吉林大学学报(工学版) ›› 2021, Vol. 51 ›› Issue (5): 1908-1918.doi: 10.13229/j.cnki.jdxbgxb20200434

• 农业工程·仿生工程 • 上一篇

基于参数化模型的零转弯半径割草机侧翻稳定性

- 江苏科技大学 机械工程学院,江苏 镇江 212001

Rollover stability of zero turning radius lawn mower based on parametric model

Xin-yan WANG( ),Quan JIANG,Feng LYU,Zheng-yang YI

),Quan JIANG,Feng LYU,Zheng-yang YI

- College of Mechanical Engineering,Jiangsu University of Science and Technology,Zhenjiang 212001,China

摘要:

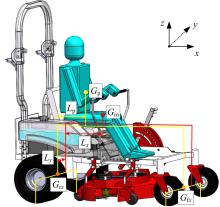

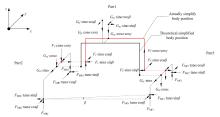

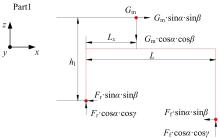

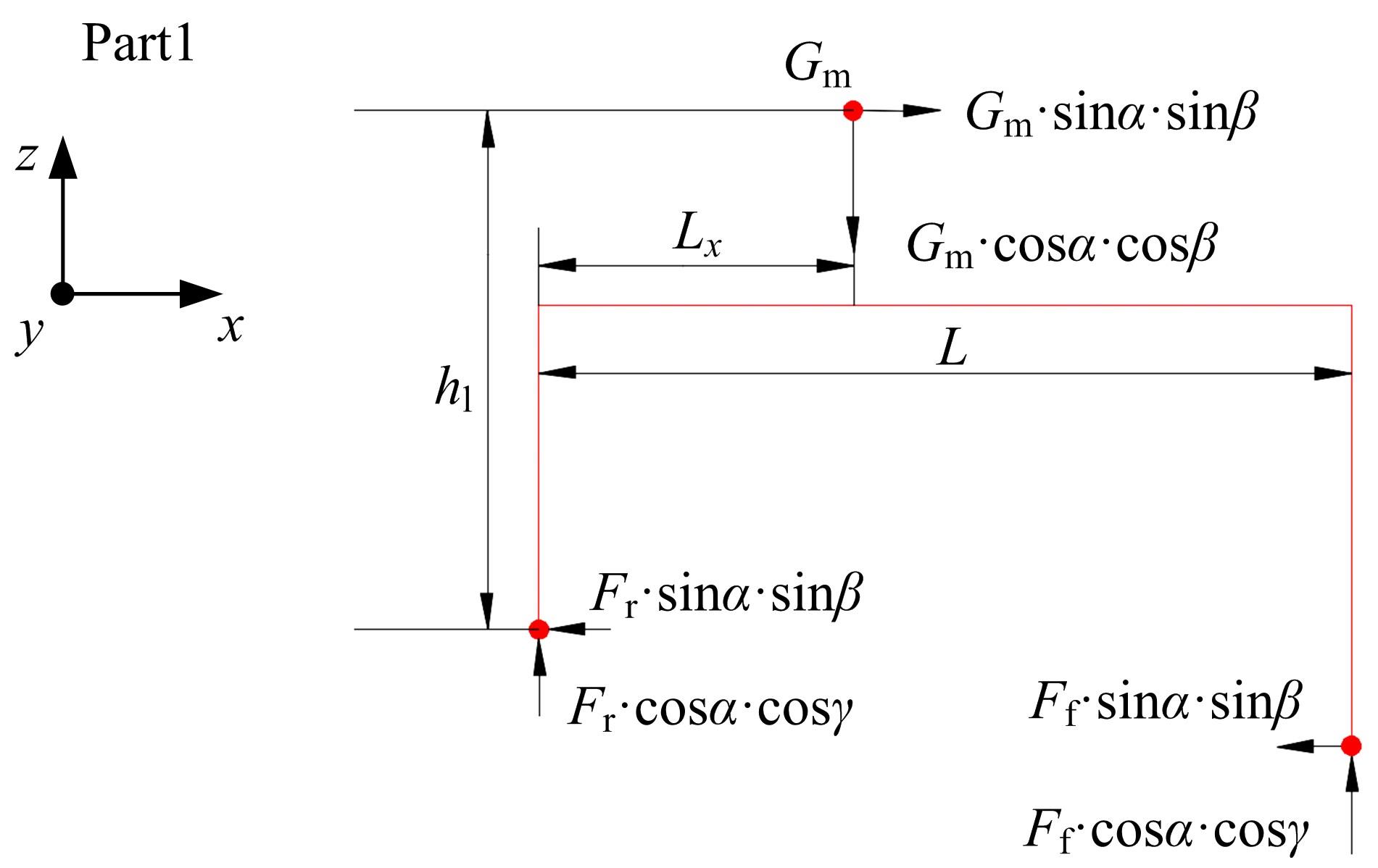

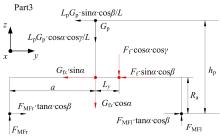

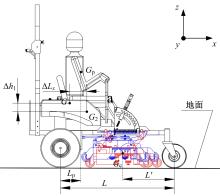

