吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (9): 2697-2707.doi: 10.13229/j.cnki.jdxbgxb.20221420

• 农业工程·仿生工程 • 上一篇

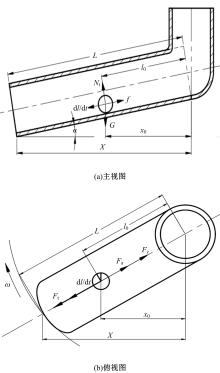

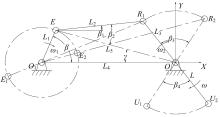

玉米条带摆管式撒肥装置设计及试验

顿国强1,2( ),吴星澎2,纪欣鑫1,2,张福利1,纪文义3,朱礼贵1

),吴星澎2,纪欣鑫1,2,张福利1,纪文义3,朱礼贵1

- 1.哈尔滨剑桥学院 智能农机装备工程实验室,哈尔滨 150069

2.东北林业大学 机电工程学院,哈尔滨 150040

3.东北农业大学 工程学院,哈尔滨 150030

Design and experiment of corn strip swing tube fertilizer spreader

Guo-qiang DUN1,2( ),Xing-peng WU2,Xin-xin JI1,2,Fu-li ZHANG1,Wen-yi JI3,Li-gui ZHU1

),Xing-peng WU2,Xin-xin JI1,2,Fu-li ZHANG1,Wen-yi JI3,Li-gui ZHU1

- 1.Intelligent Agricultural Machinery Equipment Engineering Laboratory,Harbin Cambridge University,Harbin 150069,China

2.College of Mechanical and Electrical Engineering,Northeast Forestry University,Harbin 150040,China

3.College of Engineering,Northeast Agricultural University,Harbin 150030,China

摘要:

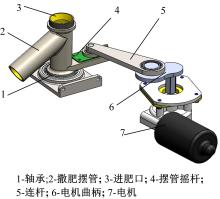

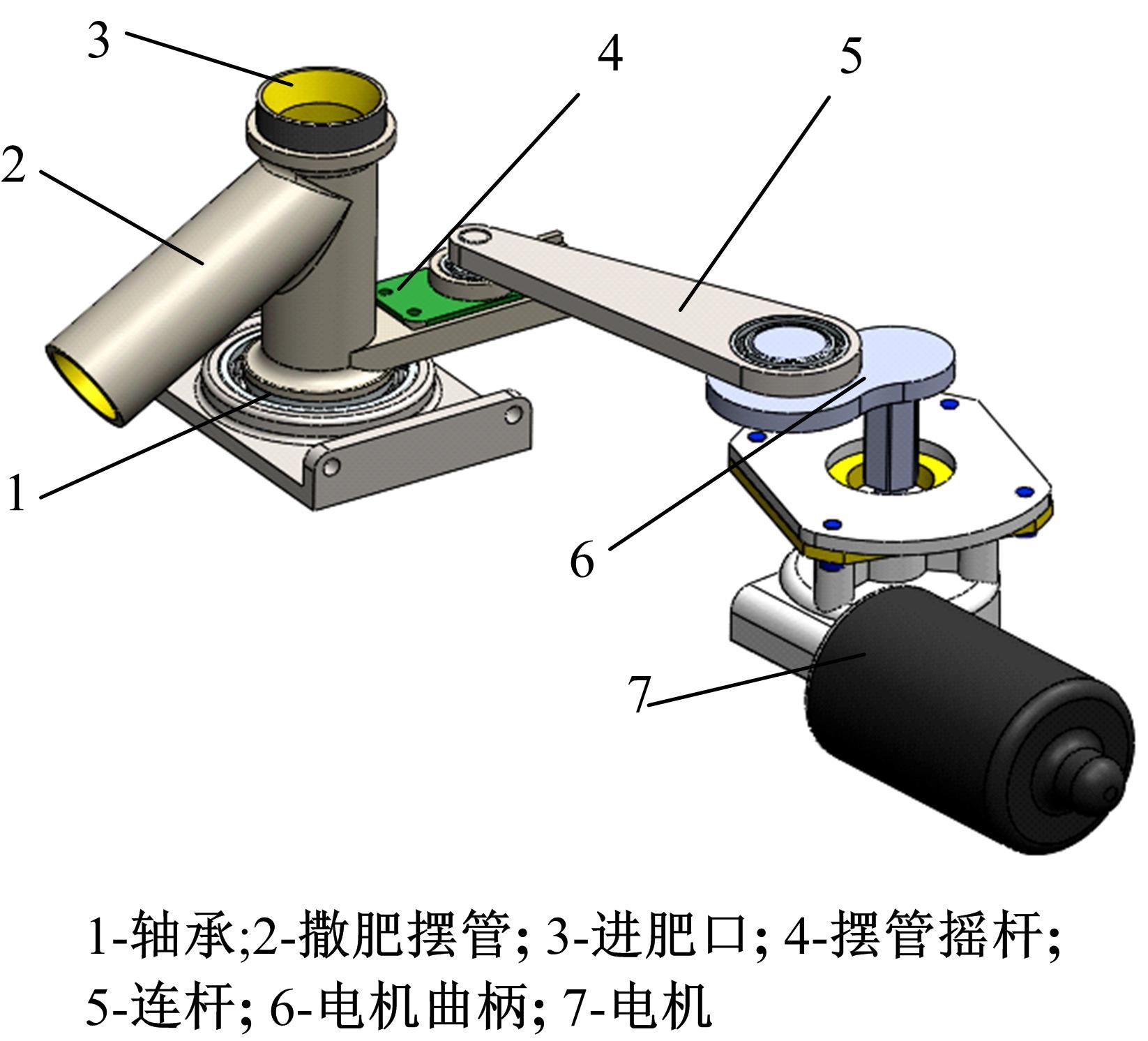

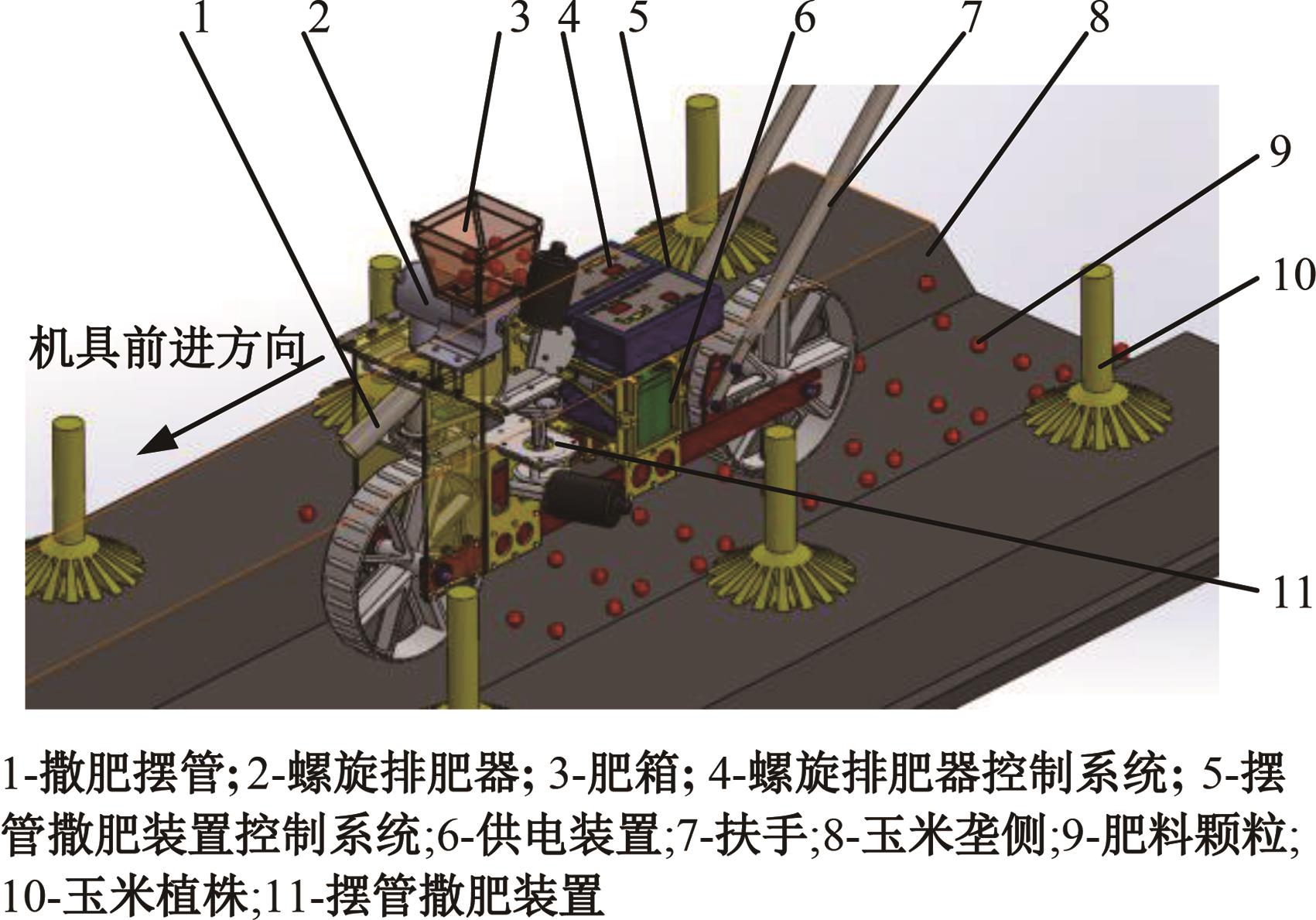

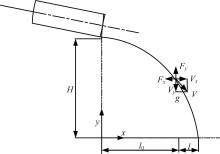

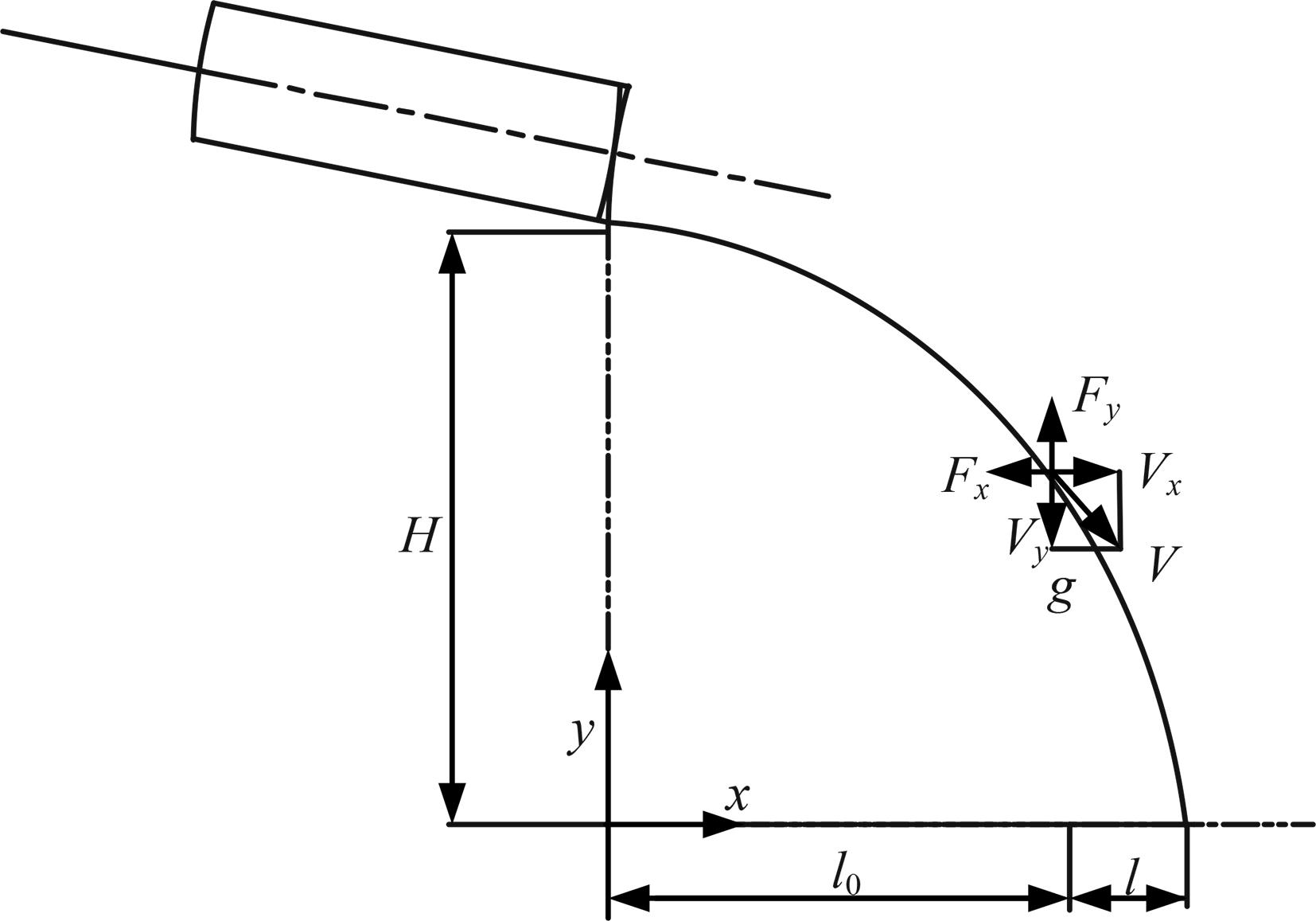

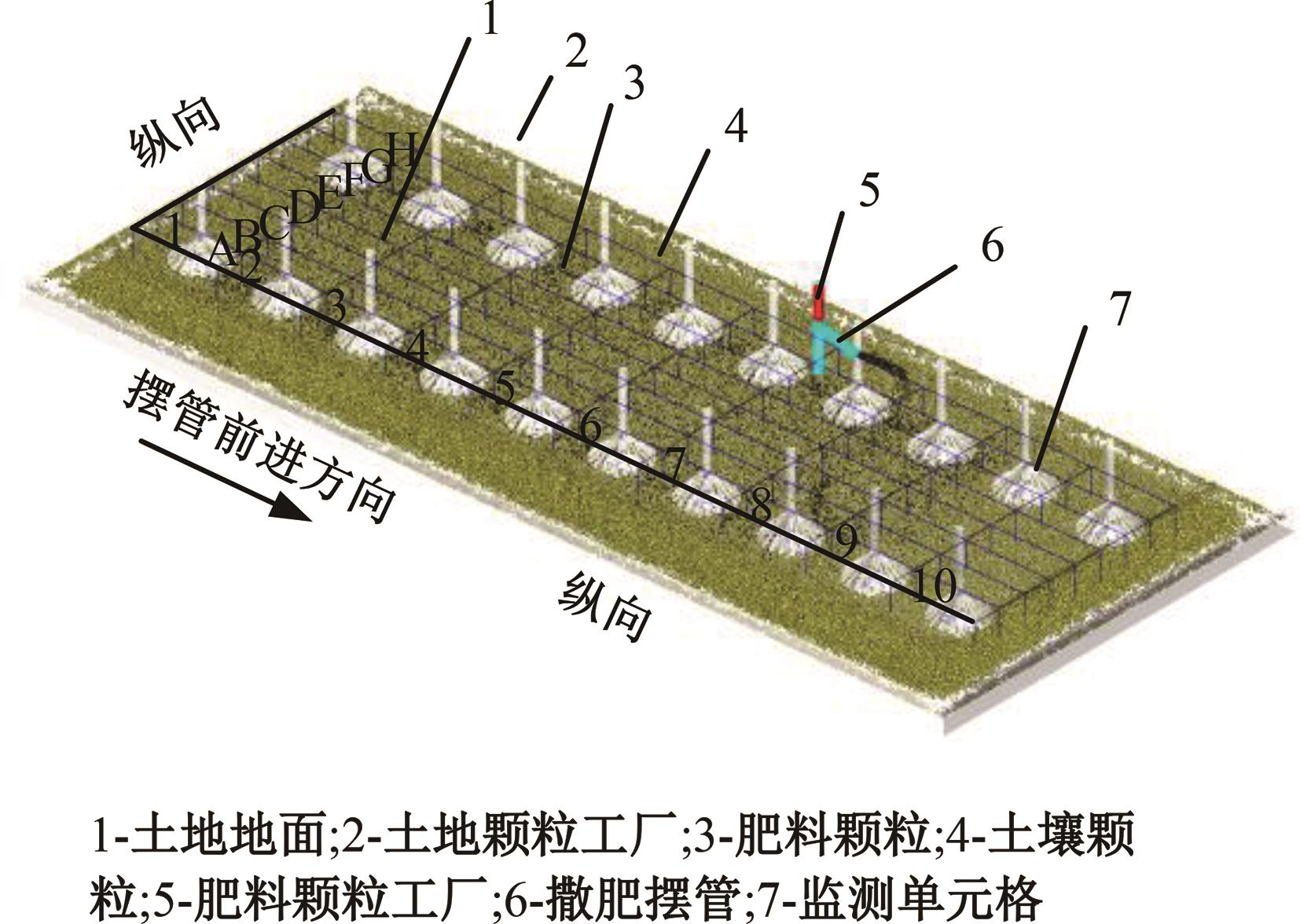

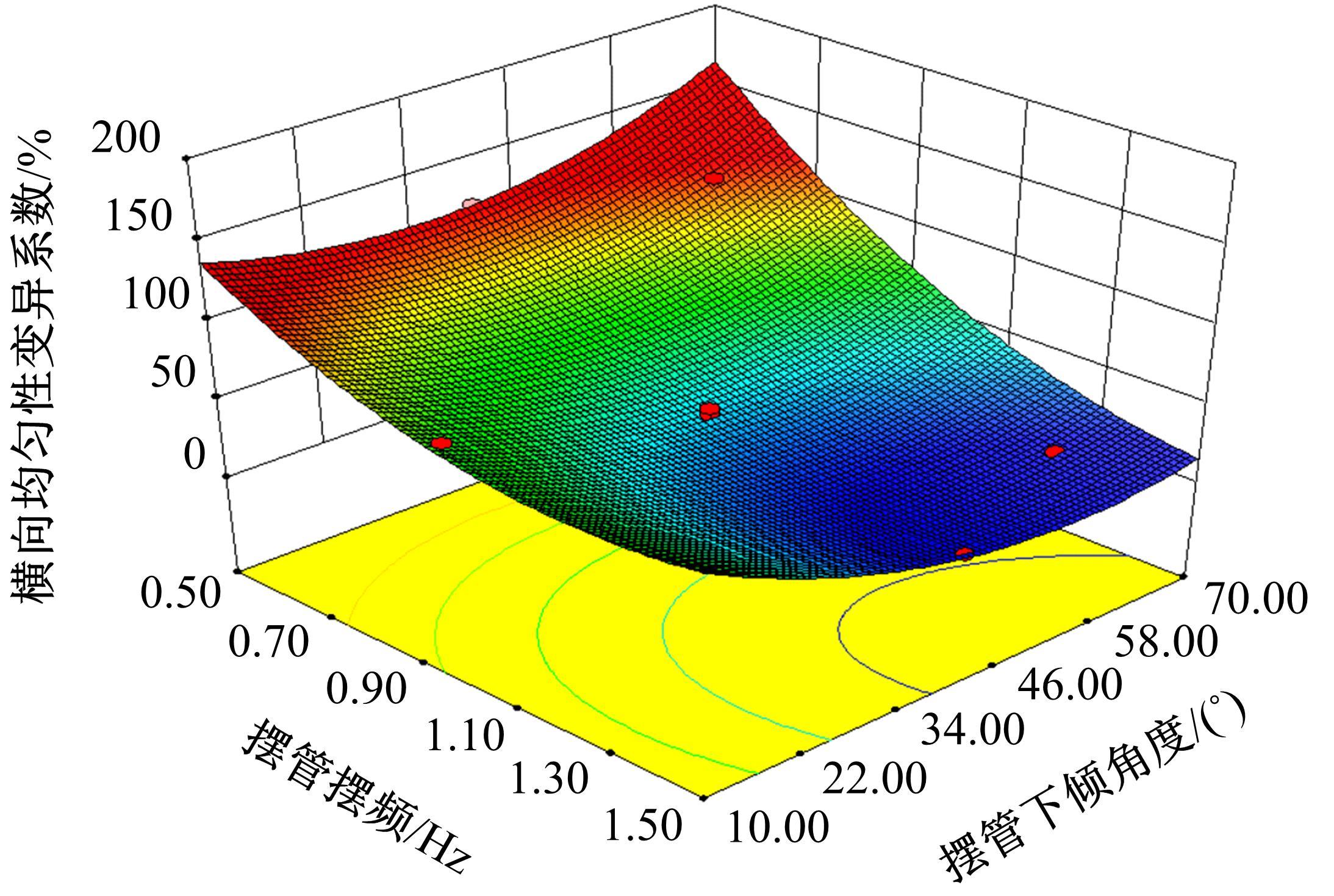

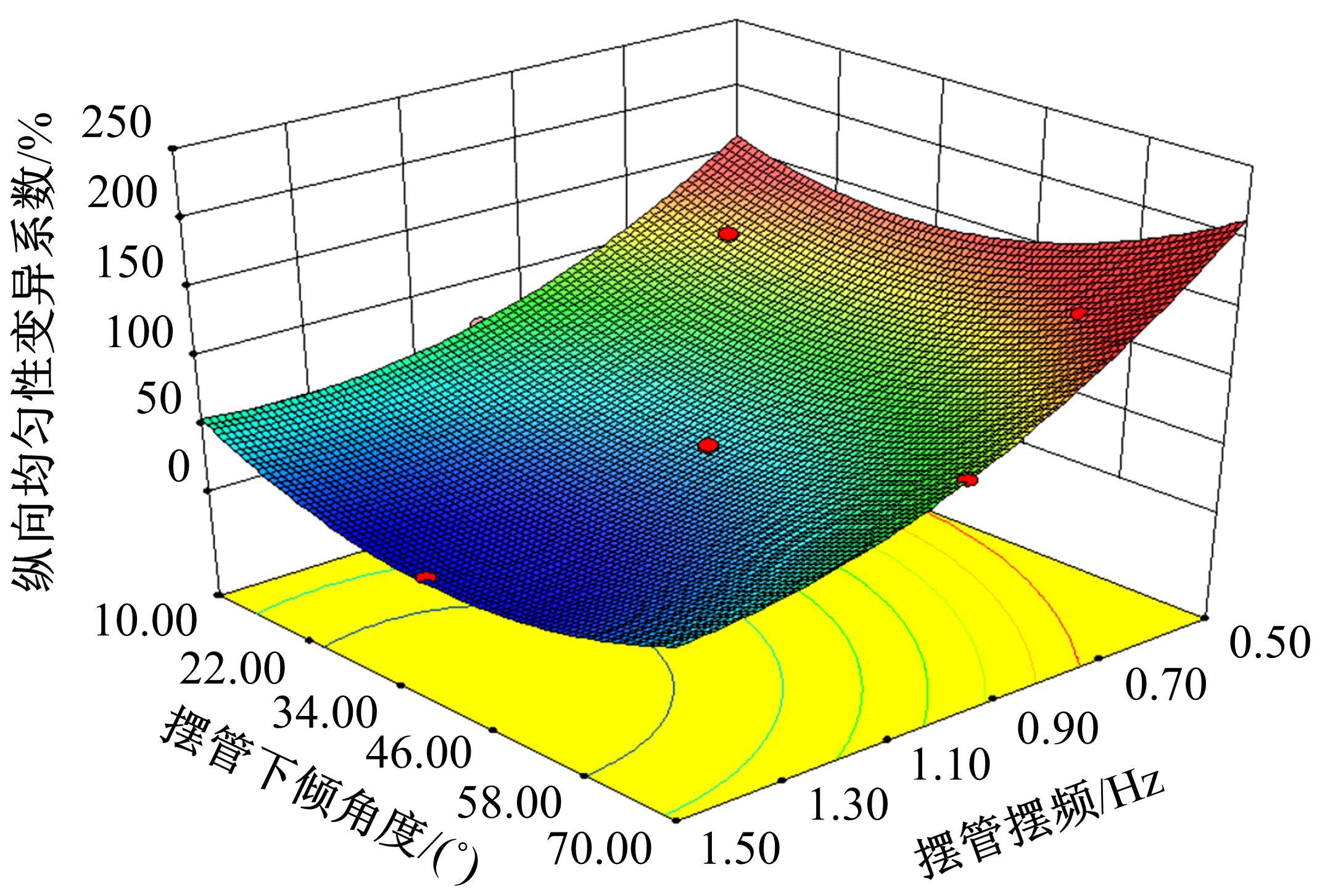

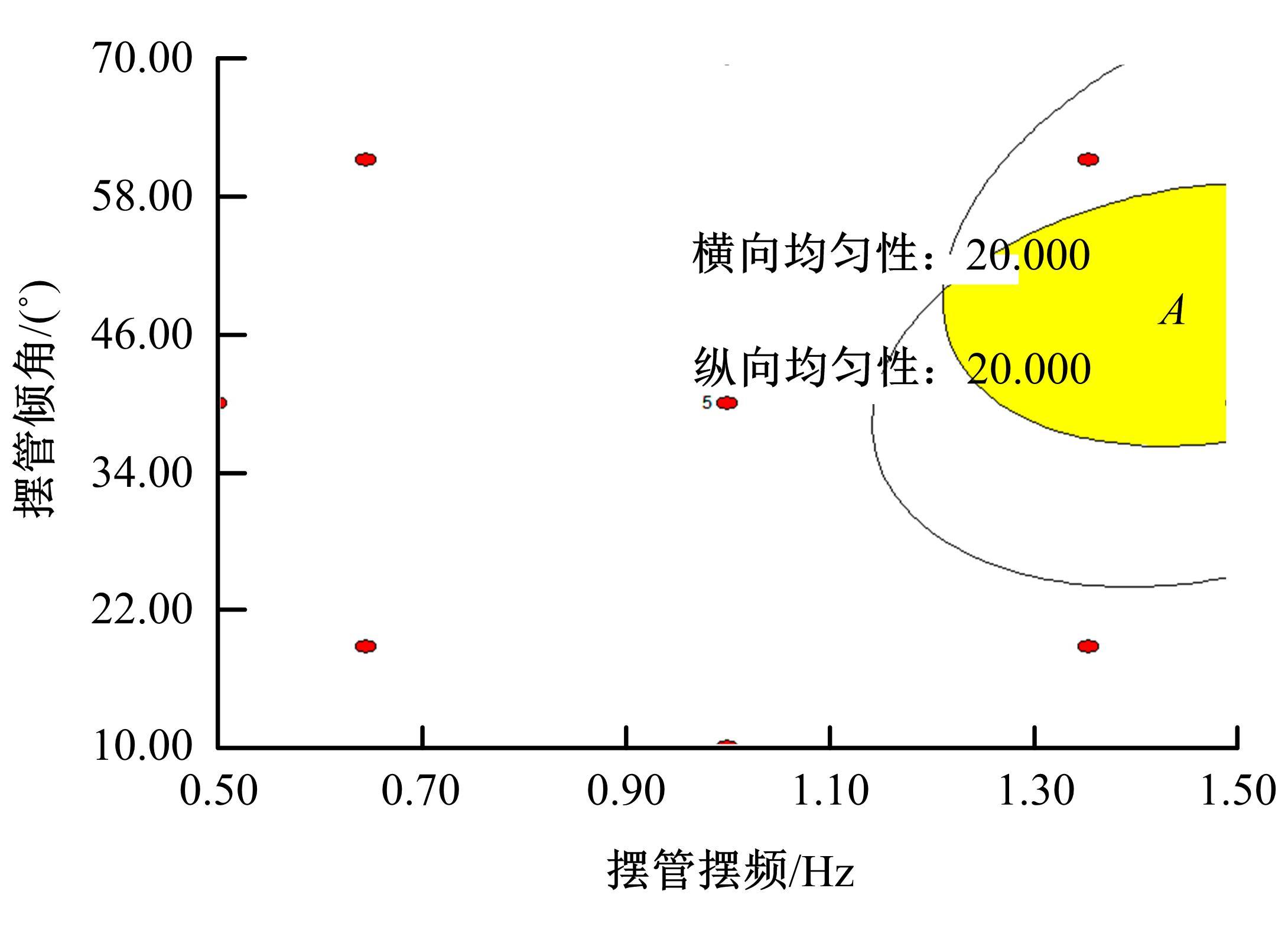

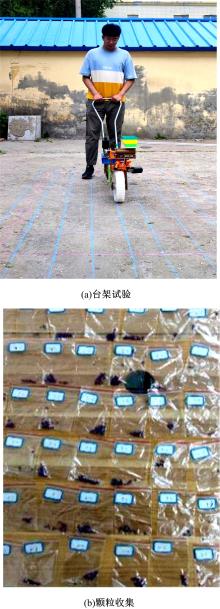

