吉林大学学报(工学版) ›› 2023, Vol. 53 ›› Issue (1): 18-30.doi: 10.13229/j.cnki.jdxbgxb20220600

碳纤维增强热塑性复合材料研究进展

邓海1,2,3( ),王超3,杨京浩4,王利忠3,王明辉4,李志刚4(

),王超3,杨京浩4,王利忠3,王明辉4,李志刚4( )

)

- 1.中南大学 交通运输工程学院,长沙 410075

2.中南大学 轨道交通安全教育部重点实验室,长沙 410075

3.中车长春轨道客车股份有限公司 国家轨道客车工程研究中心,长春 130062

4.吉林大学 材料科学与工程学院,长春 130022

Research progress of carbon fiber reinforced thermoplastic composites

Hai DENG1,2,3( ),Chao WANG3,Jing-hao YANG4,Li-zhong WANG3,Ming-hui WANG4,Zhi-gang LI4(

),Chao WANG3,Jing-hao YANG4,Li-zhong WANG3,Ming-hui WANG4,Zhi-gang LI4( )

)

- 1.Key Laboratory of Traffic Safety on Track,Ministry of Education,Central South University,Changsha 410075

2.School of Traffic & Transportation Engineering,Central South University,Changsha 410075,China

3.National Railway Vehicle Engineering Research Center,CRRC Changchun Railway Vehicles Co. ,Ltd. ,Changchun 130062,China

4.College of Material Science and Engineering,Jilin University,Changchun 130022,China

摘要:

系统介绍了碳纤维增强热塑性复合材料的研究进展,包括界面改性(物理改性和化学改性)、结构设计(仿生结构、三维编织结构和机械结构)和成型工艺(树脂传递模塑成型、自动铺放成型、长纤维增强热塑性树脂成型工艺、热压成型和3D打印成型)。最后,介绍了碳纤维增强热塑性复合材料在运载行业的应用和发展情况,并对其未来发展情况进行了展望。

中图分类号:

- TB332

| 1 | 卡里斯特, 来斯威什. 材料科学与工程基础[M].郭福等译. 北京:化学工业出版社,2015. |

| 2 | 王善元, 张汝光. 纤维增强复合材料[M]. 上海:中国纺织大学出版社,1998. |

| 3 | Wang Q, Ning H, Vaidya U, et al. Fiber content measurement for carbon fiber-reinforced thermoplastic composites using carbonization-in-nitrogen method[J]. Journal of Thermoplastic Composite Materials, 2018,31(1): 79-90. |

| 4 | Alshammari B A, Alsuhybani M S, Almushaikeh A M, et al. Comprehensive review of the properties and modifications of carbon fiber-reinforced thermoplastic composites[J]. Polymers (Basel), 2021, 13(15):2474. |

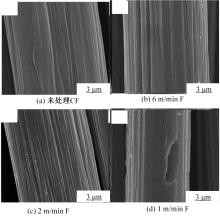

| 5 | Vinodhini J, Sudheendra K, Balachandran M, et al. Influence of argon plasma treatment on carbon fibre reinforced high performance thermoplastic composite[J]. High Performance Polymers, 2020, 33(3): 285-294. |

| 6 | Lu C, Qiu S, Lu X, et al. Enhancing the interfacial strength of carbon fiber/poly(ether ether ketone) hybrid composites by plasma treatments[J]. Polymers (Basel), 2019, 11(5):753. |

| 7 | Cho B G, Hwang S H, Park M, et al. The effects of plasma surface treatment on the mechanical properties of polycarbonate/carbon nanotube/carbon fiber composites[J]. Composites Part B: Engineering, 2019, 160: 436-445. |

| 8 | Irisawa T, Shibata M, Yamamoto T, et al. Effects of carbon nanofibers on carbon fiber reinforced thermoplastics made with in situ polymerizable polyamide 6[J]. Composites Part A: Applied Science and Manufacturing, 2020, 138: No.106051. |

| 9 | Cheon J, Kim M. Impact resistance and interlaminar shear strength enhancement of carbon fiber reinforced thermoplastic composites by introducing MWCNT-anchored carbon fiber[J]. Composites Part B: Engineering, 2021, 217: 108872. |

| 10 | Chen J, Wang K, Zhao Y. Enhanced interfacial interactions of carbon fiber reinforced PEEK composites by regulating PEI and graphene oxide complex sizing at the interface[J]. Composites Science and Technology, 2018, 154: 175-186. |

| 11 | Liu L, Jia C, He J, et al. Interfacial characterization, control and modification of carbon fiber reinforced polymer composites[J]. Composites Science and Technology, 2015, 121: 56-72. |

| 12 | Hu J, Li F, Wang B, et al. A two-step combination strategy for significantly enhancing the interfacial adhesion of CF/PPS composites: the liquid-phase oxidation followed by grafting of silane coupling agent[J]. Composites Part B: Engineering, 2020, 191:No.107966. |

| 13 | Zhang M, Qian X, Ma K, et al. Enhanced interfacial properties of high-modulus carbon fiber reinforced pekk composites by a two-step surface treatment: electrochemical oxidation followed by thermoplastic sizing [J]. Applied Composite Materials, 2022, 29: 745-764. |