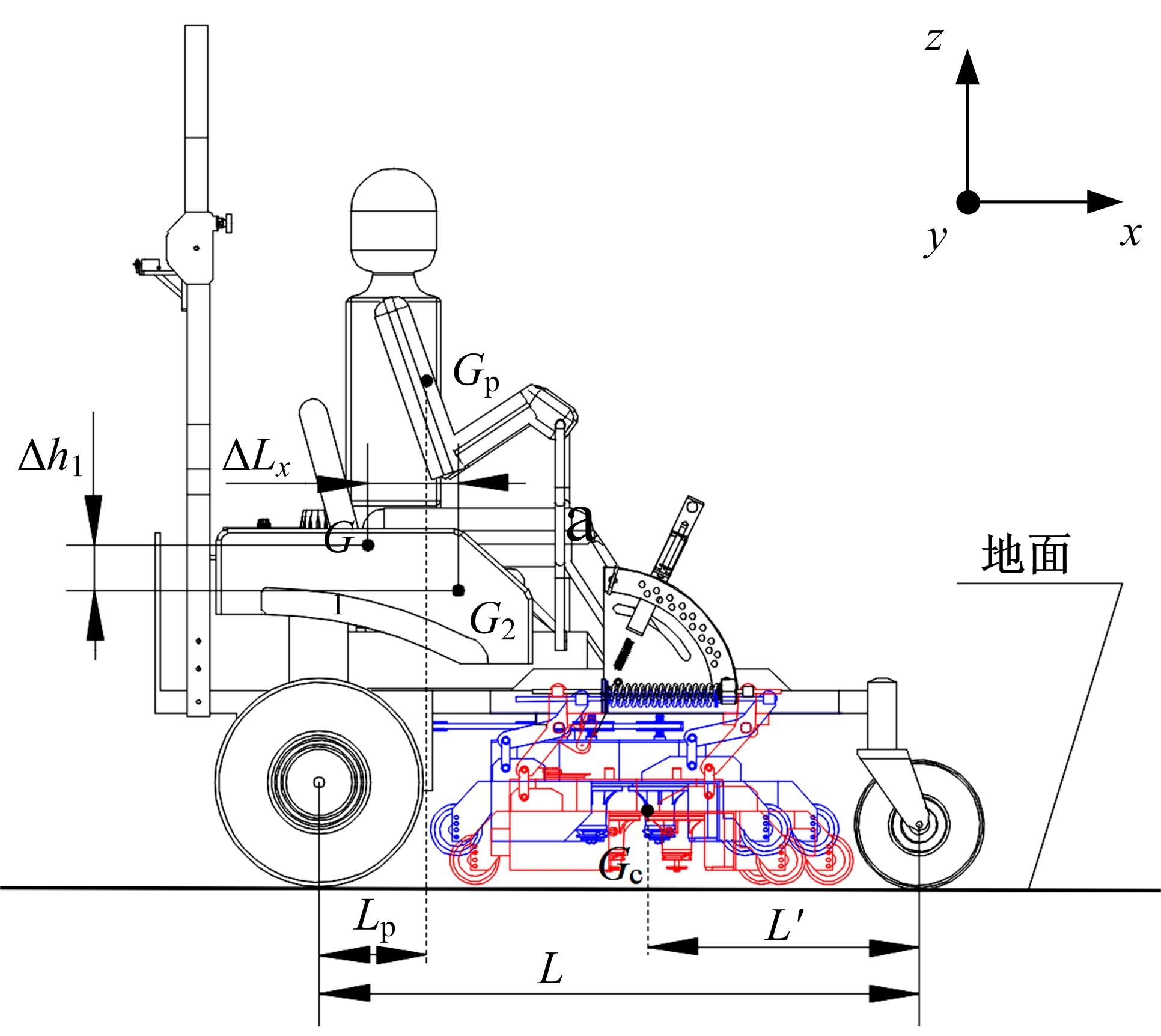

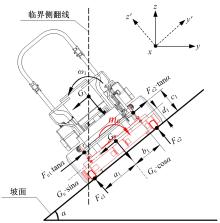

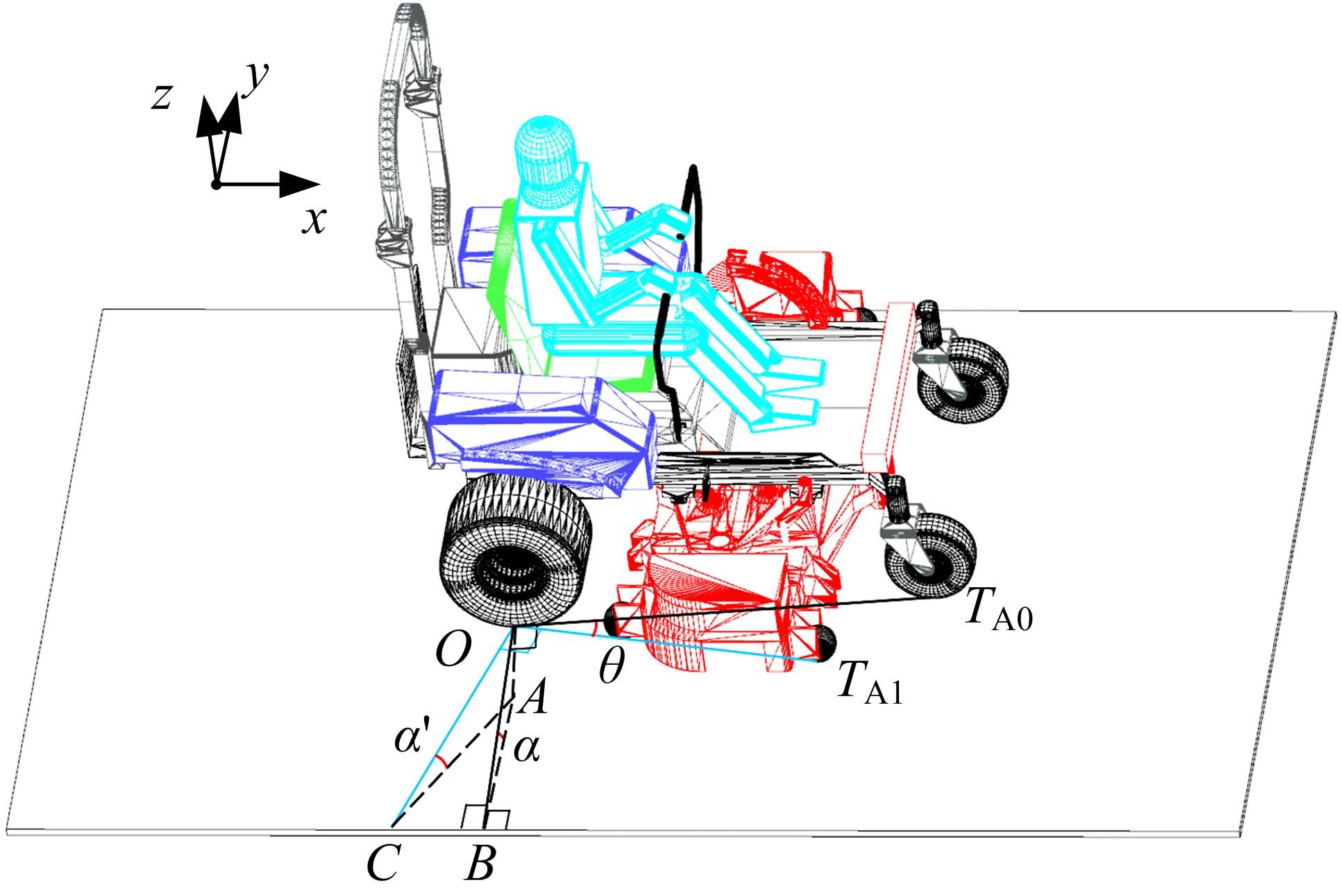

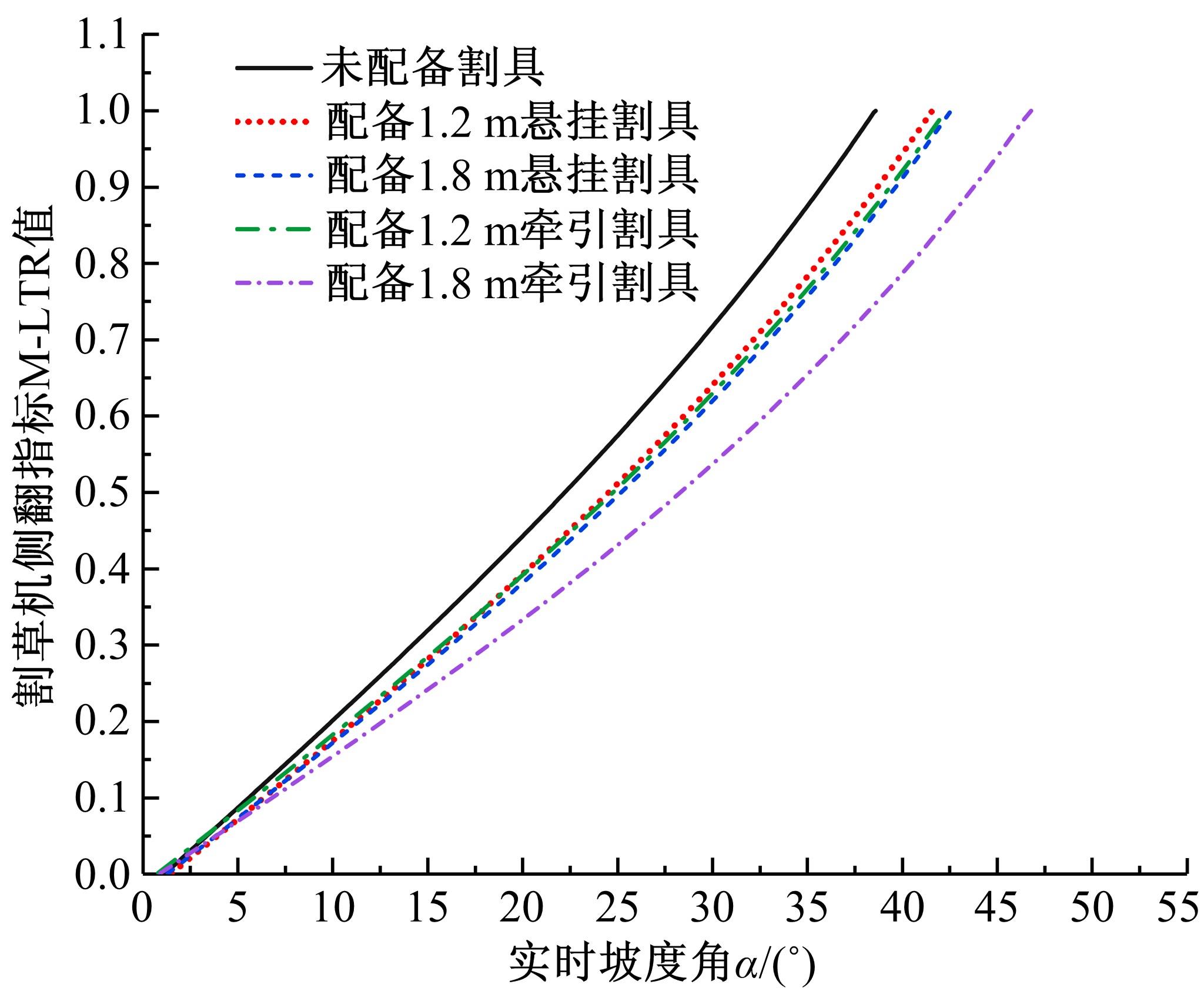

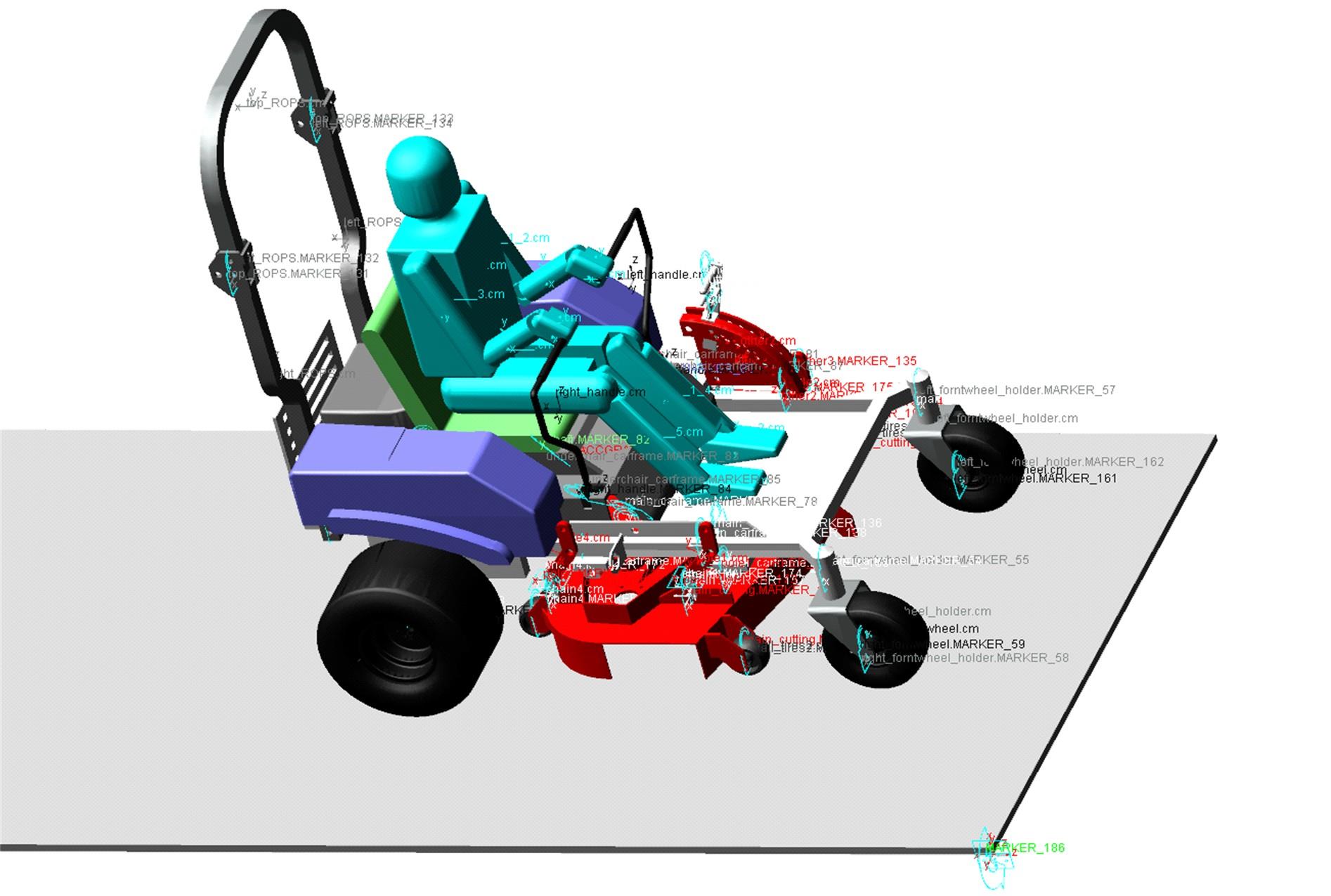

