吉林大学学报(工学版) ›› 2022, Vol. 52 ›› Issue (7): 1541-1551.doi: DOI:10.13229/j.cnki.jdxbgxb20210132

• 车辆工程·机械工程 • 上一篇

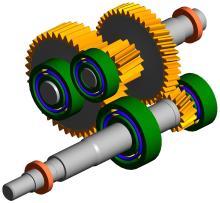

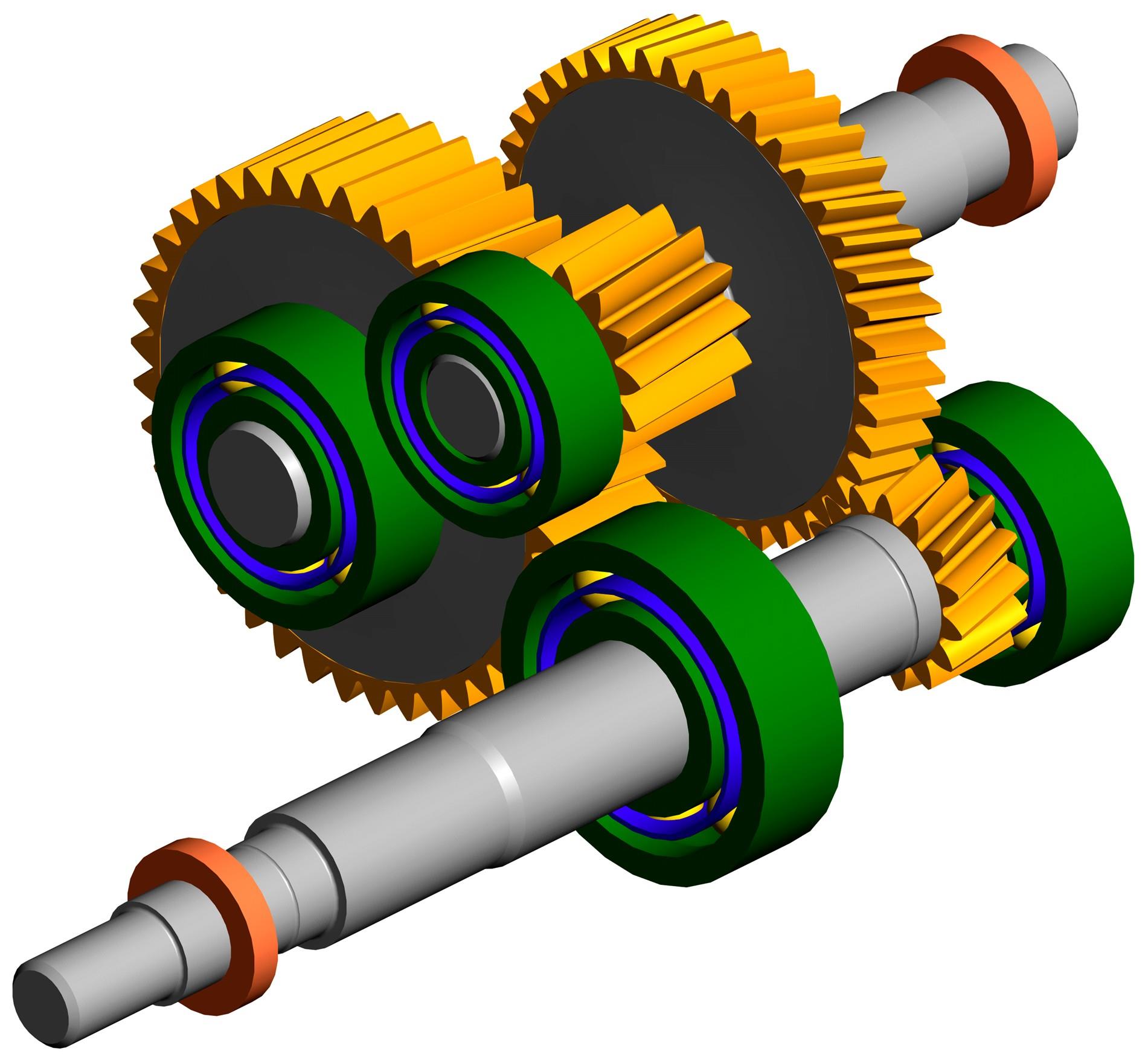

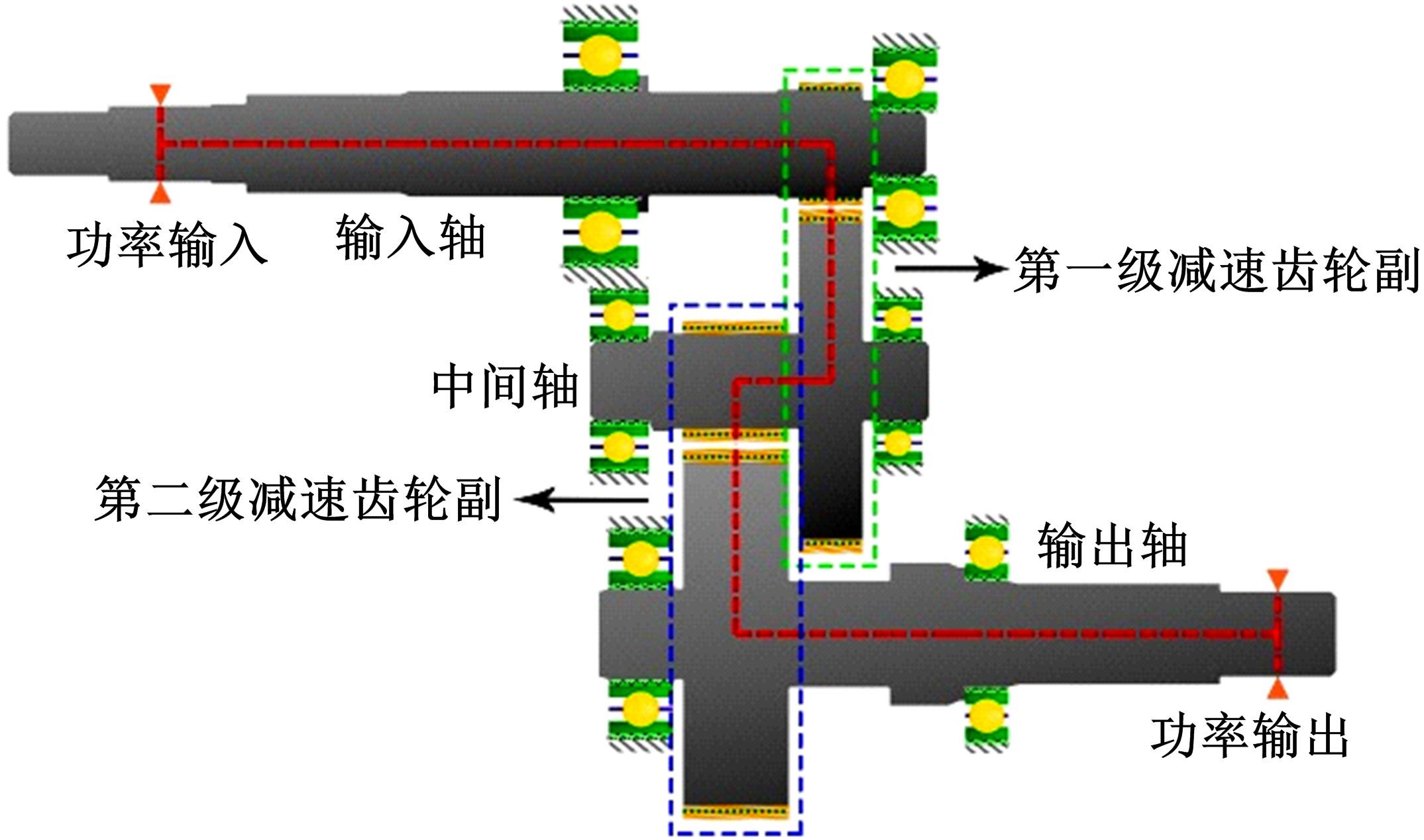

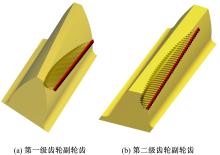

基于某二级减速齿轮系统的齿面修形优化

- 1.吉林大学 汽车仿真与控制国家重点实验室,长春 130022

2.中国重汽集团 汽车研究总院,济南 250100

Optimization of tooth surface modification based on a two-stage reduction gear system

Hong-bo YANG1( ),Wen-ku SHI1(

),Wen-ku SHI1( ),Zhi-yong CHEN1,Nian-cheng GUO2,Yan-yan ZHAO2

),Zhi-yong CHEN1,Nian-cheng GUO2,Yan-yan ZHAO2

- 1.State Key Laboratory of Automotive Simulation and Control,Jilin University,Changchun 130022,China

2.Automotive Research Institute,China National Heavy Duty Truck (Group Corp. ),Jinan 250100,China

摘要:

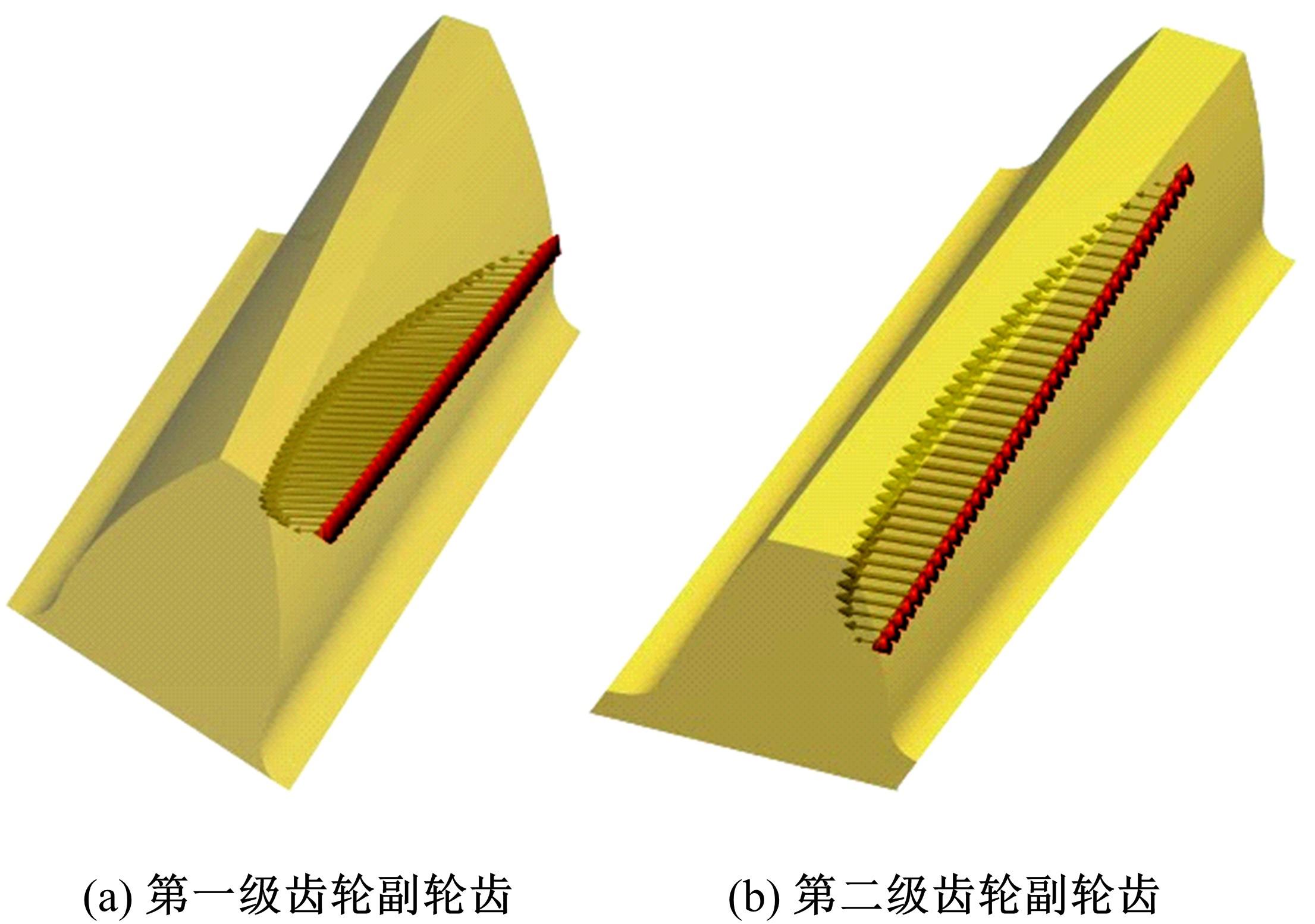

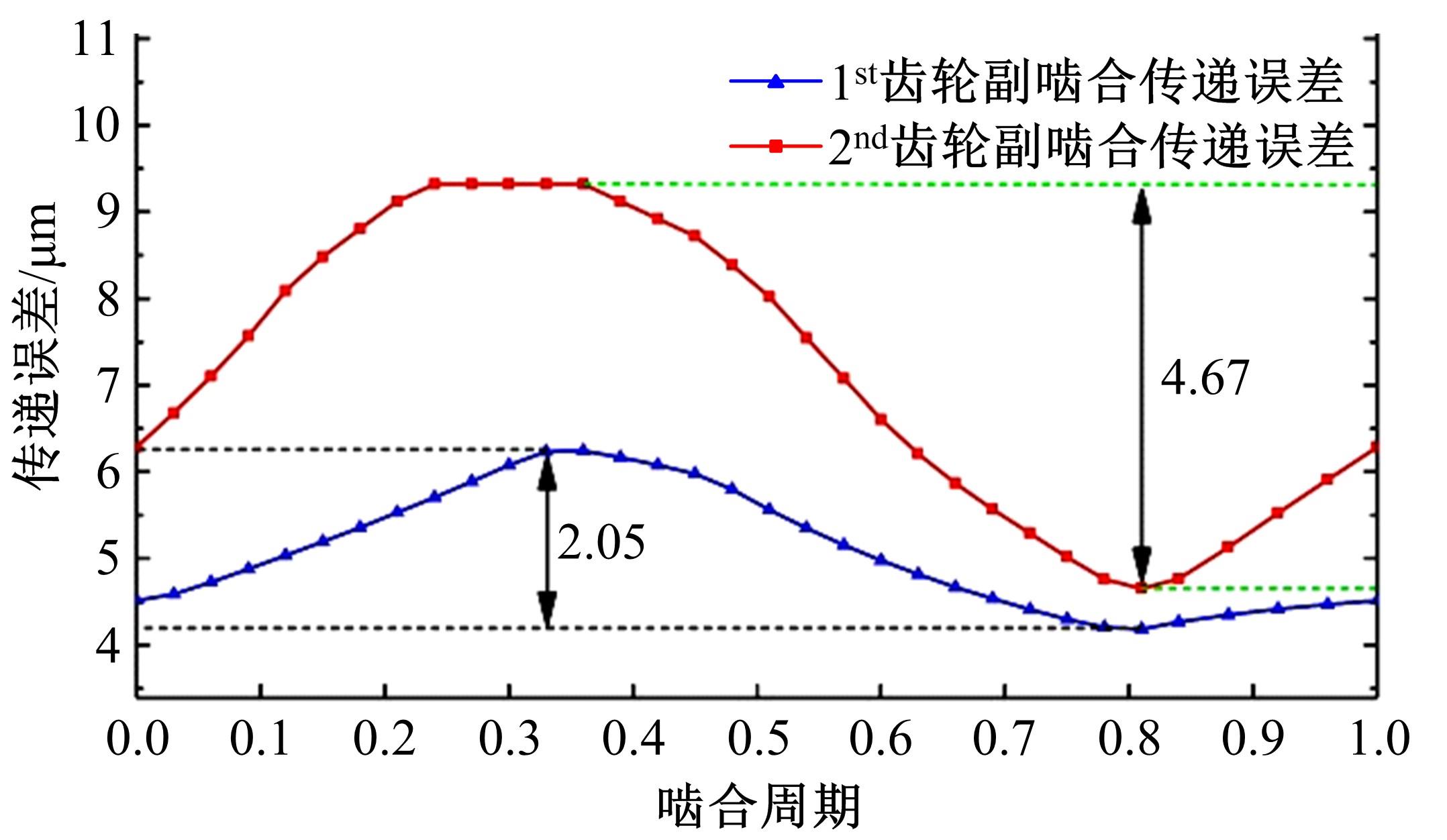

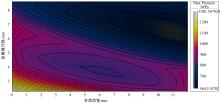

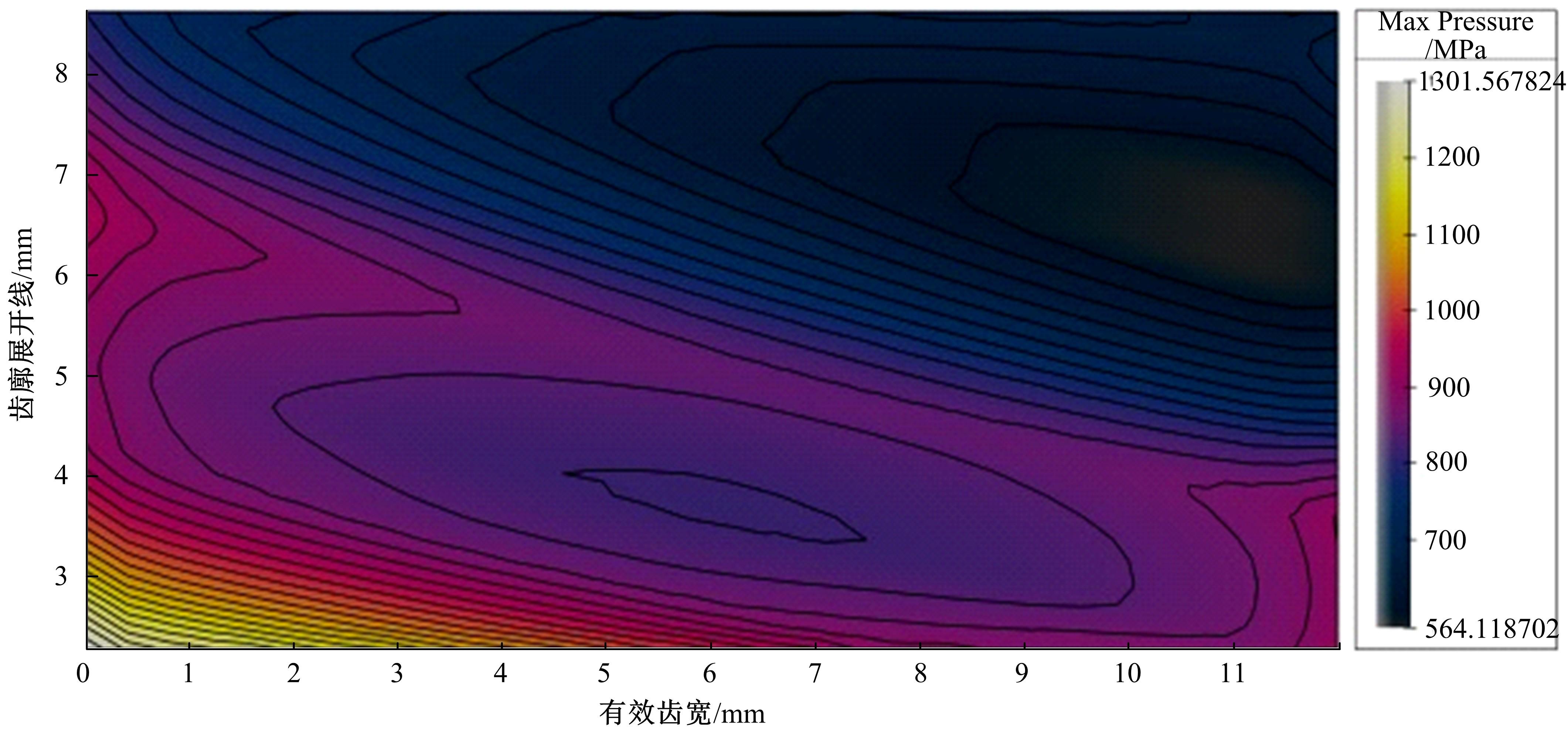

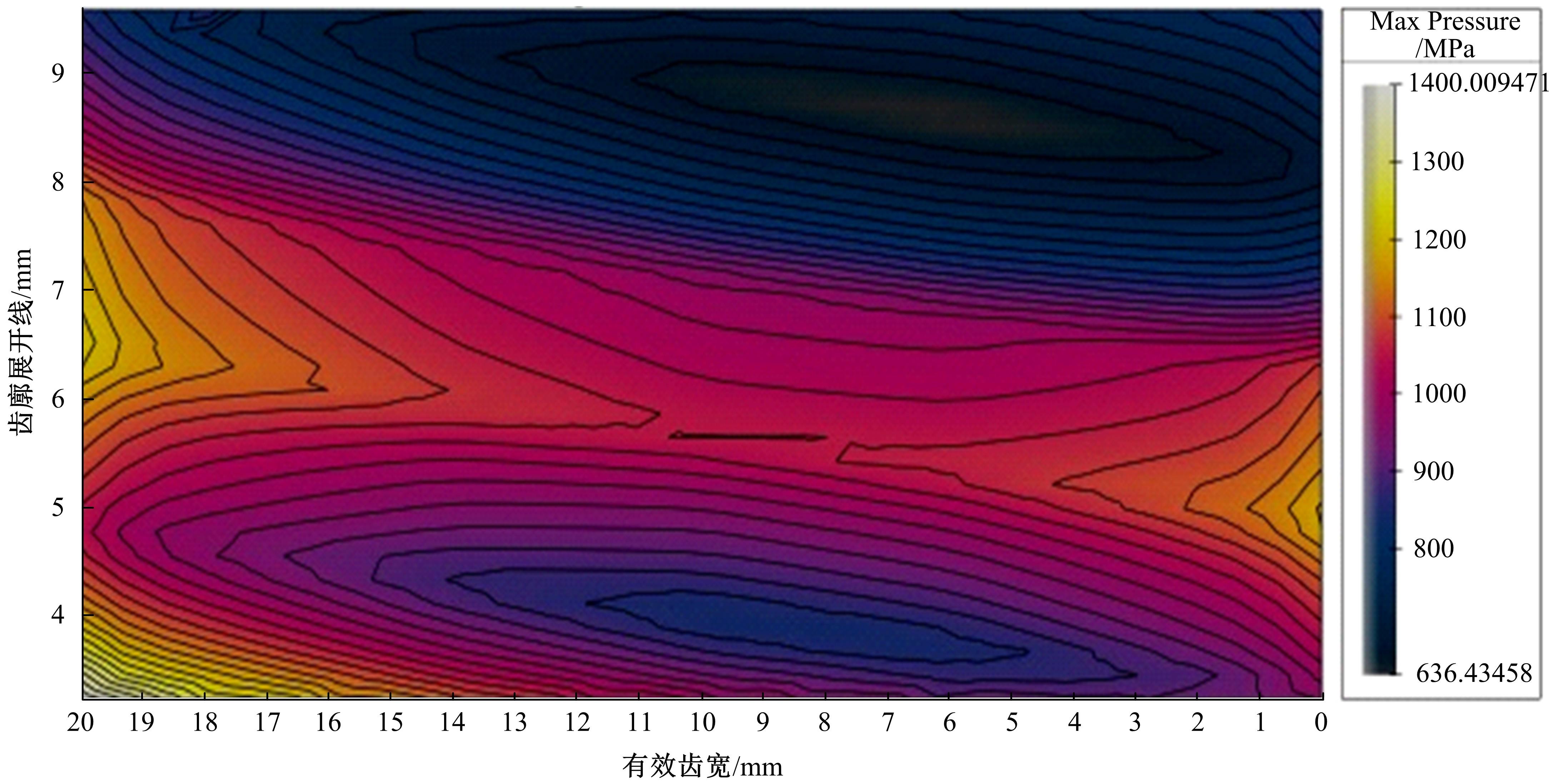

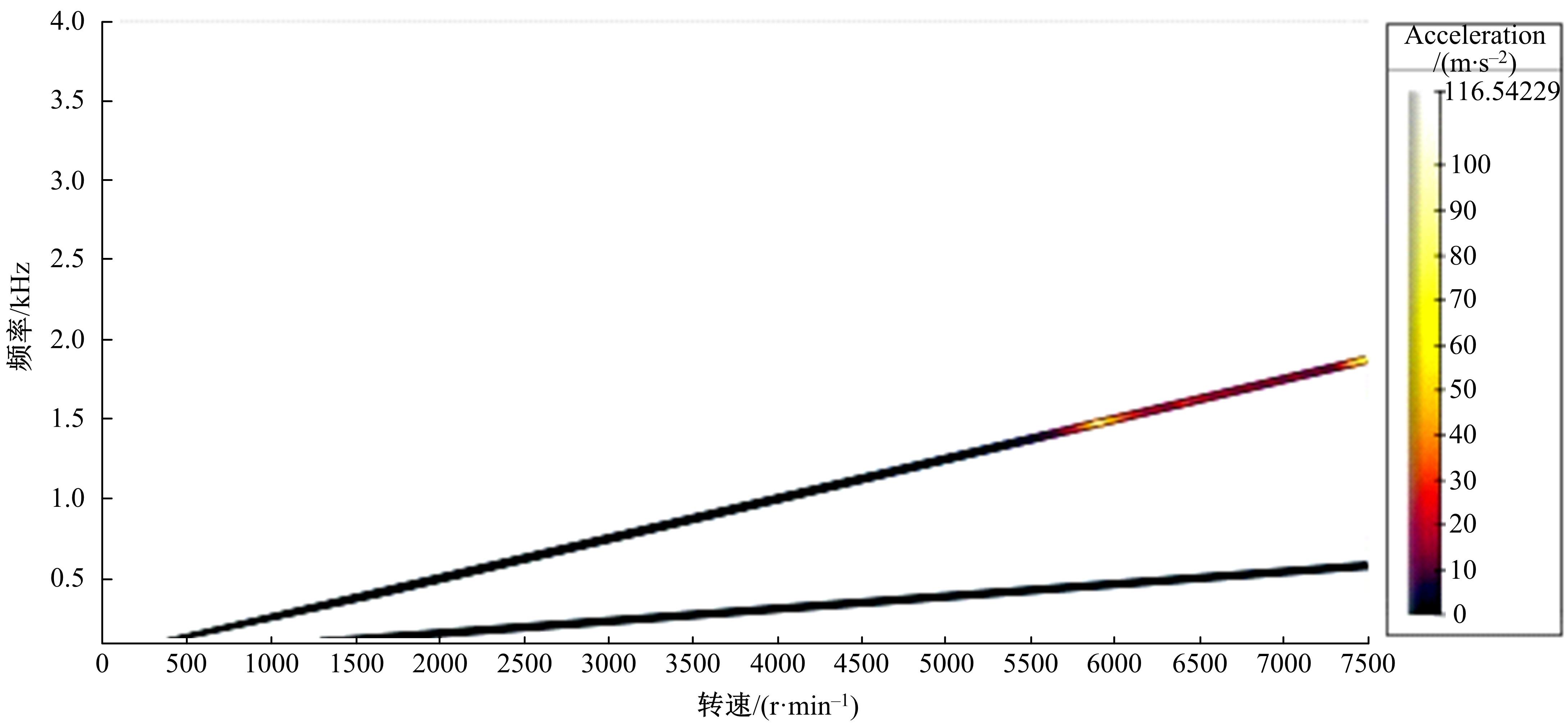

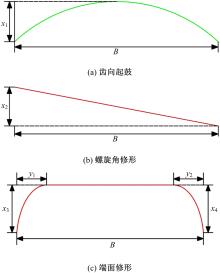

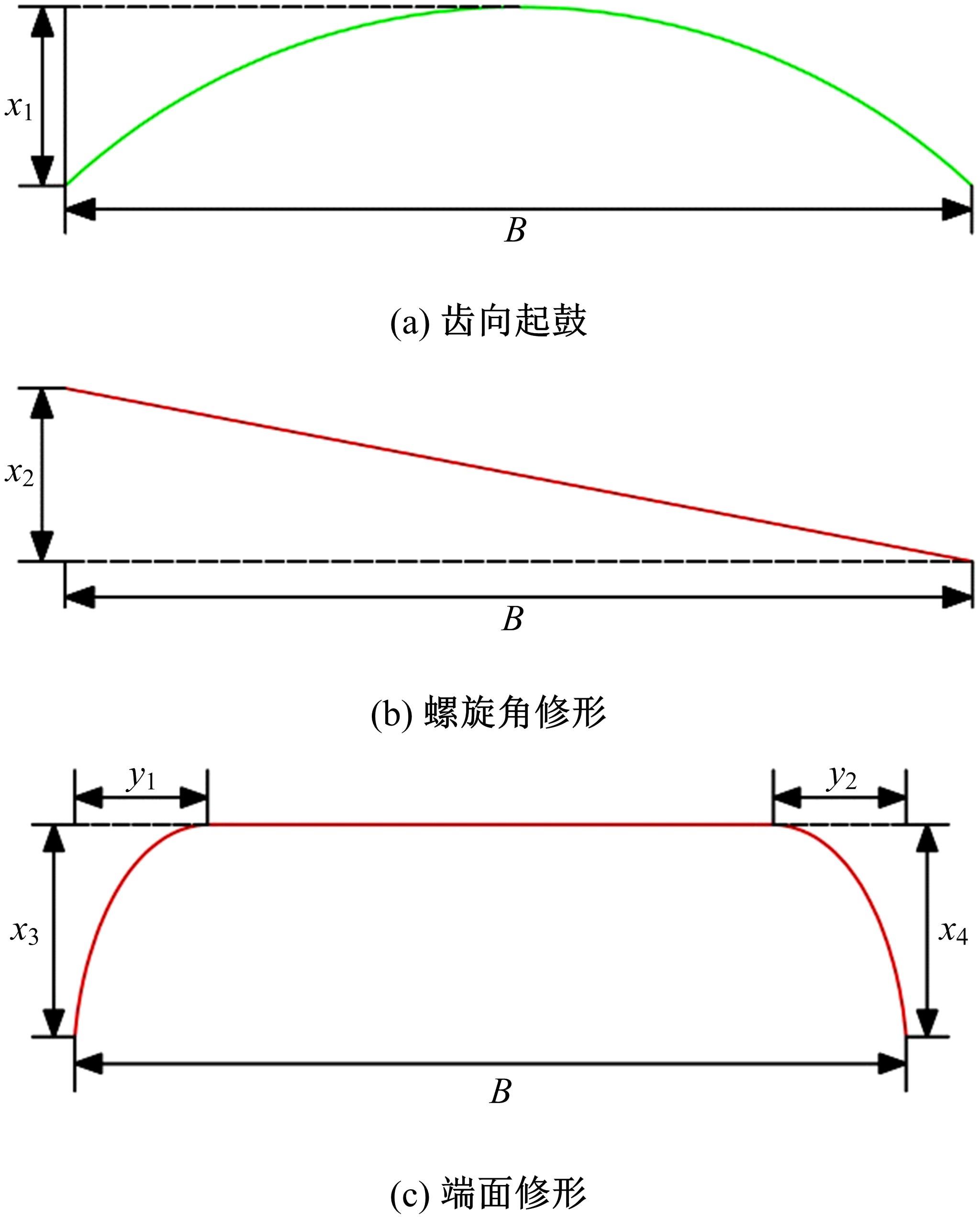

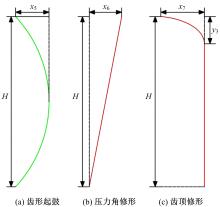