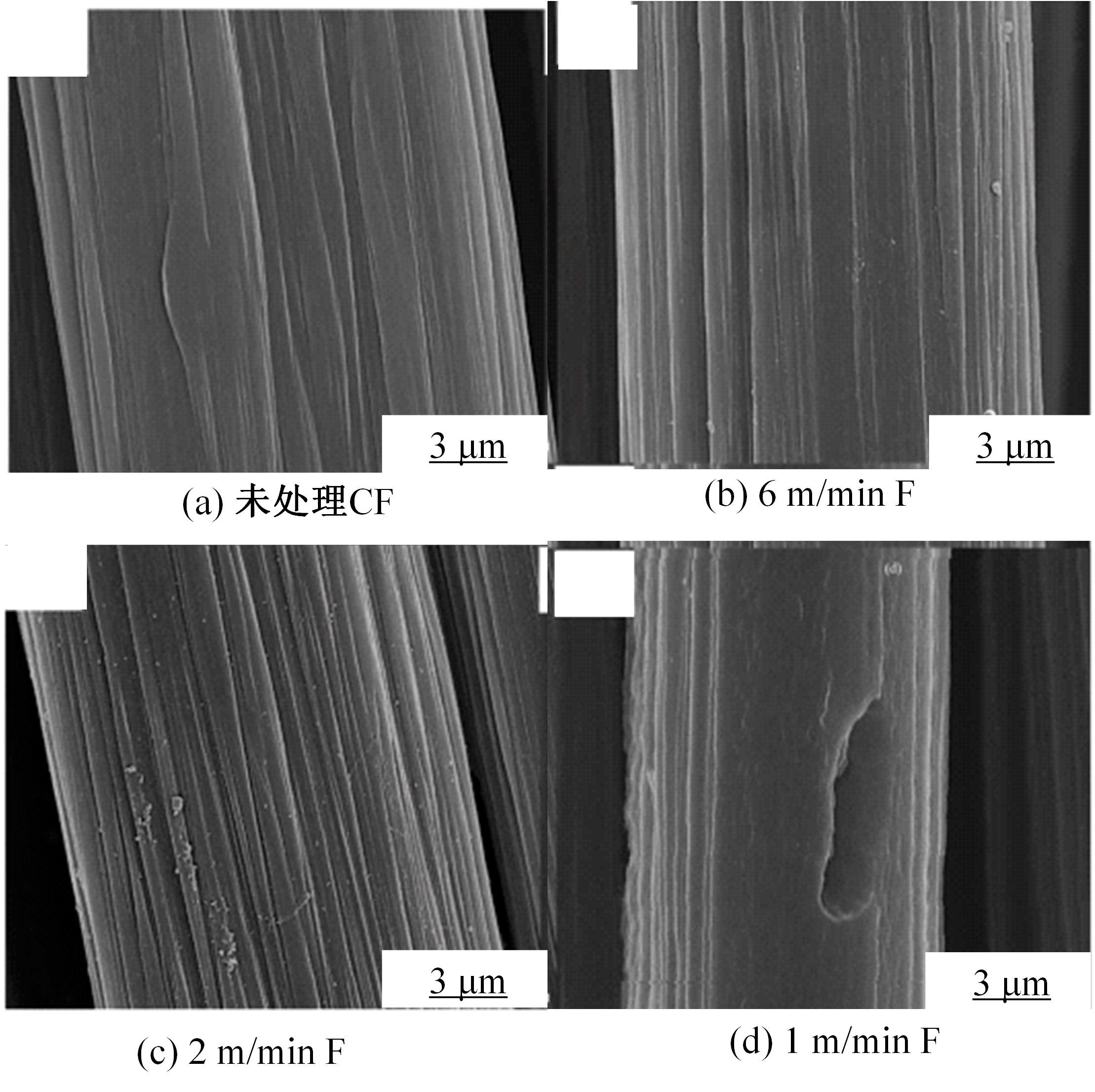

| 14 | Yi J, Lee W, Seong D, et al. Effect of phenoxy-based coating resin for reinforcing pitch carbon fibers on the interlaminar shear strength of PA6 composites [J]. Composites Part A: Applied Science and Manufacturing, 2016, 87: 212-219. |

| 15 | Kim S, Park T, Um M, et al. Effect of caprolactam modified phenoxy-based sizing material on reactive process of carbon fiber-reinforced thermoplastic polyamide-6 [J]. Composites Part A: Applied Science and Manufacturing, 2020, 139: No.106104. |

| 16 | Yuan C, Li D, Yuan X, et al. Preparation of semi-aliphatic polyimide for organic-solvent-free sizing agent in CF/PEEK composites[J]. Composites Science and Technology, 2021, 201: No.108490. |

| 17 | 张雪, 刘媛, 杨斌, 等. 碳纤维表面改性对复合材料性能的影响[J].功能高分子学报,2017, 30(4):444-449. |

| Zhang Xue, Liu Yuan, Yang Bin, et al. Effect of carbon fiber surface modification on properties of composites[J]. Journal of Functional Polymers, 2017, 30(4):444-449. | |

| 18 | Yamamoto T, Ota Y. Creating a laminated carbon fiber-reinforced thermoplastic using polypropylene and nylon with a polypropylene colloid[J]. Composite Structures, 2021, 255:No.113038. |

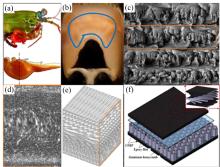

| 19 | Liang Y H, Liu C, Zhao Q, et al. Bionic design and 3D printing of continuous carbon fiber-reinforced polylactic acid composite with barbicel structure of eagle-owl feather[J]. Materials, 2021, 14(13):3618. |

| 20 | Han Q G, Qin H L, Liu Z H, et al. Experimental investigation on impact and bending properties of a novel dactyl-inspired sandwich honeycomb with carbon fiber[J]. Construction and Building Materials, 2020, 253: No.119161. |

| 21 | Qiu B W, Ni L, Zhang X Q, et al. Bio-inspired barb structure designed on the surface of carbon fibers to enhance the interfacial properties of composites in multiple scales[J]. Materials Chemistry Frontiers, 2021, 5(15): 5769-5779. |

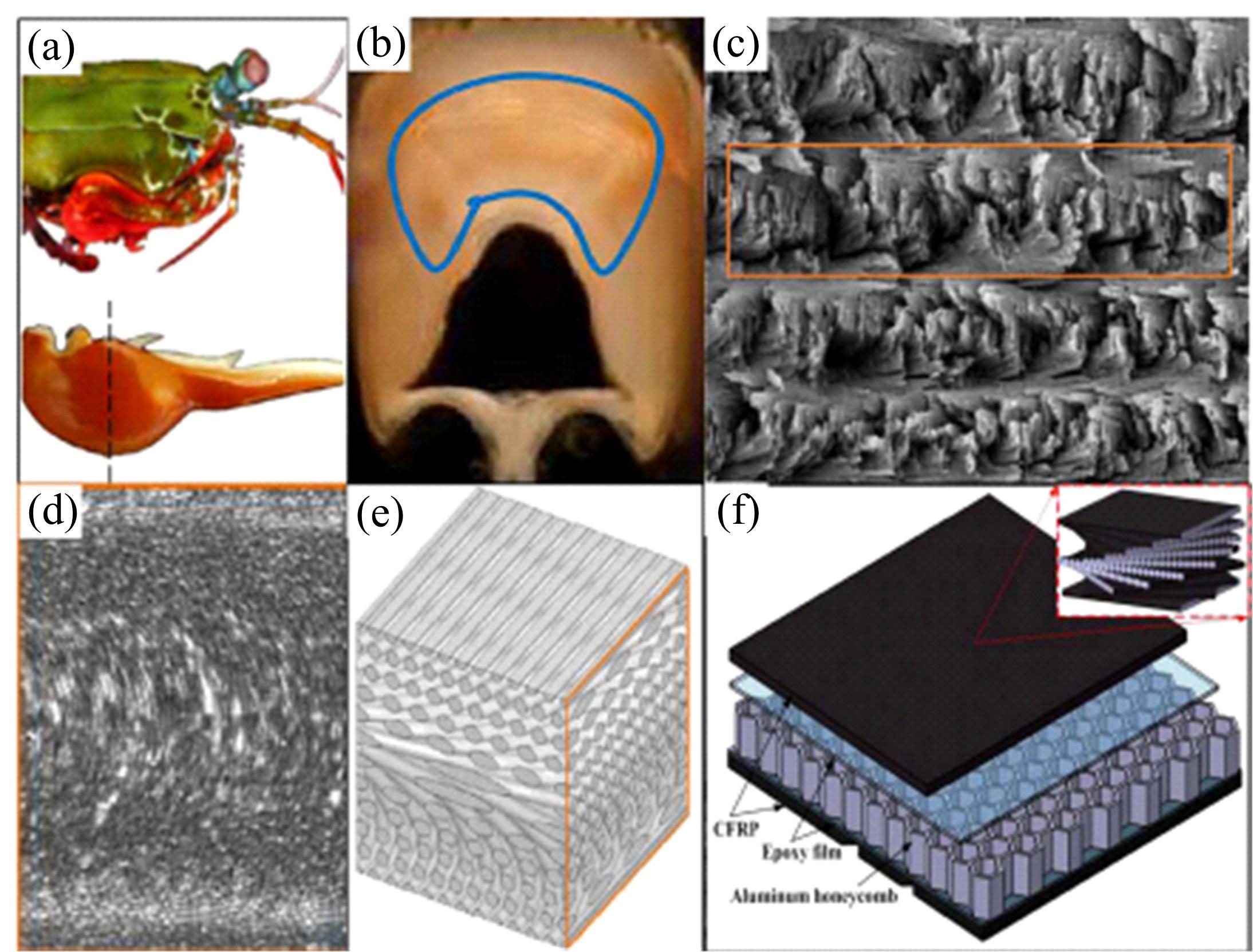

| 22 | Qi Y, Gu B, Sun B, et al. Full-field strain and temperature evolution of electroactive three-dimensional braided thermoplastic shape memory composites[J]. Composites Science and Technology, 2022,219:No.109250. |