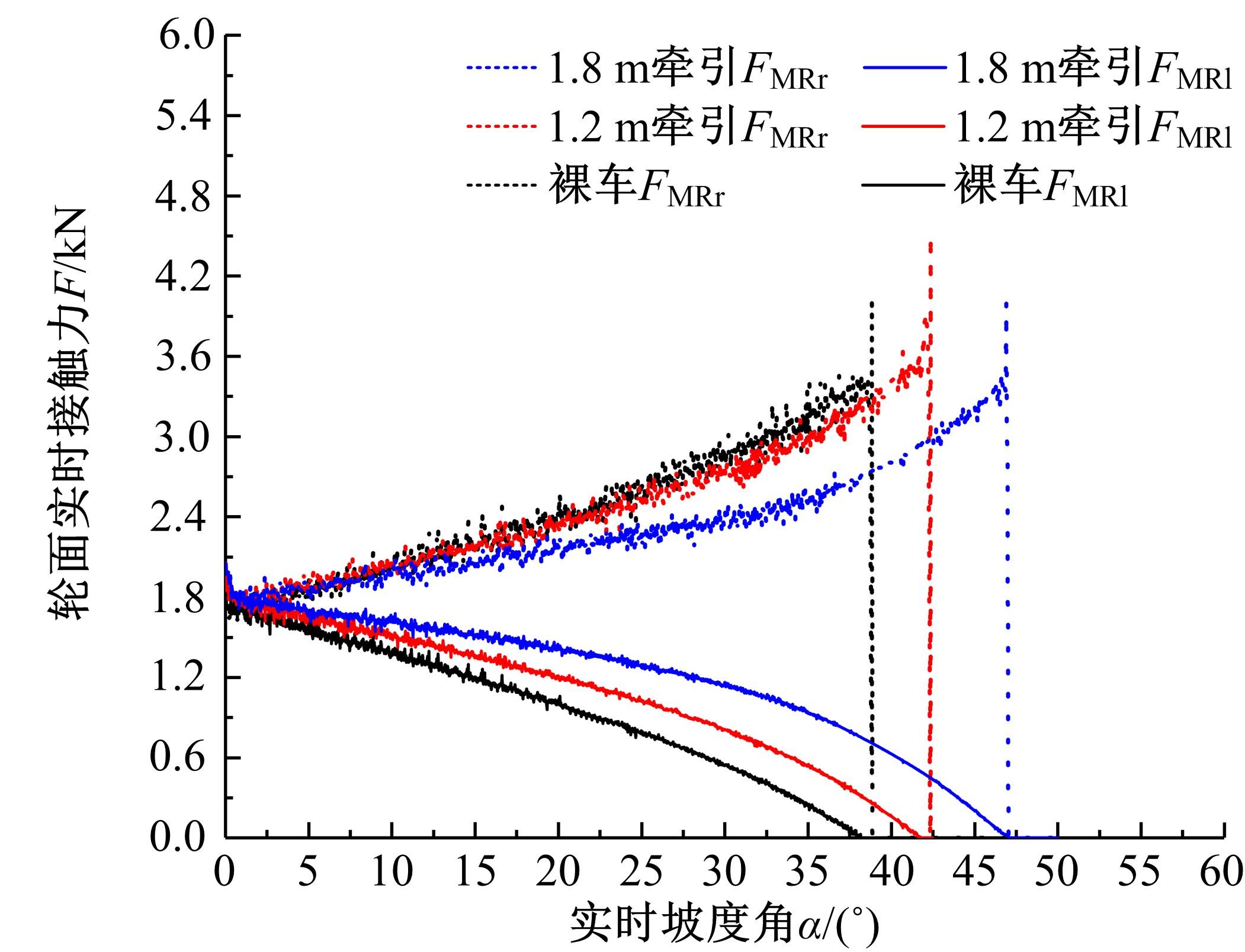

针对近年来零转弯半径(ZTR)割草机在横向坡道上频发的侧翻安全事故,基于准静态动力学理论,建立了一种坡道工况下能预测分析ZTR割草机失稳的参数化力学模型。根据割草机实际工作状态,加入了驾驶员因素以及不同规格割具在悬挂、牵引状态下对整车侧翻稳定性的影响。利用Matlab求解了理论侧翻预测方程,分析了不同工况下割草机横向载荷转移率与其侧翻敏感参数之间的关系,并利用ADAMS对割草机进行了多组仿真实验,进一步验证了参数化模型的准确性。通常,割草机底部配备悬挂割具可降低整车质心高度从而增强坡道稳定性。但通过实验发现,割草机底部配备牵引式割具比配备悬挂式割具的抗侧翻性能更强:其中配备1.2 m和1.8 m规格悬挂式割具的临界侧翻角较裸车分别提升了7%和10%;而配备1.2 m和1.8 m规格牵引式割具的整车临界侧翻角较裸车分别提升了9%和21%。根据这一特性,建议在设计农用或园林车辆的工作器械时优先考虑底部中置牵引结构,以提高各类车辆在斜坡上工作的安全性。

