吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (9): 2708-2722.doi: 10.13229/j.cnki.jdxbgxb.20221454

• 农业工程·仿生工程 • 上一篇

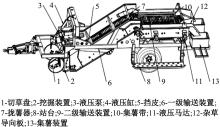

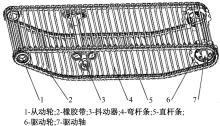

甘薯联合收获机二级输送分离装置的设计与试验

杨然兵1,2( ),张建2,尚书旗2(

),张建2,尚书旗2( ),田光博2,翟宇鸣2,潘志国2

),田光博2,翟宇鸣2,潘志国2

- 1.海南大学 机电工程学院,海口 5702283

2.青岛农业 大学机电工程学院,山东 青岛 266109

Design and test of secondary conveyor separator device for sweet potato combine harvester

Ran-bing YANG1,2( ),Jian ZHANG2,Shu-qi SHANG2(

),Jian ZHANG2,Shu-qi SHANG2( ),Guang-bo TIAN2,Yu-ming ZHAI2,Zhi-guo PAN2

),Guang-bo TIAN2,Yu-ming ZHAI2,Zhi-guo PAN2

- 1.College of Mechanical and Electrical Engineering,Hainan University,Haikou 5702283,China

2.College of Mechanical and Electrical Engineering,Qingdao Agricultural University,Qingdao 266109,China

摘要:

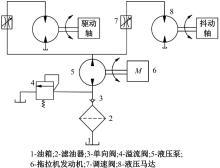

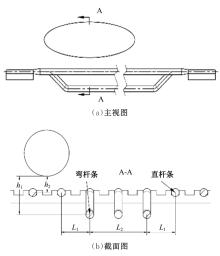

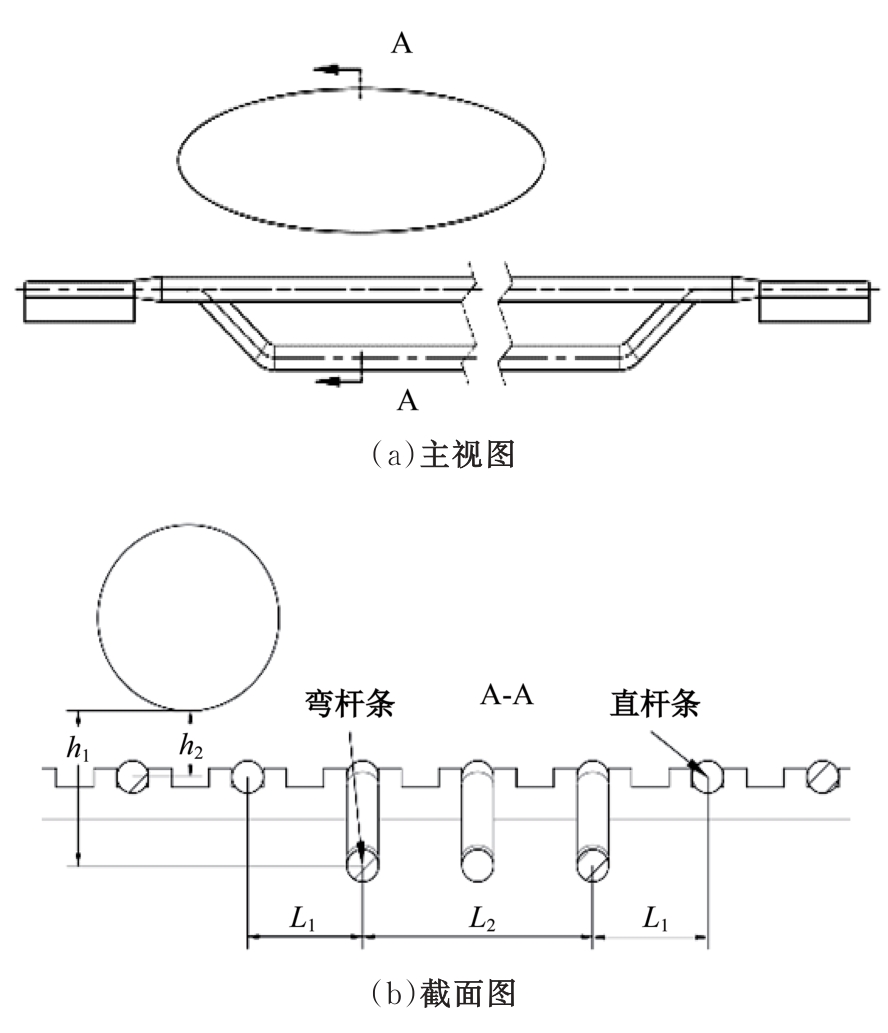

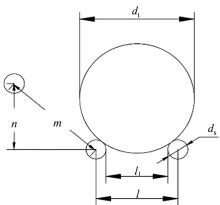

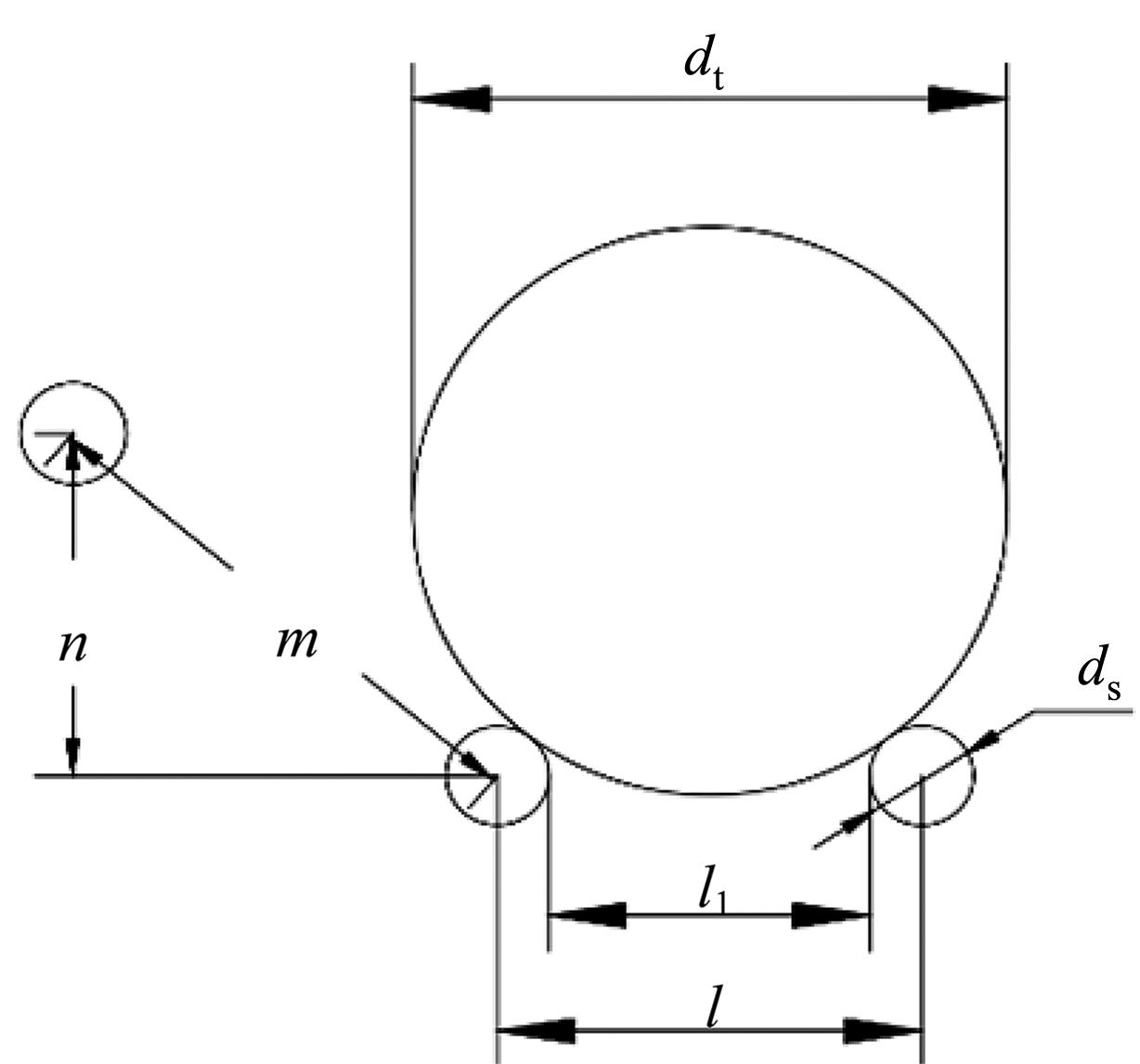

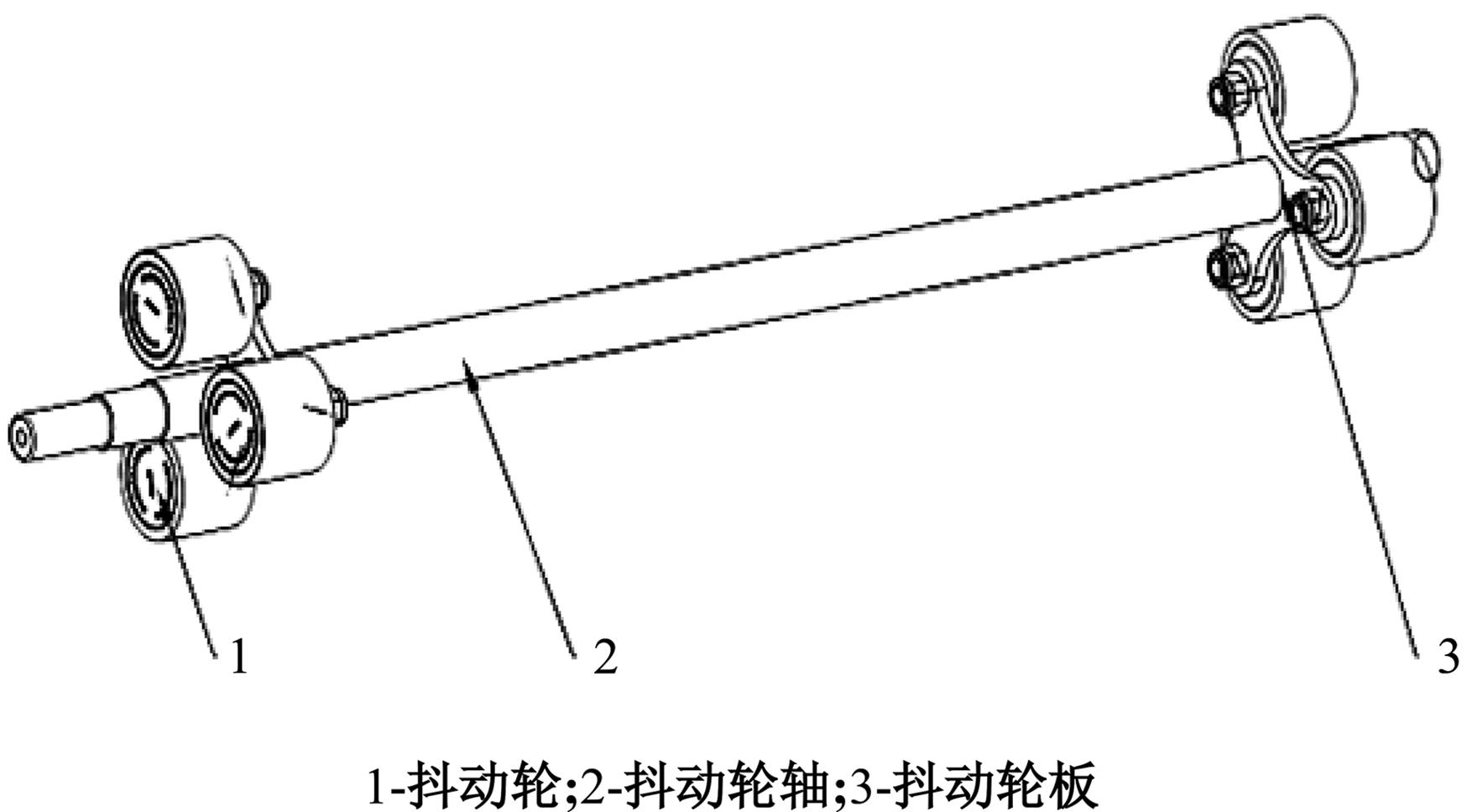

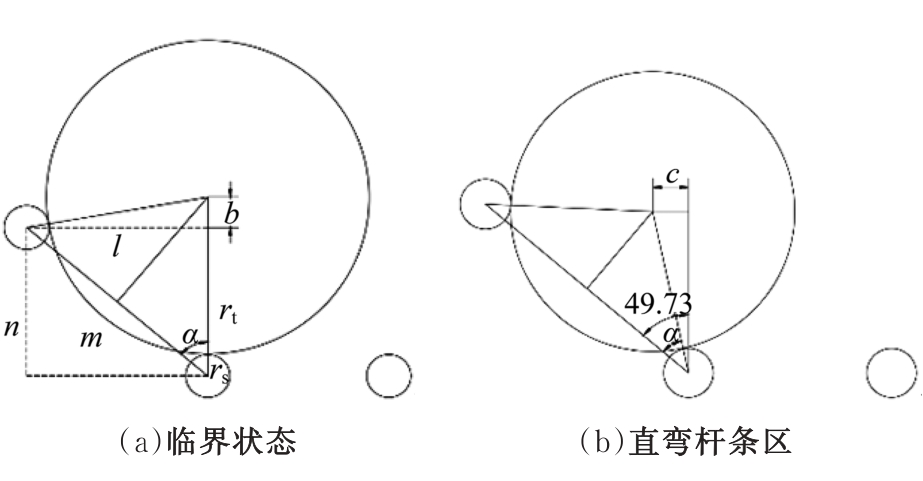

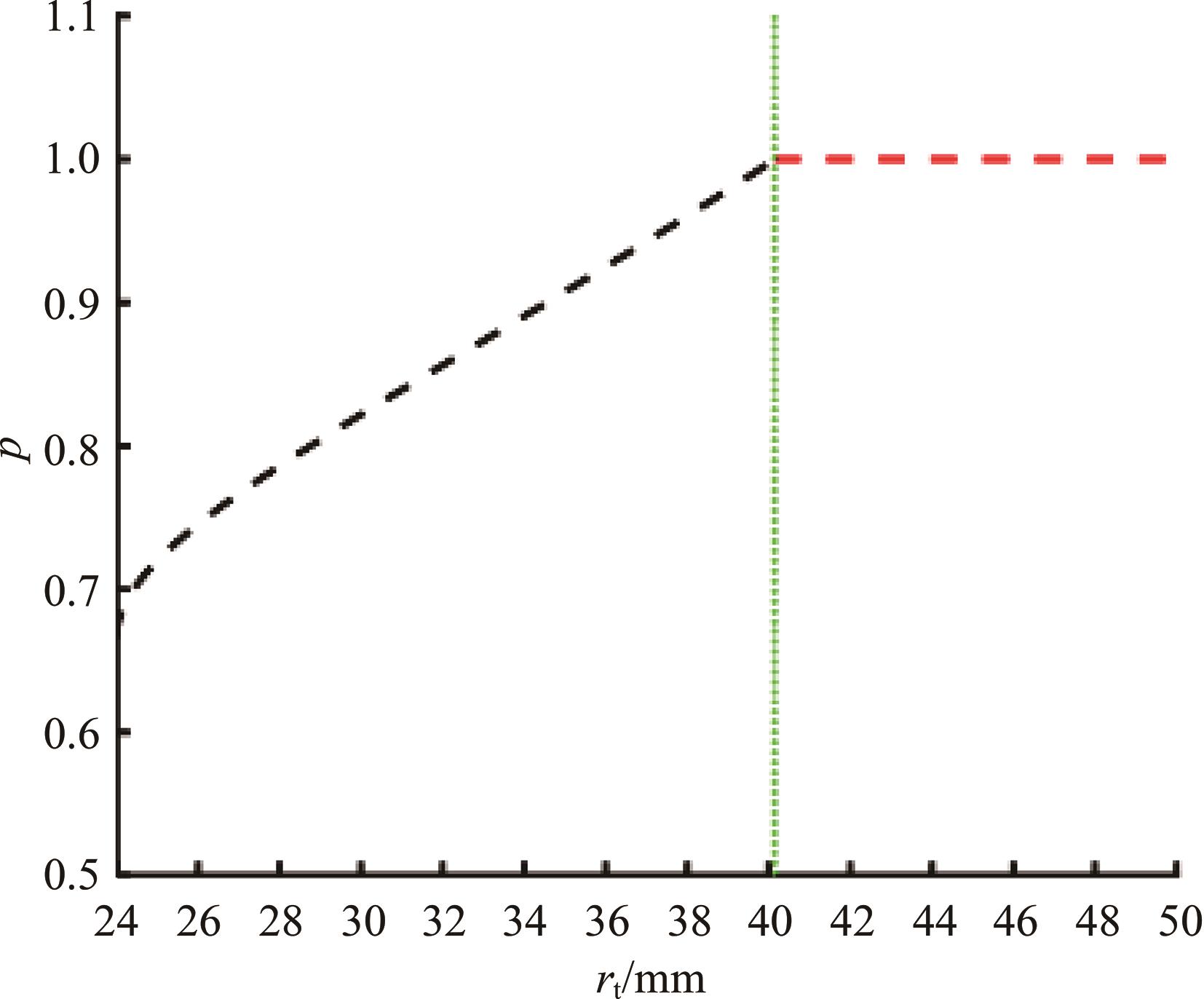

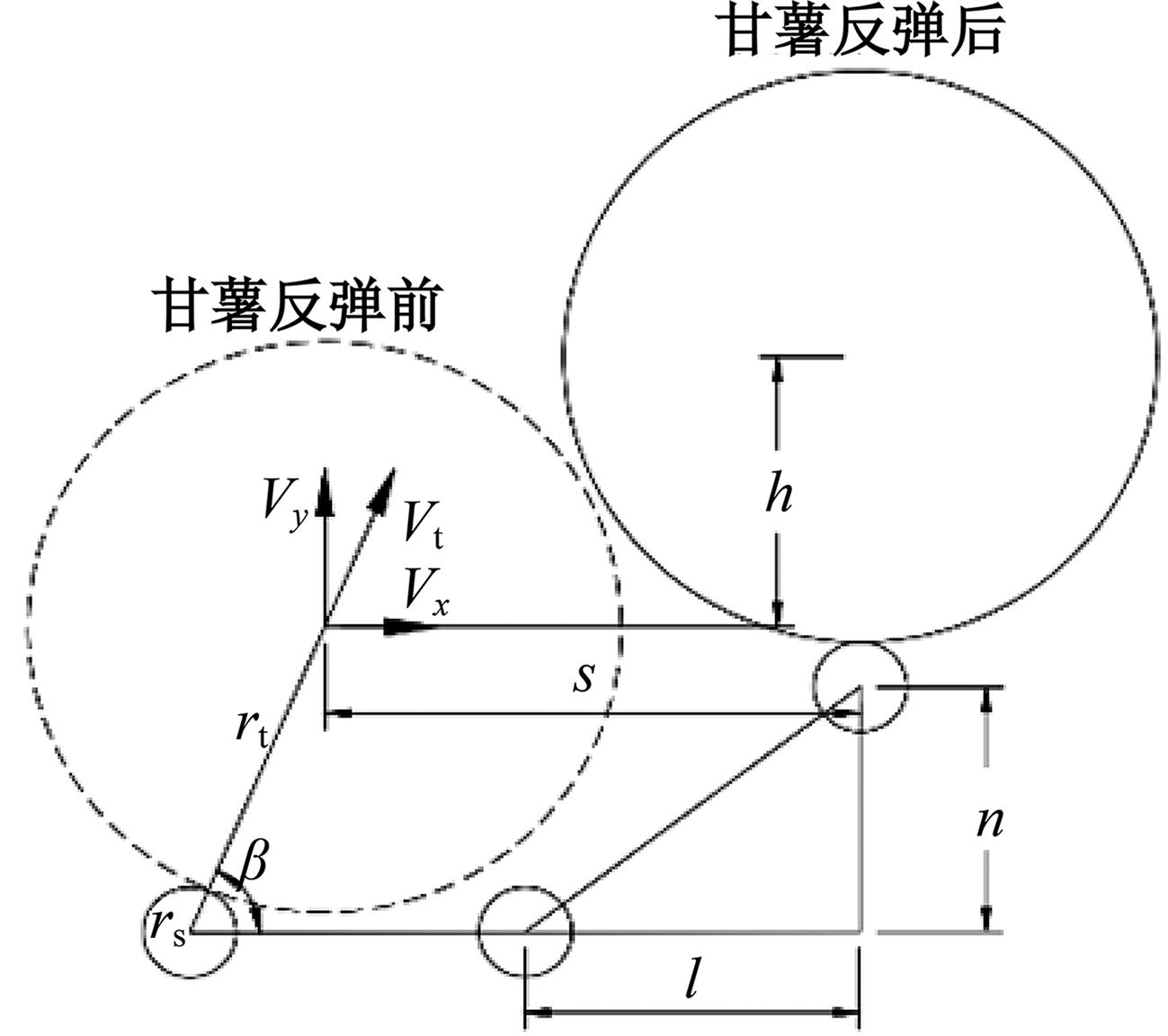

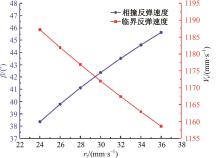

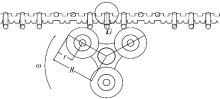

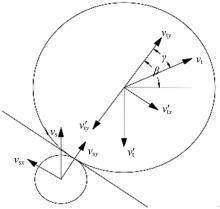

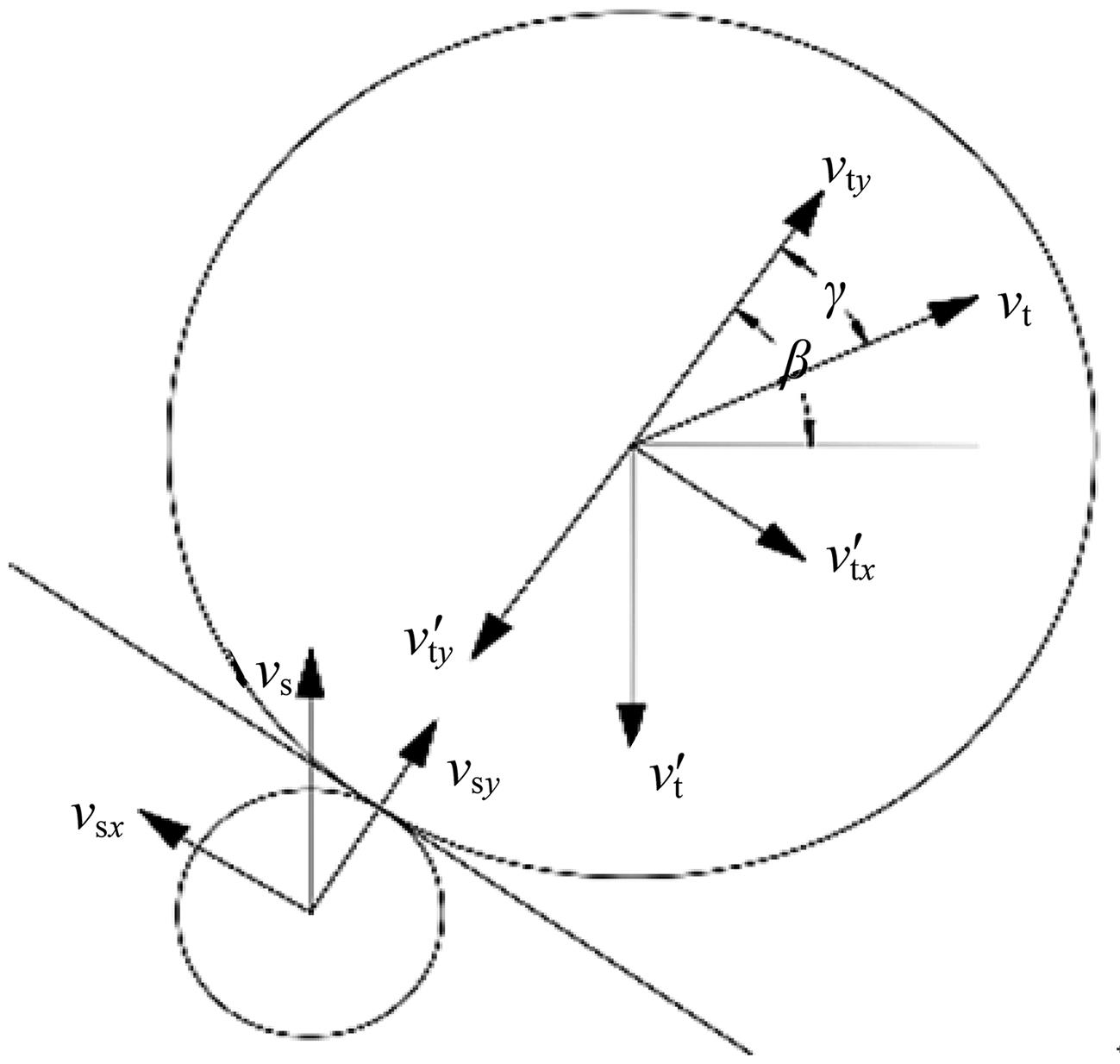

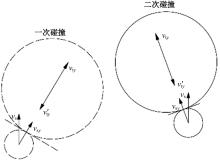

