吉林大学学报(工学版) ›› 2023, Vol. 53 ›› Issue (4): 964-972.doi: 10.13229/j.cnki.jdxbgxb.20220234

板簧式弹性金属车轮胎面弹片结构优化

金敬福1( ),董新桔1,贾志成1,王康2,贺连彬1,邹猛1,齐迎春1(

),董新桔1,贾志成1,王康2,贺连彬1,邹猛1,齐迎春1( )

)

- 1.吉林大学 生物与农业工程学院,长春 130022

2.中国空间技术研究院 北京空间飞行器总体设计部,北京 100094

Optimization of the tread plate-spring structure of flexible metal wheel with plate-spring

Jing-fu JIN1( ),Xin-ju DONG1,Zhi-cheng JIA1,Kang WANG2,Lian-bin HE1,Meng ZOU1,Ying-chun QI1(

),Xin-ju DONG1,Zhi-cheng JIA1,Kang WANG2,Lian-bin HE1,Meng ZOU1,Ying-chun QI1( )

)

- 1.College of Biological and Agricultural Engineering,Jilin University,Changchun 130022,China

2.Beijing Institute of Spacecraft System Engineering,China Academy of Space Technology,Beijing 100094,China

摘要:

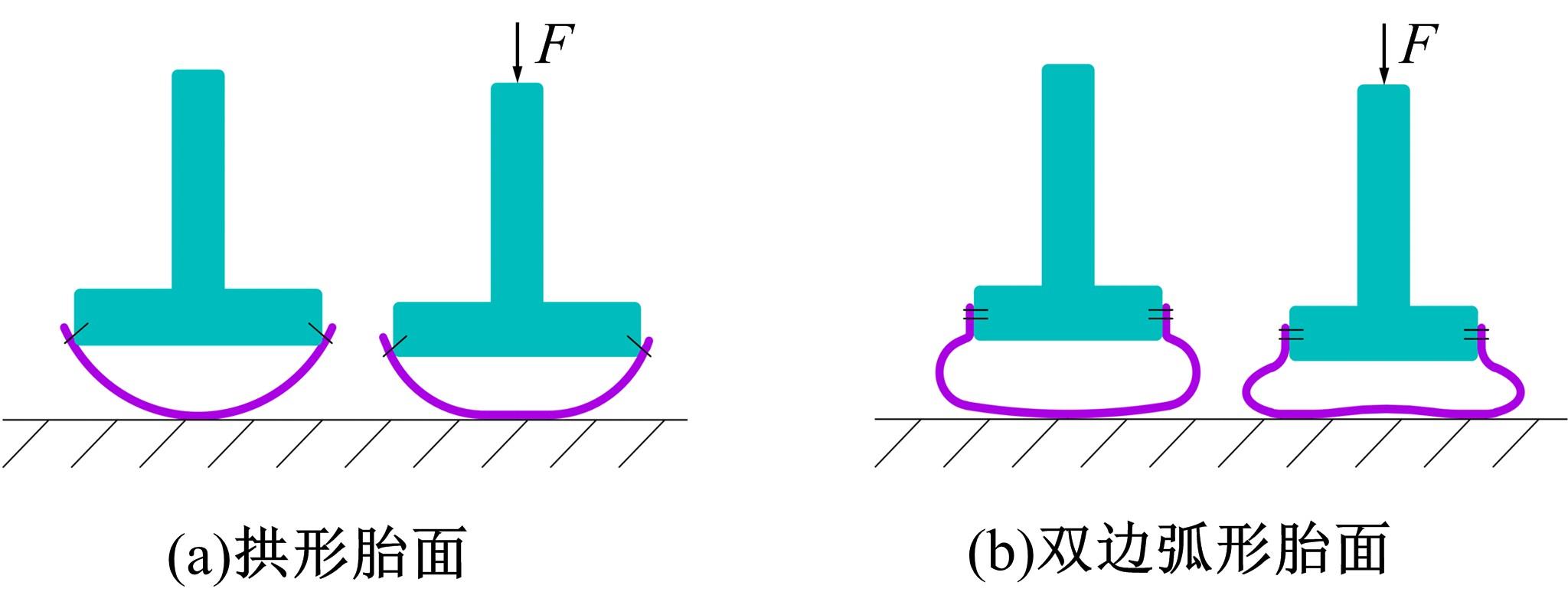

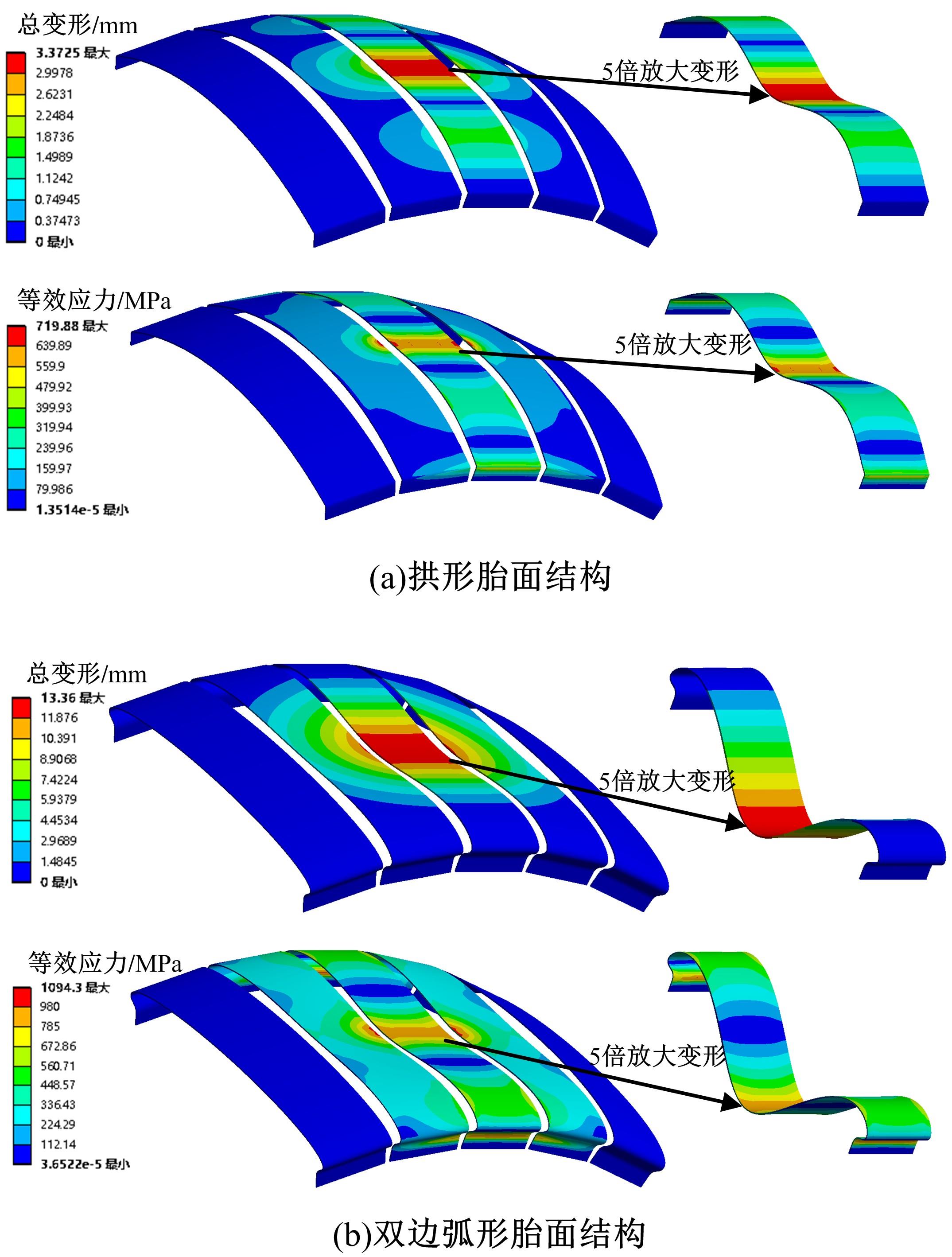

针对现有板簧式弹性金属车轮容易产生应力集中或塑性变形现象,对胎面出现应力集中和大变形原因进行了分析。建立了常规拱形胎面、双边弧形胎面结构三维模型,运用有限元分析方法,对2种胎面在平压、胎面中部承压、胎面单侧承压3种工况下的变形和受力状态模拟,分析表明,胎面两端固定的连接方式会对胎面的受力情况产生影响,造成胎面局部刚度过大或承载能力不足的缺陷。根据仿真结果进一步优化,提出耦合弹性胎面结构,改变胎面两端固定约束,将胎面径向位移转移到轮毂轴向外扩,通过轴向位移实现径向位移的拓展。有限元模拟表明,在3种相同工况下,耦合弹性胎面结构可获得更大的径向变形,且胎面具备均匀刚度,变形连续,不产生应力集中区域。试制了耦合弹性金属车轮,并进行车轮承压试验,结果表明耦合弹性胎面结构可有效扩大车轮的径向位移能力,且胎面具备足够的刚度,验证了设计耦合弹性胎面结构的优势。

中图分类号:

- V19

| 1 | Votava J E, Petro N E. Towards a selenographic information system: Apollo 15 Mission Digitization[C]∥AGU Fall Meeting Abstracts. San Francisco:American Geophysical Union,2012. |

