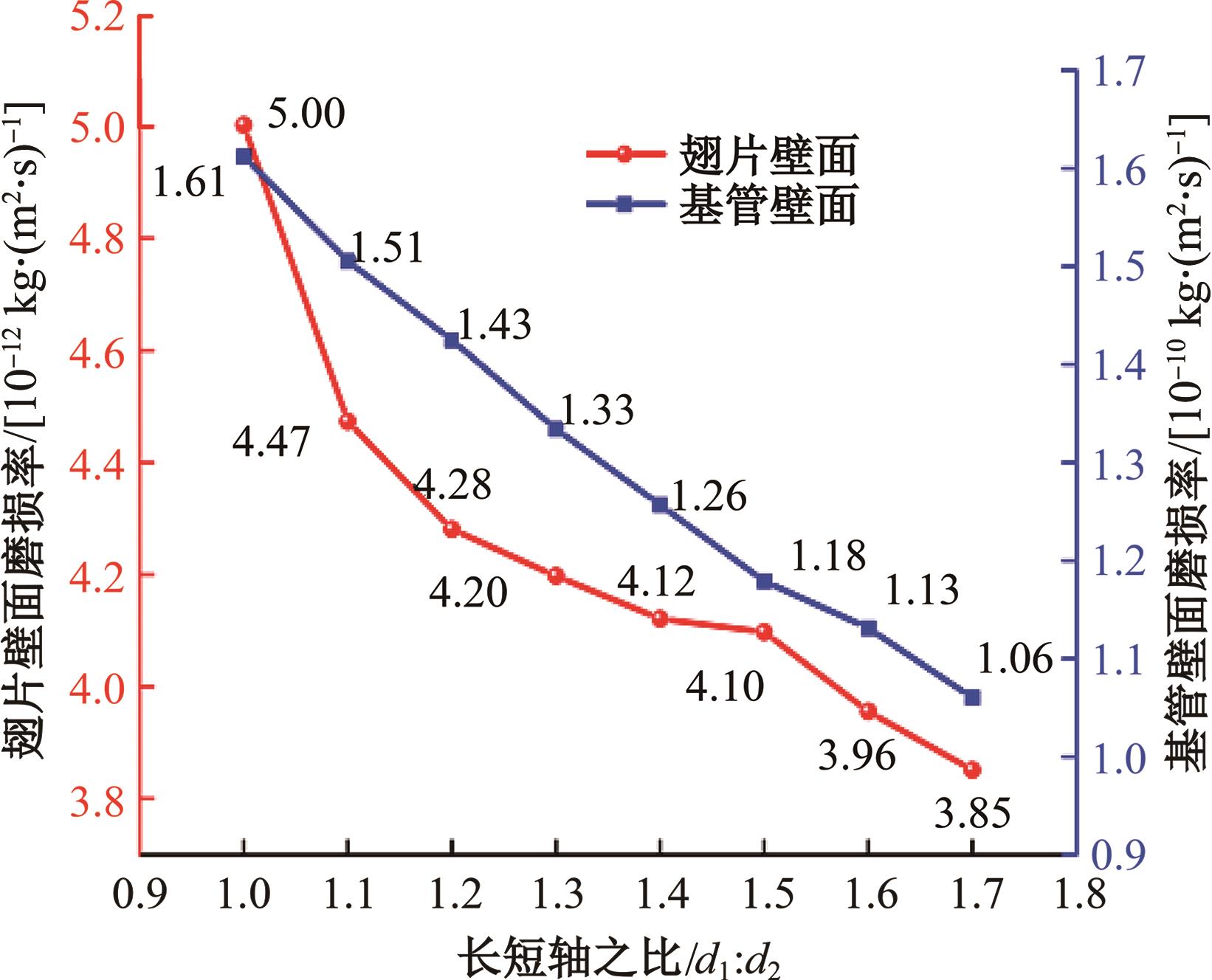

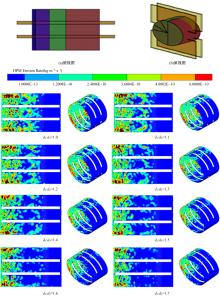

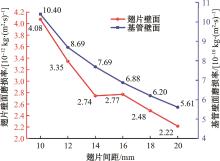

H型翅片椭圆管壁面磨损特性的数值模拟

- 郑州大学 机械与动力工程学院,郑州 450001

Numerical simulation of erosion characteristics of H-type finned elliptical tubes

