吉林大学学报(工学版) ›› 2023, Vol. 53 ›› Issue (1): 170-177.doi: 10.13229/j.cnki.jdxbgxb20210559

• 交通运输工程·土木工程 • 上一篇

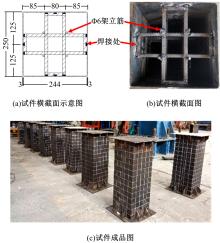

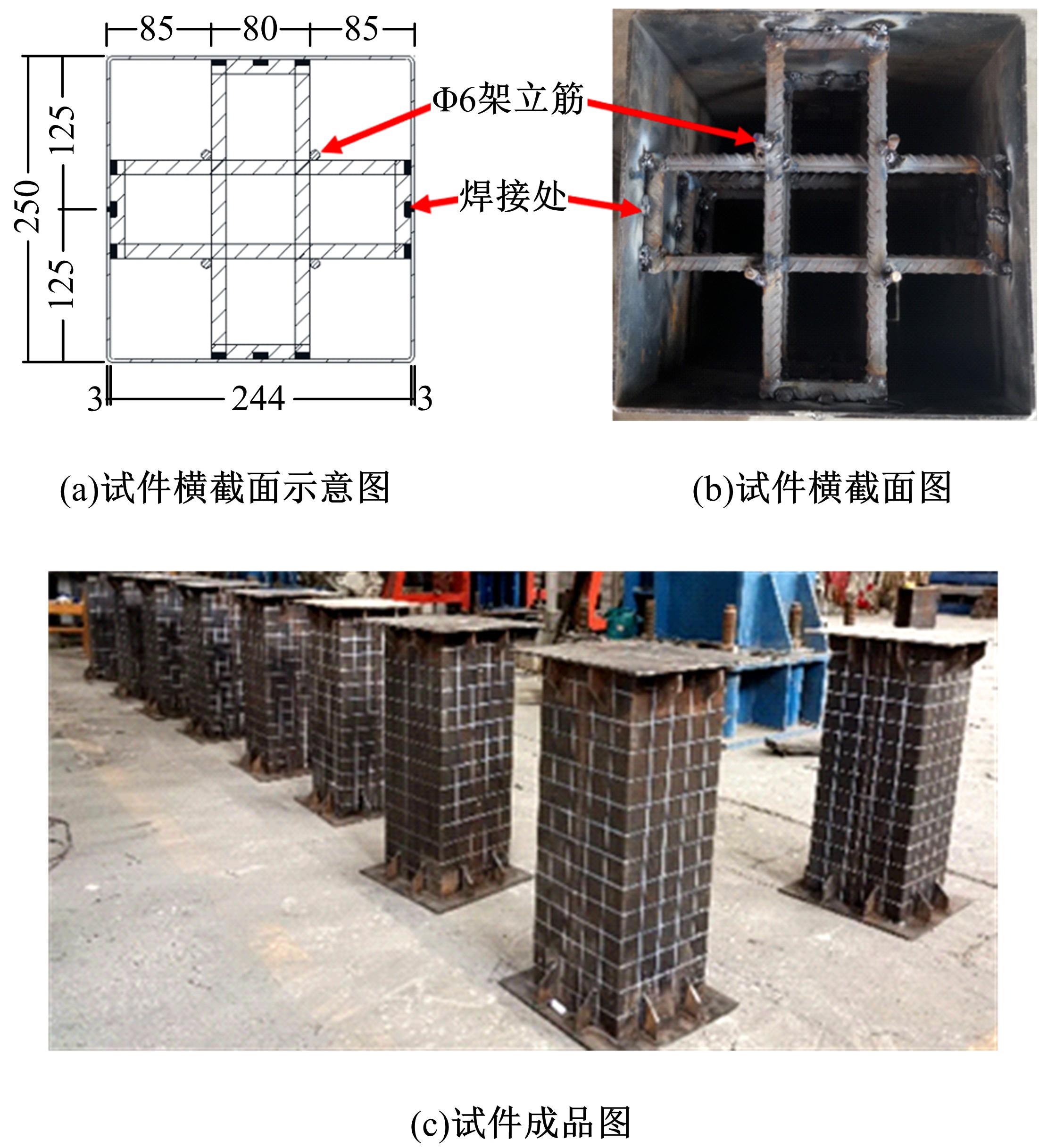

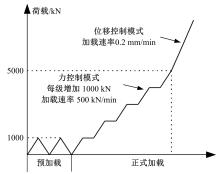

拉筋约束薄壁方钢管混凝土短柱轴压性能

- 湘潭大学 土木工程与力学学院,湖南 湘潭 411105

Axial compression performance of thin⁃walled concrete⁃filled square steel tube short columns confined by stirrup

