吉林大学学报(工学版) ›› 2021, Vol. 51 ›› Issue (2): 493-500.doi: 10.13229/j.cnki.jdxbgxb20200934

• 材料科学与工程 • 上一篇

低温下铜纳米颗粒对UHMWPE复合材料摩擦磨损性能影响

佟金1,2( ),高子博1,2,霍超1,2,王子阳1,2,马云海1,2,常志勇1,2(

),高子博1,2,霍超1,2,王子阳1,2,马云海1,2,常志勇1,2( )

)

- 1.吉林大学 生物与农业工程学院,长春 130022

2.吉林大学 工程仿生教育部重点实验室,长春 130022

Effect of Cu nanoparticles on friction and wear of ultra⁃high molecular weight polyethylene with composites at low temperature

Jin TONG1,2( ),Zi-bo GAO1,2,Chao HUO1,2,Zi-yang WANG1,2,Yun-hai MA1,2,Zhi-yong CHANG1,2(

),Zi-bo GAO1,2,Chao HUO1,2,Zi-yang WANG1,2,Yun-hai MA1,2,Zhi-yong CHANG1,2( )

)

- 1.College of Biological and Agricultural Engineering,Jilin University,Changchun 130022,China

2.Key Laboratory of Bionic Engineering,Ministry of Education,Jilin University,Changchun 130022,China

摘要:

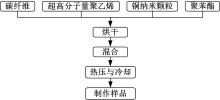

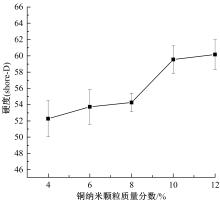

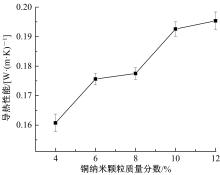

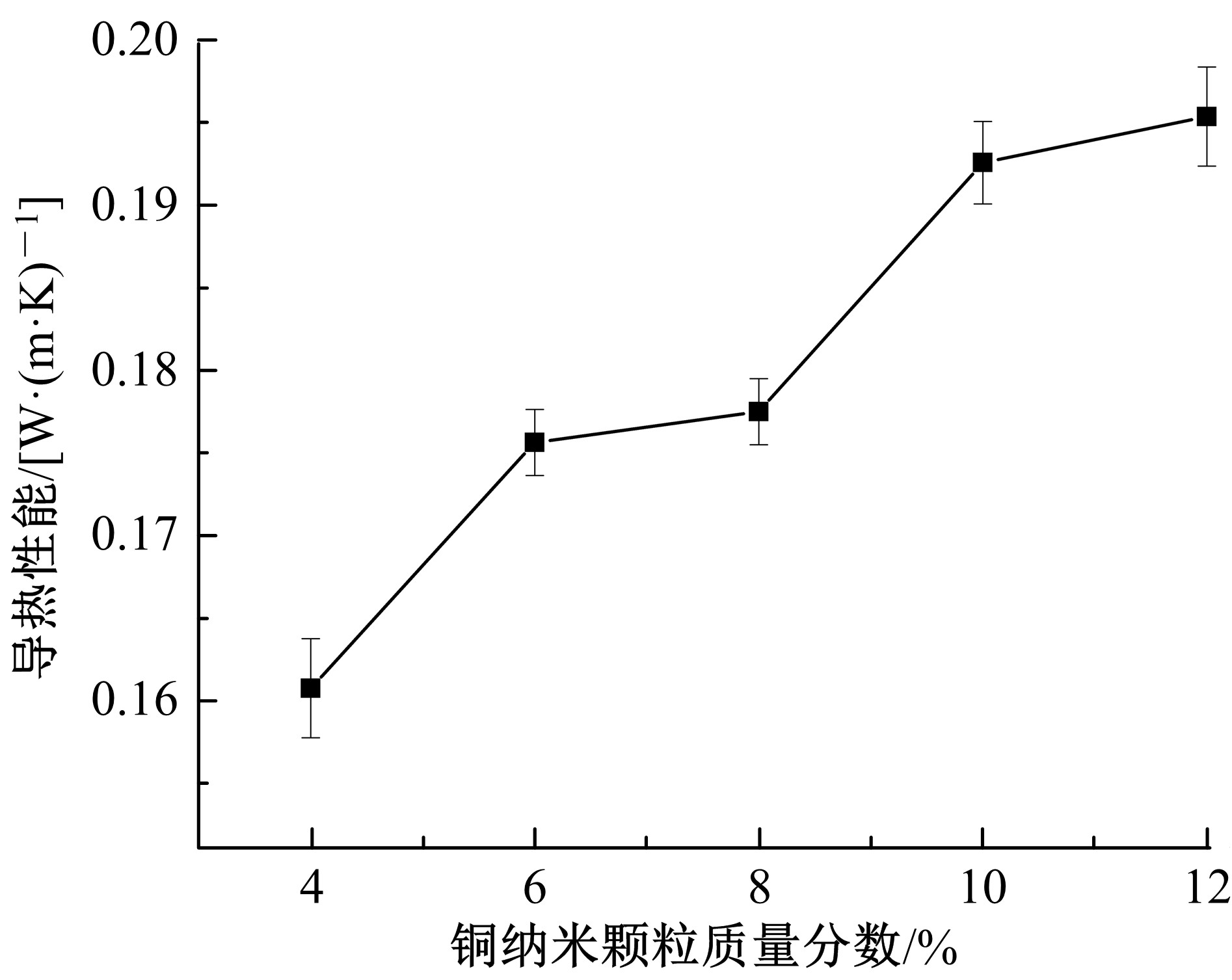

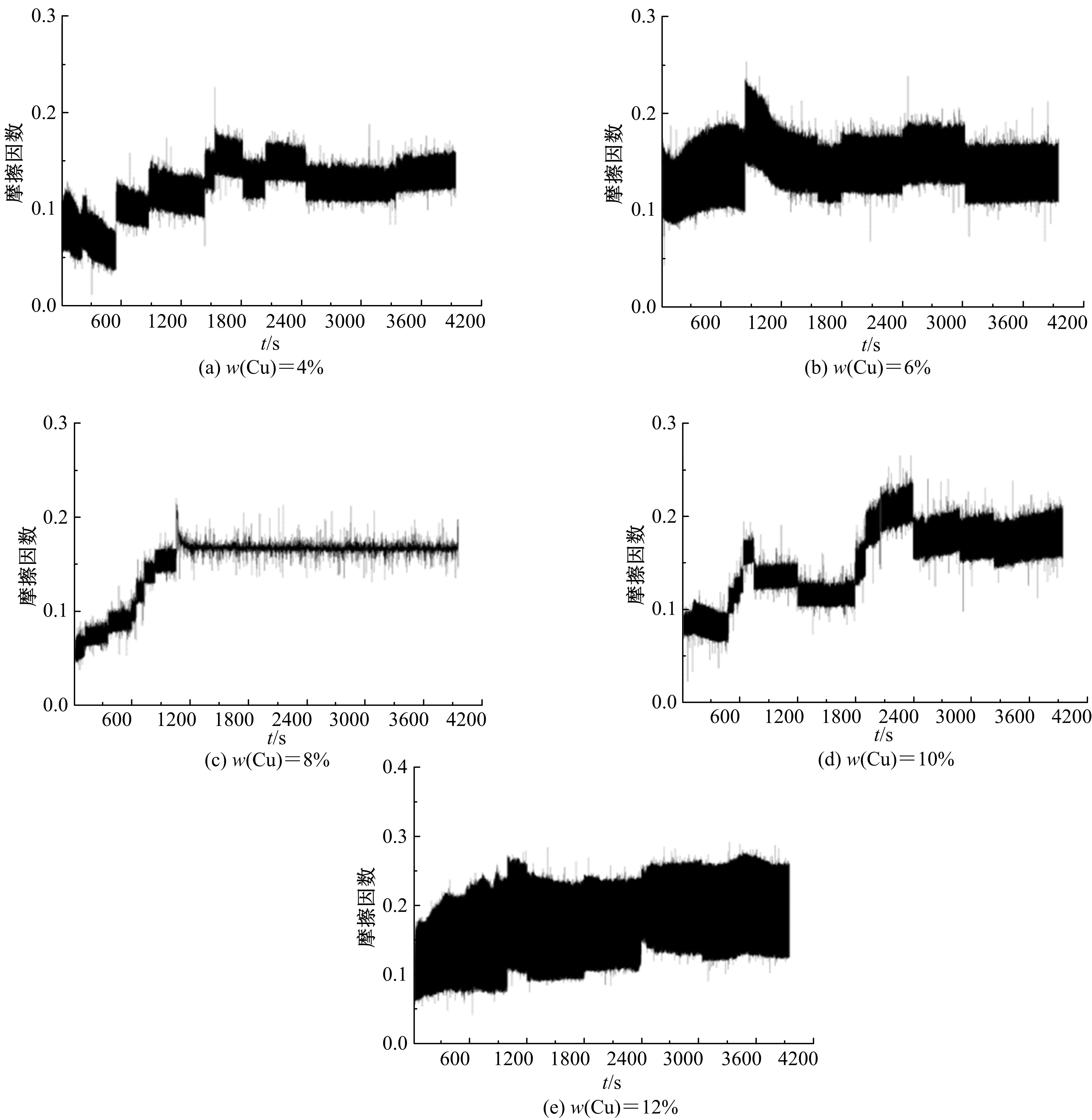

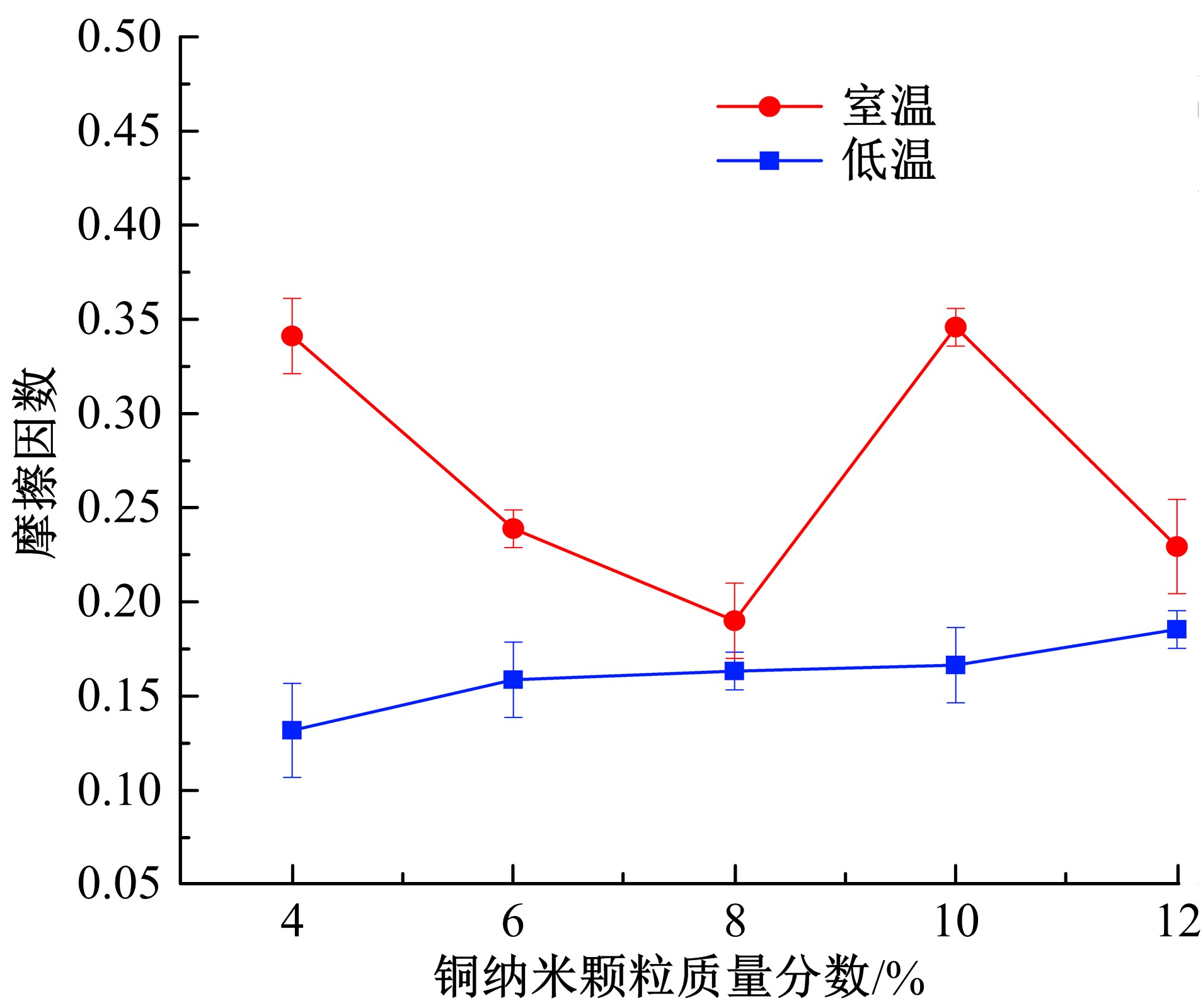

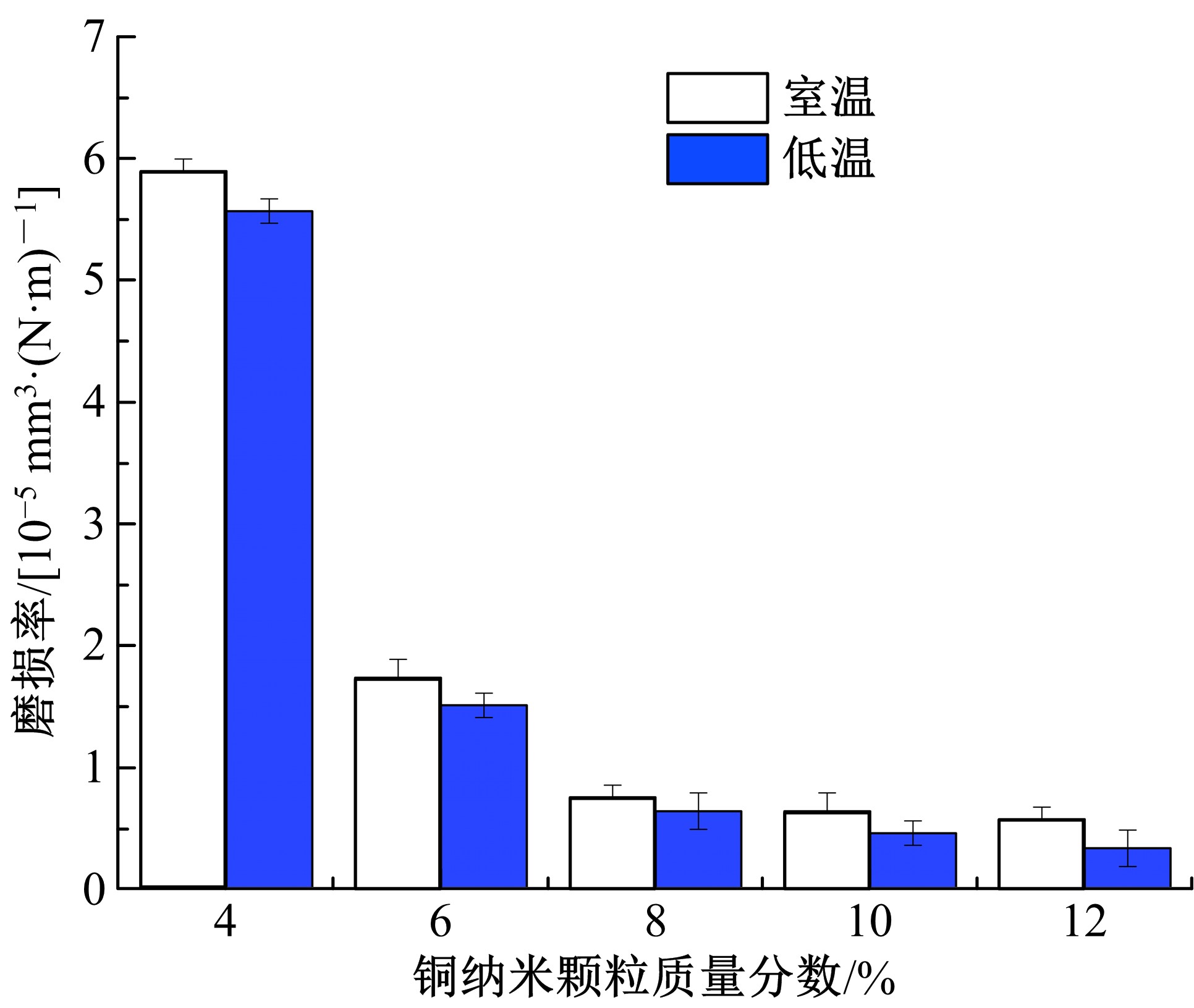

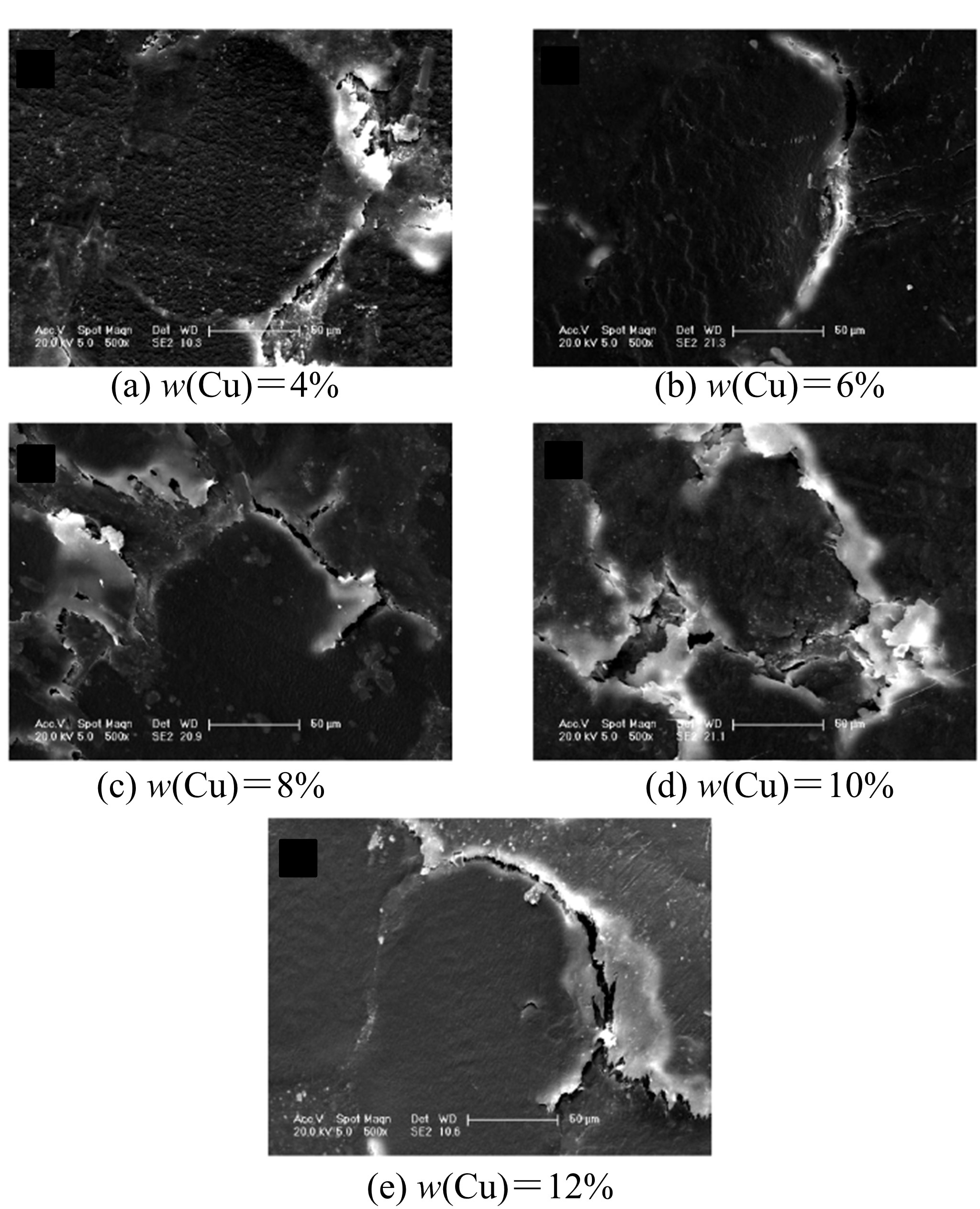

向碳纤维(CF)与聚苯酯(POB)增强超高分子量聚乙烯(UHMWPE)复合材料加入不同质量分数铜纳米颗粒,探究了加入铜纳米颗粒对复合材料的力学性能与导热性能的影响。使用扫描电子显微镜(SEM)对铜纳米颗粒改性复合材料在低温环境下时磨损微观表面进行观察。使用原子力显微镜(AFM)研究了低温环境下改性复合材料转移膜的形貌。研究表明:低温环境下该改性复合材料摩擦因数和磨损率低于室温环境下的摩擦因数和磨损率。低温环境下改性复合材料磨损机理以疲劳磨损和磨料磨损为主,加入铜纳米颗粒后形成致密且连贯的转移膜,显著降低了改性复合材料的磨损率。

中图分类号:

- TQ314.24