Jin-xing WU( ),Yu-xiang MA,Jia-bang XIAO,Yao XU,Song-ge LI

),Yu-xiang MA,Jia-bang XIAO,Yao XU,Song-ge LI

- School of Mechanical and Power Engineering,Zhengzhou University,Zhengzhou 450001,China

摘要:

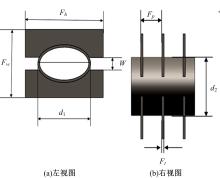

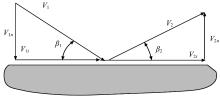

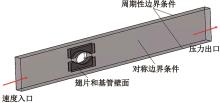

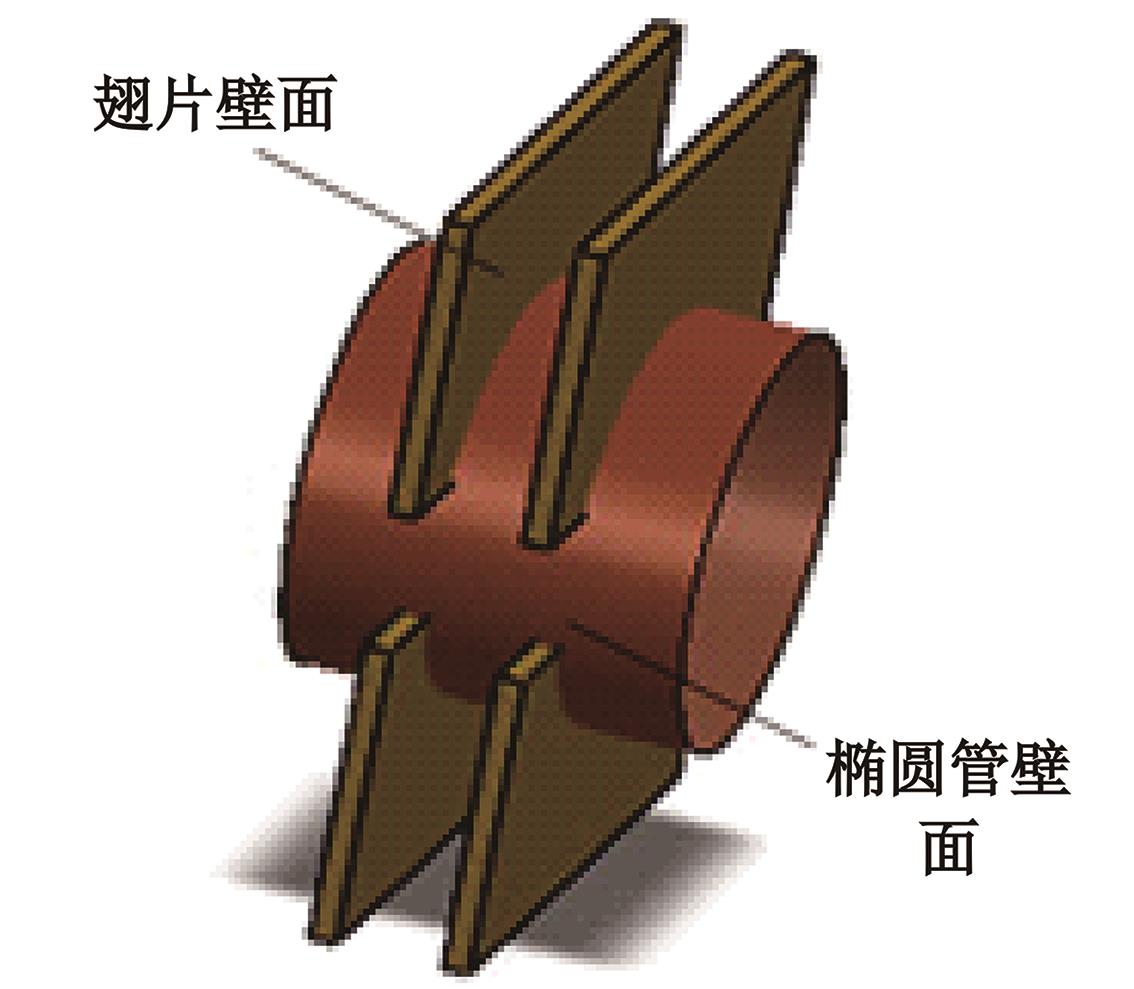