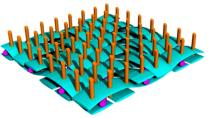

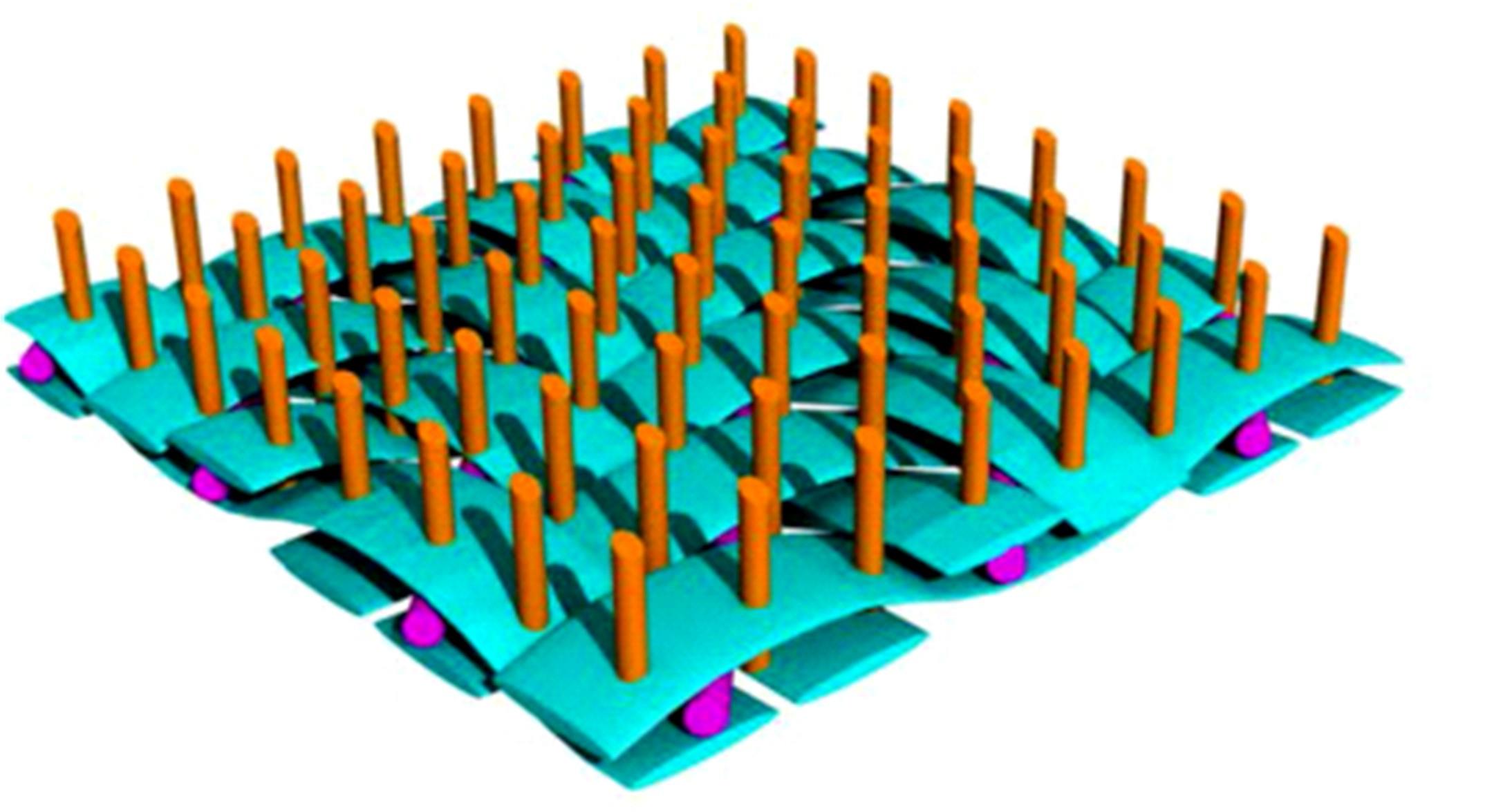

| 23 | Loh T W, Ladani R B, Ravindran A, et al. Z-pinned composites with combined delamination toughness and delamination self-repair properties[J]. Composites Part A: Applied Science and Manufacturing, 2021, 149: No.106566. |

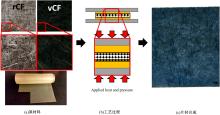

| 24 | 许小海. 三维编织碳纤维增强聚醚醚酮复合材料的制备及性能研究[D]. 天津:天津大学材料科学与工程学院, 2012. |

| Xu Xiao-hai. Study on preparation and properties of 3-D braided carbon fiber reinforced polyether-ether-ketone composites[D]. Tianjin: School of Materials Science and Engineering, Tianjin University, 2012. | |