| 1 | 晨曦. 农业机械装备进入10大重点发展领域[J]. 农业工程, 2015, 5(3): 99. |

| Chen Xi. Agricultural machinery and equipment enters 10 key development areas[J]. Agricultural Engineering, 2015, 5(3): 99. | |

| 2 | 王子阳. 常温和低温自润滑轴承复合材料性能研究与仿生轴承设计研究[D]. 长春: 吉林大学生物与农业工程学院, 2019. |

| Wang Zi-Yang. Properties study of self-lubricating bearing composite material at room temperature and low temperature and bionic of design bearing[D]. Changchun: College of Biological and Agricultural Engineering, Jilin University, 2019. | |

| 3 | Quillien M, Gras R, Collongeat L, et al. A testing device for rolling-sliding behavior in harsh environments: the twin-disk cryotribometer[J].Tribology International, 2001, 34(4): 287-292. |

| 4 | Chen J, An Y L, Yang J, et al. Tribological properties of adaptive NiCrAlY-Ag-Mo coatings prepared by atmospheric plasma spraying[J]. Surface and Coatings Technology, 2013, 235: 521-528. |

| 5 | Wang Q H, Zheng F, Wang T M. Tribological properties of polymers PI, PTFE and PEEK at cryogenic temperature in vacuum[J]. Cryogenics, 2016, 75: 19-25. |

| 6 | Zheng F, Wang Q H, Wang T M. Effects of aramid fiber and polytetrafluoroethylene on the mechanical and tribological properties of polyimide composites in a vacuum[J]. Journal of Macromolecular Science: Physics, 2015, 54(8): 927-937. |