Jun CHEN( ),Jia-gui NI,Zhe LIU,Wen-bo MA,Xu-hua DENG(

),Jia-gui NI,Zhe LIU,Wen-bo MA,Xu-hua DENG( )

)

- College of Civil Engineering and Mechanics,Xiangtan University,Xiangtan 411105,China

摘要:

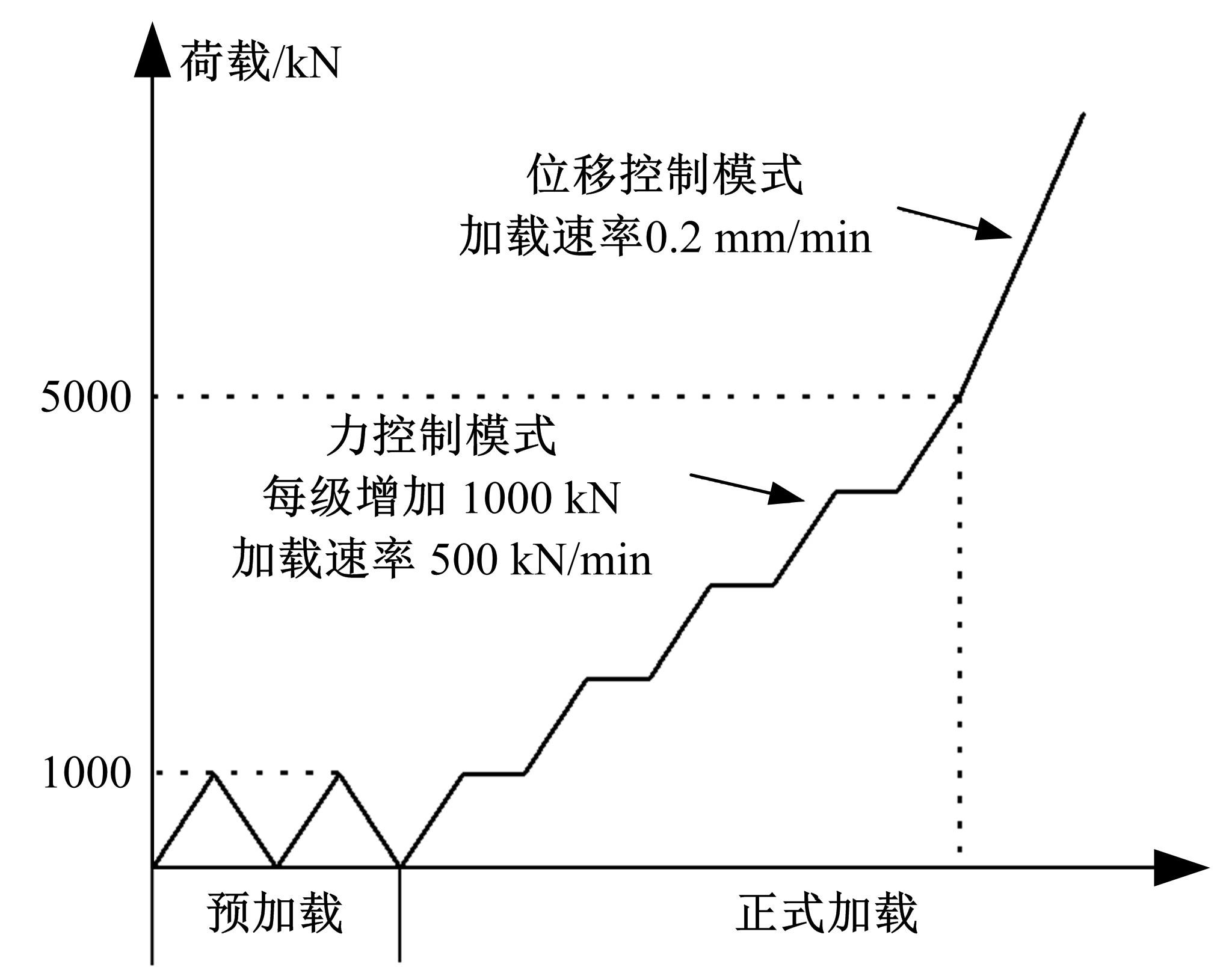

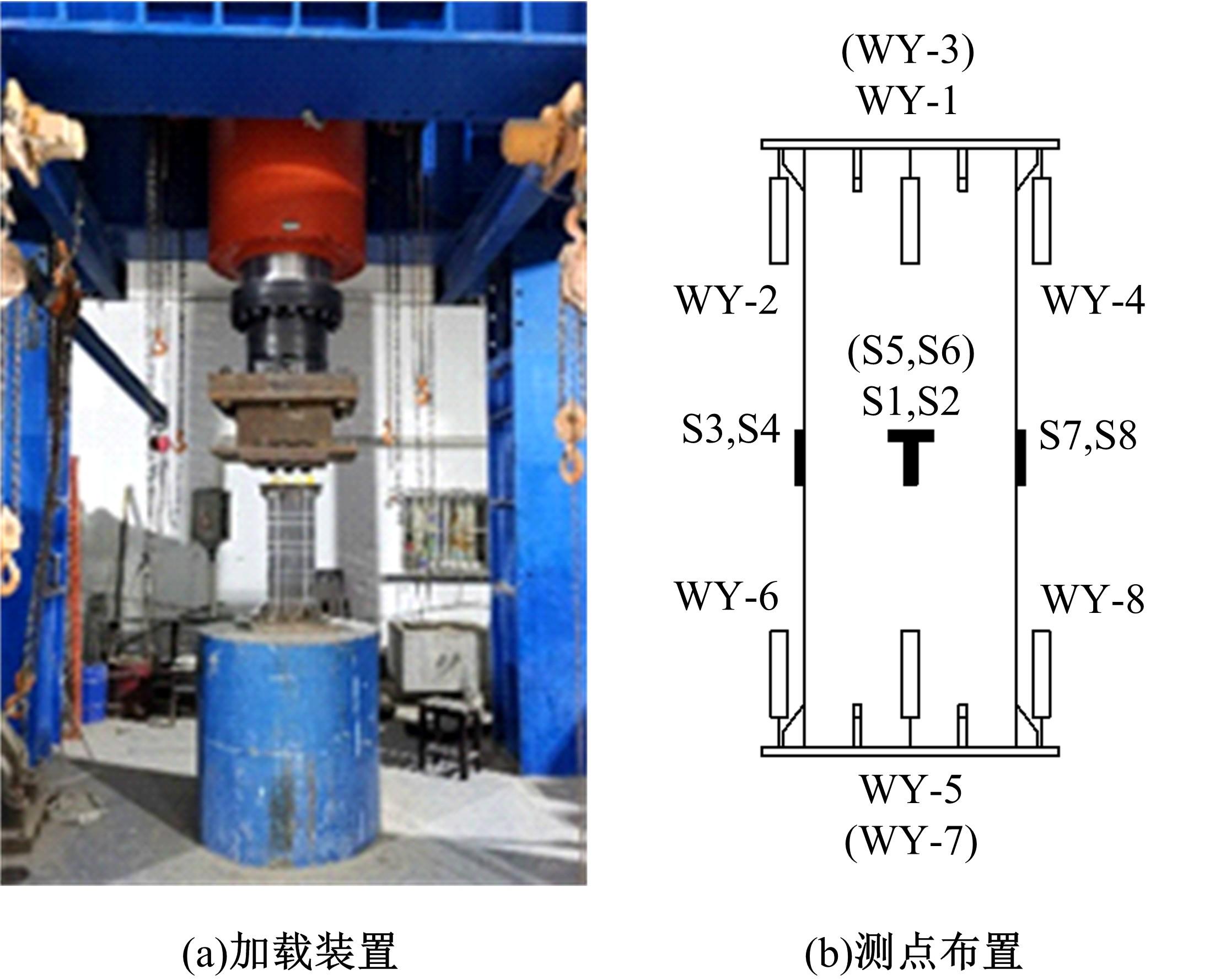

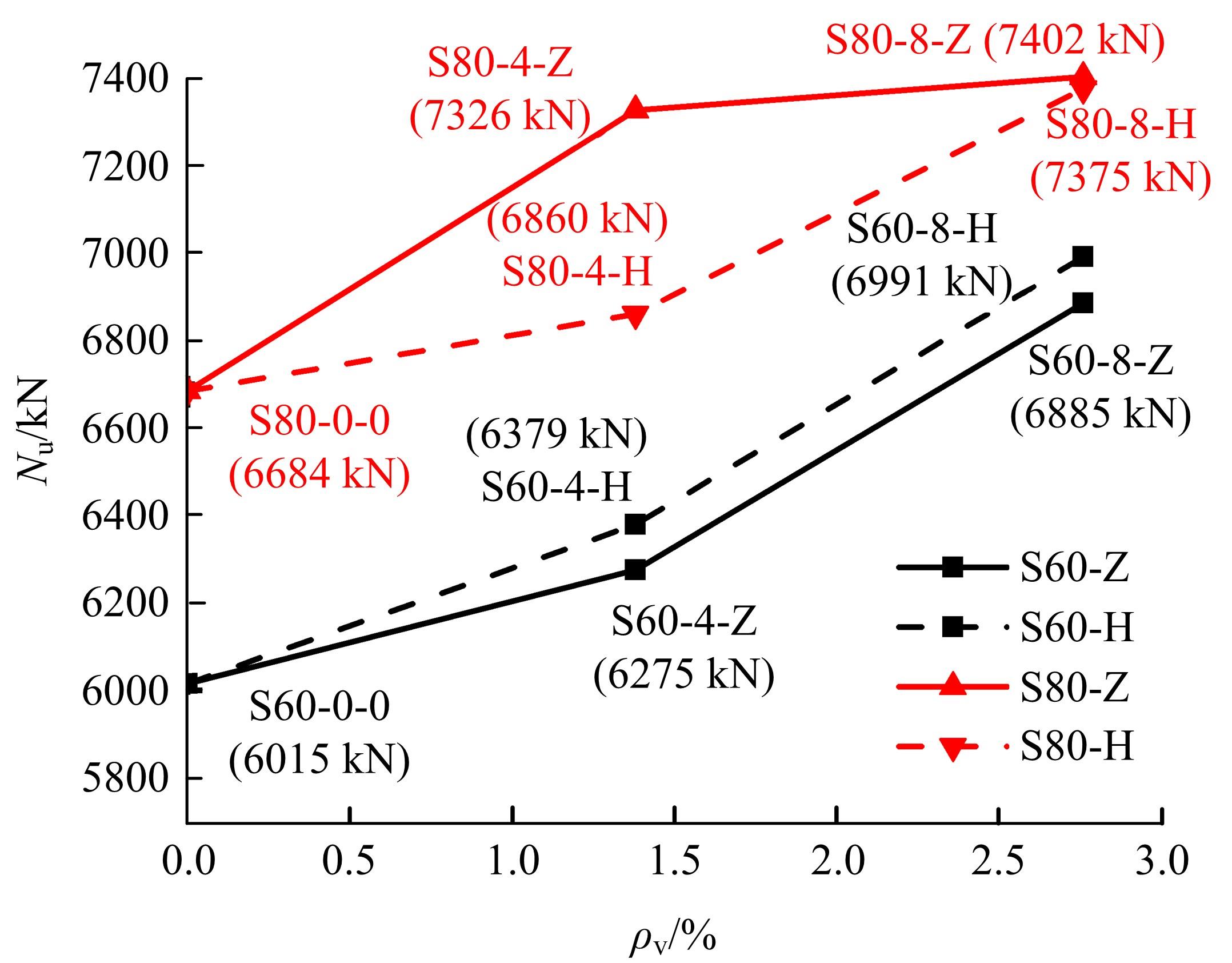