为提高玉米中耕施肥的肥料利用率及撒肥均匀性,设计一种基于无急回特性曲柄摇杆机构控制的摆管撒肥装置,通过理论分析分别确定了四杆机构尺寸及影响撒肥均匀性的主要参数。利用离散元软件EDEM模拟了摆管的摆动撒肥过程,并设计了二因素五水平二次通用旋转组合试验,分析摆管摆频、摆管倾角变化对横、纵撒肥均匀性变异系数的影响。对试验结果优化得出摆管摆频在1.21~1.5 Hz范围内,摆管倾角在36°~59°范围内时,横、纵向均匀性变异系数小于20%。在最优参数组合下进行样机试制及台架试验验证,台架试验与仿真试验的相对误差分别为1.44%、3.13%,试验结果与仿真结果一致,证明摆管撒肥装置可实现精控均匀撒肥,该研究可为摆管撒肥装置的设计提供理论参考。

中图分类号:

- S224.2

| 1 | 张东超, 汤智辉, 何义川, 等.基于EDEM离散元法的分层施肥靴仿真与试验[J]. 农机化研究, 2020,42(2): 146-151. |

| Zhang Dong-chao, Tang Zhi-hui, He Yi-chuan, et al. Simulation and experimen of layered fertilizing boots based on EDEM discrete element