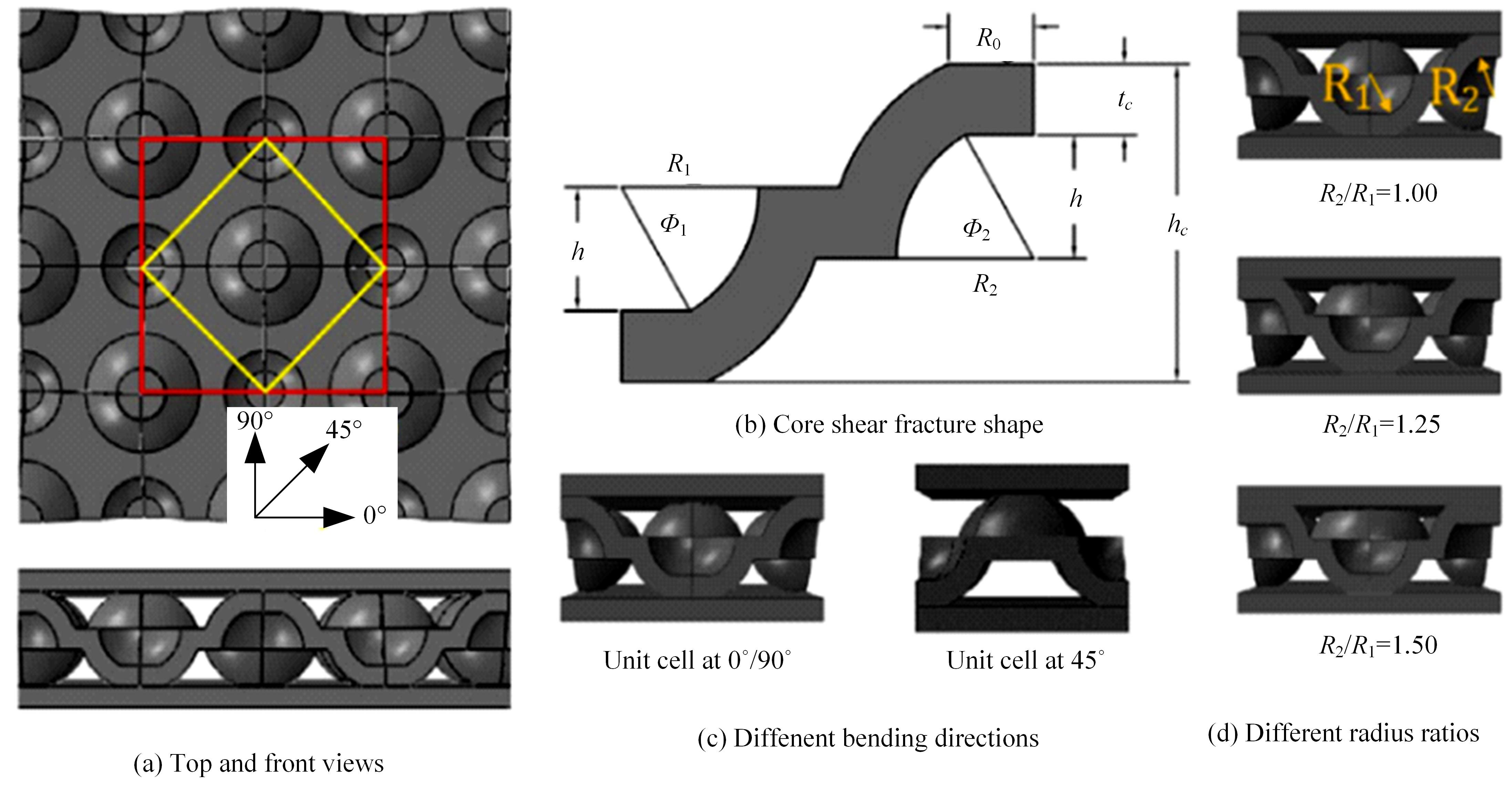

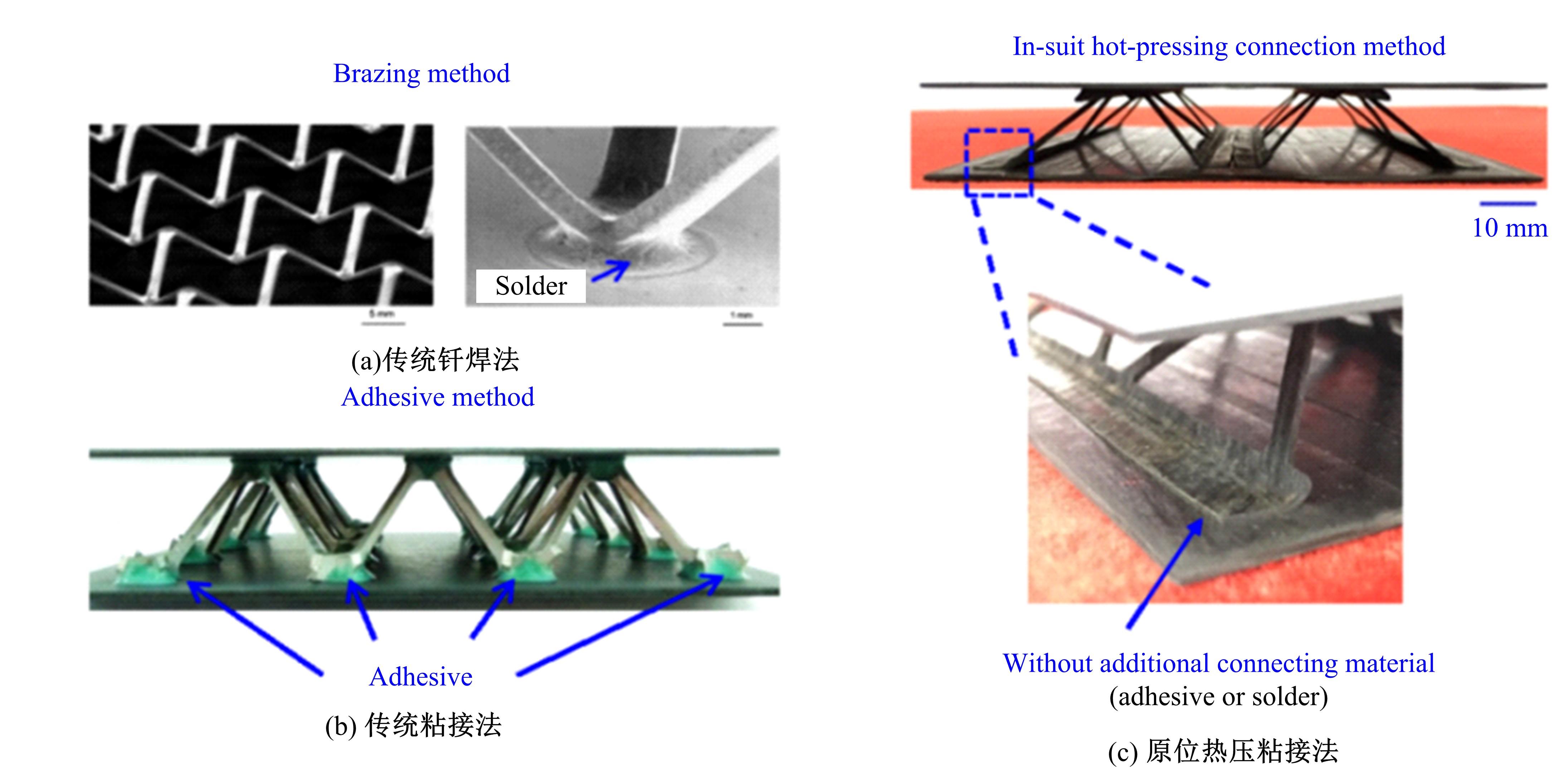

| 25 | Zhang J, Yanagimoto J. Design and fabrication of formable CFRTP core sandwich sheets[J]. CIRP Annals, 2019, 68(1): 281-284. |

| 26 | Hu J, Liu A, Zhu S, et al. Novel panel-core connection process and impact behaviors of CF/PEEK thermoplastic composite sandwich structures with truss cores[J]. Composite Structures, 2020, 251:No.112659. |

| 27 | Hu J, Zhu S, Wang B, et al. Fabrication and compression properties of continuous carbon fiber reinforced polyether ether ketone thermoplastic composite sandwich structures with lattice cores [J]. Journal of Sandwich Structures & Materials, 2020, 23(6): 2422-2442. |

| 28 | Grünewald J, Parlevliet P P, Matschinski A, et al. Mechanical performance of CF/PEEK-PEI foam core sandwich structures[J]. Journal of Sandwich Structures & Materials, 2017, 21(8): 2680-2699. |

| 29 | Santos A, Monticeli F, Ornaghi H, et al. Porosity characterization and respective influence on short-beam strength of advanced composite processed by resin transfer molding and compression molding[J]. Polymers and Polymer Composites, 2021, 29(8): 1353-1362. |

| 30 | 陶积柏, 王绍凯, 李敏, 等. 三维夹芯层连织物复合材料真空辅助成型工艺影响因素[J].复合材料学报,2010(4):81-86. |

| Tao Ji-bai, Wang Sao-kai, Li Min, et al. Influencing factors of vacuum assisted resin transfer molding process for 3D spacer fabric composites[J]. Acta Materiae Compositae Sinica, 2010(4):81-86. | |