针对甘薯两段式联合收获机作业过程中二级输送分离装置伤薯严重、土薯分离效果差等问题,设计了一种高低间隔式二级输送分离装置。通过结构参数及运动学分析,得出了影响二级输送分离装置作业效果的关键因素,同时确定了各影响因素的取值范围。基于二次正交旋转组合试验,得出了试验指标最佳的因素取值。田间收获试验表明:线速度为0.6 m/s、振动幅度为26.2 mm、振动频率为6.6 Hz时,伤薯率为0.797%、去土率为74.839%。研究结果可为甘薯两段式联合收获机的结构参数优化提供参考。

中图分类号:

- S225.7

| 1 | Rahmawati N, Sipayung R, Widya R. Analysis of yields quantity and quality of several sweet potatoes genotypes at different harvest ages[J]. Earth and Environmental Science, 2021, 782(4): 42047. |

| 2 | Gakige J K, Gachuri C, Butterbach-Bahl K, et al. Early vine harvesting of dual-purpose sweet potato (Ipomoea batatas) increases feeding quality and total biomass without comprising tuber production[J]. African Journal of Food, Agriculture, Nutrition and Development, 2020, 20(2): 15538-15548. |

| 3 | 张友良,汪兆辉,冯绍元,等. 覆膜滴灌条件下滴灌湿润比和施氮量对甘薯生长的影响[J]. 农业机械学报, 2021, 52(7): 261-270. |

| Zhang You-liang, Wang Zhao-hui, Feng Shao-yuan, et al. Effects of soil wetted percentages and nitrogen fertilizations on sweet potato growth under drip irrigation with film mulching[J]. Transactions of the Chinese Society of Agricultural Machinery, 2021, 52(7): 261-270. | |

| 4 | 俞国红,郑航,薛向磊. 自适应仿形甘薯削皮机优化设计与试验[J]. 农业机械学报, 2021, 52(3): 135-142. |

| Yu Guo-hong, Zheng Hang, Xue Xiang-lei. Optimization design and experiment of auto-adaptive profiling sweet potato peeler[J]. Transactions of the Chinese Society of Agricultural Machinery, 2021, 52(3): 135-142. | |

| 5 | 王欣,李强,曹清河,等. 中国甘薯产业和种业发展现状与未来展望[J]. 中国农业科学, 2021, 54(3): 483-492. |

