吉林大学学报(工学版) ›› 2023, Vol. 53 ›› Issue (11): 3056-3061.doi: 10.13229/j.cnki.jdxbgxb.20220768

基于多状态时间序列预测学习的超精密机床主轴故障诊断仿真

- 1.江汉大学 工程训练中心,武汉 430056

2.武汉大学 工程训练与创新实践中心,武汉 430056

Simulation of ultra-precision machine tool spindle fault diagnosis based on multi-state time series predictive learning

Chao-gang ZHANG1( ),Zhong-lou SHI1,Min LI2

),Zhong-lou SHI1,Min LI2

- 1.Engineering Training Centre,Jianghan University,Wuhan 430056,China

2.Engineering Training and Innovation Practice Center,Wuhan University,Wuhan 430056,China

摘要:

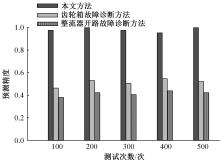

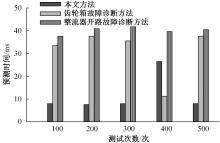

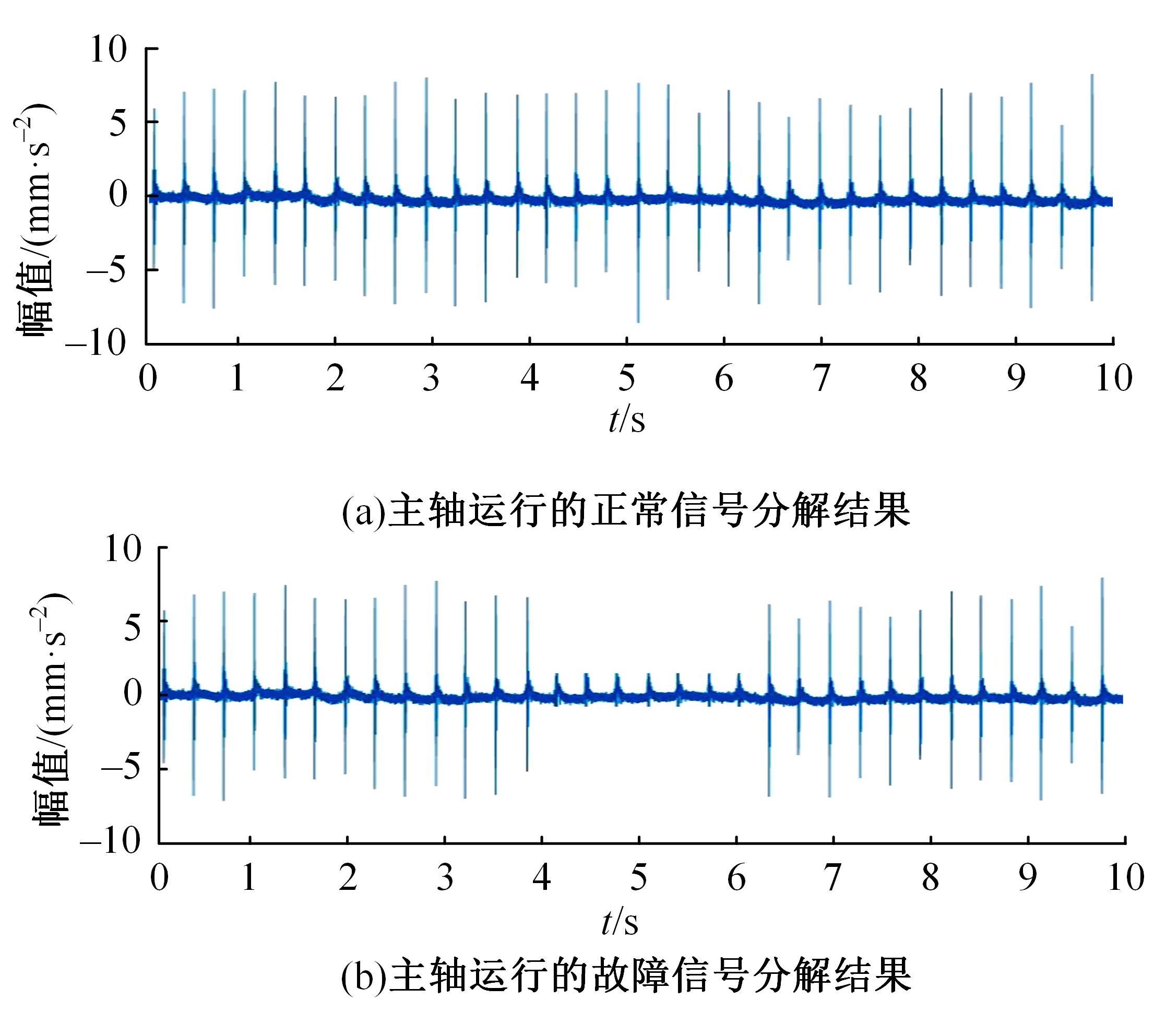

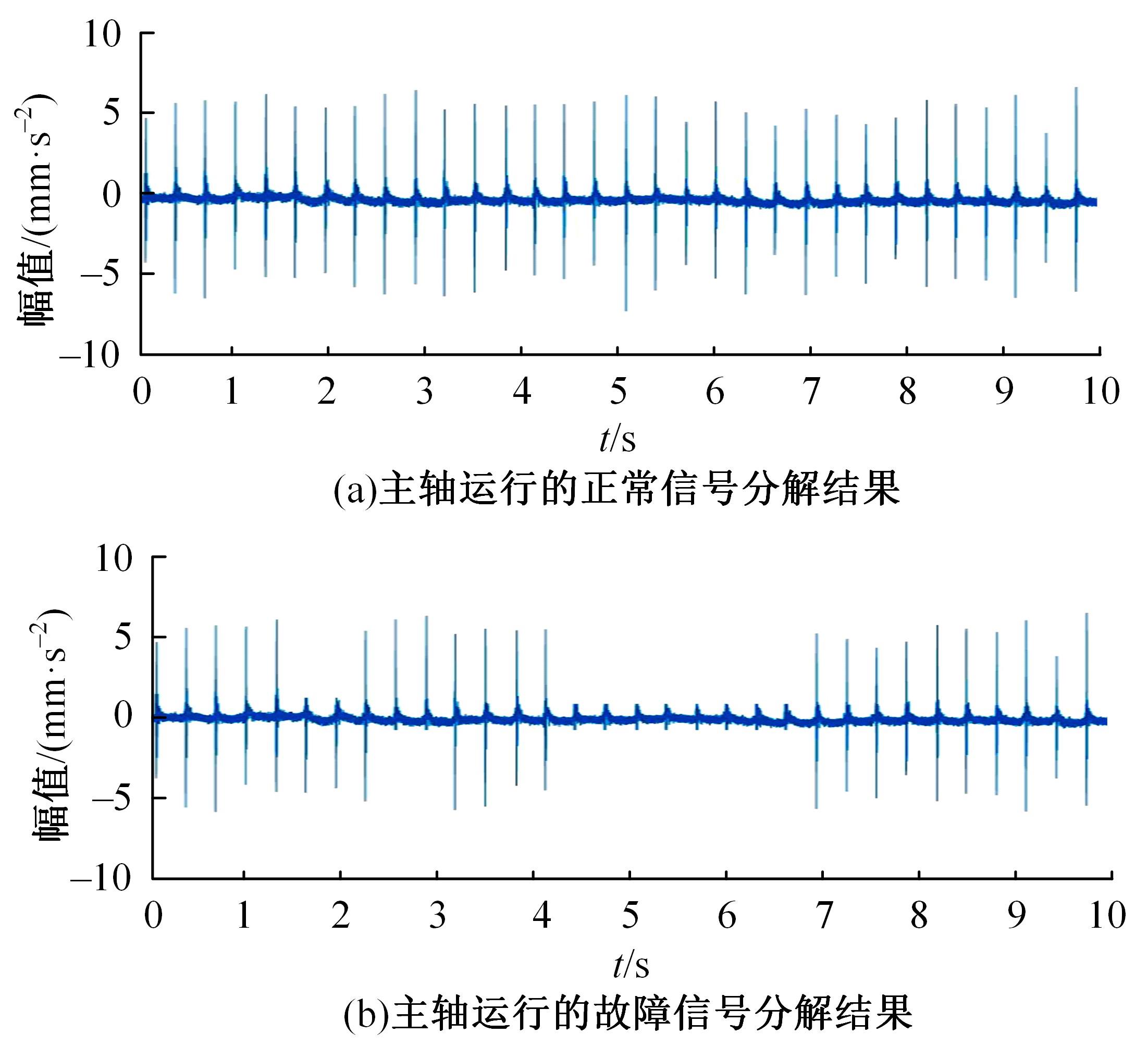

提出基于多状态时间序列预测学习的超精密机床主轴故障诊断方法,并对该方法进行了仿真测试。通过构建DAFDC-RNN模型(Dual-stage attention and full dimension convolution based recurrent neural network,时间序列预测模型),引入注意力、全维度卷积和时间注意力机制,生成运行状态过程中主轴间的相关性,模型输出即主轴运行故障预测值,同时去除预测数据内噪声,利用EMD-AR分析方法(Empirical mode decomposition-auto regressive,检验模态分解和谱分析结合法)分解时域信号中一阶分,并排除生成全新的信号,直至不再分解为止结束,在预测值范围内以及L-D算法帮助下对分解后信号计算求解,得出故障诊断结果。