| 7 | Lv M, Zheng F, Wang Q H. Friction and wear behaviors of carbon and aramid fibers reinforced polyimide composites in simulated space environment[J]. Tribology Inernational, 2015, 92: 246-254. |

| 8 | Wang L Q, Jia X M, Cui L, et al. Effect of aramid fiber and ZnO nanoparticles on friction and wear of PTFE composites in dry and LN2 conditions[J].Tribology International, 2009, 52(1): 59-65. |

| 9 | Liu H, Su X, Tao J, et al. Influence of cenosphere on tribological properties of short carbon fiber reinforced PEEK composites[J]. Journal of Applied Polymer Science, 2018, 132(12): 47245. |

| 10 | Parnian Z F.Medical-grade ultra-high molecular wei-ght polyethylene: past, current and future[J].Materials Science and Technology,2018,34(16):1940-1953. |

| 11 | Puértolas J A, Pascual F J, Martínez-Morlanes M J. Impact resistance and fractography in ultra high molecular weight polyethylenes[J]. Journal of the Mechanical Behavior of Biomedical Materials, 2014, 30: 111-122. |

| 12 | Zhang H, Zhao S, Yu X, et al. Nascent particle sizes and degrees of entanglement are responsible for the significant differences in impact strength of ultrahigh molecular weight polyethylene[J]. Journal of Polymer Science Part B: Polymer Physics, 2019, 57(10): 632-641. |