| Wang Xin, Li Qiang, Cao Qing-he, et al. Current status and future prospective of sweetpotato production and seed industry in China [J]. Scientia Agricultura Sinica, 2021, 54(3): 483-492. | |

| 6 | 殷元元,王政增,杨然兵,等. 马铃薯收获机输送链仿真分析与参数优化[J]. 农业工程, 2020, 10(10): 79-83. |

| Yin Yuan-yuan, Wang Zheng-zeng, Yang Ran-bing, et al. Simulation analysis and parameter optimization of potato harvester conveyor Chain[J]. Agricultural Engineering, 2020, 10(10): 79-83. | |

| 7 | 王冰,胡志超,胡良龙,等. 甘薯联合收获机的研究现状及发展[J]. 江苏农业科学, 2018, 46(4): 11-16. |

| Wang Bing, Hu Zhi-chao, Hu Liang-long, et al. Research status and development of sweet potato combine harvester[J]. Jiangsu Agricultural Sciences, 2018, 46(4): 11-16. | |

| 8 | 张子瑞,刘贵明,李禹红. 国内外甘薯收获机械发展概况[J]. 农业工程, 2015, 5(3): 13-15. |

| Zhang Zi-rui, Liu Gui-ming, Li Yu-hong. Development situation of sweet potato harvester at home and abroad[J]. Agricultural Engineering, 2015, 5(3): 13-15. | |

| 9 | 申海洋,王冰,胡良龙,等. 4UZL-1型甘薯联合收获机薯块交接输送机构设计[J]. 农业工程学报, 2020, 36(17): 9-17. |

| Shen Hai-yang, Wang Bing, Hu Liang-long, et al. Design of potato connecting and conveying mechanism for 4UZL-1 type sweet potato combine harvester [J]. Transactions of the Chinese Society of Agricultural Engineering, 2020, 36(17): 9-17. | |

| 10 | 申海洋,王公仆,胡良龙,等. 4UZL-1型甘薯联合收获机刮板链提升机构设计与台架试验[J]. 中国农机化学报, 2021, 42(9): 7-17. |