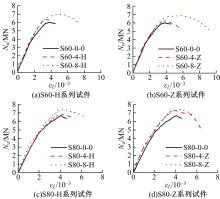

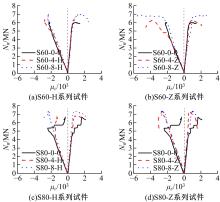

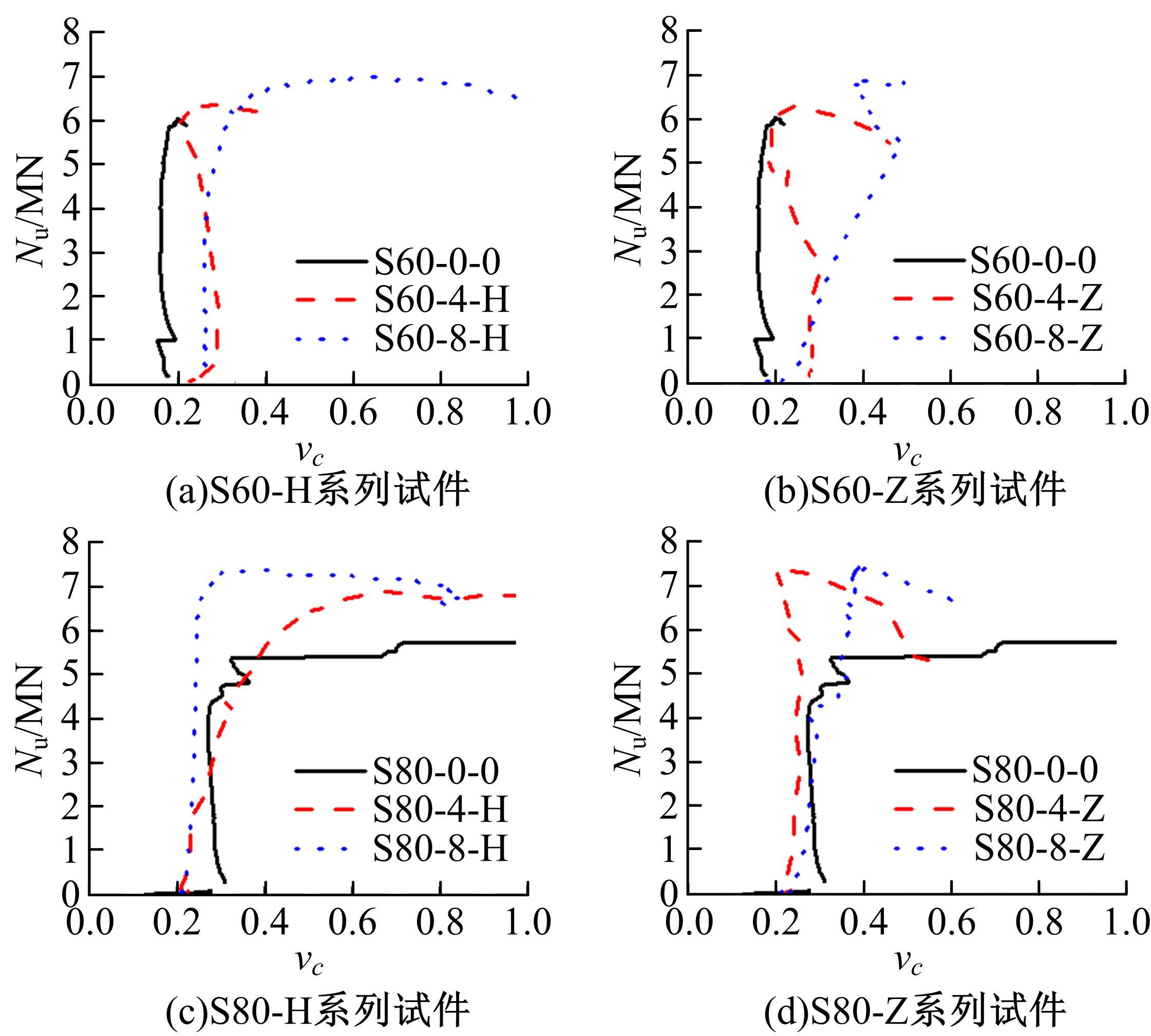