method[J]. Journal of Agricultural Mechanization Research, 2020, 42(2): 146-151. | |

| 2 | 杨文武, 方龙羽, 罗锡文, 等.螺旋排肥器排肥口参数对排肥性能影响的试验研究[J].农业工程学报,2020, 36(17): 1-8. |

| Yang Wen-wu, Fang Long-yu, Luo Xi-wen, et al. Experimental study of the effects of discharge port parameters on the fertilizing performance for fertilizer distribution apparatus with screw[J]. Transactions of the Chinese Society of Agricultural Engineering, 2020, 36(17): 1-8. | |

| 3 | 薛忠, 赵亮, 王凤花, 等.基于EDEM的螺旋式排肥器排肥性能研究[J].农机化研究, 2020, 42(6): 87-95. |

| Xue Zhong, Zhao Liang, Wang Feng-hua, et al. Study on the performance of spiral fertilizer distributor based on EDEM[J]. Journal of Agricultural Mechanization Research, 2020, 42(6):87-95. | |

| 4 | 顿国强, 于春玲, 郭艳玲, 等.叠片式啮合圆弧齿轮排肥器设计与仿真试验[J]. 中国农业科技导报,2020, 22(5): 78-85. |

| Guo-qiang Dun, Yu Chun-ling, Guo Yan-ling, et al. Design and simulation test of laminated-type meshing arc gear fertilizer device [J]. Journal of Agricultural Science and Technology,2020,22(5):78-85. | |

| 5 | 施印炎, 陈满, 汪小旵, 等.稻麦精准变量施肥机排肥性能分析与试验[J]. 农业机械学报, 2017, 48(7):97-103. |

| Shi Yin-yan, Chen Man, Wang Xiao-chan, et al. Analysis and experiment of fertilizing performance for precision fertilizer applicator in rice and wheat fields[J]. Transactions of the Chinese Society for Agricultural Machinery, 2017, 48(7): 97-103. | |

| 6 | Coetzee C J, Lombard S G. Discrete element method modelling of a centrifugal fertilizer spreader[J].Biosystems Engineering, 2011, 109(7): 308-325. |

