吉林大学学报(工学版) ›› 2022, Vol. 52 ›› Issue (2): 296-309.doi: 10.13229/j.cnki.jdxbgxb20211031

• 车辆工程·机械工程 • 上一篇

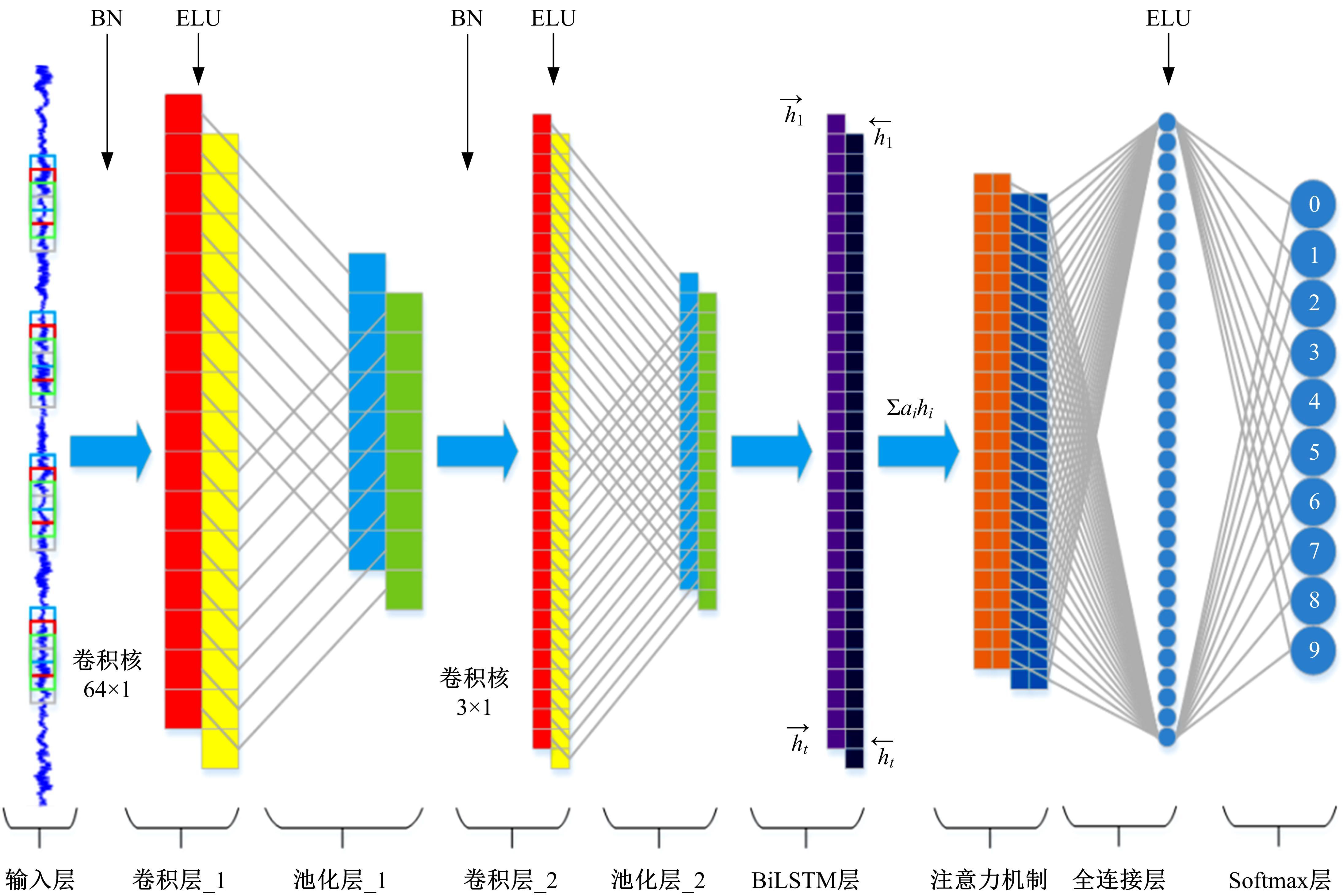

基于卷积神经网络和双向长短期记忆的稳定抗噪声滚动轴承故障诊断

陈晓雷1,2,3( ),孙永峰1,李策1,2,3,林冬梅1,2,3

),孙永峰1,李策1,2,3,林冬梅1,2,3

- 1.兰州理工大学 电气工程与信息工程学院,兰州 730050

2.兰州理工大学 甘肃省工业过程先进控制重点实验室,兰州 730050

3.兰州理工大学 电气与控制工程国家级实验教学示范中心,兰州 730050

Stable anti⁃noise fault diagnosis of rolling bearing based on CNN⁃BiLSTM

Xiao⁃lei CHEN1,2,3( ),Yong⁃feng SUN1,Ce LI1,2,3,Dong⁃mei LIN1,2,3

),Yong⁃feng SUN1,Ce LI1,2,3,Dong⁃mei LIN1,2,3

- 1.College of Electrical and Information Engineering,Lanzhou University of Technology,Lanzhou 730050,China

2.Key Laboratory of Gansu Advanced Control for Industrial Processes,Lanzhou University of Technology,Lanzhou ;730050

3.National Demonstration Center for Experimental Electrical and Control Engineering Education,Lanzhou University of Technology,Lanzhou 730050,China

摘要:

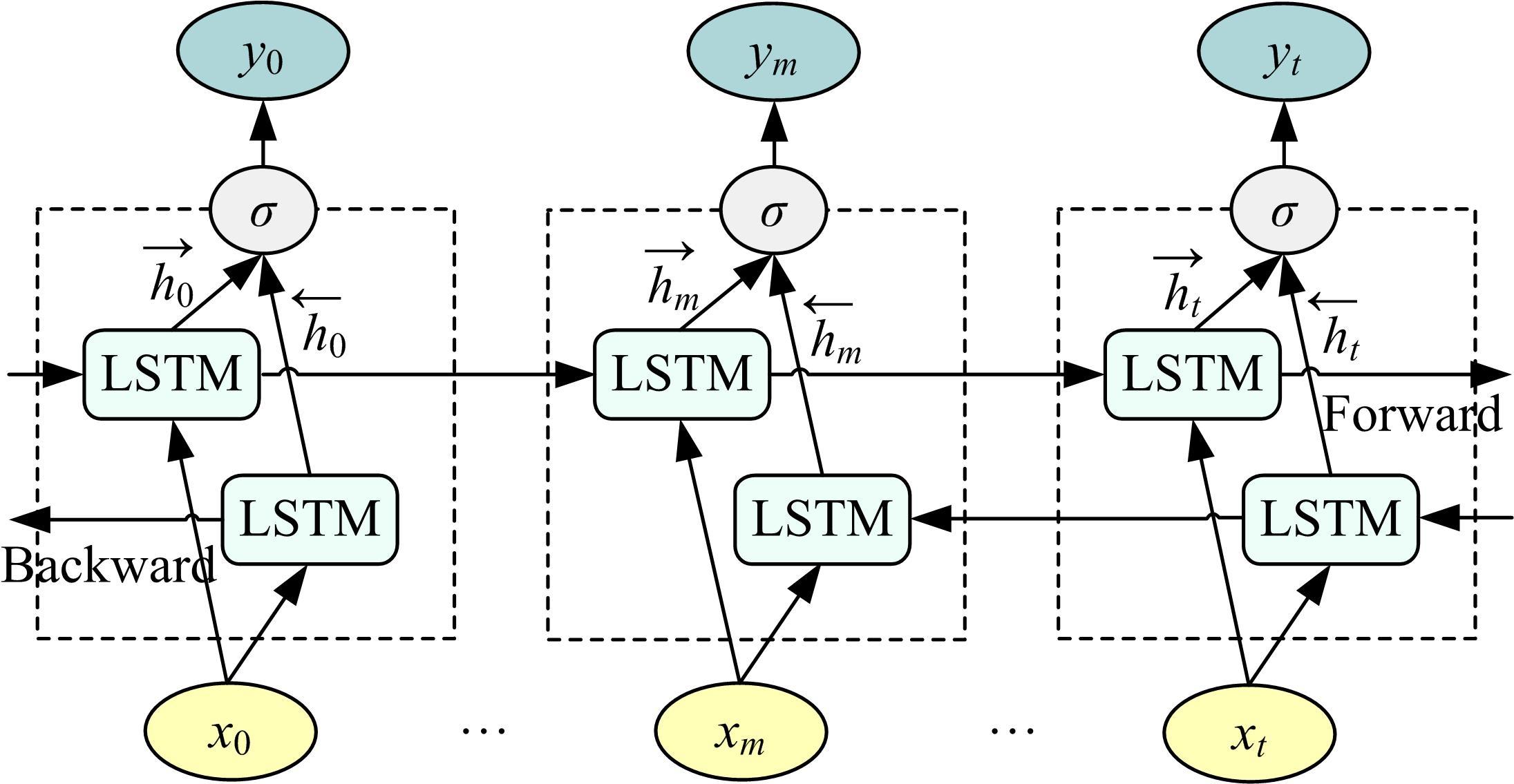

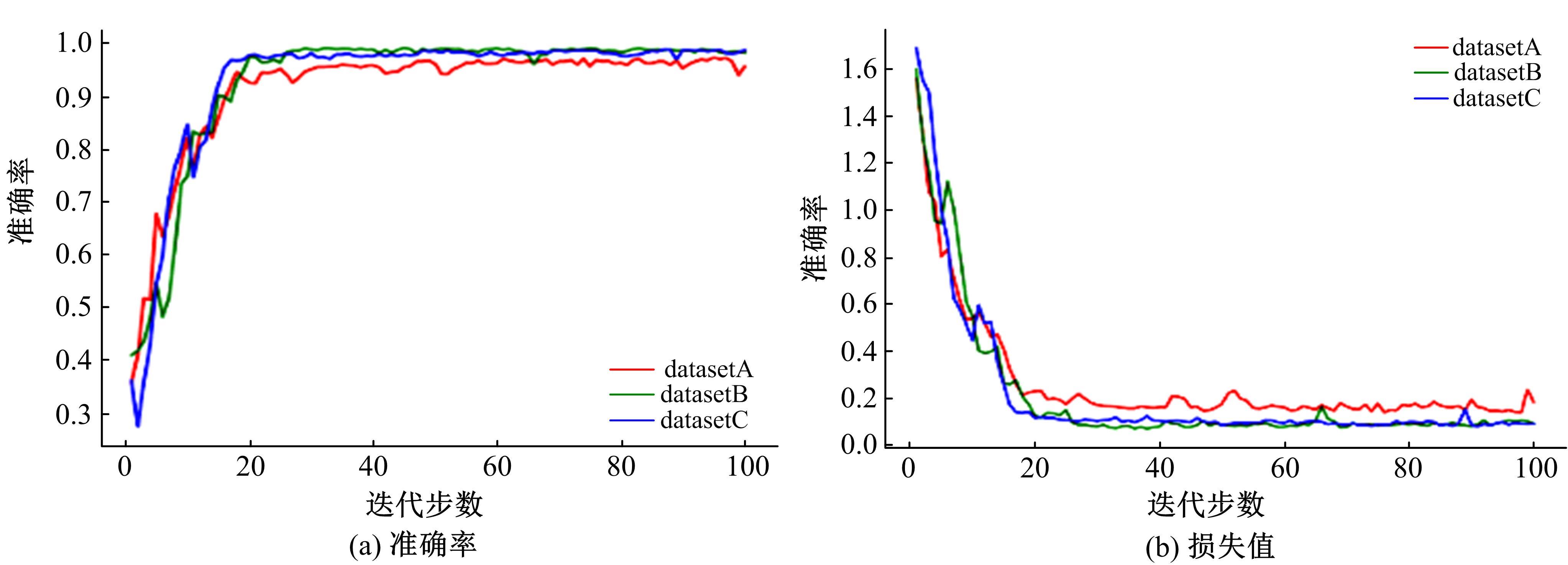

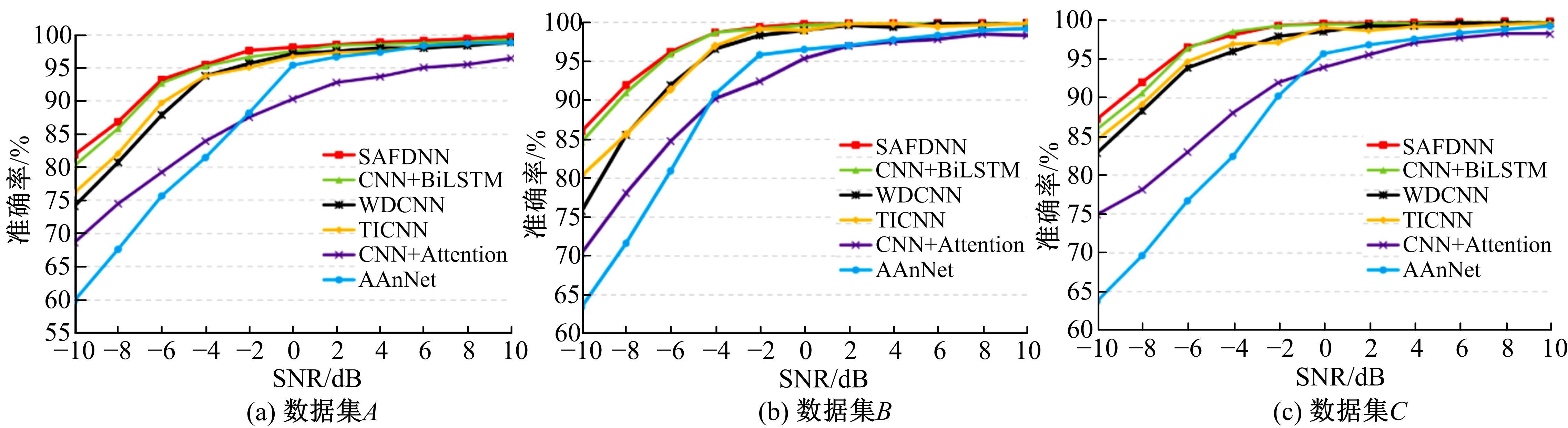

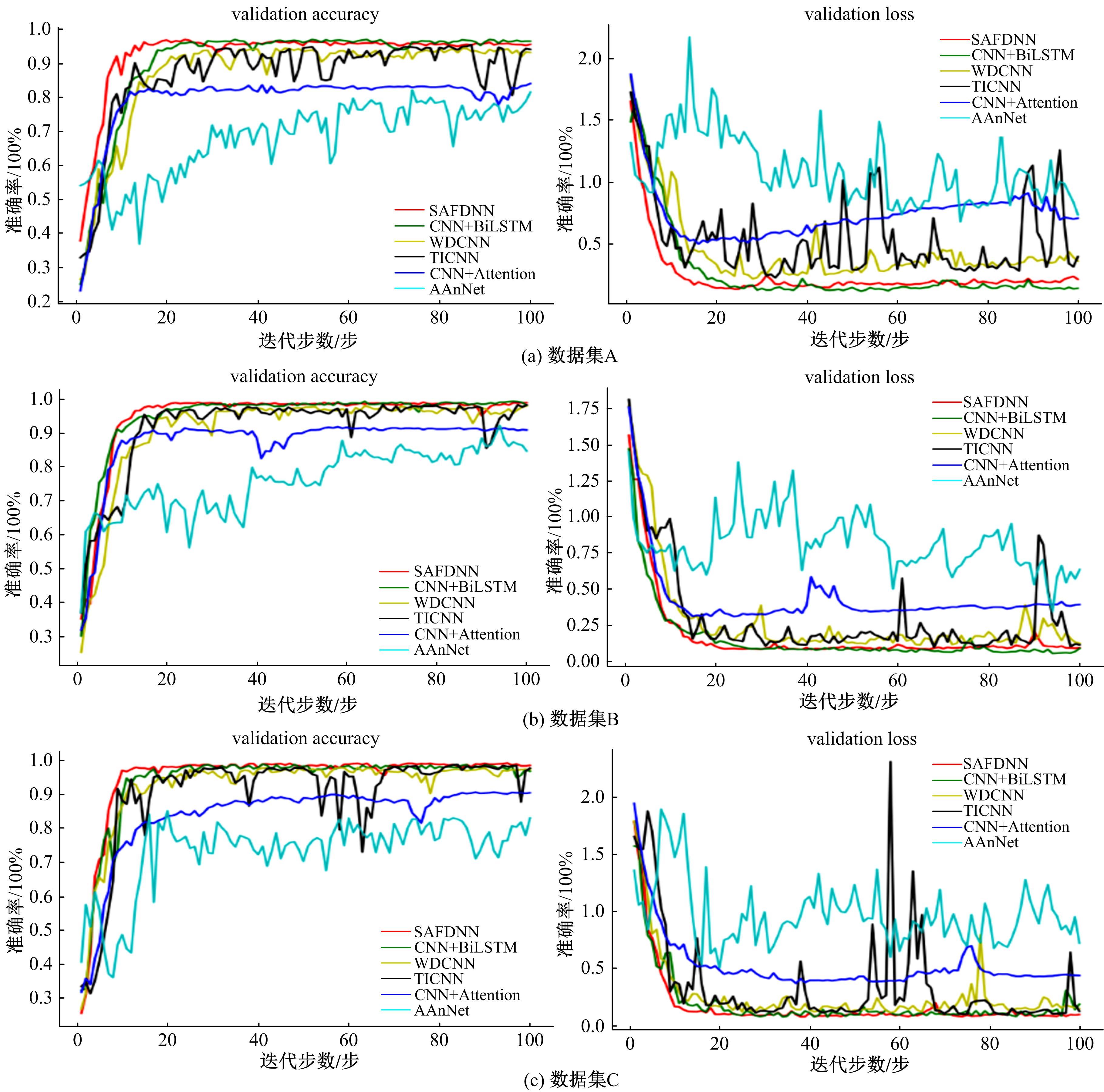

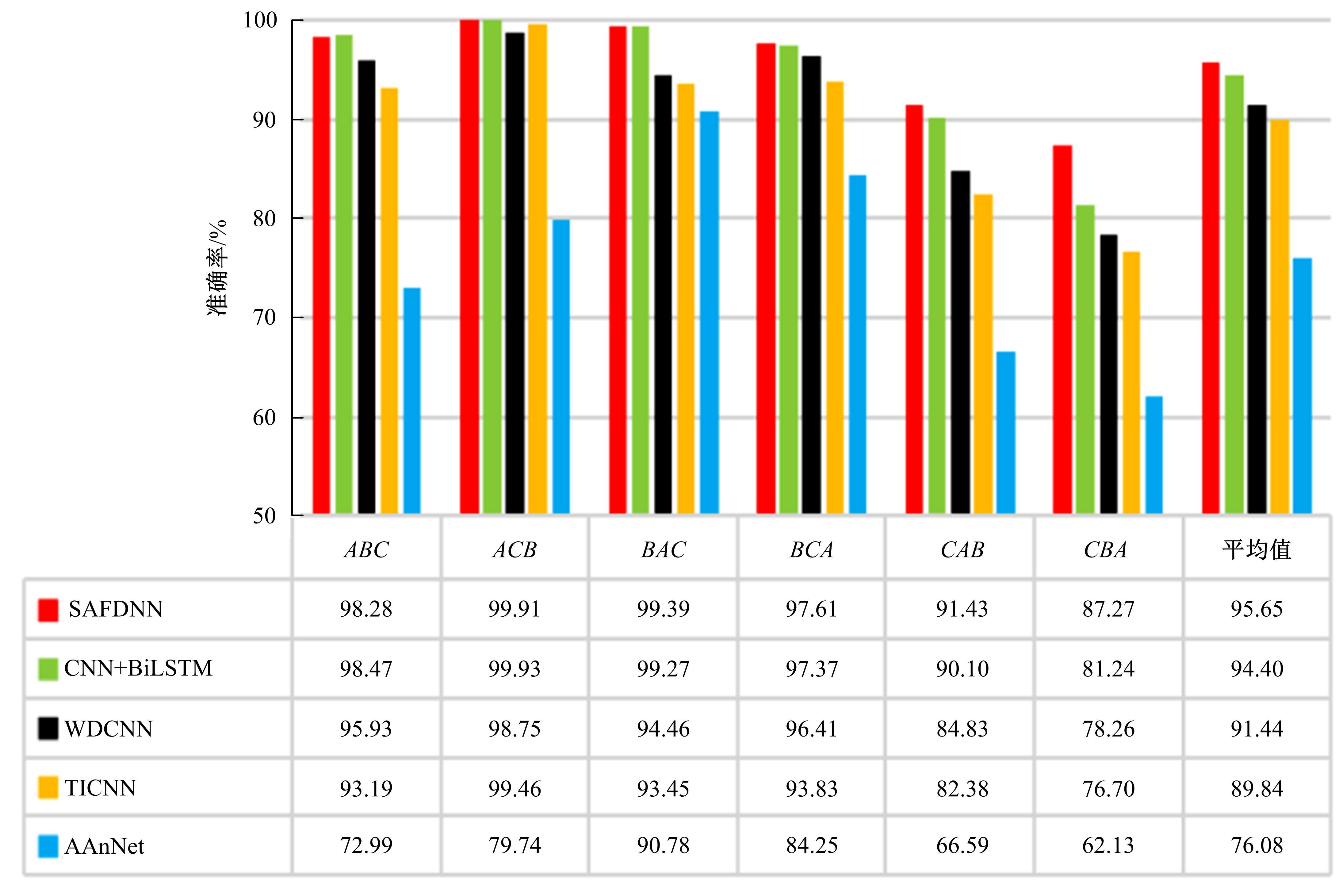

针对滚动轴承在噪声环境条件下故障诊断模型准确率较低和性能不稳定的问题,本文提出了一种稳定抗噪声故障诊断神经网络(SAFDNN)模型。该模型采用原始振动数据信号作为输入,首先使用卷积神经网络(CNN)进行数据信号特征提取,然后利用双向长短期记忆(BiLSTM)充分提取数据信号的序列特征,接着添加注意力机制进行特征融合以自动关注每种数据信号的相关信息,提高模型的诊断性能,最后通过全连接层和Softmax层进行特征分类。实验结果表明,SAFDNN在添加不同信噪比大小的额外噪声条件下能够保持较高的故障识别准确率和较好的诊断效果稳定性。

中图分类号:

- TP277

| 1 | Liu R, Yang B, Zio E, et al. Artificial intelligence for fault diagnosis of rotating machinery: a review[J]. Mechanical Systems & Signal Processing, 2018, 108:33⁃47. |