| 13 | Li Z, Ye C, Feng L, et al. Crystal morphology and corresponding physical properties of nascent ultra-high molecular weight polyethylene powder with short-branched chains[J]. Polymer, 2019, 181: 121758. |

| 14 | Gul R M, Mcgarry F J, Bragdon C R, et al. Effect of consolidation on adhesive and abrasive wear of ultra high molecular weight polyethylene[J]. Biomaterials, 2003, 24(19): 3193-3199. |

| 15 | 刘朝宗, 任露泉, 蒋蔓, 等. 填料改性UHMWPE基复合材料拉伸磨损性能的研究[J]. 吉林工业大学学报, 1996, 26(3): 42-46. |

| Liu Chao-zong, Ren Lu-quan, Jiang Man, et al. Study on abrasive wear and tensile strength of filler-reinforced UHMWPE composites[J]. Journal of Jilin University of Technology, 1996, 26(3): 42-46. | |

| 16 | 张欢. 超高分子量聚乙烯及其复合物耐磨机理研究[D]. 上海: 华东理工大学化工学院, 2020. |

| Zhang Huan. Wear resistance mechanisms of Ultra-high molecular weight polyethylene (UHMWPE) and Bulk UHMWPE composites[D]. Shanghai: School of Chemical Engineering, East China University of Science and Technology, 2020. | |

| 17 | 关庆丰, 万明珍, 邹阳, 等. 碳纤维增强摩擦材料的摩擦表面层[J]. 吉林大学学报: 工学版, 2012, 42(3): 672-676. |

| Guan Qing-feng, Wan Ming-zhen, Zou Yang, et al. Friction surface layer of carbon fiber reinforced friction material[J]. Journal of Jilin University(Engineering and Technology Edition), 2012, 42(3): 672-676. | |

| 18 | 程海正. 改性碳纳米管与液晶聚苯酯填充聚醚醚酮复合材料力学及摩擦学性能研究[D].上海:上海交通大学机械与动力工程学院,2017. |

| Cheng Hai-zheng. Mechanical and tribological properties of polyetheretherketon composites filled with liquid crystal poly(p-oxybenzoate) and functionalized carbon nanotubes[D].Shanghai: School of Mechanical Engineering, Shanghai Jiao Tong University, 2017. | |

| 19 | Wang Z, Ma Y, Guo L, et al. Influence of polyphenyl ester and nanosized copper filler on the tribological properties of carbon fibre-reinforced ultra-high-molecular-weight polyethylene composites[J]. Journal of Thermoplastic Composite Materials, 2018, 31(11): 1483-1496. |

| [1] | 杨帆,张旭东,赵蒙,折波,邓俊楷. 基于有限元计算的形状记忆合金⁃金属玻璃复合材料变形行为[J]. 吉林大学学报(工学版), 2021, 51(1): 172-180. |

| [2] | 慕文龙,那景新,谭伟,王广彬,申浩,栾建泽. 基于FTIR分析的CFRP-铝合金粘接接头剩余强度预测[J]. 吉林大学学报(工学版), 2021, 51(1): 139-146. |

| [3] | 李义,黄东迪,于开锋,梁继才,何小玲,任希彤. 硅炭黑改性玄武岩纤维增强聚酰胺6复合材料性能[J]. 吉林大学学报(工学版), 2021, 51(1): 181-187. |

| [4] | 李欣欣,李大宇,赵子瑞,周亚军. 低温等离子体处理功率对酱牛肉贮藏品质的影响[J]. 吉林大学学报(工学版), 2020, 50(5): 1934-1940. |

| [5] | 叶辉,刘畅,闫康康. 纤维增强复合材料在汽车覆盖件中的应用[J]. 吉林大学学报(工学版), 2020, 50(2): 417-425. |

| [6] | 熊锐,乔宁,褚辞,杨发,关博文,盛燕萍,牛冬瑜. 掺盐沥青胶浆低温流变及粘附特性[J]. 吉林大学学报(工学版), 2020, 50(1): 183-190. |

| [7] | 马芳武,韩露,周阳,王世英,蒲永锋. 采用聚乳酸复合材料的汽车零件多材料优化设计[J]. 吉林大学学报(工学版), 2019, 49(5): 1385-1391. |

| [8] | 叶辉,朱艳荣,蒲永锋. 纤维增强复合材料应变率效应的数值仿真[J]. 吉林大学学报(工学版), 2019, 49(5): 1622-1629. |