实验结果表明:本文方法的故障预测精度可达0.95~1.0,耗时可控制在10 ms以内,研究方法下主轴运行信号分解得到的正常信号分解幅值波动情况与实际结果基本吻合。

中图分类号:

- TM464

| 1 | 陈传海, 王成功, 杨兆军, 等. 数控机床可靠性建模研究现状及发展动态分析[J]. 吉林大学学报: 工学版, 2022, 52(2): 253-266. |

| Chen Chuan-hai, Wang Cheng-gong, Yang Zhao-jun, et al. Research status and development trend analysis of reliability modeling of CNC machine tools[J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(2): 253-266. | |

| 2 | 赵亮, 雷默涵, 朱星星, 等. 高精度数控机床主轴系统热误差的控制方法[J]. 上海交通大学学报, 2020, 54(11): 1165-1171. |

| Zhao Liang, Lei Mo-han, Zhu Xing-xing, et al. A new thermal error control method for spindle system of high precision computer numerical control machine tools[J]. Journal of Shanghai Jiaotong University, 2020, 54(11): 1165-1171. | |

| 3 | 林伟强. 基于循环神经网络的数控机床故障诊断研究[J]. 机床与液压, 2022, 50(5): 191-196. |

| Lin Wei-qiang. Research on fault diagnosis of NC machine tool based on circulating neural network[J]. Machine Tool & Hydraulics, 2022, 50(5): 191-196. | |

| 4 | 李东东, 赵耀, 赵阳, 等. 基于改进生成对抗网络的风机行星齿轮箱故障诊断方法[J]. 中国电机工程学报, 2021, 41(21): 7496-7507. |

| Li Dong-dong, Zhao Yao, Zhao Yang, et al. Fault diagnosis method of wind turbine planetary gearbox based on improved generative adversarial network[J]. Proceedings of the CSEE, 2021, 41(21): 7496-7507. | |

| 5 | 王英, 王丹, 陈小强, 等. 基于改进谱峭度与电流均值的牵引整流器开路故障诊断方法[J]. 电力自动化设备, 2020, 40(1): 112-118. |

| Wang Ying, Wang Dan, Chen Xiao-qiang, et al. Open circuit fault diagnosis method for traction rectifier based on improved spectral kurtosis and current mean value[J]. Electric Power Automation Equipment, 2020, 40(1): 112-118. | |

| 6 | 史建楠, 邹俊忠, 张见, 等. 基于DMD-LSTM模型的股票价格时间序列预测研究[J]. 计算机应用研究, 2020, 37(3): 662-666. |

| Shi Jian-nan, Zou Jun-zhong, Zhang Jian, et al. Research of stock price prediction based on DMD-LSTM model[J]. Application Research of Computers, 2020, 37(3): 662-666. | |