中图分类号:

- S224.1

| 1 | 高敏, 周仁和. 坐骑式割草机设计要素及发展分析[J]. 中国科技信息, 2008(5): 67-68. |

| Gao Min, Zhou Ren-he. Design elements and development analysis of mount mowers[J]. China Science and Technology Information, 2008(5): 67-68. | |

| 2 | 李立恒. 国内园林机械化绿化的发展应用现状[J]. 科技创新与应用, 2015(24): 161. |

| Li Li-heng. Current status of development and application of domestic mechanized greening[J]. Science and Technology Innovation and Application, 2015(24): 161. | |

| 3 | Lehtola C J, Marley S J, Melvin S W. A study of five years of tractor-related fatalities in Iowa[J]. Applied Engineering in Agriculture, 1994, 10(5): 627-632. |

| 4 | Molari G, Ayers P D, Meyer H J, et al. Special issue: engineering advances to improve the safety of agricultural machines[J]. Biosystems Engineering, 2019, 185: 1-3. |

| 5 | Harris C, Madonick J, Hartka T R. Lawn mower injuries presenting to the emergency department:2005 to 2015[J]. American Journal of Emergency Medicine, 2018, 36(9): 1565-1569. |

| 6 | Ayers P D, Khorsandi F K, Poland M J, et al. Foldable rollover protective structures: universal lift-assist design[J]. Biosystems Engineering, 2019, 185: 116-125. |

| 7 | 司俊德, 王国强, 魏秀玲, 等. 工程车辆翻车时ROPS刚度、斜坡角度和安全带方式对人体损伤的影响[J]. 吉林大学学报: 工学版, 2010, 40(6): 1583-1588. |

| Si Jun-de, Wang Guo-qiang, Wei Xiu-ling, et al. Effect of rops stiffness shope angle and seat belt restraint on operator injury in rollover of engineering vehicle[J]. Journal of Jilin University(Engineering and Technology Edition), 2010, 40(6): 1583-1588. | |

| 8 | Hammig B, Childers E, Jones C. Injuries associated with the use of riding mowers in the United States, 2002~2007[J]. Journal of Safety Research, 2009, 40(5): 371-375. |

| 9 | Ahmadi I. Dynamics of tractor lateral overturn on slopes under the influence of position disturbances (model development)[J]. Journal of Terramechanics, 2011, 48(5): 339-346. |

| 10 | Seluga K J, Baker L L, Ojalvo I U. A parametric study of golf car and personal transport vehicle braking stability and their deficiencies[J]. Accident Analysis and Prevention, 2009, 41(4): 839-848. |

| 11 | 麦莉, 宗长富, 高越, 等. 重型半挂车侧倾稳定性仿真与分析[J]. 吉林大学学报: 工学版, 2008, 38(): 5-10. |

| Mai Li, Zong Chang-fu, Gao Yue, et al. Simulation and analysis of the roll stability of heavy semi-trailers[J]. Journal of Jilin University(Engineering and Technology Edition), 2008, 38(Sup.2): 5-10. | |

| 12 | Guzzomi A L. A revised kineto-static model for phase I tractor rollover[J]. Biosystems Engineering, 2012, 113(1): 65-75. |

| 13 | Virginia B, Andrew L, Guzzomi A L. A model and comparison of 4-wheel-drive fixed-chassistractor rollover during Phase I[J]. Biosystems Engineering, 2013, 116(2): 179-189. |

| 14 | 陈东辉, 吕建华, 龙刚, 等. 基于ADAMS的半悬挂式农业机组静侧翻稳定性[J]. 吉林大学学报: 工学版, 2018, 48(4): 1176-1183. |

| Chen Dong-hui, Jian-hua Lyu, Long Gang, et al. Static rollover stability of semi-suspended agricultural units based on ADAMS[J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(4): 1176-1183. | |

| 15 | 陶金京, 廖敏, 潘群林, 等. 轮式拖拉机悬挂农具机组静态纵向稳定性[J]. 科学技术与工程, 2019, 19(34): 108-115. |

| Tao Jin-jing, Liao Min, Pan Qun-lin, et al. Static longitudinal stability of wheeled tractor suspended farm machinery units[J]. Science Technology and Engineering, 2019, 19(34): 108-115. | |