| 31 | 苏峰, 于洋, 于柏峰. 真空辅助树脂灌注工艺的创新性改进[J]. 纤维复合材料,2010(1):18-20. |

| Su Feng, Yu Yang, Yu Bo-feng. Innovative improvement of vacuum assisted resin infusion process (VARI) [J]. Fiber Composites,2010(1):18-20. | |

| 32 | 潘利剑, 刘卫平, 陈萍, 等. 真空辅助成型工艺中预成型体的厚度变化与过流控制[J].复合材料学报,2012(29):244-248. |

| Pan Li-jian, Li Wei-ping, Chen Ping, et al. Change in preform thickness throughout the vacuum assisted resin infusion process and the post-filling control[J]. Acta Materiae Compositae Sinica, 2012(29):244-248. | |

| 33 | 陈祥宝, 张宝艳, 邢丽英. 先进树脂基复合材料技术发展及应用现状[J].中国材料进展, 2009, 28(6):2-12. |

| Chen Xiang-bao, Zhang Bao-yan, Xing Li-ying. Application and development of advanced polymer matrix composites[J]. Materials China, 2009,28(6):2-12. | |

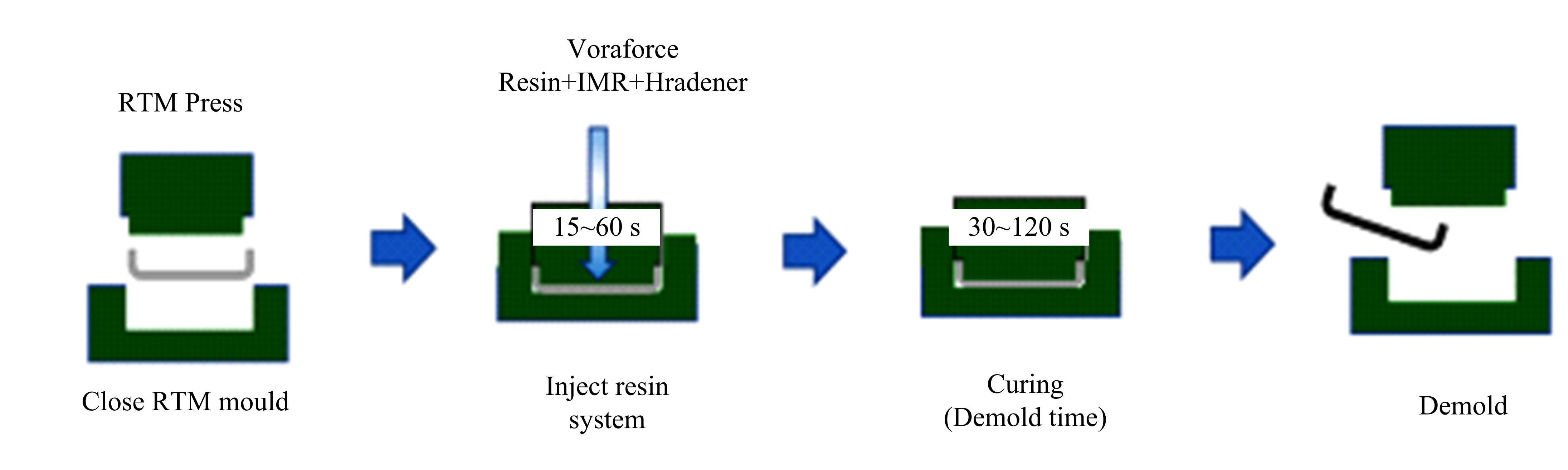

| 34 | Choi C W, Jin J W, Lee H, et al. Optimal polymerization conditions in thermoplastic-resin transfer molding process for mechanical properties of carbon fiber-reinforced PA6 composites using the response surface method[J]. Fibers and Polymers, 2019, 20(5): 1021-1028. |

| 35 | Kim B J, Cha S H, Park Y B. Ultra-high-speed processing of nanomaterial-reinforced woven carbon fiber/polyamide 6 composites using reactive thermoplastic resin transfer molding[J]. Composites Part B: Engineering, 2018, 143: 36-46. |

| 36 | Sun Z, Xiao J, Tao L, et al. Preparation of high-performance carbon fiber-reinforced epoxy composites by compression resin transfer molding [J]. Materials, 2019,12(1):No.13. |

| 37 | Smith R, Qureshi Z, Scaife R, et al. Limitations of processing carbon fibre reinforced plastic/polymer material using automated fibre placement technology [J]. Journal of Reinforced Plastics and Composites, 2016,35(21):1527-1542. |