| Shen Hai-yang, Wang Gong-pu, Hu Liang-long, et al. Design and bench test of scraper chain lifting mechanism of 4UZL-1 sweet potato combine harvester[J]. Journal of Chinese Agricultural Mechanization, 2021, 42(9): 7-17. | |

| 11 | 刘承龙. 甘薯联合收获输送分离装置设计及损伤规律研究[D]. 泰安: 山东农业大学机械电子工程学院, 2021. |

| Liu Cheng-long. Study on design and damage law of sweet potato combine harvester[D]. Taian: College of Mechanical and Electronic Engineering, Shandong Agricultural University, 2021. | |

| 12 | 吕金庆,田忠恩,杨颖,等. 4U2A型双行马铃薯挖掘机的设计与试验[J]. 农业工程学报, 2015, 31(6): 17-24. |

| Lv Jin-qing, Tian Zhong-en, Yang Ying, et al. Design and experimental analysis of 4U2A type double-row potato digger [J]. Transactions of the Chinese Society of Agricultural Engineering, 2015, 31(6): 17-24. | |

| 13 | 孙贺. 升运链式马铃薯挖掘机输送分离装置的设计与试验研究[D]. 哈尔滨: 东北农业大学工程学院, 2019. |

| Sun He. Design and experimental research on transporting and separating device of lifting chain potato digger [D]. Harbin: College of Engineering, Northeast Agricultural University, 2019. | |

| 14 | 高国华,谢海峰,李博文,等. 甘薯跌落碰撞损伤试验研究与分析[J]. 中国农机化学报, 2019, 40(9): 85-90. |

| Gao Guo-hua, Xie Hai-feng, Li Bo-wen, et al. Experimental study and analysis on collision damage of sweet potato in drop[J]. Journal of Chinese Agricultural Mechanization, 2019, 40(9): 85-90. | |

| 15 | 胡奔. 马铃薯跌落损伤机理与防损伤装置研究[D]. 成都: 西华大学机械工程学院, 2018. |

| Hu Ben. Study on potato dropping damage mechanism and damage-proof device[D]. Chengdu: School of Mechanical Engineering, Xihua University, 2018. | |

| 16 | 李东波,刘莉莎,周全卢,等. 四川丘陵地区适宜机械化甘薯新品种筛选[J]. 安徽农业科学, 2021, 49(8): 30-31. |

| Li Dong-bo, Liu Li-sha, Zhou Quan-lu, et al. Selection of new varieties of sweet potato suitable mechanization in hilly areas of Sichuan Province[J]. Journal of Anhui Agricultural Sciences, 2021, 49(8): 30-31. | |

| 17 | 吕金庆,孙贺,兑瀚,等. 粘重土壤下马铃薯挖掘机分离输送装置改进设计与试验[J]. 农业机械学报, 2017, 48(11): 146-155. |

| Lv Jin-qing, Sun He, Han Dui, et al. Design and experiment on conveyor separation device of potato digger under heavy soil condition[J]. Transactions of the Chinese Society for Agricultural Machinery, 2017, 48(11): 146-155. | |

| 18 | 葛大萌. 马铃薯收获与残膜回收联合作业机的设计[D]. 泰安: 山东农业大学机械电子工程学院, 2016. |

| Ge Da-meng. Design of the potato recovery and plastic film collector combined operating machine[D]. Taian: College of Mechanical and Electronic Engineering, Shandong Agricultural University, 2016. | |

| 19 | 张德学,秦喜田,梁荣庆,等. 一种定量堆放式马铃薯收获机的研制[J]. 农机化研究, 2019, 41(12): 74-79. |

| Zhang De-xue, Qin Xi-tian, Liang Rong-qing, et al. Design of a quantitative stacking type of potato harvester[J]. Journal of Agricultural Mechanization Research, 2019, 41(12): 74-79. | |

| 20 | 程祥勋. 新型甘薯收获机关键装置设计与试验[D]. 泰安: 山东农业大学机械电子工程学院, 2019. |

| Cheng Xiang-xun. Design and experiment of key equipment for new sweet potato harvester[D]. Taian: College of Mechanical and Electronic Engineering, Shandong Agricultural University, 2019. | |

| 21 | 陈小冬. 自走式甘薯联合收获机薯茎分离特性研究与机构优化[D]. 合肥: 安徽农业大学工学院, 2020. |

| Chen Xiao-dong. Study sweet-potato-stalk separation characteristics and structure optimization of in self-propelled sweet potato combine harvester [D]. Hefei: School of Engineering, Anhui Agricultural University, 2020. | |

| 22 | 李涛,周进,徐文艺,等. 4UGS2型双行甘薯收获机的研制[J]. 农业工程学报, 2018, 34(11): 26-33. |

| Li Tao, Zhou Jin, Xu Wen-yi, et al. Development of 4UGS2 type double-row sweet potato harvester [J]. Transactions of the Chinese Society of Agricultural Engineering, 2018, 34(11): 26-33. | |

| 23 | 蔡玉虎. 甘薯收获与秧蔓回收联合作业机的设计与仿真[D]. 泰安: 山东农业大学机械电子工程学院, 2017. |

| Cai Yu-hu. Design and simulation of joint operation of sweet potato harvest and vine recovery[D]. Taian: College of Mechanical and Electronic Engineering, Shandong Agricultural University, 2017. | |