| 2 | Wang B, Lei Y, Li N, et al. A hybrid prognostics approach for estimating remaining useful life of rolling element bearings[J]. IEEE Transactions on Reliability, 2020,69(1):401⁃412. |

| 3 | Ahmad W, Khan S A, Kim J M. A hybrid prognostics technique for rolling element bearings using adaptive predictive models[J]. IEEE Transactions on Industrial Electronics, 2018,65(2):1577⁃1584. |

| 4 | Wen L, Li X, Gao L, et al. A new convolutional neural network based data⁃driven fault diagnosis method[J]. IEEE Transactions on Industrial Electronics, 2018,65(7):5990⁃5998. |

| 5 | Li Y, Ding K, He G, et al. Non⁃stationary vibration feature extraction method based on sparse decomposition and order tracking for gearbox fault diagnosis[J]. Measurement, 2018, 124:453⁃469. |

| 6 | Wu C, Jiang P, Ding C, et al. Intelligent fault diagnosis of rotating machinery based on one⁃dimensional convolutional neural network[J]. Computers in Industry, 2019, 108:53⁃61. |

| 7 | 解晓婷,李少波,杨观赐,等.基于FFT与CS⁃SVM的滚动轴承故障诊断[J].组合机床与自动化加工技术,2019,542(4):90⁃94. |

| Xie Xiao⁃ting, Li Shao⁃bo, Yang Guan⁃ci, et al. Fault diagnosis of rolling bearing based on FFT and CS⁃SVM [J]. Modular Machine Tool and Automatic Processing Technology, 2019, 542(4):90⁃94. | |