| 38 | 何天白. 碳纤维复合材料轻量化技术[M]. 北京:科学出版社,2015. |

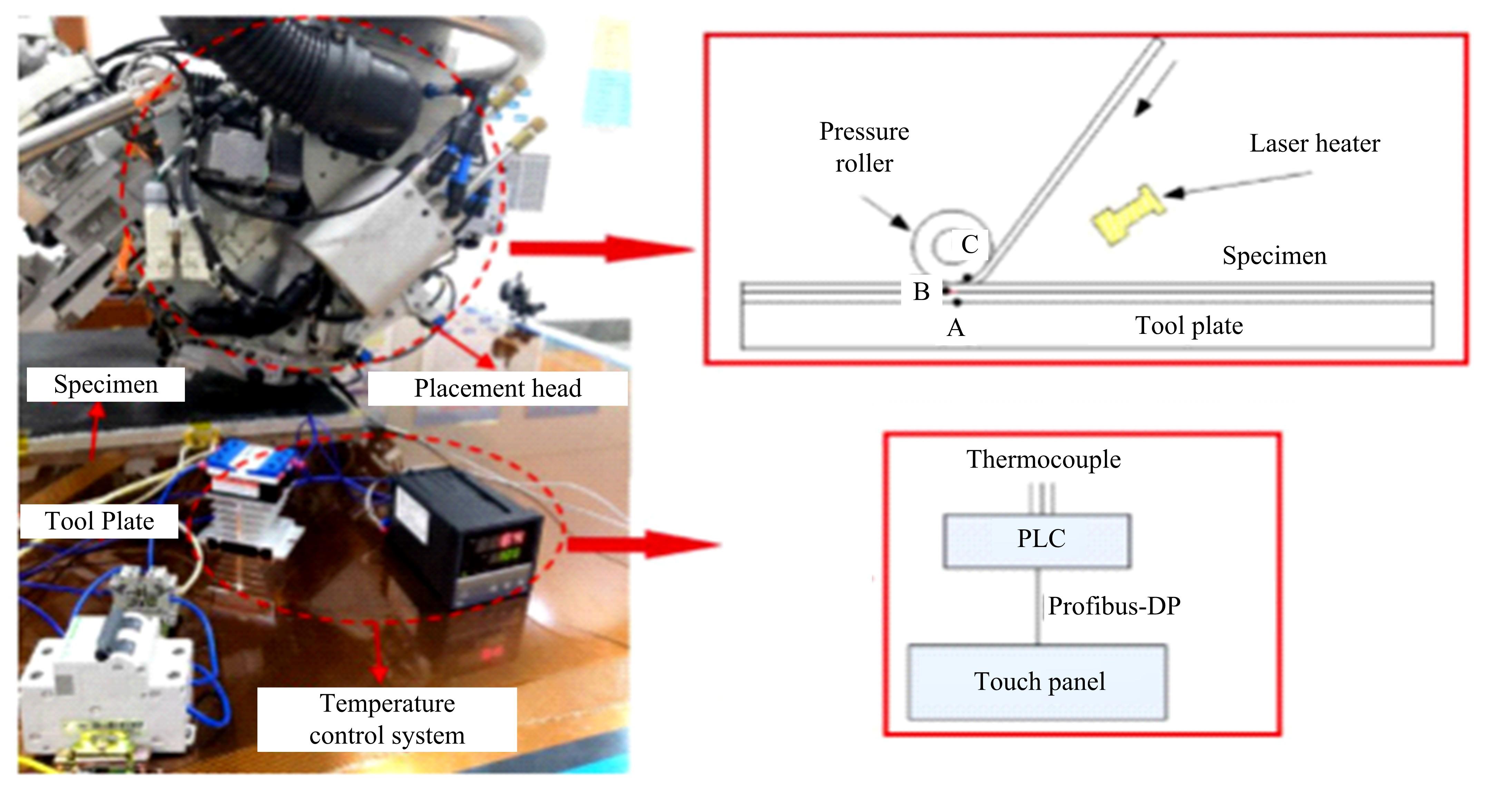

| 39 | Sebaey T A, Bouhrara M, O'dowd N. Fibre alignment and void assessment in thermoplastic carbon fibre reinforced polymers manufactured by automated tape placement[J]. Polymers (Basel), 2021, 13(3):473. |

| 40 | Chen J, Fu K, Li Y. Understanding processing parameter effects for carbon fibre reinforced thermoplastic composites manufactured by laser-assisted automated fibre placement (AFP) [J].Composites Part A: Applied Science and Manufacturing, 2021,140:No.106160. |

| 41 | Jin Z, Han Z, Liu X, et al. The interlaminar performance of carbon fiber reinforced polyetheretherketone composites reinforced by doped buckypaper[J]. Materials Letters, 2022, 321: No.132426. |

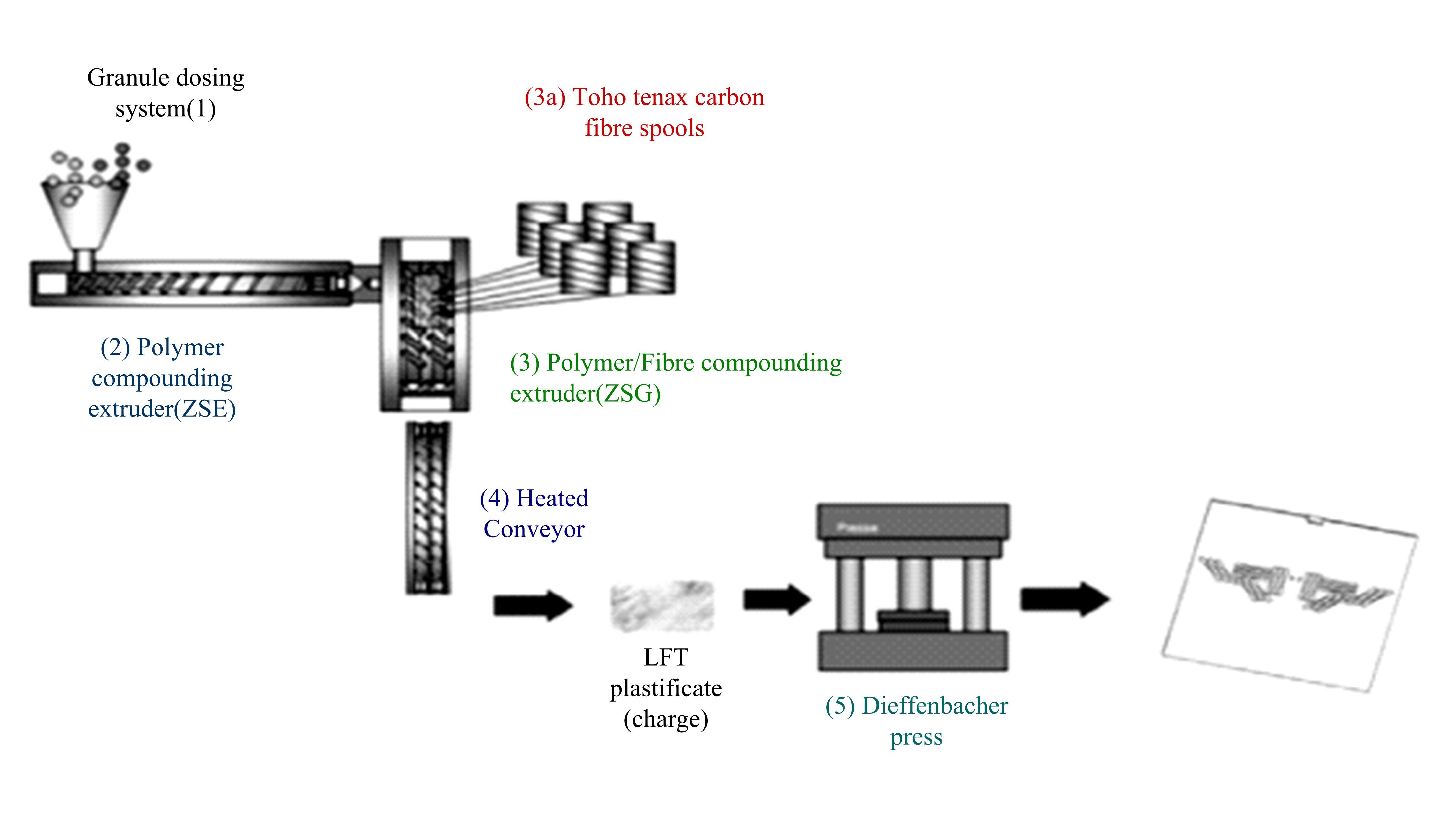

| 42 | Bondy M, Rodgers W, Altenhof W. Tensile fatigue characterization of polyamide 66/carbon fiber direct/in-line compounded long fiber thermoplastic composites[J]. Composites Part B-Engineering, 2019,173:No.106984. |

| 43 | Bondy M, Altenhof W. Experimental characterisation of the mechanical properties of a carbon fibre/PA66 LFT automotive seatback under quasi-static and impact loading[J]. International Journal of Crashworthiness, 2019, 25(4): 1-20. |

| 44 | Lin M C, Lin J H, Bao L. Applying TPU blends and composite carbon fibers to flexible electromagnetic-shielding fabrics: long-fiber-reinforced thermoplastics technique[J]. Composites Part A: Applied Science and Manufacturing, 2020, 138: No.106022. |

| 45 | Wan Y, Suganuma H, Takahashi J. Effects of fabrication processes and tape thickness on tensile properties of chopped carbon fiber tape reinforced thermoplastics[J]. Composites Communications, 2020, 22: No.100434. |

| 46 | Wan Y, Takahashi J. Tensile and compressive properties of chopped carbon fiber tapes reinforced thermoplastics with different fiber lengths and molding pressures[J]. Composites Part A: Applied Science and Manufacturing, 2016, 87: 271-281. |