| 24 | 杨小平,魏宏安,赵武云,等. 4U1600型集堆式马铃薯挖掘机设计与试验[J]. 农业机械学报, 2020, 51(6): 83-92. |

| Yang Xiao-ping, Wei Hong-an, Zhao Wu-yun, et al. Design and experiment of 4U 1600 set of pile type potato digger[J]. Transactions of the Chinese Society for Agricultural Machinery, 2020, 51(6): 83-92. | |

| 25 | 韩嫣,屈雪,黄东,等. 甘薯收获环节损失率测算及影响因素分析[J]. 西南农业学报, 2019, 32(6): 1383-1390. |

| Han Yan, Qu Xue, Huang Dong, et al. Harvest loss rate of sweet potato and its influencing factors[J]. Southwest China Journal of Agricultural Sciences, 2019, 32(6): 1383-1390. | |

| 26 | . 马铃薯收获机质量评价技术规范 [S]. |

| 27 | 杨然兵,杨红光,尚书旗,等. 拨辊推送式马铃薯收获机设计与试验[J]. 农业机械学报, 2016, 47(7): 119-126. |

| Yang Ran-bing, Yang Hong-guang, Shang Shu-qi, et al. Design and test of poking roller shoving type potato harvester[J]. Transactions of the Chinese Society for Agricultural Machinery, 2016, 47(7): 119-126. | |

| 28 | 葛宜元,梁秋艳,王桂莲. 试验设计方法与Design-Expert软件应用[M]. 哈尔滨:哈尔滨工业大学出版社, 2015. |

| [1] | 刘元义,于圣洁,胥备,王宪良,宋发成. 基于离散元的设施农业就地翻土犁的研究与试验[J]. 吉林大学学报(工学版), 2024, 54(4): 1153-1165. |

| [2] | 张延安,杜岳峰,孟青峰,栗晓宇,刘磊,朱忠祥. 基于改进遗传算法的湿式离合器压力自适应控制[J]. 吉林大学学报(工学版), 2024, 54(3): 852-864. |

| [3] | 陈学深,熊悦淞,程楠,马旭,齐龙. 自适应振动式稻田株间柔性机械除草性能试验[J]. 吉林大学学报(工学版), 2024, 54(2): 375-384. |

| [4] | 王永烁,康建明,彭强吉,陈英凯,方会敏,牛萌萌,王少伟. 果树株间避障除草机设计与试验[J]. 吉林大学学报(工学版), 2023, 53(8): 2410-2420. |

| [5] | 金小俊,孙艳霞,于佳琳,陈勇. 基于深度学习与图像处理的蔬菜苗期杂草识别方法[J]. 吉林大学学报(工学版), 2023, 53(8): 2421-2429. |

| [6] | 吕锋,李念,冯壮壮,张杨航. 面向用户的个性化产品服务系统协同过滤推介方法[J]. 吉林大学学报(工学版), 2023, 53(7): 1935-1942. |

| [7] | 谢守勇,张小亮,刘凡一,刘军,苑晓亮,刘伟,王鹏. 基于钵苗力学特性取投苗装置动力学分析与试验[J]. 吉林大学学报(工学版), 2023, 53(11): 3293-3304. |

| [8] | 耿端阳,孙延成,王宗源,王其欢,明家锐,杨昊霖,徐海港. 玉米籽粒直收机板齿式脱粒装置设计与试验[J]. 吉林大学学报(工学版), 2023, 53(11): 3281-3292. |

| [9] | 王斌,何丙辉,林娜,王伟,李天阳. 基于随机森林特征选择的茶园遥感提取[J]. 吉林大学学报(工学版), 2022, 52(7): 1719-1732. |

| [10] | 耿端阳,孙延成,牟孝栋,张国栋,姜慧新,朱俊科. 基于差速辊的青贮玉米籽粒破碎仿真试验及优化[J]. 吉林大学学报(工学版), 2022, 52(3): 693-702. |

| [11] | 温昌凯,谢斌,宋正河,韩建刚,杨倩雯. 拖拉机耐久性加速结构试验设计方法[J]. 吉林大学学报(工学版), 2022, 52(3): 703-715. |

| [12] | 王国伟,朱庆辉,于海业,黄东岩. 基于数字化农机装备的青贮饲料可追溯系统[J]. 吉林大学学报(工学版), 2022, 52(1): 242-252. |

| [13] | 耿端阳,牟孝栋,张国栋,王宗源,朱俊科,徐海刚. 小麦联合收获机清选机理分析与优化试验[J]. 吉林大学学报(工学版), 2022, 52(1): 219-230. |

| [14] | 梁方,王德成,尤泳,王光辉,王宇兵,张晓明,冯金奎. 草地切根施肥补播复式改良机设计与试验[J]. 吉林大学学报(工学版), 2022, 52(1): 231-241. |

| [15] | 王新彦,江泉,吕峰,易政洋. 基于参数化模型的零转弯半径割草机侧翻稳定性[J]. 吉林大学学报(工学版), 2021, 51(5): 1908-1918. |

|

||