| 8 | 陈彦龙,张培林,李兵,徐超,王国德.基于DCT和GA-SVM的轴承故障诊断[J].计算机工程,2012,38(19):247-249, 253. |

| Chen Yan-long, Zhang Pei-lin, Li Bing, Xu Chao, Wang Guo-de.Bearing fault diagnosis based on DCT and GA-SVM[J].Computer Engineering,2012,38(19):247-249, 253. | |

| 9 | Lee C Y, Cheng Y H. Motor fault detection using wavelet transform and improved PSO⁃BP neural network[J]. Processes, 2020, 8(10):1322. |

| 10 | Zhu H, Wang X, Yang Z, et al. Sparse representation based on adaptive multiscale features for robust machinery fault diagnosis[J]. Proceedings of the Institution of Mechanical Engineers Part C Journal of Mechanical Engineering Science, 2015, 229(12):2303⁃2313. |

| 11 | Zhao H, Guo S, Gao D. Fault feature extraction of bearing faults based on singular value decomposition and variational modal decomposition[J]. Journal of Vibration and Shock, 2016,35(22):183⁃188. |

| 12 |

王进花,胡佳伟,曹洁,黄涛.基于自适应VMD和IELM的滚动轴承多故障诊断[J/OL].吉林大学学报:工学版:1-10.[2022-01-21].DOI:10.13229/j.cnki.jdxbgxb20200856.

doi: 10.13229/j.cnki.jdxbgxb20200856 |

|

Wang Jin-hua, Hu Jia-wei, Cao Jie, Huang Tao.Multiple fault diagnosis of rolling bearing based on adaptive VMD and IELM[J/OL].Journal of Jilin University(Engineering Edition):1-10.[2022-01-21].DOI:10.13229/j.cnki.jdxbgxb20200856.