| 2 | Asnani V, Delap D, Creager C. The development of wheels for the Lunar Roving Vehicle[J].Journal of Terramechanics,2009,46(3):89-103. |

| 3 | Murphy Jr T W, Adelberger E G, Battat J B R, et al. Laser ranging to the lost Lunokhod 1 reflector[J]. Icarus, 2011, 211(2):1103-1108. |

| 4 | Abdrakhimov A M, Basilevsky A T, Head J W, et al. Luna 17/Lunokhod 1 and Luna 21/Lunokhod 2 landing sites as seen by the Lunokhod and LRO cameras[C]∥Lunar and Planetary Science Conference. Texas:Lunar and Planetary Institute,2011. |

| 5 | 路达,刘金国,高海波.星球表面着陆巡视一体化探测机器人研究进展[J].航空学报,2020,41(1): 523742. |

| Lu Da, Liu Jin-guo, Gao Hai-bo. Integrated exploration robots forplanetary surface landing and patrolling:a review[J]. ActaAeronatica et Astronautica Sinica,2020,41(1): 523742. | |

| 6 | 陈百超,邹猛,党兆龙,等.CE-3月球车筛网轮月面沉陷行为试验研究[J].吉林大学学报:工学版,2019,49(6):1836-1843. |

| Chen Bai-chao, Zou Meng, Dang Zhao-long, et al. Experiment on pressuresinkage for mesh wheels of CE-3 lunar rover on lunar regolith[J].Journal of Jilin University(Engineering and Technology Edition),2019,49(6):1836-1843. | |

| 7 | Shirley D L. Touching Mars: 1998 status of the Mars robotic exploration program[J]. Acta Astronautica, 1999, 45(4-9): 249-265. |

| 8 | Leger P C, Trebi-Ollennu A, Wright J R, et al. Mars exploration rover surface operations: Driving spirit at gusev crater[C]∥2005 IEEE International Conference on Systems Man and Cybernetics Proceedings.Waikoloa, HI: IEEE,2005:1815-1822. |

