吉林大学学报(工学版) ›› 2020, Vol. 50 ›› Issue (5): 1574-1583.doi: 10.13229/j.cnki.jdxbgxb20190458

• 车辆工程·机械工程 • 上一篇

高温和荷电状态对锂离子电池单体力学响应的耦合影响

高菲1,2( ),肖阳3(

),肖阳3( ),张文华3,祁锦轩3,李子樵3,马骁远3

),张文华3,祁锦轩3,李子樵3,马骁远3

- 1.吉林大学 汽车仿真与控制国家重点实验室, 长春 130022

2.吉林大学 生物与农业工程学院,长春 130022

3.吉林大学 汽车工程学院, 长春 130022

Influence of coupling of elevated temperature and state of charge on mechanical response of Li⁃ion battery cells

Fei GAO1,2( ),Yang XIAO3(

),Yang XIAO3( ),Wen-hua ZHANG3,Jin-xuan QI3,Zi-qiao LI3,Xiao-yuan MA3

),Wen-hua ZHANG3,Jin-xuan QI3,Zi-qiao LI3,Xiao-yuan MA3

- 1.State Key Laboratory of Automotive Simulation and Control, Jilin University, Changchun 130022, China

2.College of Biological and Agricultural Engineering, Jilin University, Changchun 130022, China

3.College of Automotive Engineering, Jilin University, Changchun 130022, China

摘要:

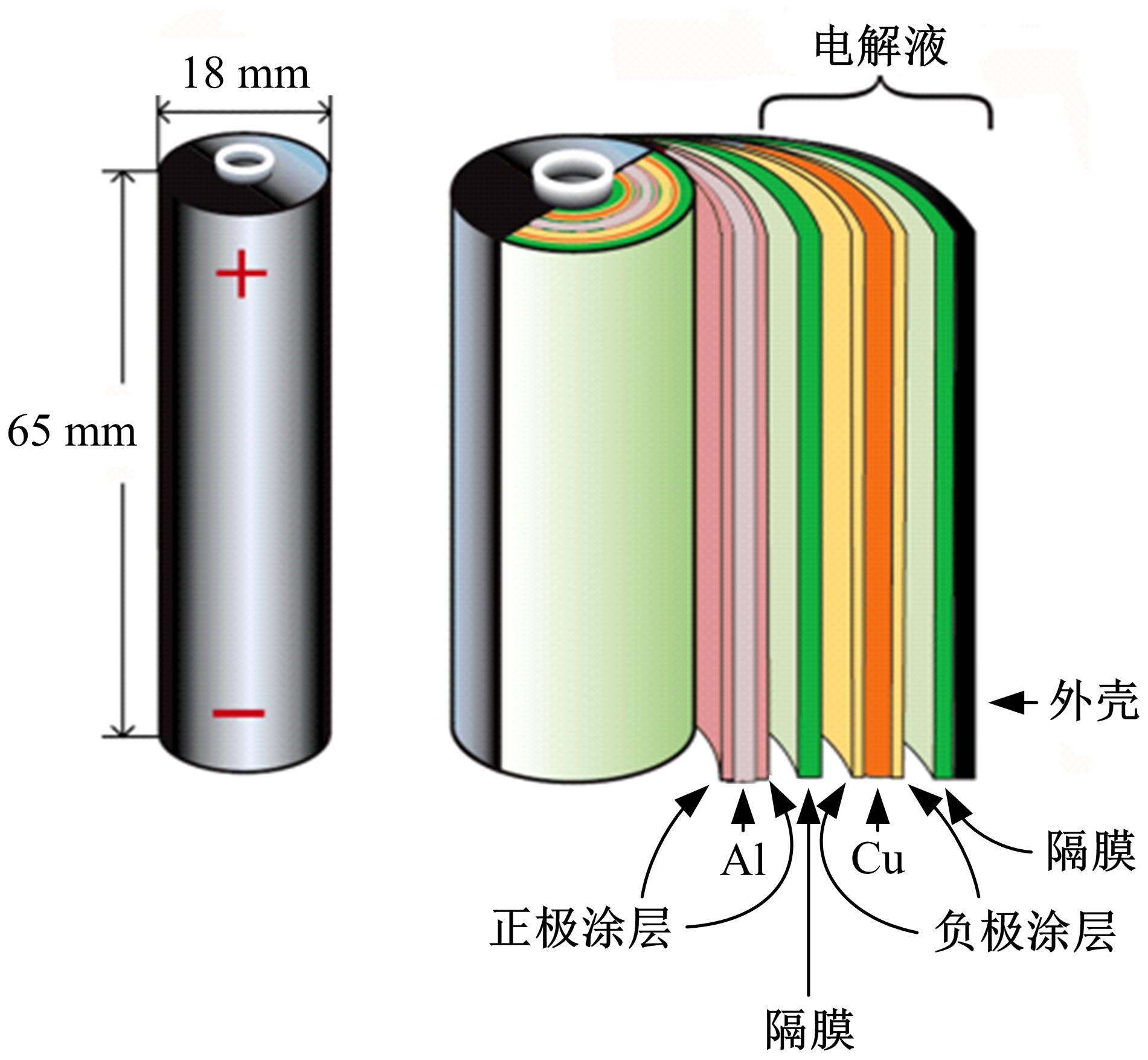

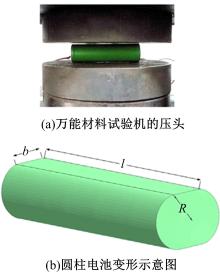

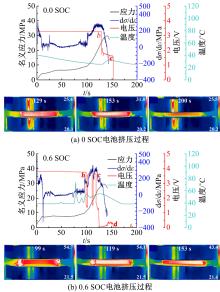

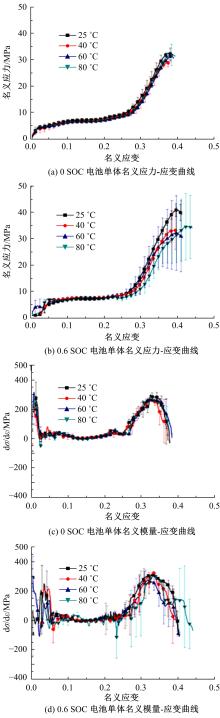