doi: 10.13229/j.cnki.jdxbgxb20200856 |

|

| 13 | 王普,李天垚,高学金,等. 分层自适应小波阈值轴承故障信号降噪方法[J]. 振动工程学报, 2019, 32(3): 548⁃556. |

| Wang Pu, Li Tian⁃yao, Gao Xue⁃jin, et al. Hierarchical adaptive wavelet threshold denoising method for bearing fault signals[J]. Chinese Journal of Vibration Engineering, 2019, 32(03): 548⁃556. | |

| 14 | 朱军,闵祥敏,孔凡让,等. 基于分量筛选奇异值分解的滚动轴承故障诊断方法研究[J].振动与冲击, 2015, 34(20): 61⁃65. |

| Zhu Jun, Min Xiang⁃min, Kong Fan⁃rang, et al. Research on fault diagnosis method of rolling bearing based on component screening singular value decomposition[J]. Vibration and Shock, 2015, 34(20): 61⁃65. | |

| 15 | Bakir T, Boussaid B, Hamdaoui R, et al. Fault detection in wind turbine system using wavelet transform: multi⁃resolution analysis[C]//International Multi conference on Systems, IEEE, 2015: 1⁃6. |

| 16 | Wang H, Xu J, Yan R, et al. Intelligent bearing fault diagnosis using multi⁃head attention⁃based CNN[J]. Procedia Manufacturing, 2020, 49: 112⁃118. |

| 17 | 曲建岭,余路,袁涛,等. 基于卷积神经网络的层级化智能故障诊断算法[J]. 控制与决策, 2019, 34(12): 2619⁃2626. |

| Qu Jian⁃ling, Yu Lu, Yuan Tao, et al. A hierarchical intelligent fault diagnosis algorithm based on convolutional neural network[J]. Control and Decision, 2019, 34(12): 2619⁃2626. | |

| 18 | Chen X, Zhang B, Gao D. Bearing fault diagnosis base on multi⁃scale CNN and LSTM model[J]. Journal of Intelligent Manufacturing, 2021, 32: 971⁃987. |

| 19 | 张根保,李浩,冉琰,等. 一种用于轴承故障诊断的迁移学习模型[J].吉林大学学报:工学版, 2020, 50(5): 1617⁃1626. |

| Zhang Gen⁃bao, Li Hao, Ran Yan, et al. A transfer learning model for bearing fault diagnosis[J]. Journal of Jilin University (Engineering and Technology Edition), 2020, 50(5): 1617⁃1626. | |

| 20 | Wei Z, Peng G, Li C, et al. A new deep learning model for fault diagnosis with good anti⁃noise and domain adaptation ability on raw vibration signals[J]. Sensors, 2017, 17(2): 425. |

| 21 | Zhang W, Li C, Peng G, et al. A deep convolutional neural network with new training methods for bearing fault diagnosis under noisy environment and different working load[J]. Mechanical Systems and Signal Processing, 2018, 100: 439⁃453. |

| 22 | Li X, Zhang W, Din Q. A robust intelligent fault diagnosis method for rolling element bearings based on deep distance metric learning[J]. Neurocomputing, 2018, 310(8): 77⁃95. |

| 23 | Jin G, Zhu T, Akram M W, et al. An adaptive anti⁃noise neural network for bearing fault diagnosis under noise and varying load conditions[J]. IEEE Access, 2020, 8: 74793⁃74807. |

| 24 | Hamada M S, Ryan K J. Combined analysis of overlapping stratified random sample and simple random sample data[J]. Quality and Reliability Engineering International, 2016, 32(1): 309⁃314. |

| 25 | Smith W A, Randall R B. Rolling element bearing diagnostics using the case Western Reserve University data: a benchmark study[J]. Mechanical Systems and Signal Processing, 2015, 64⁃65: 100⁃131. |

| 26 | 黄南天,杨学航,蔡国伟,等. 采用非平衡小样本数据的风机主轴承故障深度对抗诊断[J]. 中国电机工程学报, 2020, 40(2): 215⁃226. |

| Huang Nan⁃tian, Yang Xue⁃hang, Cai Guo⁃wei, et al. Depth counter⁃diagnosis of fan main bearing faults using unbalanced small sample data[J]. Proceedings of the Chinese Society of Electrical Engineering, 2020, 40(2): 215⁃226. | |