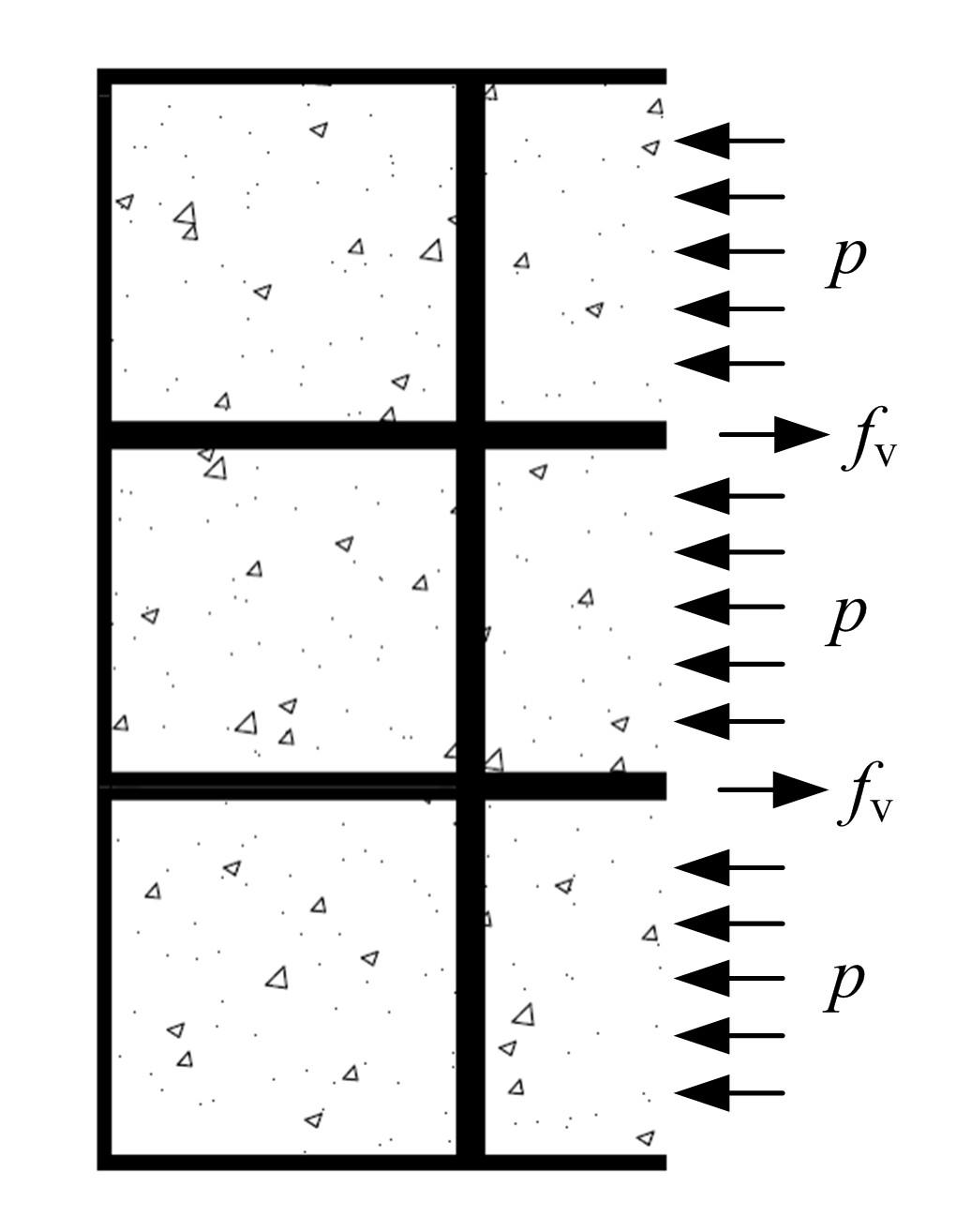

通过对拉筋约束薄壁方钢管混凝土短柱的轴压试验,研究了混凝土强度、拉筋体积配箍率以及拉筋与钢管壁的连接方式对试件极限承载力、刚度、延性以及横向变形系数的影响。研究结果表明:内置拉筋有助于提高试件的极限承载力及延性,提高效果随着混凝土强度的提升而降低,随着拉筋体积配箍率的增大而提升;拉筋与钢管壁焊接处理后,试件的各项力学性能并无明显改变;利用极限强度理论对极限状态下的试件进行力学分析,推导出拉筋约束方钢管混凝土轴压短柱极限承载力的计算公式,并结合其他文献中类似试件的试验数据对公式进行了验证,证明了本公式的正确性。

中图分类号:

- TU398

| 1 | 李斌,郭世壮,高春彦.带肋薄壁方钢管混凝土短柱轴压力学性能试验研究[J].混凝土,2018(3):53-55, 59. |

| Li Bin, Guo Shi-zhuang, Gao Chun-yan. Experimental research on mechanics behavior of stub-column concrete-filled thin-walled stiffened square steel tube under axial load[J]. Concrete, 2018(3): 53-55, 59. | |

| 2 | 张信龙,陈勇,刘庆东,等.配筋方钢管混凝土短柱受压试验和承载力计算[J].混凝土,2020(12):11-14, 20. |

| Zhang Xin-long, Chen Yong, Liu Qing-dong, et al. Axial compression test and calculation of bar-reinforced concrete filled square steel tubular stub column[J]. Concrete, 2020(12):11-14, 20. | |

| 3 | 万城勇,查晓雄.配筋钢管混凝土轴压短柱受力性能试验研究[J].建筑结构学报,2013,34():259-266. |

| Wan Cheng-yong, Zha Xiao-xiong. Experiment study of reinforced concrete filled steel tubular columns subjected to axial compression[J]. Journal of Building Structures, 2013,34(Sup.1):259-266. | |

| 4 | Wang Qing-xiang, Zhao Da-zhou, Guan Ping. Experimental study on the strength and ductility of steel tubular columns filled with steel-reinforced concrete[J]. Engineering Structures,2004,26(7):907-915. |

| 5 | Ding Fa-xing, Zhu Jiang, Cheng Shan-shan, et al. Comparative study of stirrup-confined circular concrete-filled steel tubular stub columns under axial loading[J]. Thin-walled Structures,2018,123:294-304. |

| 6 | Ding Fa-xing, Lu De-ren, Bai Yu, et al. Comparative study of square stirrup-confined concrete-filled steel tubular stub columns under axial loading[J]. Thin-walled Structures,2016,98:443-453. |

| 7 | 朱江,丁发兴,王莉萍.带拉筋圆钢管混凝土轴压短柱受力性能研究[J].建筑结构学报,2017,38():285-290. |

| Zhu Jiang, Ding Fa-xing, Wang Li-ping. Mechanical behavior of stirrup-confined circular concrete-filled steel tubular stub columns under axial loading[J]. Journal of Building Structures, 2017,38(Sup.1):285-290. | |

| 8 | 饶玉龙,张继承,李勇,等.高强冷弯矩形钢管混凝土短柱轴压承载力试验[J].华侨大学学报:自然科学版,2019,40(3):338-343. |

| Rao Yu-long, Zhang Ji-cheng, Li Yong, et al. Experiment on mechanical behavior of concrete-filled high-strength cold-formed steel tube short column under axial load[J]. Journal of Huaqiao University (Natural Science),2019,40(3):338-343. | |

| 9 | 丁发兴,刘怡岑,吕飞,等.拉筋接触方式对高轴压比大尺寸钢管混凝土柱滞回性能影响试验研究[J]. 建筑结构学报,2021,42(9):62-72. |

| Ding Fa-xing, Liu Yi-cen, Lv Fei, et al. Pseudo-static tests of stirrup-confined concrete-filled steel tube columns under high axial pressure: the influence of contact mode between stirrup and steel tube[J]. Journal of Building Structures,2021,42(9):62-72. | |

| 10 | 丁发兴,付磊,龚永智,等.方钢管混凝土轴压短柱的力学性能研究[J].深圳大学学报:理工版,2014,31(6):583-592. |

| Ding Fa-xing, Fu Lei, Gong Yong-zhi, et al. Behavior of concrete-filled square steel tubular stub columns under axially compressive loading[J]. Journal of Shenzhen University Science and Engineering, 2014,31(6):583-592. | |

| 11 | 蔡绍怀.现代钢管混凝土结构[M].北京:人民交通出版社,2007. |

| 12 | 韩林海,杨有福.矩形钢管混凝土轴心受压构件强度承载力的试验研究[J].土木工程学报,2001,34(4):22-31. |

| Han Lin-hai, Yang You-fu. Study on axial bearing capacity of concrete filled steel tube columns with rectangular section[J]. China Civil Engineering Journal, 2001,34(4): 22-31. | |

| 13 | ACI 318―14. Building code requirements for structural concrete and commentary [S]. |