| 47 | Barnett P R, Cook Z A, Hulett B M, et al. Influence of processing parameters on permeability and infiltration of compression molded discontinuous carbon fiber organosheet composites[J]. Composites Part A: Applied Science and Manufacturing, 2022, 152:No.106682. |

| 48 | Song Y, Gandhi U, Sekito T, et al. CAE method for compression molding of carbon fiber-reinforced thermoplastic composite using bulk materials[J]. Composites Part A: Applied Science and Manufacturing, 2018, 114: 388-397. |

| 49 | Yin H, Peng X, Du T, et al. Forming of thermoplastic plain woven carbon composites: An experimental investigation[J]. Journal of Thermoplastic Composite Materials, 2013, 28(5): 730-742. |

| 50 | Tümer E H, Erbil H Y. Extrusion-based 3D printing applications of PLA composites: a review[J]. Coatings, 2021, 11(4):No.390. |

| 51 | Dickson A N, Abourayana H M, Dowling D P. 3D printing of fibre-reinforced thermoplastic composites using fused filament fabrication―a review [J].Polymers, 2020, 12(10): 2188. |

| 52 | 田小永, 刘腾飞, 杨春成, 等. 高性能纤维增强树脂基复合材料3D打印及其应用探索[J]. 航空制造技术,2016(15):26-31. |

| Tian Xiao-yong, Liu Teng-fei, Yang Chun-cheng, et al. 3D printing of high-performance fiber-reinforced resin matrix composites and its application exploration[J]. Aeronautical Manufacturing Technology, 2016(15):26-31. | |

| 53 | Ning F, Cong W, Qiu J, et al. Additive manufacturing of carbon fiber reinforced thermoplastic composites using fused deposition modeling [J]. Composites Part B:Engineering, 2015, 80: 369-378. |

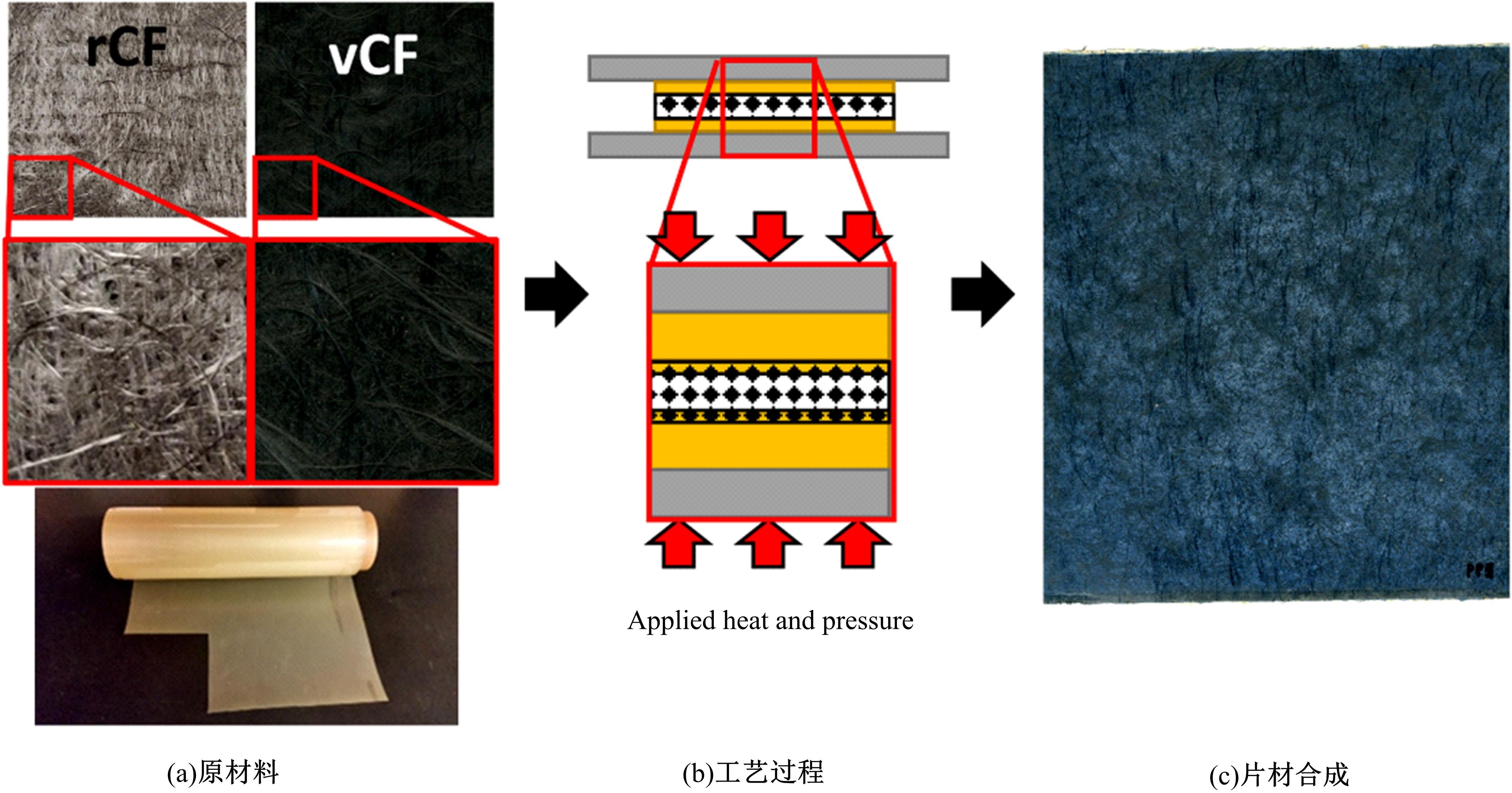

| 54 | Kumar V, Alwekar S P, Kunc V, et al. High-performance molded composites using additively manufactured preforms with controlled fiber and pore morphology[J]. Additive Manufacturing, 2021, 37:No.101733. |

| 55 | Ye W, Lin G, Wu W, et al. Separated 3D printing of continuous carbon fiber reinforced thermoplastic polyimide[J]. Composites Part A: Applied Science and Manufacturing, 2019, 121: 457-464. |

| 56 | 李志刚, 杨京浩, 刘雪强, 等. 一种连续纤维编织体增强纤维复合材料 3D打印方法[P]. 中国: CN114248437A,2021-12-06. |

| 57 | Das T K, Ghosh P, Das N C. Preparation, development, outcomes, and application versatility of carbon fiber-based polymer composites: a review [J]. Advanced Composites and Hybrid Materials, 2019, 2(2): 214-233. |

| 58 | 曹维宇, 杨学萍, 张藕生. 我国高性能高分子复合材料发展现状与展望[J]. 中国工程科学,2020, 22 (5):112-120. |

| Cao Wei-yu, Yang Xue-ping, Zhang Ou-sheng. Development and prospect of high performance polymer composites in China[J]. Strategic Study of CAE,2020,22(5):112-120. | |