| 9 | Biesiadecki J J, Baumgartner E T, Bonitz R G, et al. Mars exploration rover surface operations[J].IEEE Robotics & Automation Magazine,2006,13(2):63-71. |

| 10 | Andrew G. Mars 2020 mission Perseverance rover [EB/OL].[2021/04/01]. |

| 11 | 潘冬, 贾阳, 袁宝峰, 等. 祝融号火星车主动悬架式移动系统设计与验证[J].中国科学:技术科学,2022, 52(02): 278-291. |

| Pan Dong, Jia Yang, Yuan Bao-feng, et al. Design and verification of the active suspension mobility system of the Zhurong Mars rover[J].Sci Sin Tech, 2022,52:278⁃291. | |

| 12 | Andy B. NASA & goodyear design airless spring tire for extraterrestrial surfaces[EB/OL]. [2021-04-01]. |

| 13 | Masursky H. An overview of geological results from Mariner 9[J]. Journal of Geophysical Research, 1973, 78(20):4009⁃4030. |

| 14 | Nakashima H. Soil⁃wheel interactions[J]. Encyclopedia of Earth Sciences Series, 2011,4:810-813. |

| 15 | 路达.基于驱动性能试验的载人月球车车轮结构设计[D].哈尔滨:哈尔滨工业大学机电工程学院,2015. |

| Lu Da. Research on the wheel design of manned lunar rover vehicle based on experiment of driving performance[D]. Harbin: School of Mechatronics Engineering, Harbin Institute of Technology,2015. | |

| 16 | Zou M, Zhu J Z, Wang K, et al. Design and mechanical behavior evaluation of flexible metal wheel for crewed lunar rover[J]. Acta Astronautica,2020,176:69-76. |