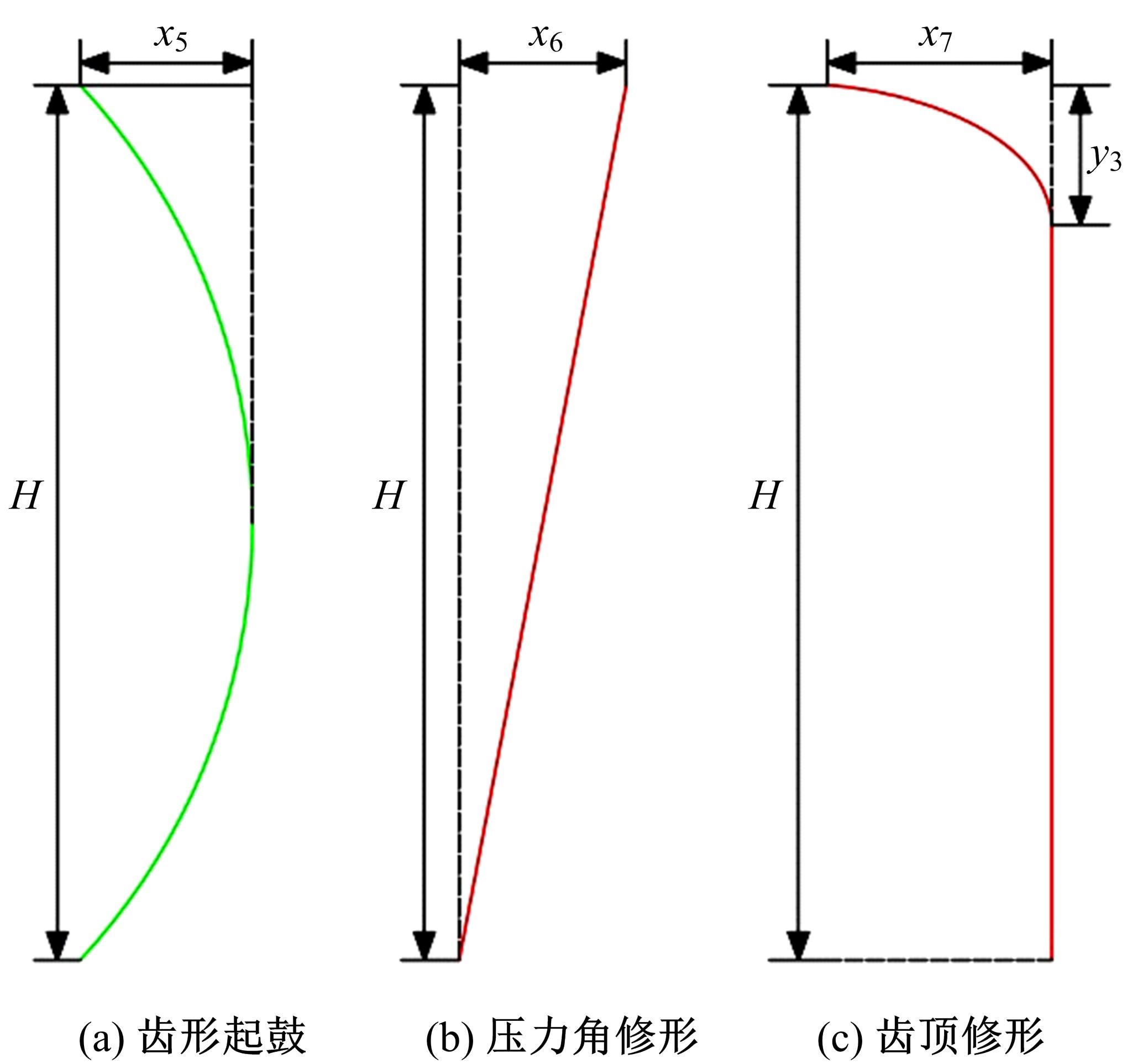

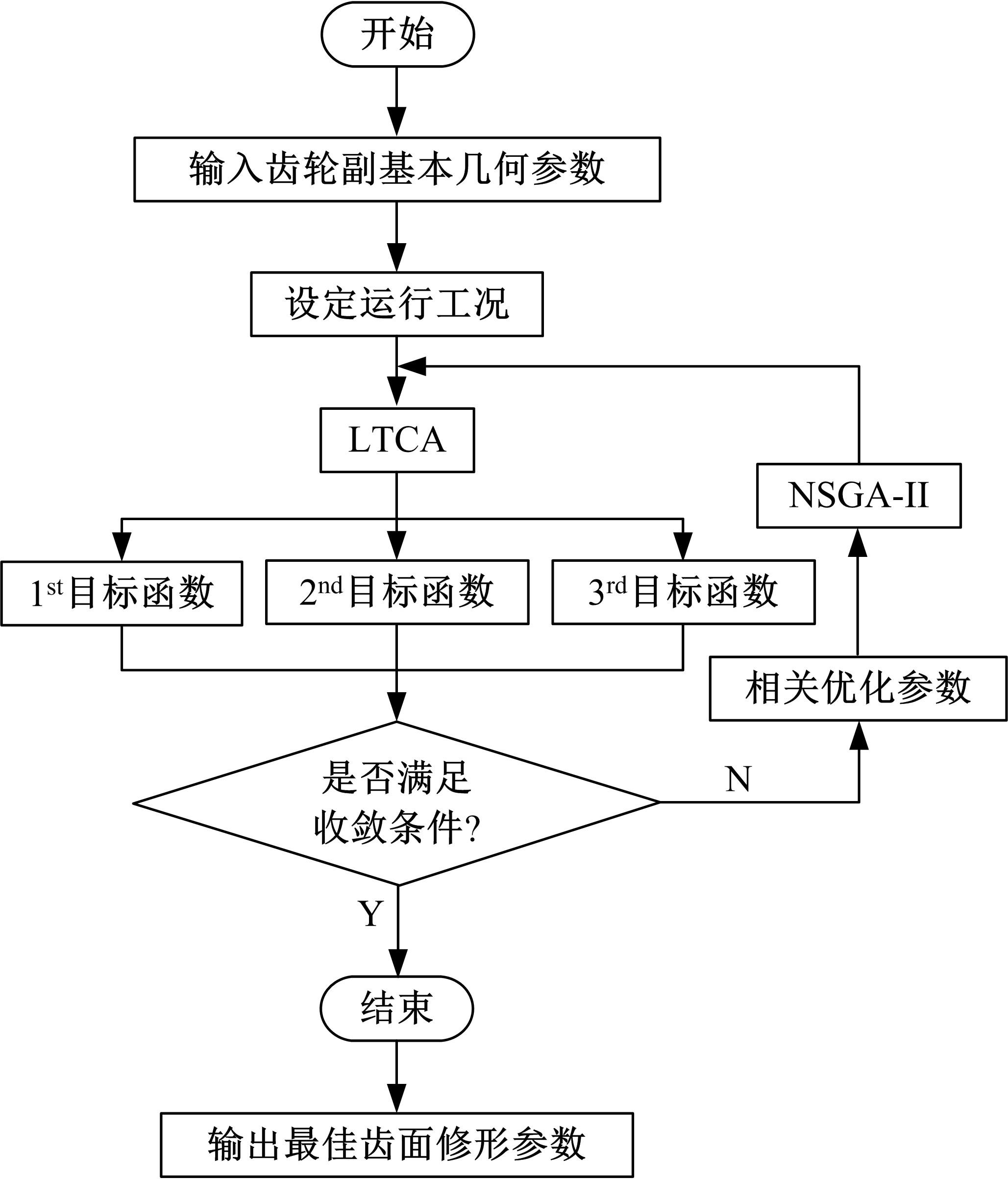

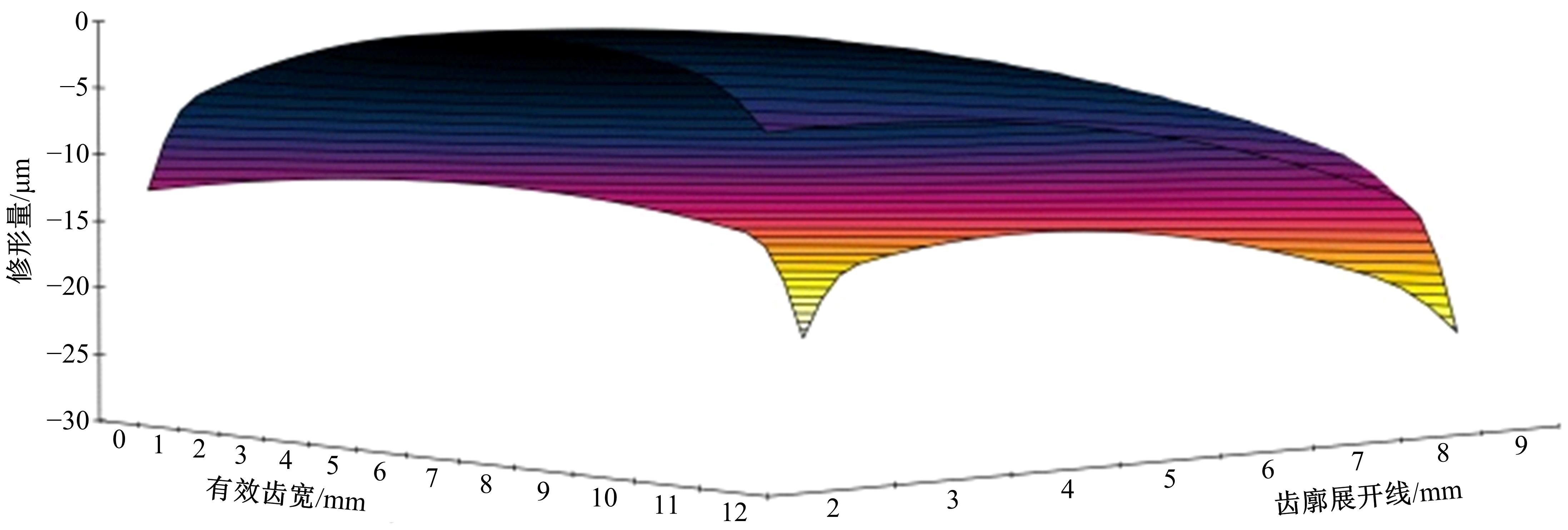

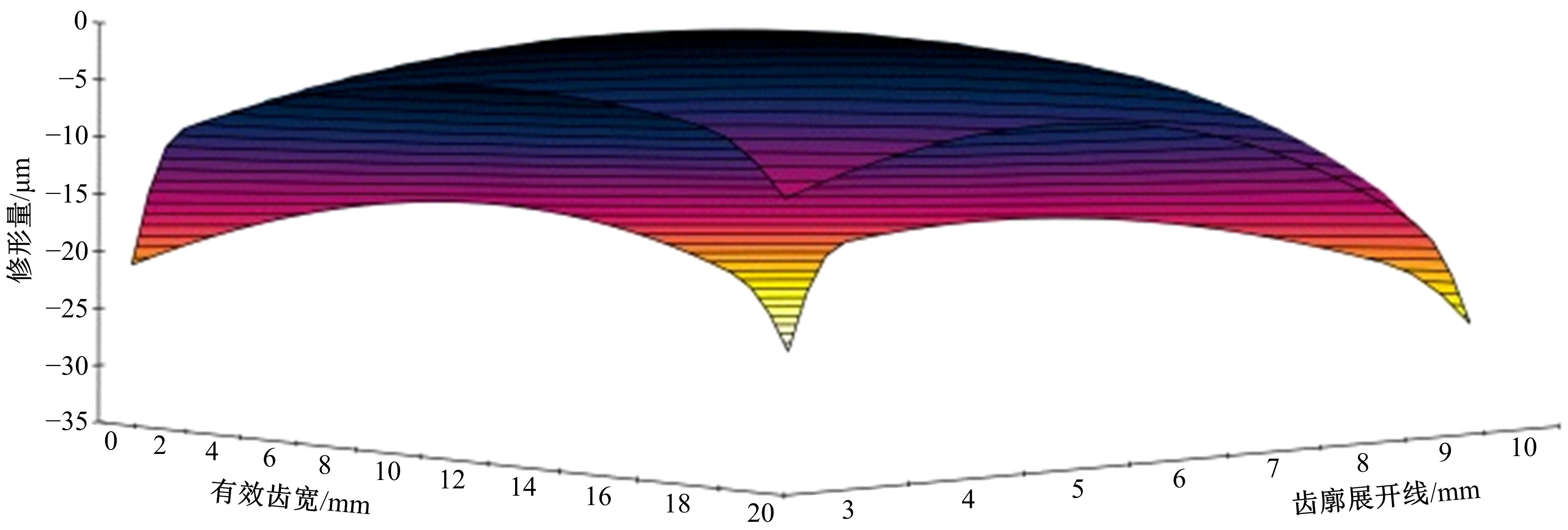

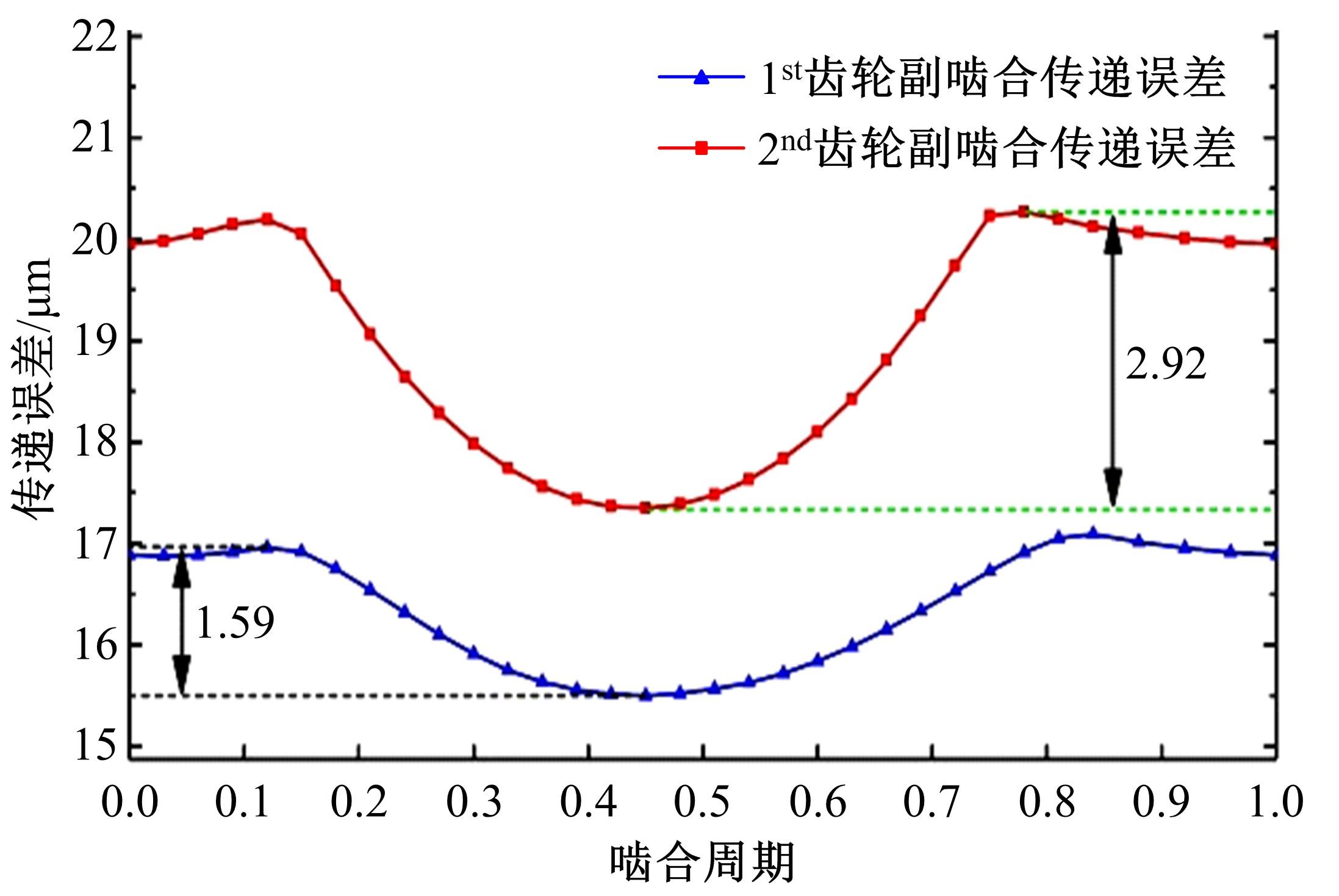

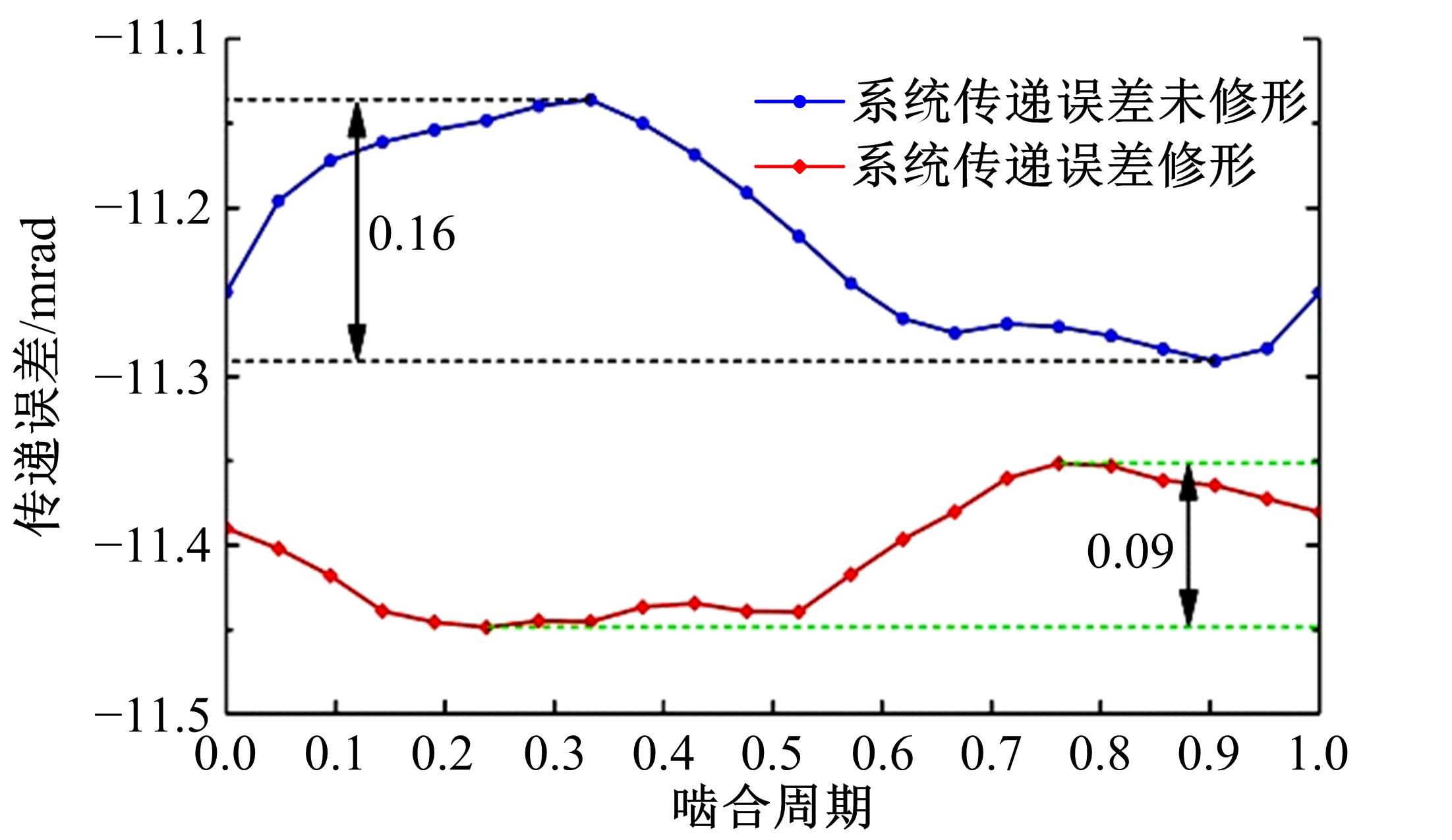

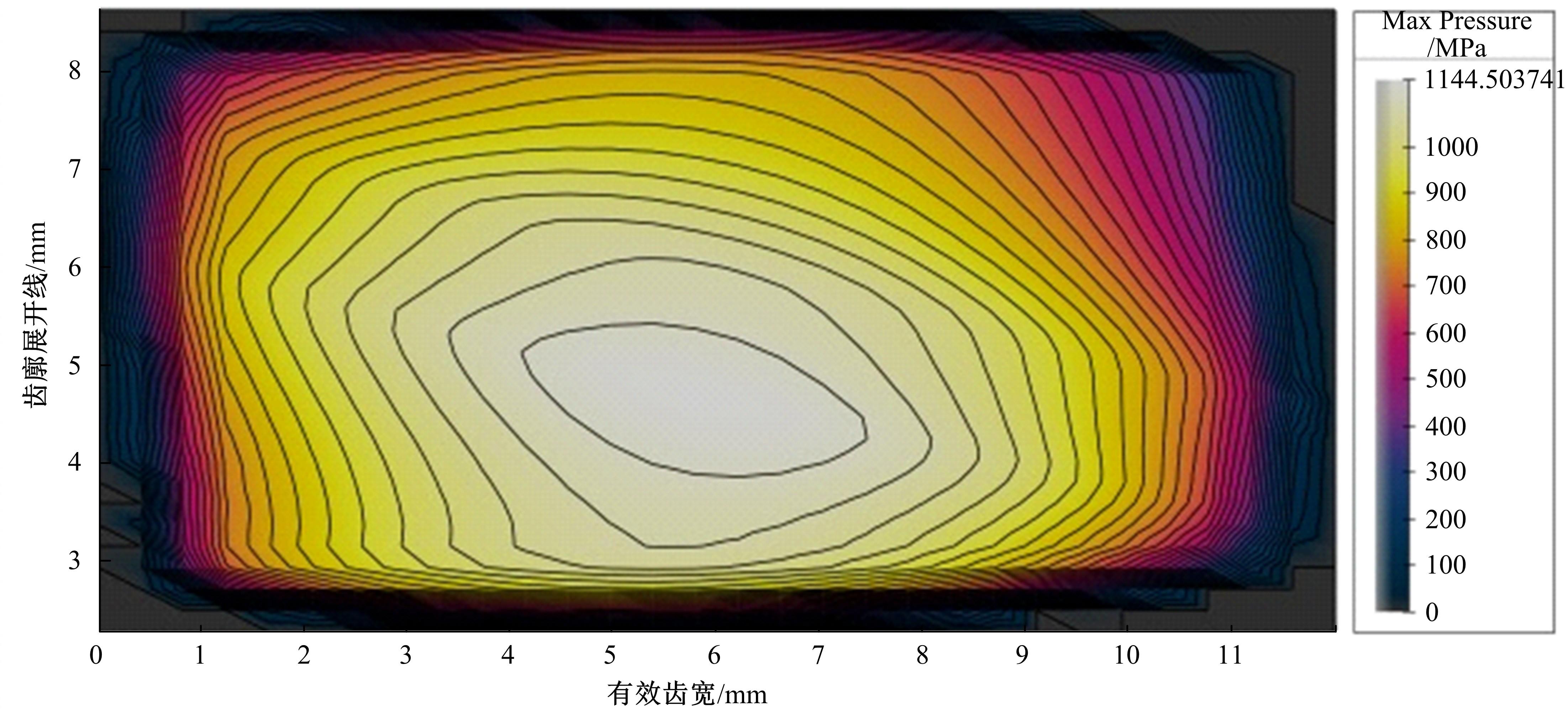

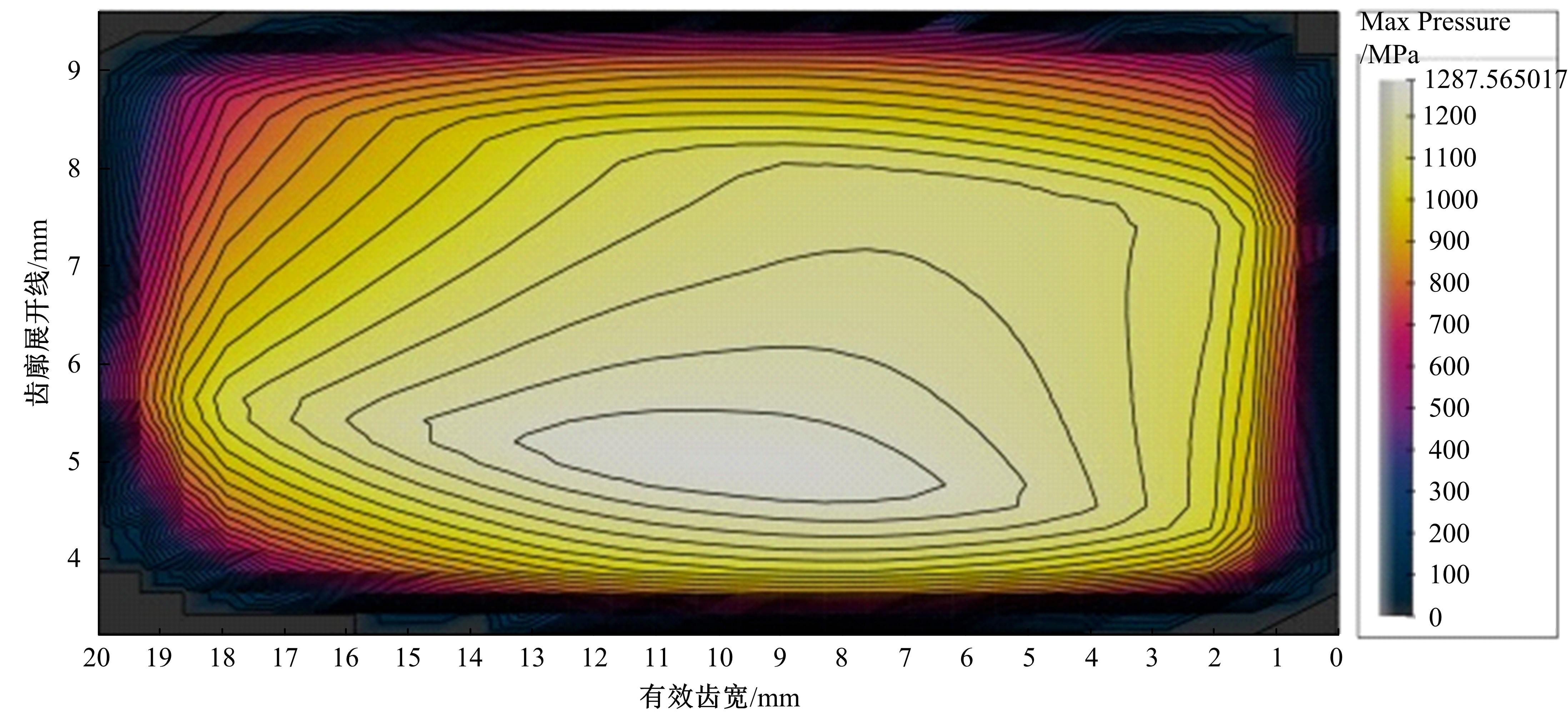

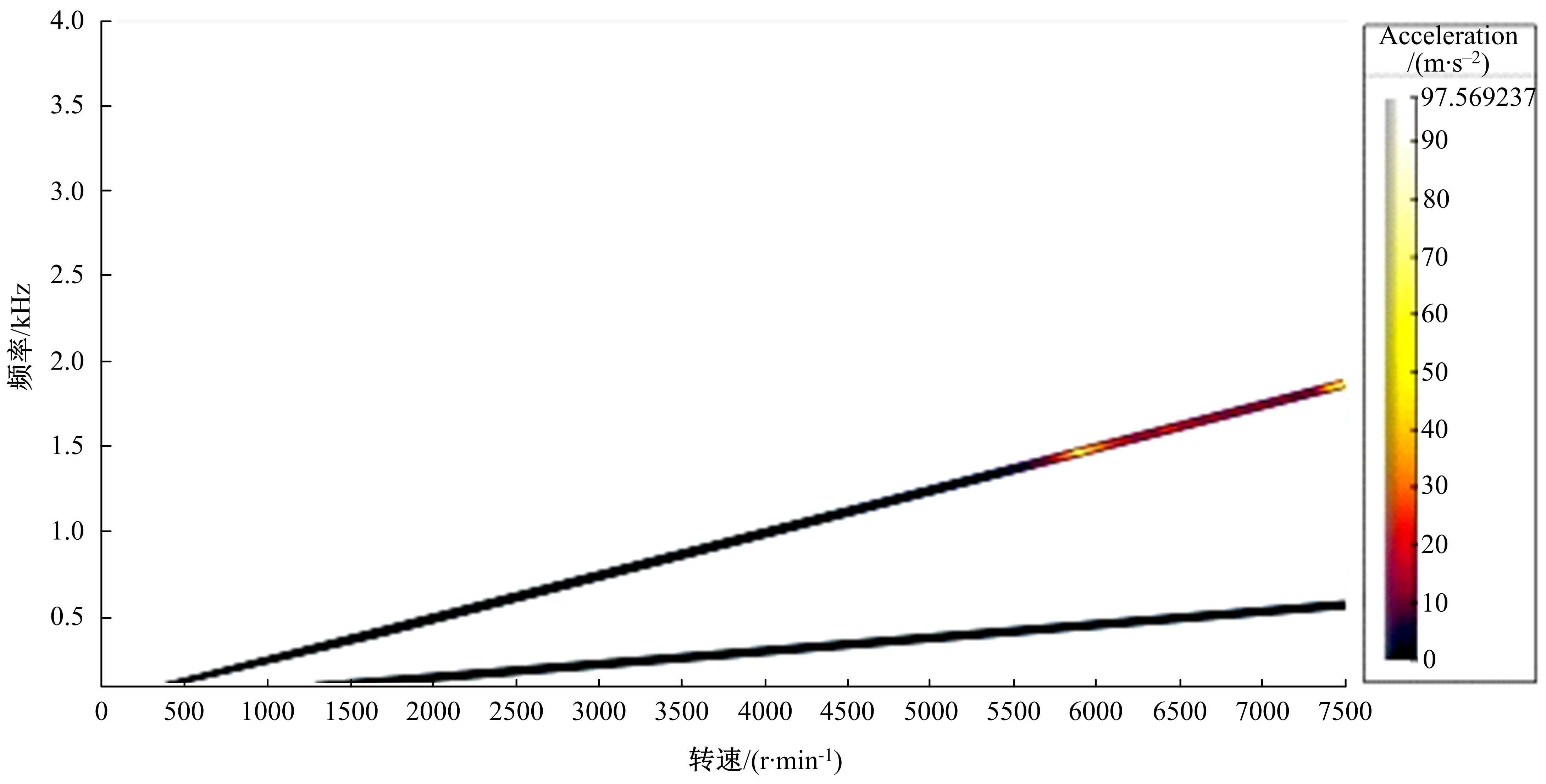