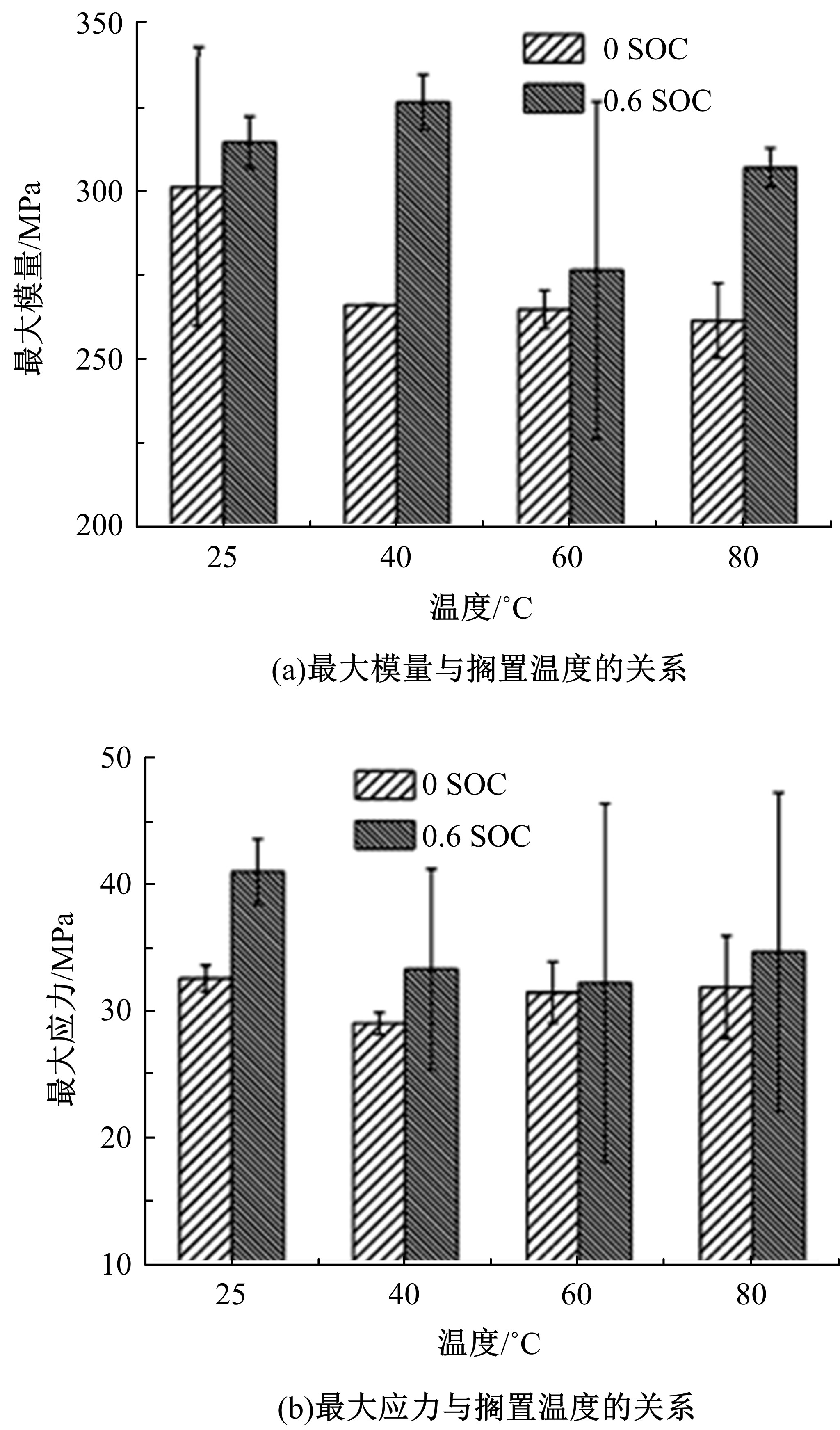

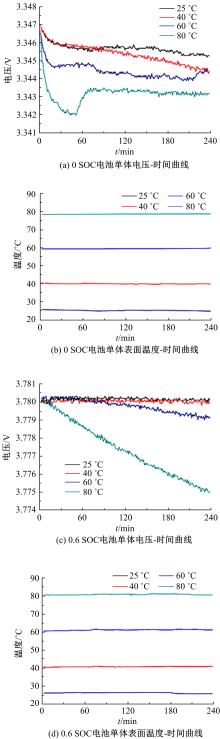

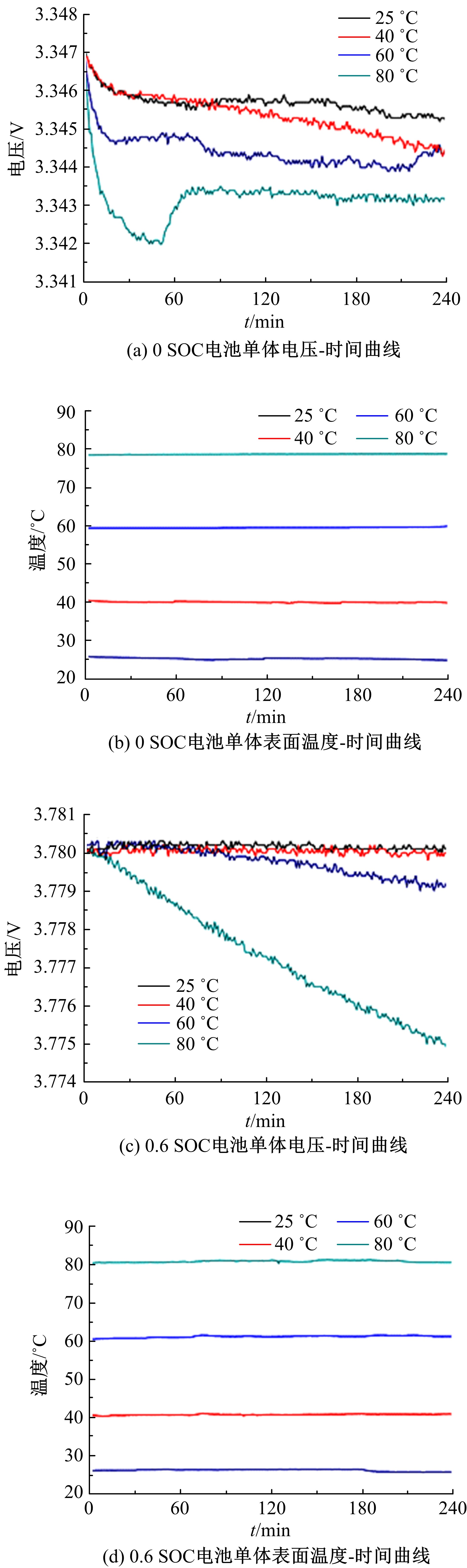

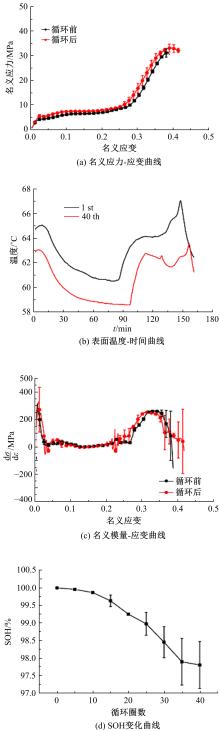

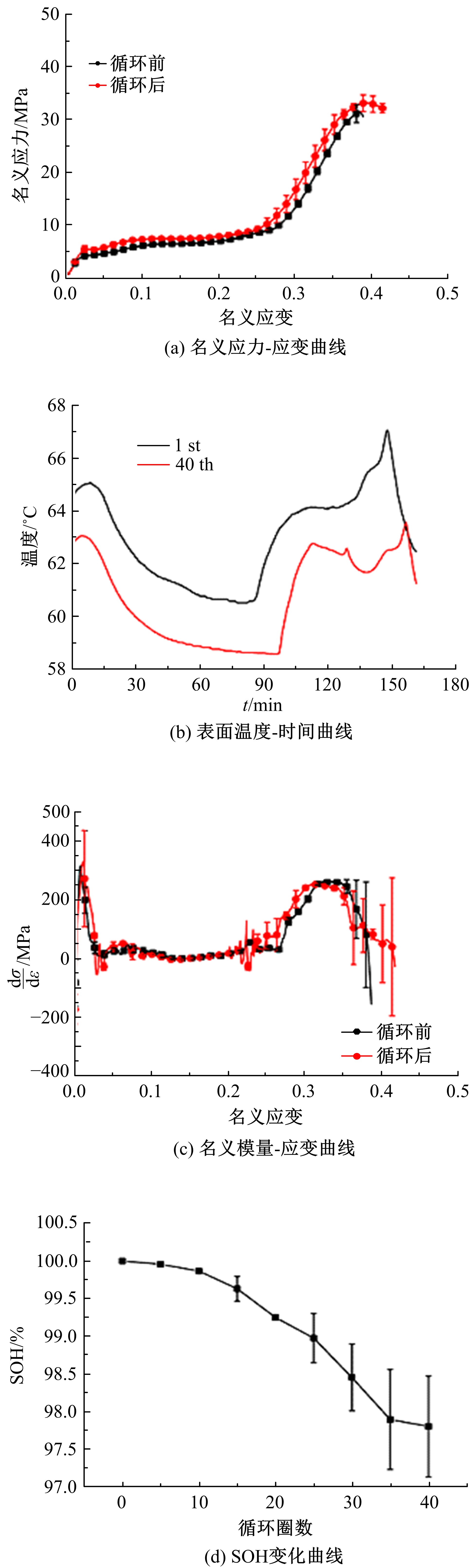

针对锂离子电池机械完整性在高温环境下的研究需求,本文对不同荷电状态(SOC)的圆柱型锂离子电池单体进行高温搁置和高温循环处理,并对处理后的电池单体进行径向挤压试验。试验结果表明:高SOC的电池单体经40 °C以上的高温搁置后受压时往往会因结构软化而提早发生内短路,搁置温度越高电池抗变形能力越低;高温短期循环会提高电池单体的抗变形能力。