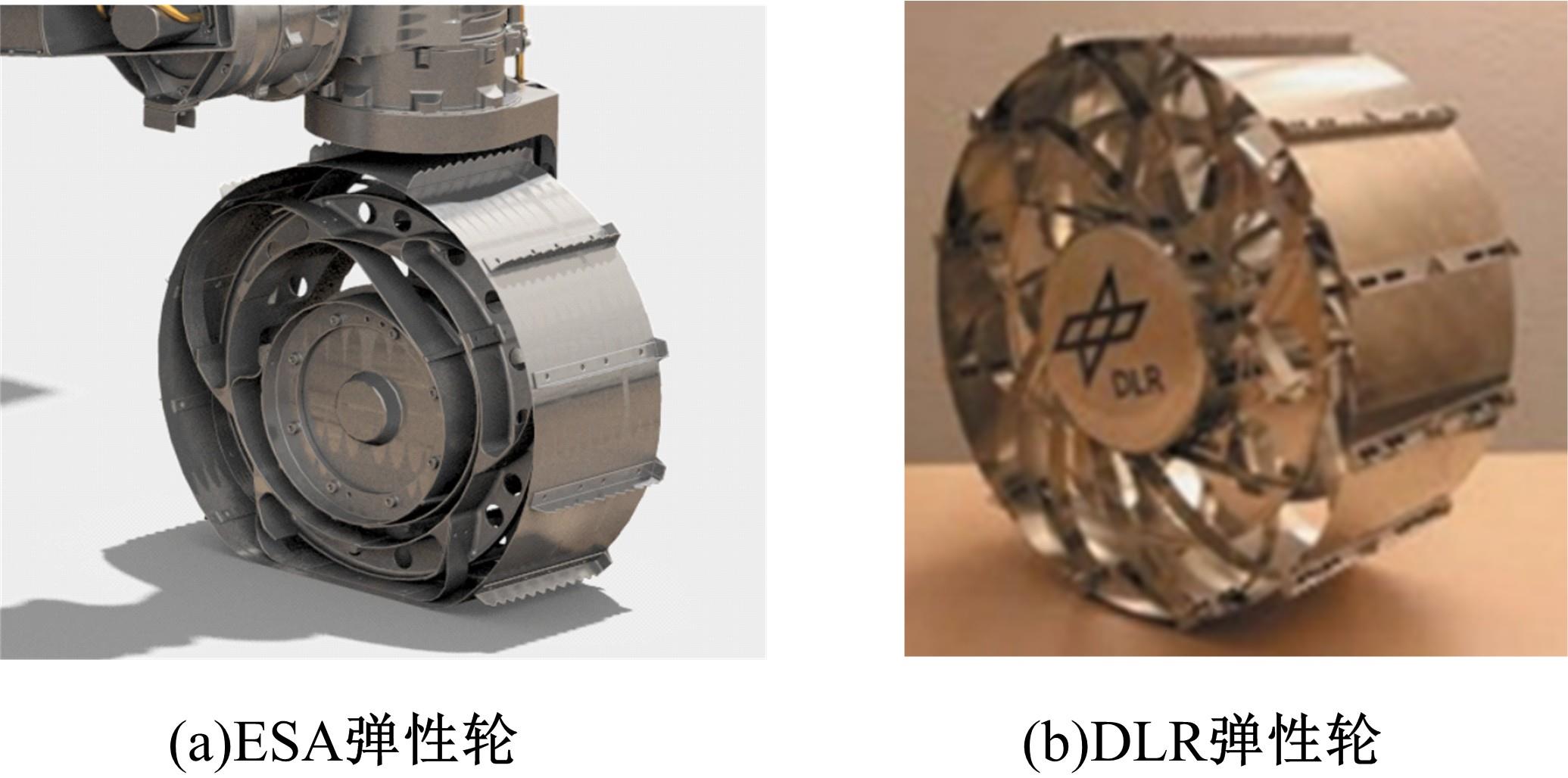

| 17 | Patel N, Slade R, Clemmet J. The ExoMars rover locomotion subsystem[J].Journal of Terramechanics,2010,47(4):227-242. |