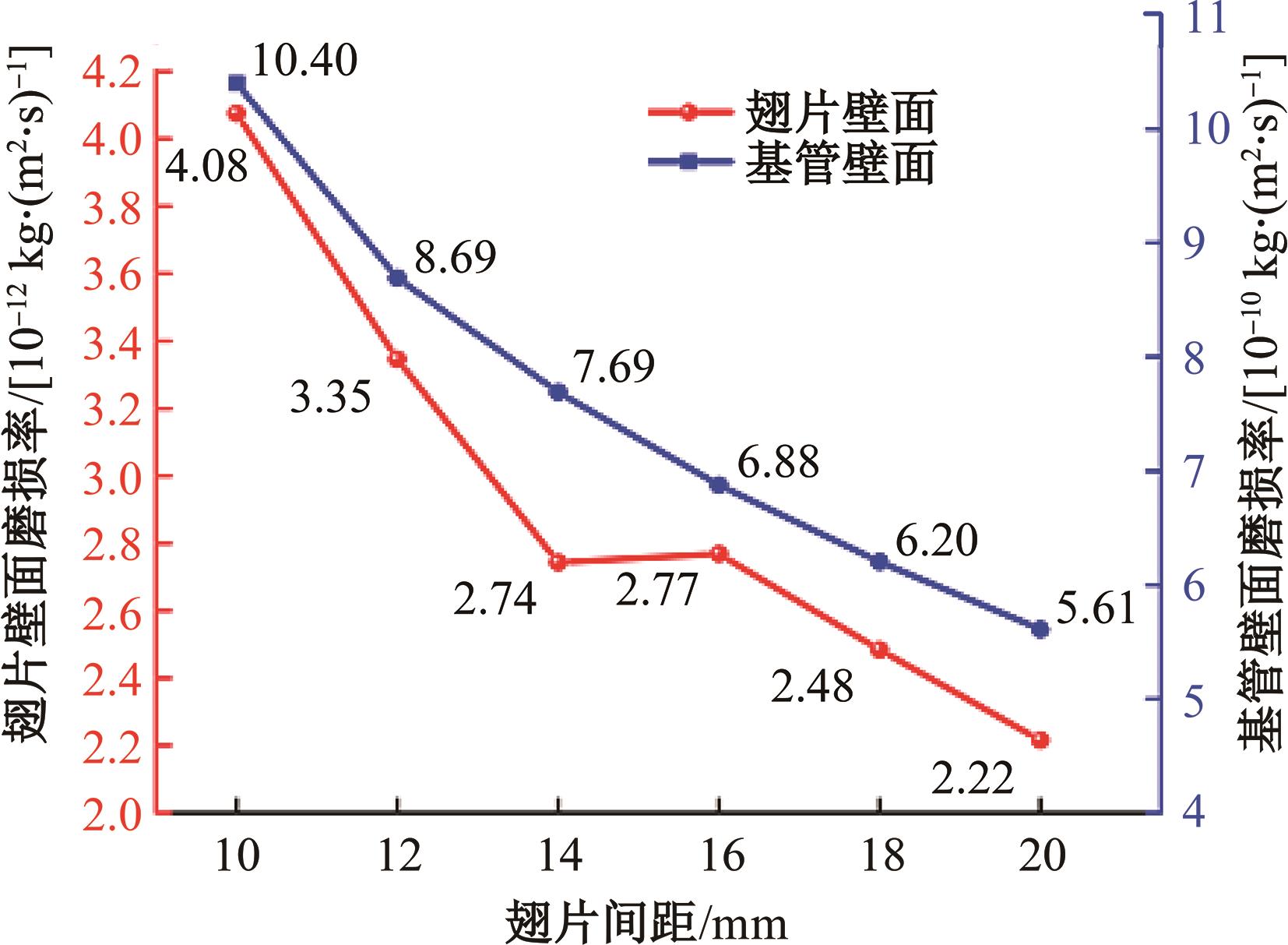

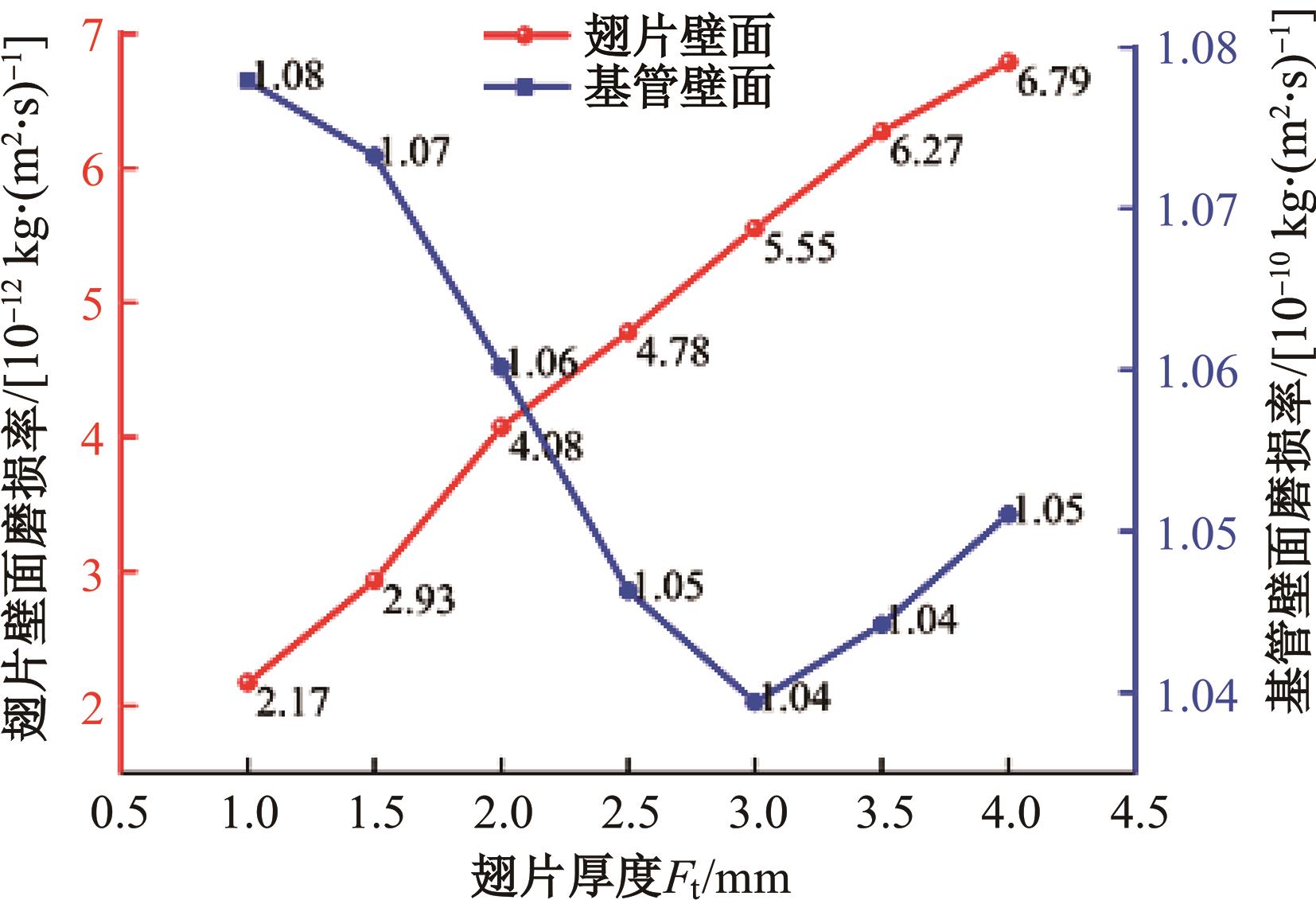

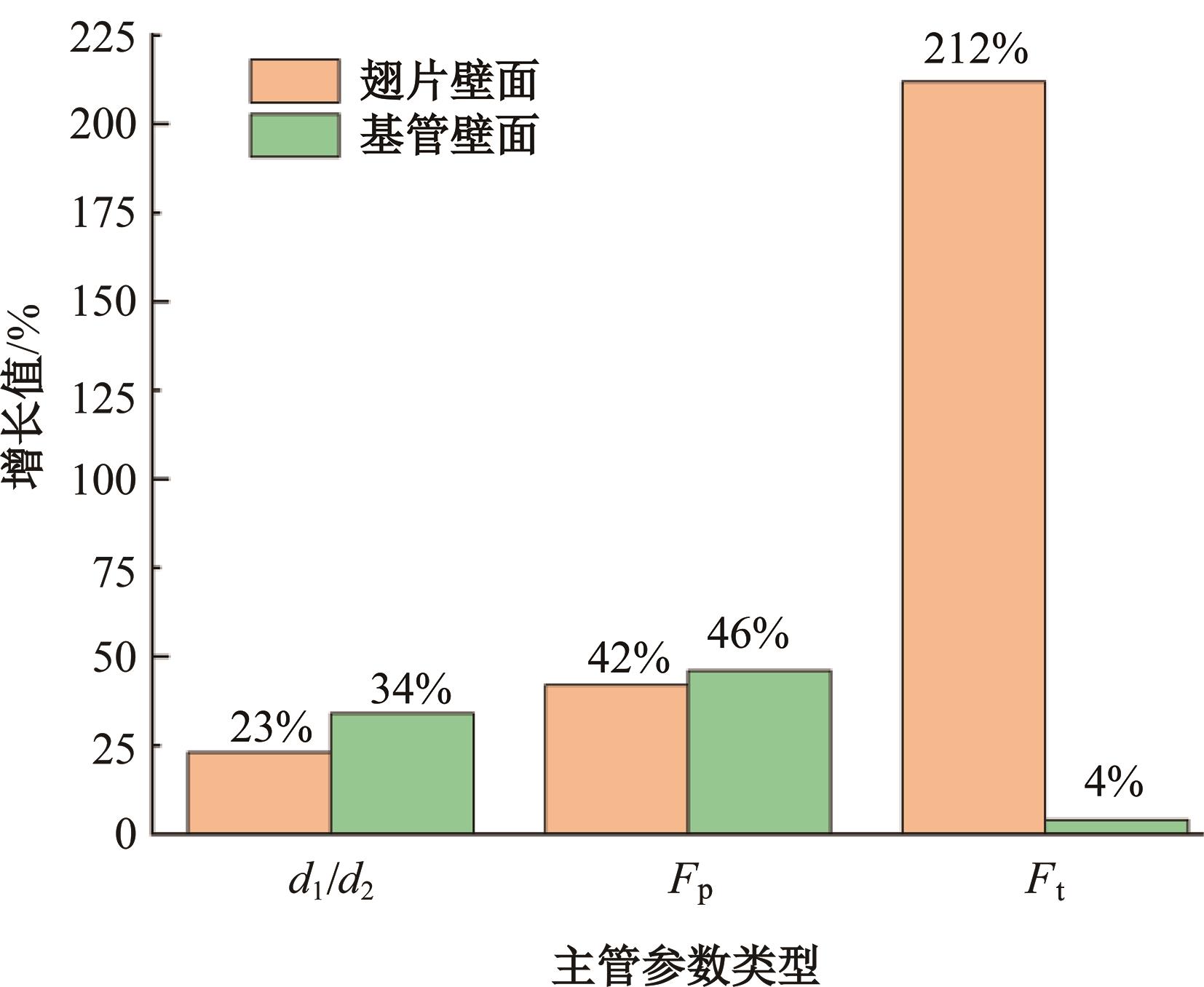

为确定H型翅片椭圆管的修复周期,本文使用离散相模型(DPM)对烟气冲蚀H型翅片椭圆管进行三维数值模拟,得到壁面的磨损特性,并研究了长短轴之比、翅片厚度、翅片节距对主管壁面及翅片壁面的磨损规律。结果表明:主管壁面和翅片磨损率都随着长短轴之比和翅片节距的增加而不断下降,翅片壁面的磨损率随着翅片厚度的增加而不断上升。通过改变翅片间距,能使基管壁面磨损率下降46%;通过改变翅片厚度,能将翅片壁面磨损率增大212%。

中图分类号:

- TK172

| 1 | 黄丹,曾小义,杨建军,等. 超临界W火焰锅炉水冷壁管频繁拉裂泄漏事故原因分析[J]. 热加工工艺,2022,51(15):150-154, 158. |

| Huang Dan, Zeng Xiao-yi, Yang Jian-jun, et al. Analysis on causes of frequent rupture and leakage of water wall pipe of supercritical W Flame Boiler[J]. Hot Working Technology, 2022, 51(15): 150-154, 158. | |

| 2 | 张晓东,唐丽丽,翟璇,等. 燃煤发电机组烟气余热回收系统优化与经济性分析[J]. 锅炉技术,2022,53(4):74-78. |

| Zhang Xiao-dong, Tang Li-li, Zhai Xuan, et al. Optimization and economic analysis of flue gas wasteheat recovery system of coalfired power plants[J]. Boiler Technology, 2022, 53(4): 74-78. | |

| 3 | 徐承美,谢英柏,弓学敏. 燃煤锅炉烟气余热利用途径分析[J]. 热能动力工程,2020,35(8):151-157. |

| Xu Cheng-mei, Xie Ying-bai, Gong Xue-min. Analysis on waste heat utilization way of flue gas in coal-fired boiler[J]. Joumal of Engineering for Thermal Energy and Power, 2020, 35(8): 151-157. | |

| 4 | 李增亮,杜明超,董祥伟,等.固体颗粒冲蚀磨损模型的建立及有限元分析[J].计算机仿真,2018,35(6):275-281. |

| Li Zeng-liang, Du Ming-chao, Dong Xiang-wei, et al. Modeling and analysis of solid particle erosion process based on finite element method[J]. Computer Simulation, 2018, 35(6): 275-281. | |

| 5 | 叶侠丰,丁红蕾,潘卫国,等. 带拓展面椭圆管束的换热、积灰及磨损特性研究[J]. 中国电力,2018,51(6):26-32. |

| Ye Xia-feng, Ding Hong-lei, Pan Wei-guo, et al. Numerical study on the heat transfer, fouling and erosion characteristics of the elliptical tube bundle with different extended heating surfaces[J]. Electric Power, 2018, 51(6): 26-32. | |

| 6 | 叶侠丰,丁红蕾,潘卫国,等. 圆管束与椭圆管束换热、磨损及积灰特性的数值研究[J]. 中国电机工程学报,2018,38(11):3289-3294. |

| Ye Xia-feng, Ding Hong-lei, Pan Wei-guo, et al. Numerical study on heat transfer, wear and fouling performance of circular tube bundle and elliptical tube bundle[J]. Proceedings of the CSEE, 2018, 38(11): 3289-3294. | |

| 7 | 凌冬冬,李永光,马昕霞,等. 开缝宽度对H型椭圆翅片管束换热及流动的影响[J]. 上海电力学院学报, 2018,34(2): 106-110. |

| Ling Dong-dong, Li Yong-guang, Ma Xin-xia, et al. Influence of slot width on heat transfer and flow of h type elliptical finned tubes[J]. Journal of Shanghai University of Electric Power, 2018, 34(2): 106-110. | |

| 8 | 蒋涛.火力发电厂锅炉屏式过热器弯管泄漏失效原因分析及预防措施[J].铸造技术,2022,43(3):224-228. |

| Jiang Tao. Analysis and prevention of platen superheater elbow leakage of supercritical boiler in a coal-fired power plant[J]. Foundry Technology, 2022, 43(3): 224-228. | |

| 9 | 谌康,蔡文河,杜双明,等.电站锅炉水冷壁管的泄漏原因及应对措施[J].腐蚀与防护,2022,43(2):62-67. |

| Shen Kang, Cai Wen-he, Du Shuang-ming, et al. Cause analysis and treatment measures of water cooling wall pipe leakage ina power station boiler[J]. Corrosion & Protection, 2022, 43(2): 62-67. | |

| 10 | 闫廷庆,支卫峰. 对冲燃烧锅炉侧墙水冷壁高温腐蚀原因的空气动力研究[J]. 锅炉技术,2022,53(1):22-25, 31. |

| Yan Ting-qing, Zhi Wei-feng. Flow-field investigation of high-temperature corrosionon side waterwall of opposed firing boilers[J]. Boiler Technology, 2022, 53(1): 22-25, 31. | |

| 11 | 杨子江,袁益超,杨雨峤,等. 椭圆管H型翅片的翅片效率计算[J]. 锅炉技术,2019,50(3):18-23. |

| Yang Zi-jiang, Yuan Yi-chao, Yang Yu-giao,et al. Calculation for fin efficiency of H-type finned elliptical tube[J]. Boiler Technology, 2019, 50(3): 18-23. | |