| 7 | 刘宏新, 王佳兴, 苏航, 等.倾斜对置圆盘侧抛式有机肥撒播机设计及关键部件研究[J].东北农业大学学报,2018, 49(8): 83-90, 98. |

| Liu Hong-xin, Wang Jia-xing, Su Hang, et al. Design on side type discharge organic fertilizer spreader with inclined opposite discs and research on its key components[J]. Journal of Northeast Agricultural University, 2018, 49(8): 83-90, 98. | |

| 8 | 张李娴, 吕新民.摆管式撒肥机的研究设计[J].西北农业学报,2009,18(4):372-374. |

| Zhang Li-xian, Lv Xin-min. Research and design on fertilizer spreading machines of swing tube type[J]. Acta Agriculturae Boreali-occidentalis Sinica, 2009,18(4): 372-374. | |

| 9 | 张李娴. 摆管式撒肥机的研究与设计[D]. 杨凌: 西北农林科技大学机械与电子工程学院, 2009. |

| Zhang Li-xian. Research and design on fertilizer spreading machines of swing tube type[D]. Yangling: College of Mechanical and Electronic Engineering,Northwest A&F University, 2009. | |

| 10 | 苟于江,李华英,王大明,等.基于EDEM的小型变量撒肥机设计与仿真优化[J].农机化研究,2022,44(11):65-71, 76. |

| Gou Yu-jiang, Li Hua-ying, Wang Da-ming, et al. Design and simulation parameter optimization of small intelligent variable fertilizer spreader based on EDEM[J]. Journal of Agricultural Mechanization Research, 2022, 44(11): 65-71, 76. | |

| 11 | 李鹏. 摆管式撒肥机机理与试验研究[D].武汉:华中农业大学,2013. |

| Li Peng. Theoretical and experimental study on fertilizer spreading machines of swing tube type[D]. Wuhan: Huazhong Agricultural University, 2013. | |

| 12 | 何亚凯,赵学观,李翠玲,等.玉米追肥机械施肥技术研究现状与分析[J].农机化研究,2021,43(7):1-9. |

| He Ya-kai, Zhao Xue-guan, Li Cui-ling, et al. Research status and analysis on fertilization technology of corn topdressing machinery[J]. Journal of Agricultural Mechanization Research, 2021,43(7):1-9. | |

| 13 | 顿国强, 于春玲, 郭艳玲, 等. 间隙啮合渐开线齿轮排肥器的结构优化仿真及试验[J]. 华中农业大学学报, 2020, 39(1): 171-179. |

| Guo-qiang Dun, Yu Chun-ling, Guo Yan-ling, et al. Optimization simulation and experiment of structure of interval meshing involute meshing involute gear fertilizer apparatus[J]. Journal of Huazhong Agricultural University, 2020,39(1): 171-179. | |

| 14 | 祝清震, 武广伟, 陈立平, 等. 槽轮结构参数对直槽轮式排肥器排肥性能的影响[J]. 农业工程学报, 2018, 34(18): 12-20. |

| Zhu Qing-zhen, Wu Guang-wei, Chen Li-ping, et al.Influences of structure parameters of straight flute wheel on fertilizing performance of fertilizer apparatus[J]. Transactions of the Chinese Society of Agricultural Engineering, 2018, 34(18): 12-20. | |

| 15 | Liu C L, Wang Y L, Song J N, et al. Experimental determination and numerical simulation of granular material restitution coefficient[J]. International Agricultural Engineering Journal, 2016, 25(4): 48-56. |

| 16 | 顿国强, 于春玲, 郭艳玲, 等.双齿轮式排肥器设计与试验[J].农业机械学报,2020,51(3):87-96. |

| Guo-qiang Dun, Yu Chun-ling, Guo Yan-ling, et al. Design and experiment of double-gear type fertilizer apparatus[J]. Transactions of the Chinese Society for Agricultural Machinery,2020,51(3):87-96. | |

| 17 | 顿国强, 刘文辉, 吴星澎, 等. 螺旋挤压式精量排肥器的仿真优化设计及试验[J].吉林大学学报: 工学版, 2023, 53(10): 3026-3037. |

| Guo-qiang Dun, Liu Wen-hui, Wu Xing-peng, et al. Simulation optimization design and experiment of screw extrusion precision fertilizer ejector[J]. Journal of Jilin University (Engineering and Technology Edition), 2023, 53(10): 3026-3037. | |

| 18 | 刘宏新, 杜春利, 尹林伟, 等. 倾斜对置圆盘有机肥侧抛射流形态与控制研究[J]. 农业机械学报,2022, 53(1): 168-177. |

| Liu Hong-xin, Du Chun-li, Yin Lin-wei, et al. Shooting flow shape and control of organic fertilizer side throwing on inclined opposite discs[J]. Transactions of the Chinese Society for Agricultural Machinery,2022, 53(1): 168-177. | |

| 19 | 吕金庆, 王泽明, 孙雪松, 等.马铃薯螺旋推进式排肥器研究与试验[J].农机化研究, 2015, 37(6): 194-196, 200. |

| Lv Jin-qing, Wang Ze-ming, Sun Xue-song, et al. Design and experimental study of fFeed screw potato planter propulsion[J]. Journal of Agricultural Mechanization Research, 2015, 37(6): 194-196, 200. | |