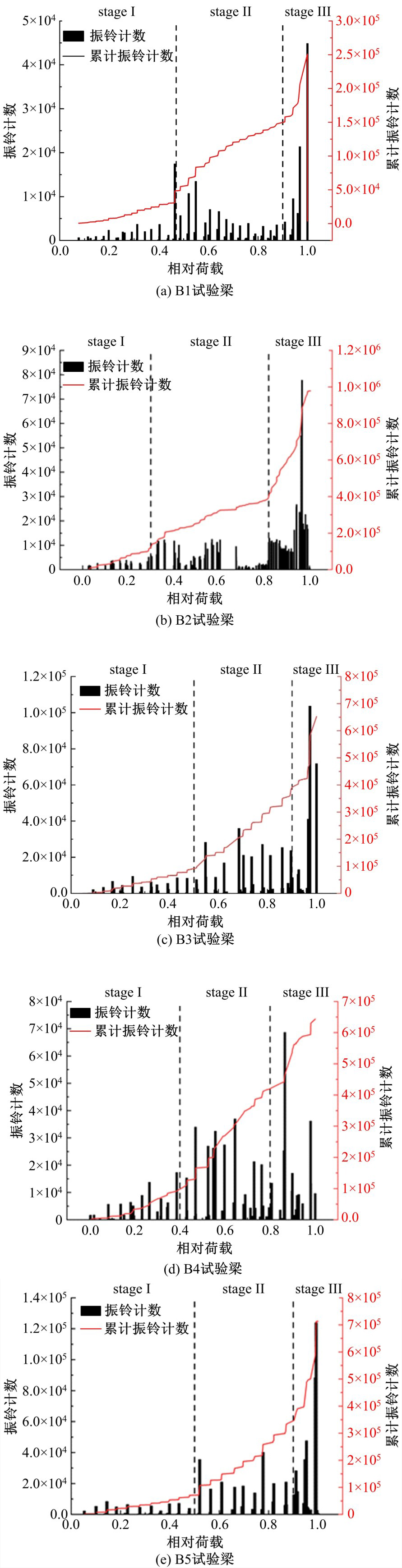

| [9] | 李碧雄,廖桥,章一萍,周练,隗萍,刘侃. 超高强钢筋工程用水泥基复合材料梁受弯计算理论[J]. 吉林大学学报(工学版), 2019, 49(4): 1153-1161. |

| [10] | 程永春, 毕海鹏, 马桂荣, 宫亚峰, 田振宏, 吕泽华, 徐志枢. 纳米TiO2/CaCO3-玄武岩纤维复合改性沥青的路用性能[J]. 吉林大学学报(工学版), 2018, 48(2): 460-465. |

| [11] | 胡志清, 郑会会, 徐亚男, 张春玲, 党停停. 表面微沟槽对Al/CFRP胶结性能的影响[J]. 吉林大学学报(工学版), 2018, 48(1): 229-235. |

| [12] | 刘耀辉, 陈乔旭, 宋雨来, 沈艳东. 火山灰-SBS、胶粉-SBS和SBS改性沥青压缩变形行为及机理[J]. 吉林大学学报(工学版), 2017, 47(6): 1861-1867. |

| [13] | 郑传峰, 马壮, 郭学东, 张婷, 吕丹, 秦泳. 矿粉宏细观特征耦合对沥青胶浆低温性能的影响[J]. 吉林大学学报(工学版), 2017, 47(5): 1465-1471. |

| [14] | 李静, 王哲. 真三轴加载条件下混凝土的力学特性[J]. 吉林大学学报(工学版), 2017, 47(3): 771-777. |

| [15] | 杨悦, 李雪, 徐晓丹. Ti-B-C-N粉末烧结的微观组织及其性能[J]. 吉林大学学报(工学版), 2017, 47(2): 552-556. |

|

||