中图分类号:

- U41

| 1 | 呙晓兵, 范小平, 刘新军, 等. 磷酸铁锂正极锂离子电池的高温循环性能[J]. 电池, 2013, 43(1): 35-37. |

| Guo Xiao-bing, Fan Xiao-ping, Liu Xin-jun, et al. High temperature cycle performance of lithium iron phosphate cathode Li-ion battery[J]. Battery Bimonthly, 2013, 43(1): 35-37. | |

| 2 | 何鹏林. 锂离子电池高温使用安全测试研究[J]. 安全与电磁兼容, 2012(3): 18-20. |

| He Peng-lin. Research on safety test of high temperature for Li-ion battery[J]. Safety & EMC, 2012(3): 18-20. | |

| 3 | Andersson A M, Edstrom K, Rao N, et al. Temperature dependence of the passivation layer on graphite[J]. Journal of Power Sources, 1999, 81/82: 286-290. |

| 4 | Sloop S E, Pugh J K, Kerr J B, et al. Chemical reactivity of PF5 and LiPF6 in ethylene carbonate/dimethyl carbonate solutions[J]. Electrochemical and Solid State Letters, 2001, 4(4): 357-364. |

| 5 | Lin X R, Salari M, Arava L M R, et al. High temperature electrical energy storage: advances, challenges, and frontiers[J]. Chemical Society Reviews, 2016, 45(21): 5848-5887. |

| 6 | 邢海霞. 锂离子电池高温存储性能的影响因素和机理研究[D]. 上海: 上海复旦大学化学系, 2014. |

| Xin Hai-xia. Study on the influence factors and mechanisms of Li-ion battery during high temperature storage[D]. Shanghai: Department of Chemistry, Fudan University, 2014. | |

| 7 | 范光辉, 余剑武, 罗红, 等. 混合动力汽车电池性能影响因素分析与试验[J]. 吉林大学学报: 工学版, 2019, 49(5): 1451-1458. |

| Fan Guang-hui, Yu Jian-wu, Luo Hong, et al. Influencing factors analysis and experimental study of battery performances in hybrid electric vehicle[J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(5): 1451-1458. | |

| 8 | 陈吉清, 刘蒙蒙, 兰凤崇. 三元动力电池及其成组后的过充安全性试验[J]. 吉林大学学报: 工学版, 2019, 49(4): 1072-1080. |

| Chen Ji-qing, Liu Meng-meng, Lan Feng-chong. Experiment on overcharge safety of NCM battery and battery pack[J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1072-1080. | |

| 9 | Avdeev I V, Martinsen M J, Francis A B. Materials testing of a lithium ion battery separator for use in finite element analysis[C]∥ASME International Mechanical Engineering Congress and Exposition, Houston, Texas, USA, 2012: 475-481. |

| 10 | Lin Y C, Chen X M. A critical review of experimental results and constitutive descriptions for metals and alloys in hot working[J]. Materials & Design, 2011, 32(4): 1733-1759. |

| 11 | 刘琨, 祖敏辉. PEBA/PVDF复合膜的溶胀及渗透汽化性能研究[J]. 膜科学与技术, 2010, 30(1): 60-64. |

| Liu Kun, Zu Min-hui. Study on swelling and pervaporation behavior of PEBA/PVDF composite membrane[J]. Membrane Science and Technology, 2010, 30(1): 60-64. | |

| 12 | 吴正国, 张剑波, 李哲, 等. 锂离子电池加速老化温度应力的滥用边界[J]. 汽车安全与节能学报, 2018, 9(1): 99-109. |

| Wu Zheng-guo, Zhang Jian-bo, Li Zhe, et al. Aging abuse boundary of lithium-ion cell above room temperature[J]. Journal of Automotive Safety and Energy, 2018, 9(1): 99-109. | |

| 13 | Taniguchi S, Shironita S, Konakawa K, et al. Thermal characteristics of 80 °C storage-degraded 18650-type lithium-ion secondary cells[J]. Journal of Power Sourses, 2019, 416: 148-154. |