| 27 | Ioffe S, Szegedy C. Batch normalization: accelerating deep network training by reducing internal covariate shift[J]. JMLR org, 2015, arXiv:. |

| 28 | Li Y, Fan C, Li Y, et al. Improving deep neural network with multiple parametric exponential linear units[J]. Neurocomputing, 2016, 301(2): 11⁃24. |

| 29 | Hochreiter S, Schmidhuber J. Long short⁃term memory[J]. Neural Computation, 1997, 9(8): 1735⁃1780. |

| 30 | Brocki L, Marasek K. Deep belief neural networks and bidirectional long⁃short term memory hybrid for speech recognition[J]. Archives of Acoustics, 2015, 40(2): 191⁃195. |

| 31 | Kingma D P, Ba J. Adam: A method for stochastic optimization[J]. arXiv preprint arXiv:, 2014. |

| 32 | Rusiecki A. Trimmed categorical cross‐entropy for deep learning with label noise[J]. Electronics Letters, 2019, 55(6): 319-320. |

| [1] | 李国发,王彦博,何佳龙,王继利. 机电装备健康状态评估研究进展及发展趋势[J]. 吉林大学学报(工学版), 2022, 52(2): 267-279. |

| [2] | 董绍江,朱朋,裴雪武,李洋,胡小林. 基于子领域自适应的变工况下滚动轴承故障诊断[J]. 吉林大学学报(工学版), 2022, 52(2): 288-295. |

| [3] | 段亮,宋春元,刘超,魏苇,吕成吉. 基于机器学习的高速列车轴承温度状态识别[J]. 吉林大学学报(工学版), 2022, 52(1): 53-62. |

| [4] | 许鸿奎,姜彤彤,李鑫,姜斌祥,王永雷. 结合降噪自编码与极限学习机的LTE上行干扰分析[J]. 吉林大学学报(工学版), 2022, 52(1): 195-203. |

| [5] | 刘桂霞,裴志尧,宋佳智. 基于深度学习的蛋白质⁃ATP结合位点预测[J]. 吉林大学学报(工学版), 2022, 52(1): 187-194. |

| [6] | 邝先验,罗会超,钟蕊,欧阳鹏. 基于天牛须小波神经网络的公交到站时间预测[J]. 吉林大学学报(工学版), 2022, 52(1): 110-117. |

| [7] | 王宏志,王婷婷,胡黄水,鲁晓帆. 基于Q学习优化BP神经网络的BLDCM转速PID控制[J]. 吉林大学学报(工学版), 2021, 51(6): 2280-2286. |

| [8] | 刘远红,郭攀攀,张彦生,李鑫. 基于黎曼流形的稀疏图保持投影的特征提取[J]. 吉林大学学报(工学版), 2021, 51(6): 2268-2279. |

| [9] | 杨世军,裴玉龙,潘恒彦,程国柱,张文会. 城市公交车辆驻站时间特征分析及预测[J]. 吉林大学学报(工学版), 2021, 51(6): 2031-2039. |

| [10] | 欧阳丹彤,张必歌,田乃予,张立明. 结合格局检测与局部搜索的故障数据缩减方法[J]. 吉林大学学报(工学版), 2021, 51(6): 2144-2153. |

| [11] | 钟辉,康恒,吕颖达,李振建,李红,欧阳若川. 基于注意力卷积神经网络的图像篡改定位算法[J]. 吉林大学学报(工学版), 2021, 51(5): 1838-1844. |

| [12] | 滕文龙,丛炳虎,商云坤,张予宸,白天. 基于MEA⁃BP神经网络的建筑能耗预测模型[J]. 吉林大学学报(工学版), 2021, 51(5): 1857-1865. |

| [13] | 陈涛,秦静,赵华,苏庆鹏,吕永,钟凯,王膺博,裴毅强. 基于模型群预测法对汽油机稳态原排的预测[J]. 吉林大学学报(工学版), 2021, 51(5): 1565-1574. |

| [14] | 院老虎,连冬杉,张亮,刘义. 基于密集连接卷积网络和支持向量机的飞行器机械部件故障诊断[J]. 吉林大学学报(工学版), 2021, 51(5): 1635-1641. |

| [15] | 朱小龙,谢忠. 基于海量文本数据的知识图谱自动构建算法[J]. 吉林大学学报(工学版), 2021, 51(4): 1358-1363. |

|

||