| 7 | 章子玲, 胡雄, 亓寅, 等. 基于向量投影响应面的数控机床几何误差分配方法[J]. 吉林大学学报: 工学版, 2022, 52(2): 384-391. |

| Zhang Zi-ling, Hu Xiong, Qi Yan, et al. An approach for error allocation of machine tool based on vector projection response surface method[J]. Journal of Jilin University(Engineering and Technology Edition), 2022,52(2): 384-391. | |

| 8 | 崔少华, 李素文, 汪徐德. BP神经网络和SVD算法联合的地震数据去噪方法[J]. 电子测量与仪器学报, 2020, 34(2): 12-19. |

| Cui Shao-hua, Li Su-wen, Wang Xu-de. Joint de-noising method of seismic data via BP neural network and SVD algorithm[J]. Journal of Electronic Measurement and Instrumentation, 2020, 34(2): 12-19. | |

| 9 | 张强, 杨吉斌, 张雄伟, 等. CS-Softmax:一种基于余弦相似性的Softmax损失函数[J]. 计算机研究与发展, 2022, 59(4): 936-949. |

| Zhang Qiang, Yang Ji-bin, Zhang Xiong-wei, et al. CS-Softmax: a cosine similarity-based softmax loss function[J]. Journal of Computer Research and Development, 2022, 59(4): 936-949. | |

| 10 | 孟月波, 石德旺, 刘光辉, 等. 多维度卷积融合的密集不规则文本检测[J]. 光学精密工程, 2021, 29(9): 2210-2221. |

| Meng Yue-bo, Shi De-wang, Liu Guang-hui, et al. Dense irregular text detection based on multi-dimensional convolution fusion[J]. Optics and Precision Engineering, 2021, 29(9): 2210-2221. | |

| 11 | 张峰瑞, 姜谙男, 赵亮, 等. 基于多变量GP-DE模型的隧道变形时间序列预测研究[J]. 现代隧道技术, 2021, 58(1): 109-116. |

| Zhang Feng-rui, Jiang An-nan, Zhao Liang, et al. Study on time series prediction of the tunnel deformation based on the multivariable GP-DE Model[J]. Modern Tunnelling Technology, 2021, 58(1): 109-116. | |

| 12 | 刘新田, 马牧洲, 何佳龙. 基于模糊耦合的机床零件加工精度可靠性预测方法[J]. 吉林大学学报: 工学版, 2022, 52(2): 377-383. |

| Liu Xin-tian, Ma Mu-zhou, He Jia-long. Reliability prediction method of machining precision of machine tool parts based on fuzzy coupling[J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(2): 377-383. | |

| 13 | 余孟阳, 杨帆. 信息链接技术下自动化设备现场故障运维仿真[J]. 计算机仿真, 2021, 38(12): 475-479. |

| Yu Meng-yang, Yang Fan. Field failure operation and maintenance simulation of automation equipment based on information link technology[J]. Computer Simulation, 2021, 38(12): 475-479. | |

| 14 | 赵寿生, 汪卫国, 王丰华, 等. 基于统计特征与EMD算法的有载分接开关振动信号去噪[J]. 电工电能新技术, 2020, 39(1): 51-58. |

| Zhao Shou-sheng, Wang Wei-guo, Wang Feng-hua, et al. Denoising method of vibration signal of on-load tap changer based on statistical feature and EMD algorithm[J]. Advanced Technology of Electrical Engineering and Energy, 2020, 39(1): 51-58. | |

| 15 | Li J, Sacchi M D. An l p-space matching pursuit algorithm and its application to robust seismic data denoising via time-domain Radon transforms[J]. Geophysics, 2021, 86(3): 1-90. |

| 16 | Zeng Y, Li J, Wei C, et al. mbDenoise: microbiome data denoising using zero-inflated probabilistic principal components analysis[J]. Genome Biology, 2022, 23(1): 1-29. |

| 17 | 李水利, 周建民, 孙定邦. 自适应MED降噪和EMD分解在注塑机轴承故障诊断中的应用[J]. 塑料科技, 2020, 48(6): 124-128. |

| Li Shui-li, Zhou Jian-min, Sun Ding-bang. Application of adaptive MED noise reduction and EMD decomposition in fault diagnosis of mechanical Bearings[J]. Plastics Science and Technology, 2020, 48(6): 124-128. | |