| 14 | Yayathi S, Walker W, Doughty D, et al. Energy distributions exhibited during thermal runaway of commercial lithium ion batteries used for human spaceflight applications[J]. Journal of Power Sources, 2016, 329: 197-206. |

| 15 | 端方勇, 陈亮. 内外饰颜色对车辆暴晒后车内温度影响的研究[J]. 汽车实用技术, 2017(12): 129-131. |

| Duan Fang-yong, Chen Liang. Study on the influence of interior and exterior color on vehicle temperature after exposure[J]. Automobile Applied Technology, 2017(12): 129-131. | |

| 16 | 闵磊, 仲昭佩. 汽车暴晒试验方法的探讨[J]. 吐鲁番科技, 2010(3): 36-39. |

| Min Lei, Zhong Zhao-pei. Discussion on the test method of automobile exposure[J]. Turpan Technology, 2010(3): 36-39. | |

| 17 | Avdeev I, Gilaki M. Structural analysis and experimental characterization of cylindrical lithium-ion battery cells subject to lateral impact[J]. Journal of Power Sources, 2014, 271: 382-391. |

| 18 | Xu J, Liu B, Wang X, et al. Computational model of 18650 lithium-ion battery with coupled strain rate and SOC dependencies[J]. Applied Energy, 2016, 172: 180-189. |

| 19 | Greve L, Fehrenbach C. Mechanical testing and macro-mechanical finite element simulation of the deformation, fracture, and short circuit initiation of cylindrical Lithium ion battery cells[J]. Journal of Power Sources, 2012, 214: 377-385. |

| 20 | Cannarella J, Liu X, Leng C Z, et al. Mechanical properties of a battery separator under compression and tension[J]. Journal of The Electrochemical Society, 2014, 161(11): 3117-3122. |

| 21 | Gao Z, Zhang X, Xiao Y, et al. Influence of coupling of overcharge state and short-term cycle on the mechanical integrity behavior of 18650 Li-ion batteries subject to lateral compression[J]. International Journal of Hydrogen Energy, 2018, 43(10): 5261-5271. |

| 22 | Gao Z, Zhang X, Xiao Y, et al. Influence of low-temperature charge on the mechanical integrity behavior of 18650 lithium-ion battery cells subject to lateral compression[J]. Energies, 2019, 12(5): 797-813. |

| 23 | Wierzbicki T, Sahraei E. Homogenized mechanical properties for the jellyroll of cylindrical lithium-ion cells[J]. Journal of Power Sources, 2013, 241: 467-476. |

| 24 | Kisters T, Sahraei E, Wierzbicki T. Dynamic impact tests on lithium-ion cells[J]. International Journal of Impact Engineering, 2017, 108: 205-216. |

| 25 | Leng F, Tan C M, Pecht M. Effect of temperature on the aging rate of Li-ion battery operating above room temperature[J]. Scientific Reports, 2015, 5: 1-12. |

| 26 | Xu J, Liu B H, Hu D Y. State of charge dependent mechanical integrity behavior of 18650 lithium-ion batteries[J]. Scientific Reports, 2016(6): 1-11. |

| 27 | Gao Z H, Zhang X T, Hu H Y, et al. Influencing factors of low-and high-temperature behavior of Co-doped Zn2SnO4-graphene-carbon nanocomposite as anode material for lithium-ion batteries[J]. Journal of Electroanalytical Chemistry, 2017, 791: 56-63. |

| 28 | Andersson A M, Edstrom K. Chemical composition and morphology of the elevated temperature SEI on graphite[J]. Journal of the Electrochemical Society, 2001, 148(10): 1100-1109. |

| 29 | 杜国栋, 努丽燕娜, 冯真真, 等. LiNi0.5Mn1.5O4-xFx高电压电极高温保存下的电化学行为[J]. 物理化学学报, 2008, 24(1): 165-170. |

| Du Guo-dong, Yan-na Nuli, Feng Zhen-zhen, et al. Electrochemical behavior of high-voltage LiNi0.5Mn1.5O4-xFx electrodes at elevated storage temperature[J]. Acta Physico-Chimica Sinica, 2008, 24(1): 165-170. | |