| 18 | Armin W, Rebele B, Josef R, et al. LRU-lightweight rover unit[C]∥13th Symposium on Advanced Space Technologies in Robotics and Automation (ASTRA). Niederlande:Aerospace Center,2015:1-8. |

| 19 | 申学慧.载人月球车柔性金属车轮结构设计与分析[D].重庆:重庆大学汽车工程学院,2016. |

| Shen Xue-hui. Structure design and analysis of manned lunar rover flexible metal wheel[D]. Chongqing:College of Automotive Engineering,Chongqing University,2016. |

| [1] | 刘状壮,张有为,季鹏宇,Abshir Ismail Yusuf,李林,郝亚真. 电热型融雪沥青路面传热特性研究[J]. 吉林大学学报(工学版), 2023, 53(2): 523-530. |

| [2] | 华琛,牛润新,余彪. 地面车辆机动性评估方法与应用[J]. 吉林大学学报(工学版), 2022, 52(6): 1229-1244. |

| [3] | 郑植,耿波,王福敏,董俊宏,魏思斯. 既有低等级混凝土护栏防护能力提升[J]. 吉林大学学报(工学版), 2022, 52(6): 1362-1374. |

| [4] | 孙健,彭斌,朱兵国. 新型无油涡旋压缩机内部热力学特性和性能测试[J]. 吉林大学学报(工学版), 2022, 52(12): 2778-2787. |

| [5] | 商拥辉,徐林荣,刘维正,蔡雨. 重载铁路改良土和A组填料过渡段的动力特性[J]. 吉林大学学报(工学版), 2021, 51(6): 2128-2136. |

| [6] | 于征磊,陈立新,徐泽洲,信仁龙,马龙,金敬福,张志辉,江山. 基于增材制造的仿生防护结构力学及回复特性分析[J]. 吉林大学学报(工学版), 2021, 51(4): 1540-1547. |

| [7] | 于征磊,信仁龙,陈立新,朱奕凝,张志辉,曹青,金敬福,赵杰亮. 仿蜂窝防护结构的承载特性[J]. 吉林大学学报(工学版), 2021, 51(3): 1140-1145. |

| [8] | 宫亚峰,逄蕴泽,王博,谭国金,毕海鹏. 基于吉林省路况的新型预制装配式箱涵结构的力学性能[J]. 吉林大学学报(工学版), 2021, 51(3): 917-924. |

| [9] | 苏畅,韩颖,张英朝,苗振华. 轮辐设计特征参数对整车气动特性的影响[J]. 吉林大学学报(工学版), 2021, 51(1): 107-113. |

| [10] | 谷诤巍,陈琳,赵立辉,徐虹,李欣,于歌. 轨道车辆窗下补强板冲压成形模拟[J]. 吉林大学学报(工学版), 2020, 50(2): 504-511. |

| [11] | 陈鑫,王宁,沈传亮,冯晓,杨昌海. 后视镜造型对前侧窗气动噪声的影响[J]. 吉林大学学报(工学版), 2020, 50(2): 426-436. |

| [12] | 施卫平,赵旭,胡兴军,余天明,柳博文,段彦. 天然气开采阻水装置AICD的设计和数值模拟[J]. 吉林大学学报(工学版), 2019, 49(6): 1986-1991. |

| [13] | 宫亚峰,王博,谭国金,张立敏,吴文丁,毕海鹏. 吉林省两种典型装配式箱涵受力特性对比分析[J]. 吉林大学学报(工学版), 2019, 49(6): 1865-1870. |

| [14] | 依卓,付文智,李明哲. 双层剖分式超高压模具数值模拟及实验[J]. 吉林大学学报(工学版), 2019, 49(5): 1593-1599. |

| [15] | 李欣,孙延朋,王丹,陈军绪,谷诤巍,徐虹. 汽车前地板成形有限元数值模拟[J]. 吉林大学学报(工学版), 2019, 49(5): 1608-1614. |

|

||