针对齿轮系统在初始设计阶段普遍存在的振动噪声突出问题,本文以某电驱动系统搭载的二级减速齿轮系统为研究对象,以传递误差波动量最小、啮合线方向振动加速度均方根值最小和啮合线离散点载荷密度最小为优化目标,以齿面修形参数为设计变量,采用NSGA-Ⅱ进行了多目标寻优。基于MASTA软件进行了加载齿面接触分析(LTCA),结果表明,相比于未修形阶段,经过微观修形优化后的齿轮系统啮合传递误差和系统传递误差波动量均大幅降低,齿面载荷分布更加均匀,最大接触应力和轴承座振动加速度幅值均显著降低,系统动力学性能得到整体改善。本文的研究思路和方法可为更广泛的齿轮系统优化设计提供指导。

中图分类号:

- TH132.41

| 1 | 齿轮手册编委会. 齿轮手册(上册)[M]. 北京:机械工业出版社, 1990. |

| 2 | Lee C, Lin H H, Oswald F B, et al. Influence of linear profile modification and loading conditions on the dynamic tooth load and stress of high-contact-ratio spur gears[J]. ASME Journal of Mechanical Design, 1991, 113(2): 473-480. |

| 3 | Cai Y, Hayashi T. The optimum modification of tooth profile for a pair of spur gears to make its rotational vibration equal zero[J]. Transactions of the Japan Society of Mechanical Engineers Series C, 1992, 57: 3957-3963. |

| 4 | Reagor C P. An optimal gear design method for minimization of transmission error and vibration excitation [D]. Philadelphia: The Pennsylvania State University, 2010. |

| 5 | 袁冰, 常山, 吴立言, 等. 对角修形对斜齿轮系统准静态及动态特性的影响研究[J]. 西北工业大学学报, 2017, 35(2): 232-239. |

| Yuan Bing, Chang Shan, Wu Li-yan, et al. Effect of cross modification on the quasi-static and dynamic characteristics of helical gear system [J]. Journal of Northwestern Polytechnical University, 2017, 35(2): 232-239. | |

| 6 | 付学中, 方宗德, 贾超, 等. 面齿轮传动啮合刚度分析与修形减振优化[J]. 振动与冲击, 2019, 38(5): 265-272. |

| Fu Xue-zhong, Fang Zong-de, Jia Chao, et al. Meshing stiffness analysis and optimization of vibration reduction and modification for face-gear drives [J]. Journal of Vibration and Shock, 2019, 38(5): 265-272. | |