| 14 | 熊公玉,熊明祥.高强钢丝网片增强矩形钢管混凝土短柱轴压力学性能研究[J]. 广东建材,2019,35(2):56-60, 19. |

| Xiong Gong-yu, Xiong Ming-xiang. Study on axial pressure performance of rectangular steel tube concrete short column reinforced by high-strength steel mesh sheet[J]. Guangdong Building Materials, 2019,35(2): 56-60, 19. | |

| 15 | Lu De-ren, Wang Wen-jun, Ding Fa-xing, et al. The impact of stirrups on the composite action of concrete-filled steel tubular stub columns under axial loading[J]. Structures, 2021(30):756-802. |

| 16 | Ding Fa-xing, Lu De-ren, Bai Yu, et al. Comparative study of square stirrup-confined concrete-filled steel tubular stub columns under axial loading[J]. Thin-walled Structures, 2016(98):443-453. |

| [1] | 吴迪,耿文华,李洪梅,孙大千. 铝/钢等离子弧熔⁃钎焊接头界面电子背散射衍射分析[J]. 吉林大学学报(工学版), 2023, 53(5): 1331-1337. |

| [2] | 王毅红,田桥罗,兰官奇,姚圣法,张建雄,刘喜. 630 MPa高强钢筋混凝土大偏压柱受力性能试验[J]. 吉林大学学报(工学版), 2022, 52(11): 2626-2635. |

| [3] | 许博,李传习. 基于灰色理论的大跨度钢管混凝土拱桥承载能力检测方法[J]. 吉林大学学报(工学版), 2022, 52(10): 2360-2366. |

| [4] | 周靖,黎亚军,赵卫锋,罗宗健,补国斌. 胶合竹板-钢管约束收尘石粉混凝土柱的偏压性能[J]. 吉林大学学报(工学版), 2021, 51(6): 2096-2107. |

| [5] | 刁延松,郭荡,屠康,焦圣伦,刘芸,刘秀丽. 新型异形钢管混凝土柱⁃钢梁节点抗震性能试验[J]. 吉林大学学报(工学版), 2021, 51(5): 1724-1733. |

| [6] | 杨德磊,童乐为. 支管受轴向受拉工况下CHS-CFSHS T型节点应力集中系数计算公式[J]. 吉林大学学报(工学版), 2019, 49(6): 1891-1899. |

| [7] | 李碧雄,廖桥,章一萍,周练,隗萍,刘侃. 超高强钢筋工程用水泥基复合材料梁受弯计算理论[J]. 吉林大学学报(工学版), 2019, 49(4): 1153-1161. |

| [8] | 邱小明, 王银雪, 姚汉伟, 房雪晴, 邢飞. 基于灰色关联的DP1180/DP590异质点焊接头工艺参数优化[J]. 吉林大学学报(工学版), 2018, 48(4): 1147-1152. |

| [9] | 庄蔚敏, 赵文增, 解东旋, 李兵. 超高强钢/铝合金热铆连接接头性能[J]. 吉林大学学报(工学版), 2018, 48(4): 1016-1022. |

| [10] | 吕萌萌, 谷诤巍, 徐虹, 李欣. 超高强度防撞梁热冲压成形工艺优化[J]. 吉林大学学报(工学版), 2017, 47(6): 1834-1841. |

| [11] | 张志强, 贾晓飞, 袁秋菊. 基于Yoshida-Uemori模型的TRIP800高强钢回弹分析[J]. 吉林大学学报(工学版), 2015, 45(6): 1852-1856. |

| [12] | 庄蔚敏, 解东旋, 余天明, 于皖东. 基于损伤-相变本构模型的高强钢热成形数值模拟分析[J]. 吉林大学学报(工学版), 2015, 45(4): 1206-1212. |

| [13] | 杨慧艳, 何晓聪, 周森. 压印接头强度的有限元模型及理论计算方法[J]. 吉林大学学报(工学版), 2015, 45(3): 864-871. |

| [14] | 云迪, 刘贺, 张素梅. 中承式钢管混凝土拱桥弹塑性地震时程分析[J]. 吉林大学学报(工学版), 2014, 44(6): 1633-1638. |

| [15] | 郭俊平1, 邓宗才1, 卢海波2, 林劲松2. 预应力高强钢绞线网抗剪加固钢筋混凝土梁试验[J]. 吉林大学学报(工学版), 2014, 44(4): 968-977. |

|

||