| 16 | Wang X, Gao L, Ayers P D, et al. The influence of the lift angle on the center of gravity measurements for zero turning radius mowers[J]. Applied Engineering in Agriculture, 2016, 32(2): 189-199. |

| 17 | Wang X, Ayers P D, Womac A R, et al. Sensitivity analyses and validation of continuous roll prediction model for front drive mowers[J]. Applied Engineering in Agriculture, 2007, 23(4): 455-461. |

| 18 | Wang X, Peng I M, Ayers P D, et al. Measurement of the moment of inertia for a zero turning radius mower[J]. Applied Engineering in Agriculture, 2016, 32(4): 323-332. |

| [1] | 钱震杰,金诚谦,袁文胜,倪有亮,张光跃. 柔性脱粒齿杆与谷物含摩擦打击动力学模型[J]. 吉林大学学报(工学版), 2021, 51(3): 1121-1130. |

| [2] | 程超,付君,陈志,任露泉. 玉米籽粒收获机清选筛堵塞规律及脱附试验[J]. 吉林大学学报(工学版), 2021, 51(2): 761-771. |

| [3] | 丛茜,徐金,马博帅,张晓超,陈廷坤. 基于虚拟仿真的拖拉机后悬挂检测装置设计与实验[J]. 吉林大学学报(工学版), 2021, 51(2): 754-760. |

| [4] | 陈学深,黄柱健,马旭,齐龙,方贵进. 水稻机械除草避苗控制系统设计与试验[J]. 吉林大学学报(工学版), 2021, 51(1): 386-396. |

| [5] | 耿端阳,谭德蕾,于兴瑞,苏国粱,王骞,鹿秀凤,金诚谦. 玉米柔性脱粒滚筒脱粒元件设计与试验[J]. 吉林大学学报(工学版), 2020, 50(5): 1923-1933. |

| [6] | 高锐涛,单建,杨洲,文晟,兰玉彬,张泉勇,汪洋. 植保无人机变量喷雾处方图实时解译系统的设计与试验[J]. 吉林大学学报(工学版), 2020, 50(1): 361-374. |

| [7] | 刘恩泽,吴文福. 基于综合指标品质评价算法的单色水果生长状态检测互联网架构[J]. 吉林大学学报(工学版), 2019, 49(6): 2019-2026. |

| [8] | 秦嘉浩,李臻,光岡宗司,井上英二,宋正河,朱忠祥. 基于模型实验的拖拉机配置对稳定性的影响差异[J]. 吉林大学学报(工学版), 2019, 49(4): 1236-1245. |

| [9] | 梁方,尤泳,王德成,王光辉,贺长彬,李帅. 运动参数对草地切根刀具与土壤作用关系的影响[J]. 吉林大学学报(工学版), 2019, 49(3): 903-911. |

| [10] | 王扬, 王晓梅, 陈泽仁, 于建群. 基于离散元法的玉米籽粒建模[J]. 吉林大学学报(工学版), 2018, 48(5): 1537-1547. |

| [11] | 陈东辉, 吕建华, 龙刚, 张宇晨, 常志勇. 基于ADAMS的半悬挂式农业机组静侧翻稳定性[J]. 吉林大学学报(工学版), 2018, 48(4): 1176-1183. |

| [12] | 贾洪雷, 王万鹏, 陈志, 庄健, 王文君, 刘慧力. 基于土壤坚实度的仿形弹性镇压辊镇压力实时测量方法[J]. 吉林大学学报(工学版), 2018, 48(4): 1169-1175. |

| [13] | 王扬, 吕凤妍, 徐天月, 于建群. 大豆籽粒形状和尺寸分析及其建模[J]. 吉林大学学报(工学版), 2018, 48(2): 507-517. |

| [14] | 贾洪雷, 郑嘉鑫, 袁洪方, 郭明卓, 王文君, 于路路. 大豆播种机双V型筑沟器设计与试验[J]. 吉林大学学报(工学版), 2017, 47(1): 323-331. |

| [15] | 肖志锋, 乐建波, 吴南星, 刘相东. 操作压力对过热蒸汽流化床干燥的影响[J]. 吉林大学学报(工学版), 2015, 45(4): 1375-1380. |

|

||