| 7 | 刘欣荣, 汪中厚, 久保爱三. 基于混沌蚁群算法优化算法的齿轮传动误差研究[J]. 系统仿真学报, 2019, 31(9): 1942-1949. |

| Liu Xin-rong, Wang Zhong-hou, Aizoh Kubo. Research on gear transmission error based on chaotic ant swarm optimization [J]. Journal of System Simulation, 2019, 31(9): 1942-1949. | |

| 8 | 张容川, 周云山, 胡哓岚, 等. 双排行星齿轮系统的齿轮优化修形[J]. 汽车工程, 2018, 40(9): 1118-1124. |

| Zhang Rong-chuan, Zhou Yun-shan, Hu Xiao-lan, et al. The optimized gear modification for double-row planetary gear train[J]. Automotive Engineering, 2018, 40(9): 1118-1124. | |

| 9 | 赵宁, 康士朋, 郭辉, 等. 基于遗传算法的弧齿锥齿轮动态特性优化设计[J]. 航空动力学报, 2010, 25(10): 2396-2402. |

| Zhao Ning, Kang Shi-peng, Guo Hui, et al. Optimization design of spiral bevel gear's dynamic characteristics based on genetic algorithm[J]. Journal of Aerospace Power, 2010, 25(10): 2396-2402. | |

| 10 | 赵宁, 秋朋园, 刘贵立. 高重合度人字齿轮传动动态性能优化设计[J]. 国防科技大学学报, 2015, 37(2): 166-174. |

| Zhao Ning, Qiu Peng-yuan, Liu Gui-li. Optimized design of dynamic behavior of double helical gears with high contact ratio[J]. Journal of National University of Defense Technology, 2015, 37(2): 166-174. | |

| 11 | Marcello F, Farhad S S, Gabriele B, et al. Dynamic optimization of spur gears[J]. Mechanism and Machine Theory, 2011, 46(4): 544-557. |

| 12 | 杨硕文, 唐进元. 一种新的直齿轮复合修形设计方法 [J]. 中南大学学报:自然科学版, 2019, 50(5): 1082-1088. |

| Yang Shuo-wen, Tang Jin-yuan. A new design method for compound modification of spur gear[J]. Journal of Central South University (Science and Technology), 2019, 50(5): 1082-1088. | |

| 13 | 蒋进科, 方宗德, 苏进展. 宽斜齿轮多目标修形优化设计[J]. 西安交通大学学报, 2014, 48(8): 91-97. |

| Jiang Jin-ke, Fang Zong-de, Su Jin-zhan. Multi-objective optimal and modified design for wide helical gear[J]. Journal of Xi'an Jiaotong University, 2014, 48(8): 91-97. | |

| 14 | 贾超, 方宗德. 高速齿轮传递误差和啮入冲击的激励模拟及齿面优化修形[J].振动与冲击, 2019, 38(23): 103-109, 138. |

| Jia Chao, Fang Zong-de. Simulation for transmission error and mesh-in impact excitation of high speed gears and their tooth surface optimal modification[J]. Journal of Vibration and Shock, 2019, 38(23): 103-109, 138. | |

| 15 | Lei Y L, Hou L G, Fu Y, et al. Research on vibration and noise reduction of electric bus gearbox based on multi-objective optimization[J]. Applied Acoustics, 2020,158: 107037. |

| 16 | Lei Y L, Hou L G, Fu Y, et al. Transmission gear whine control by multi-objective optimization and modification design[R]. Detroit: SAE World Congress Experience-Autonomous Technology, 2018. |

| 17 | 赵宁, 秋朋园, 刘贵立. 高重合度人字齿轮轮齿最佳修形优化设计[J]. 国防科技大学学报, 2015, 37(1): 165-170. |

| Zhao Ning, Qiu Peng-yuan, Liu Gui-li. Modification optimization of double helical gears with high contact ratio [J]. Journal of National University of Defense Technology, 2015, 37(1): 165-170. | |

| 18 | 王峰, 方宗德, 李声晋, 等. 人字齿轮系统振动传递分析优化与试验验证 [J]. 机械工程学报, 2015, 51(1): 34-42. |

| Wang Feng, Fang Zong-de, Li Sheng-jin, et al. Analysis optimization and experimental verification of herringbone gear transmission system[J]. Journal of Mechanical Engineering, 2015, 51(1): 34-42. | |

| 19 | 贾超, 方宗德, 张永振. 高速啮合人字齿轮多目标优化修形[J]. 哈尔滨工业大学学报, 2017, 49(1): 166-172. |

| Jia Chao, Fang Zong-de, Zhang Yong-zhen. Multi-objective optimal modification for internal double helical gears with high speed[J]. Journal of Harbin Institute of Technology, 2017, 49(1): 166-172. | |

| 20 | 刘玄, 方宗德, 赵宁. 人字齿轮小轮轴向窜动的多目标复合修行优化[J]. 西安交通大学学报, 2021, 55(1): y1-y9. |

| Liu Xuan, Fang Zong-de, Zhao Ning. Multi-objective compound modification optimization of pinion axial floating for the double helical gears[J]. Journal of Xi'an Jiaotong University, 2021, 55(1): y1-y9. | |

| 21 | 刘艳芳, 赖俊斌, 岳会军, 等. 斜齿轮振动噪声分析方法[J]. 振动、测试与诊断, 2016, 36(5): 960-966. |

| Liu Yan-fang, Lai Jun-bin, Yue Hui-jun, et al. Research on the noise and vibration of the helical gear[J]. Journal of Vibration, Measurement & Diagnosis, 2016, 36(5): 960-966. | |

| 22 | Deb K, Member A, Pratap A, et al. A fast and elitist multiobjective genetic algorithm: NSGA-Ⅱ[J]. Transactions on Evolutionary Computation, 2002, 6(2): 182-197. |

| 23 | Ahmed F, Deb K. Multi-objective optimal path planning using elitist non-dominated sorting genetic algorithms[J]. Soft Computing, 2013, 17(7):1283-1299. |

| 24 | 高媛. 非支配排序遗传算法(NSGA)的研究与应用 [D]. 杭州: 浙江大学信息科学与工程学院, 2006. |

| Gao Yuan. Reaserch and application of fast non-dominated sorting genetic algorithm[D]. Hangzhou: College of Information Science and Engineering, Zhejiang University, 2006. |

| [1] | 郝帅,程川泰,王军年,张君媛,俞有. 运动型SUV驾驶室布置人机优化设计与测试评价[J]. 吉林大学学报(工学版), 2022, 52(7): 1477-1488. |

| [2] | 华琛,牛润新,余彪. 地面车辆机动性评估方法与应用[J]. 吉林大学学报(工学版), 2022, 52(6): 1229-1244. |

| [3] | 李雄,兰凤崇,陈吉清,童芳. Hybird III假人模型与CHUBM人体生物力学模型的正碰损伤对比[J]. 吉林大学学报(工学版), 2022, 52(6): 1264-1272. |

| [4] | 刘兴涛,刘晓剑,武骥,何耀,刘新天. 基于曲线压缩和极限梯度提升算法的锂离子电池健康状态估计[J]. 吉林大学学报(工学版), 2022, 52(6): 1273-1280. |

| [5] | 张英朝,李昀航,郭子瑜,王国华,张喆,苏畅. 长头重型卡车气动减阻优化[J]. 吉林大学学报(工学版), 2022, 52(4): 745-753. |

| [6] | 史文库,张曙光,张友坤,陈志勇,江逸飞,林彬斌. 基于改进海鸥算法的磁流变减振器模型辨识[J]. 吉林大学学报(工学版), 2022, 52(4): 764-772. |

| [7] | 李杰,陈涛,郭文翠,赵旗. 汽车非平稳随机振动空间域虚拟激励法及应用[J]. 吉林大学学报(工学版), 2022, 52(4): 738-744. |

| [8] | 李伟,宋海生,陆浩宇,史文库,王强,王晓俊. 复合材料板簧迟滞特性线性辨识方法[J]. 吉林大学学报(工学版), 2022, 52(4): 829-836. |

| [9] | 庄蔚敏,陈沈,吴迪. 碳纤维增强复合材料包裹强化形式对钢管横向冲击性能的影响[J]. 吉林大学学报(工学版), 2022, 52(4): 819-828. |

| [10] | 姚玉权,仰建岗,高杰,宋亮. 基于性能-费用模型的厂拌再生沥青混合料优化设计[J]. 吉林大学学报(工学版), 2022, 52(3): 585-595. |

| [11] | 姜斌祥,姜彤彤,王永雷. 基于文化遗传算法的毒品检验区块链共识算法优化[J]. 吉林大学学报(工学版), 2022, 52(3): 684-692. |

| [12] | 张立杰,阿喜塔,田笑,李稳. 基于Gamma过程的加速退化试验多目标优化设计[J]. 吉林大学学报(工学版), 2022, 52(2): 361-367. |

| [13] | 赵泓荀,杨兆军,陈传海,田海龙,王立平. 考虑参数权重的数控机床电主轴加速试验优化设计[J]. 吉林大学学报(工学版), 2022, 52(2): 409-416. |

| [14] | 段亮,宋春元,刘超,魏苇,吕成吉. 基于机器学习的高速列车轴承温度状态识别[J]. 吉林大学学报(工学版), 2022, 52(1): 53-62. |

| [15] | 庄蔚敏,陈沈,王楠. 温度对车身钢铝胶铆连接结构热应力变化的影响[J]. 吉林大学学报(工学版), 2022, 52(1): 70-78. |

|

||