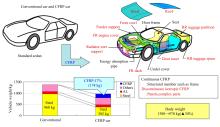

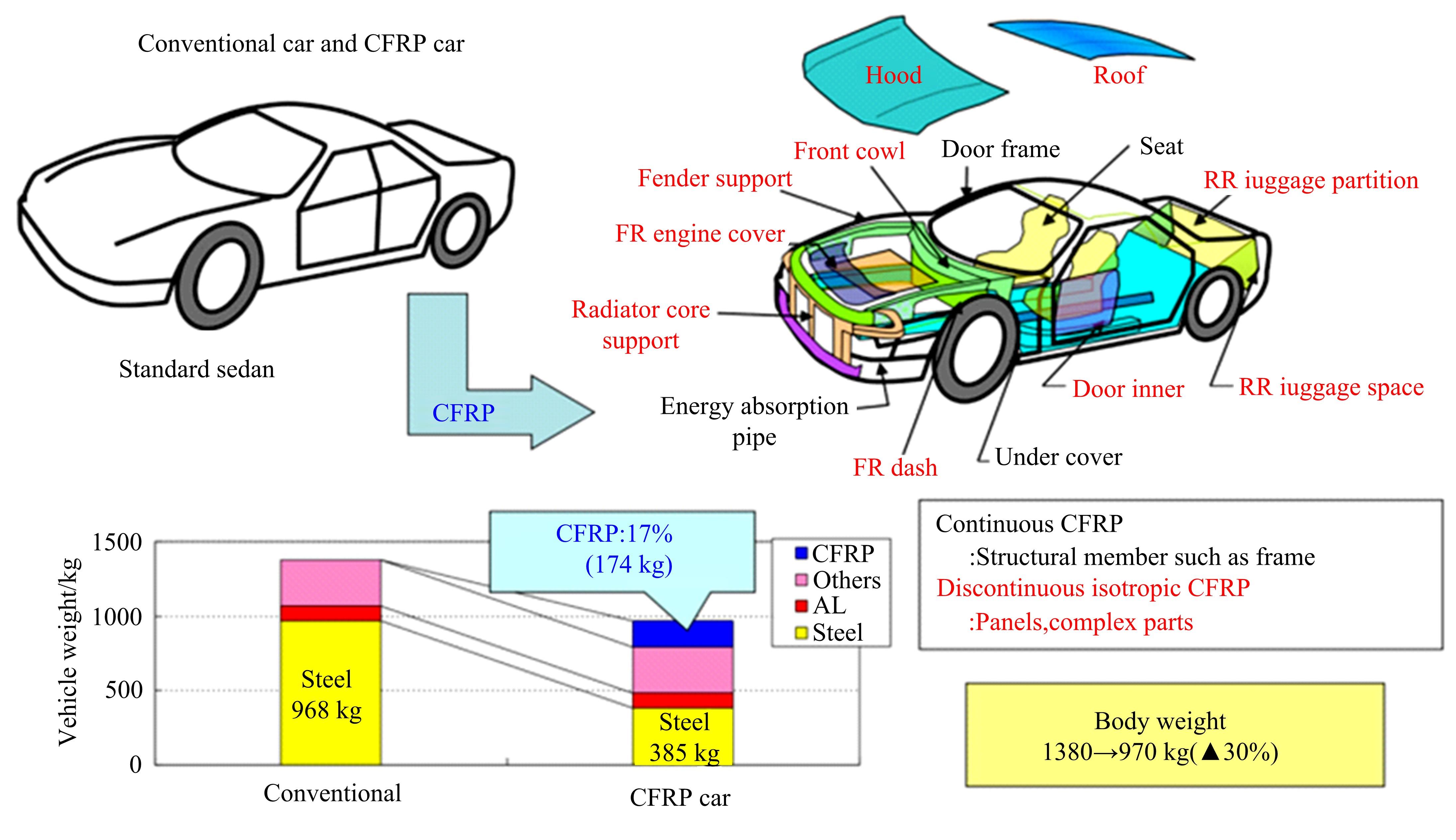

| 59 | Wan Y, Takahashi J. Development of carbon fiber-reinforced thermoplastics for mass-produced automotive applications in Japan[J]. Journal of Composites Science, 2021, 5(3): No.86. |

| 60 | friedrich K. Carbon fiber reinforced thermoplastic composites for future automotive applications[J]. AIP Conference Proceedings, 2016, 1736(1): No.020001. |

| 61 | 巴斯夫. 巴斯夫推出滑动摩擦性能优越的工程塑料[DB/OL]. [2020-12-10]. . |

| [1] | 金敬福,董新桔,贾志成,王康,贺连彬,邹猛,齐迎春. 板簧式弹性金属车轮胎面弹片结构优化[J]. 吉林大学学报(工学版), 2023, 53(4): 964-972. |

| [2] | 庄蔚敏,陈沈,吴迪. 碳纤维增强复合材料包裹强化形式对钢管横向冲击性能的影响[J]. 吉林大学学报(工学版), 2022, 52(4): 819-828. |

| [3] | 谷拴成,聂红宾. 极温冻融-荷载作用下碳纤维复合材料修复试件损伤分析[J]. 吉林大学学报(工学版), 2021, 51(6): 2108-2120. |

| [4] | 于征磊,信仁龙,陈立新,朱奕凝,张志辉,曹青,金敬福,赵杰亮. 仿蜂窝防护结构的承载特性[J]. 吉林大学学报(工学版), 2021, 51(3): 1140-1145. |

| [5] | 慕文龙,那景新,谭伟,王广彬,申浩,栾建泽. 基于FTIR分析的CFRP-铝合金粘接接头剩余强度预测[J]. 吉林大学学报(工学版), 2021, 51(1): 139-146. |

| [6] | 万世成,黄侨,关健,郭赵元. 预应力碳纤维板加固钢⁃混凝土组合连续梁负弯矩区试验[J]. 吉林大学学报(工学版), 2019, 49(4): 1114-1123. |

| [7] | 胡志清, 郑会会, 徐亚男, 张春玲, 党停停. 表面微沟槽对Al/CFRP胶结性能的影响[J]. 吉林大学学报(工学版), 2018, 48(1): 229-235. |

| [8] | 张君媛, 纪梦雪, 王楠, 叶威. 汽车正面25%重叠率碰撞车身前端结构设计[J]. 吉林大学学报(工学版), 2018, 48(1): 57-64. |

| [9] | 于天来, 刘兴国, 姚爽, 穆罕默德马苏. 碳纤维筋体外预应力加固钢筋混凝土梁的疲劳性能[J]. 吉林大学学报(工学版), 2016, 46(6): 1867-1873. |

| [10] | 郭学东, 马立军, 张云龙. 集中力作用下考虑剪切滑移效应的双层结合面组合梁解析解[J]. 吉林大学学报(工学版), 2016, 46(2): 432-438. |

| [11] | 刘坤, 赵建琛, 李超, 闫鹏飞, 韩宣. 基于Hyperworks的下肢康复训练系统机械结构设计与优化[J]. 吉林大学学报(工学版), 2015, 45(5): 1474-1480. |

| [12] | 何仁, 王晶, 胡东海. 永磁式缓速器的制动力矩分级结构设计[J]. 吉林大学学报(工学版), 2015, 45(4): 1056-1062. |

| [13] | 王庆年, 刘松山, 王伟华, 魏昊. 滚珠丝杠式馈能型减振器的结构设计及参数匹配[J]. , 2012, 42(05): 1100-1106. |

| [14] | 关庆丰, 万明珍, 邹阳, 蔡杰, 陈康敏. 碳纤维增强摩擦材料的摩擦表面层 [J]. , 2012, (03): 672-676. |

| [15] | 代汉达, 曲建俊, 庄乾兴. 模压工艺对CF+G/PEEK复合材料力学性能的影响[J]. 吉林大学学报(工学版), 2010, 40(02): 457-0460. |

|

||