| 20 | 刘宇轩, 高志勇, 顿国强, 等. 手扶式三岔条带中耕施肥机的设计与仿真[J].农业装备与车辆工程, 2021, 59(6): 29-32. |

| Liu Yu-xuan, Gao Zhi-yong, Guo-qiang Dun, et al. Design and simulation of walk-behind three-chamber strip cultivating fertilizer applicator[J]. Agricultural Equipment & Vehicle Engineering, 2021, 59(6): 29-32. | |

| 21 | 张睿, 王秀, 赵春江, 等. 链条输送式变量施肥抛撒机的设计与试验[J].农业工程学报, 2012, 28(6): 20-25. |

| Zhang Rui, Wang Xiu, Zhao Chun-jiang, et al. Design and experiment of variable rate fertilizer spreader with conveyor chain[J]. Transactions of the Chinese Society of Agricultural Engineerin,2012,28(6):20-25. | |

| 22 | 刘彩玲, 黎艳妮, 宋建农, 等.基于EDEM的离心甩盘撒肥器性能分析与试验[J].农业工程学报, 2017,33(14): 32-39. |

| Liu Cai-ling, Li Yan-ni, Song Jian-nong, et al. Performance analysis and experiment on fertilizer spreader with centrifugal swing disk based on EDEM[J]. Transactions of the Chinese Society of Agricultural Engineerin,2017,33(14):32-39. | |

| 23 | .Equipment for distributing fertilizers-Test methods-part 2: fertilizer distributors in lines [S]. |

| 24 | Garía-Ramos FJ, Boné A, Vidal M, et al. Application of a 3-D laser scanner for characterizing centrifugal fertiliser spreaders[J]. Biosystems Engineering, 2012, 113(1): 33-41. |

| 25 | 吕金庆,尚琴琴,杨颖,等.锥盘式撒肥装置的性能分析与试验[J].农业工程学报,2016,32(11):16-24. |

| Jin-qing Lyu, Shang Qin-qin, Yang Ying, et al. Performance analysis and experiment on granular fertilizer spreader with cone disc[J]. Transactions of the Chinese Society of Agricultural Engineerin, 2016,32(11): 16-24. |

| [1] | 李玲,杜旭阳,王晶晶,阮晓光,蔡安江. 凸面法兰连接下的螺栓载荷均匀性分析[J]. 吉林大学学报(工学版), 2024, 54(9): 2451-2459. |

| [2] | 谢朋书,崔达,王国强,李凯. 基于离散元方法的立式螺旋搅拌磨机工作性能[J]. 吉林大学学报(工学版), 2024, 54(9): 2423-2431. |

| [3] | 余萍,赵康,曹洁. 基于优化A-BiLSTM的滚动轴承故障诊断[J]. 吉林大学学报(工学版), 2024, 54(8): 2156-2166. |

| [4] | 舒彩霞,杨佳,廖庆喜,万星宇,袁佳诚. 油菜联合收获导流式双筒旋风分离清选装置设计及试验[J]. 吉林大学学报(工学版), 2024, 54(6): 1807-1820. |

| [5] | 孙雅珍,薛博欣,孙岩,王志臣,潘嘉伟. 考虑非均匀性的沥青混合料开裂行为细观模拟[J]. 吉林大学学报(工学版), 2024, 54(6): 1708-1718. |

| [6] | 赵晓康,胡哲,牛振兴,张久鹏,裴建中,温永. 基于非均质模型的水稳碎石材料细观开裂行为[J]. 吉林大学学报(工学版), 2024, 54(5): 1258-1266. |

| [7] | 张国忠,丁凯权,李正博,陈龙,唐楠锐,刘婉茹,黄海东,周勇,王洪昌. 基于泥鳅体表的水稻直播机仿生滑板设计与试验[J]. 吉林大学学报(工学版), 2024, 54(5): 1482-1492. |

| [8] | 李房云,夏容,张怡欣. 考虑电池荷电状态的混合动力汽车复合电源协同控制[J]. 吉林大学学报(工学版), 2024, 54(4): 1114-1119. |

| [9] | 张伏,娄立民,钱丹,王世强,冯春凌,赵一荣. 大方捆打捆机压缩机构优化设计及试验[J]. 吉林大学学报(工学版), 2024, 54(4): 1166-1174. |

| [10] | 周鹏飞,陈学庚,蒙贺伟,梁荣庆,张炳成,坎杂. 滚筒式机收膜杂除土装置设计及试验[J]. 吉林大学学报(工学版), 2023, 53(9): 2718-2731. |

| [11] | 刘伟健,罗锡文,曾山,文智强,曾力. 履带式再生稻收获机田间转弯机理和性能试验[J]. 吉林大学学报(工学版), 2023, 53(9): 2695-2705. |

| [12] | 张茂健,金敬福,陈奕颖,陈廷坤. 轮式拖拉机对称结构的振动特性[J]. 吉林大学学报(工学版), 2023, 53(7): 2136-2142. |

| [13] | 司春棣,崔亚宁,许忠印,凡涛涛. 层间粘结失效后桥面沥青铺装层细观力学行为分析[J]. 吉林大学学报(工学版), 2023, 53(6): 1719-1728. |

| [14] | 于贵申,陈鑫,武子涛,陈轶雄,张冠宸. AA6061⁃T6铝薄板无针搅拌摩擦点焊接头结构及性能分析[J]. 吉林大学学报(工学版), 2023, 53(5): 1338-1344. |

| [15] | 朱光强,李天宇,周福君,王文明. 鲜食玉米仿生摘穗装置设计与试验[J]. 吉林大学学报(工学版), 2023, 53(4): 1231-1244. |

|

||