| 30 | Gomez J, Nelson R, Kalu E E, et al. Equivalent circuit model parameters of a high-power Li-ion battery: Thermal and state of charge effects[J]. Journal of Power Sources, 2011, 196(10): 4826-4831. |

| 31 | Campion C L, Li W T, Lucht B L. Thermal decomposition of LiPF6-based electrolytes for lithium-ion batteries[J]. Journal of the Electrochemical Society, 2005, 152(12): 2327-2334. |

| 32 | Zinigrad E, Larush-Asraf L, Gnanaraj J S, et al. On the thermal stability of LiPF6[J]. Thermochimica Acta, 2005, 438(1/2): 184-191. |

| 33 | Guan T, Sun S, Gao Y Z, et al. The effect of elevated temperature on the accelerated aging of LiCoO2/mesocarbon microbeads batteries[J]. Applied Energy, 2016, 177: 1-10. |

| [1] | 杜常清,曹锡良,何彪,任卫群. 基于混合粒子群算法的双离合变速器参数优化设计[J]. 吉林大学学报(工学版), 2020, 50(5): 1556-1564. |

| [2] | 李静,石求军,洪良,刘鹏. 基于车辆状态估计的商用车ESC神经网络滑模控制[J]. 吉林大学学报(工学版), 2020, 50(5): 1545-1555. |

| [3] | 陈吉清,蓝庆生,兰凤崇,刘照麟. 基于轮胎力预判与拟合的轨迹跟踪控制[J]. 吉林大学学报(工学版), 2020, 50(5): 1565-1573. |

| [4] | 陈鑫,王宁,沈传亮,冯晓,杨昌海. 后视镜造型对前侧窗气动噪声的影响[J]. 吉林大学学报(工学版), 2020, 50(2): 426-436. |

| [5] | 李小雨,许男,仇韬,郭孔辉. 各向异性刚度对轮胎力学特性及车辆操纵性的影响[J]. 吉林大学学报(工学版), 2020, 50(2): 389-398. |

| [6] | 李银平,靳添絮,刘立. 纯电动铲运机弓网续能系统设计与动态特性仿真[J]. 吉林大学学报(工学版), 2020, 50(2): 454-463. |

| [7] | 赖晨光,王擎宇,胡博,文凯平,陈彦宇. 静气动弹性影响下带小翼汽车尾翼的设计与优化[J]. 吉林大学学报(工学版), 2020, 50(2): 399-407. |

| [8] | 叶辉,刘畅,闫康康. 纤维增强复合材料在汽车覆盖件中的应用[J]. 吉林大学学报(工学版), 2020, 50(2): 417-425. |

| [9] | 马芳武,梁鸿宇,赵颖,杨猛,蒲永锋. 内凹三角形负泊松比结构耐撞性多目标优化设计[J]. 吉林大学学报(工学版), 2020, 50(1): 29-35. |

| [10] | 郭孔辉,黄世庆,吴海东. 适用于高频激励的面内轮胎动态模型[J]. 吉林大学学报(工学版), 2020, 50(1): 19-28. |

| [11] | 王哲,谢怡,臧鹏飞,王耀. 基于极小值原理的燃料电池客车能量管理策略[J]. 吉林大学学报(工学版), 2020, 50(1): 36-43. |

| [12] | 史文库,陈龙,张贵辉,陈志勇. 多级刚度双质量飞轮扭转特性建模与试验验证[J]. 吉林大学学报(工学版), 2020, 50(1): 44-52. |

| [13] | 管欣,金号,段春光,卢萍萍. 汽车行驶道路侧向坡度估计[J]. 吉林大学学报(工学版), 2019, 49(6): 1802-1809. |

| [14] | 陈鑫,阮新建,李铭,王宁,王佳宁,潘凯旋. 基于大涡模拟的离散格式改进方法及应用[J]. 吉林大学学报(工学版), 2019, 49(6): 1756-1763. |

| [15] | 马芳武,倪利伟,吴量,聂家弘,徐广健. 轮腿式全地形移动机器人位姿闭环控制[J]. 吉林大学学报(工学版), 2019, 49(6): 1745-1755. |

|

||