| 12 | Om P, Arvind K, Basant S S. CFD modeling of slurry flow erosion wear rate through mitre pipe bend[J]. Proceedings of the Institution of Mechanical Engineers Part C-Journal of Mechanical Engineering Science, 2022, 236(5): 2256-2267. |

| 13 | 汪洋,郑志敏,张银森,等. 椭圆型管束的积灰特性数值研究[J]. 工程热物理学报,2022,43(3):720-728. |

| Wang Yang, Zheng Zhi-min Zhang Yin-sen, et al. Numerical study on ash deposition of the elliptical tube bundles[J]. Journal of Engineering Thermophysics, 2022, 43(3): 720-728. |

| [1] | 何华飞,李兆平,符瑞安,马绍麟,黄明利. 考虑地层约束效应的预制侧墙节点抗震性能试验[J]. 吉林大学学报(工学版), 2024, 54(6): 1601-1611. |

| [2] | 娄淑梅,李一明,李鑫,陈鹏,白雪峰,程宝嘉. 基于BP神经网络和Arrhenius本构模型的石墨烯/7075复合材料热变形行为[J]. 吉林大学学报(工学版), 2024, 54(5): 1237-1245. |

| [3] | 赵秋,陈鹏,赵煜炜,余澳. 台后设置拱形结构的无缝桥梁整体受力性能[J]. 吉林大学学报(工学版), 2024, 54(4): 1016-1027. |

| [4] | 卫星,高亚杰,康志锐,刘宇辰,赵骏铭,肖林. 低温环境下栓钉环焊缝焊接残余应力场数值模拟[J]. 吉林大学学报(工学版), 2024, 54(1): 198-208. |

| [5] | 郑植,袁佩,金轩慧,魏思斯,耿波. 桥墩复合材料柔性防撞护舷试验[J]. 吉林大学学报(工学版), 2023, 53(9): 2581-2590. |

| [6] | 王峰,刘双瑞,王佳盈,宋佳玲,王俊,张久鹏,黄晓明. 尺寸和形状效应对多孔结构风阻系数的影响[J]. 吉林大学学报(工学版), 2023, 53(6): 1677-1685. |

| [7] | 顾正伟,张攀,吕东冶,吴春利,杨忠,谭国金,黄晓明. 基于数值仿真的简支梁桥震致残余位移分析[J]. 吉林大学学报(工学版), 2023, 53(6): 1711-1718. |

| [8] | 魏海斌,韩栓业,毕海鹏,刘琼辉,马子鹏. 智能感知道路主动除冰雪系统及实验技术[J]. 吉林大学学报(工学版), 2023, 53(5): 1411-1417. |

| [9] | 金敬福,董新桔,贾志成,王康,贺连彬,邹猛,齐迎春. 板簧式弹性金属车轮胎面弹片结构优化[J]. 吉林大学学报(工学版), 2023, 53(4): 964-972. |

| [10] | 刘状壮,张有为,季鹏宇,Abshir Ismail Yusuf,李林,郝亚真. 电热型融雪沥青路面传热特性研究[J]. 吉林大学学报(工学版), 2023, 53(2): 523-530. |

| [11] | 解方喜,赵士杰,王梓森,刘爽,李小平,张程. 多孔喷油器闪急沸腾喷雾坍塌影响因素的仿真分析[J]. 吉林大学学报(工学版), 2023, 53(12): 3314-3325. |

| [12] | 戴理朝,周亮,杨晓文,王磊. 基于Connector单元的锈蚀RC梁界面粘结性能细观数值模拟[J]. 吉林大学学报(工学版), 2023, 53(10): 2886-2896. |

| [13] | 卢晓红,乔金辉,周宇,马冲,隋国川,孙卓. 搅拌摩擦焊温度场研究进展[J]. 吉林大学学报(工学版), 2023, 53(1): 1-17. |

| [14] | 郑植,耿波,王福敏,董俊宏,魏思斯. 既有低等级混凝土护栏防护能力提升[J]. 吉林大学学报(工学版), 2022, 52(6): 1362-1374. |

| [15] | 华琛,牛润新,余彪. 地面车辆机动性评估方法与应用[J]. 吉林大学学报(工学版), 2022, 52(6): 1229-1244. |

|

||