| 18 | Rakotondramanana A L H, Randrianirina H H R, Randriamiharisoa M A, et al. Contributions of IMFs programs to household financial resilience: financial evolution of households in rural areas—the case of malagasy IMFs[J]. Modern Economy, 2021, 12(12): 1212102. |

| 19 | Shankar V F, Cockle J, et al. IMG-18. Assessment of suspected disease progression using multiparametric 18f-choline pet/mri in childhood and teenage-young adult gliomas[J]. Neuro-Oncology, 2020, 22(3): 358. |

| 20 | Hou S, Guo X. Research on fault location of distribution lines based on the standing wave principle[J]. Processes, 2021, 9(8): 9081436. |

| [1] | 欧阳丹彤,孙睿,田新亮,高博涵. 基于集合阻塞的不确定系统中传感器选择方法[J]. 吉林大学学报(工学版), 2023, 53(2): 547-554. |

| [2] | 陈永刚,许继业,王海涌,熊文祥. 基于自适应神经模糊网络的转辙机故障诊断方法[J]. 吉林大学学报(工学版), 2023, 53(11): 3274-3280. |

| [3] | 曹洁,马佳林,黄黛麟,余萍. 一种基于多通道马尔可夫变迁场的故障诊断方法[J]. 吉林大学学报(工学版), 2022, 52(2): 491-496. |

| [4] | 高文志,王彦军,王欣伟,张攀,李勇,董阳. 基于卷积神经网络的柴油机失火故障实时诊断[J]. 吉林大学学报(工学版), 2022, 52(2): 417-424. |

| [5] | 王进花,胡佳伟,曹洁,黄涛. 基于自适应变分模态分解和集成极限学习机的滚动轴承多故障诊断[J]. 吉林大学学报(工学版), 2022, 52(2): 318-328. |

| [6] | 董绍江,朱朋,裴雪武,李洋,胡小林. 基于子领域自适应的变工况下滚动轴承故障诊断[J]. 吉林大学学报(工学版), 2022, 52(2): 288-295. |

| [7] | 罗巍,卢博,陈菲,马腾. 基于PSO-SVM及时序环节的数控刀架故障诊断方法[J]. 吉林大学学报(工学版), 2022, 52(2): 392-399. |

| [8] | 邓飞跃,吕浩洋,顾晓辉,郝如江. 基于轻量化神经网络Shuffle⁃SENet的高速动车组轴箱轴承故障诊断方法[J]. 吉林大学学报(工学版), 2022, 52(2): 474-482. |

| [9] | 张龙,徐天鹏,王朝兵,易剑昱,甄灿壮. 基于卷积门控循环网络的齿轮箱故障诊断[J]. 吉林大学学报(工学版), 2022, 52(2): 368-376. |

| [10] | 陈晓雷,孙永峰,李策,林冬梅. 基于卷积神经网络和双向长短期记忆的稳定抗噪声滚动轴承故障诊断[J]. 吉林大学学报(工学版), 2022, 52(2): 296-309. |

| [11] | 杜先君,贾亮亮. 基于优化堆叠降噪自编码器的滚动轴承故障诊断[J]. 吉林大学学报(工学版), 2022, 52(12): 2827-2838. |

| [12] | 陈菲,杨峥,张志成,罗巍. 面向无标签数据的旋转机械故障诊断方法[J]. 吉林大学学报(工学版), 2022, 52(11): 2514-2522. |

| [13] | 曹洁,何智栋,余萍,王进花. 数据不平衡分布下轴承故障诊断方法[J]. 吉林大学学报(工学版), 2022, 52(11): 2523-2531. |

| [14] | 欧阳丹彤,张必歌,田乃予,张立明. 结合格局检测与局部搜索的故障数据缩减方法[J]. 吉林大学学报(工学版), 2021, 51(6): 2144-2153. |

| [15] | 院老虎,连冬杉,张亮,刘义. 基于密集连接卷积网络和支持向量机的飞行器机械部件故障诊断[J]. 吉林大学学报(工学版), 2021, 51(5): 1635-1641. |

|