吉林大学学报(工学版) ›› 2022, Vol. 52 ›› Issue (2): 368-376.doi: 10.13229/j.cnki.jdxbgxb20200930

• 车辆工程·机械工程 • 上一篇

基于卷积门控循环网络的齿轮箱故障诊断

- 1.华东交通大学 机电与车辆工程学院,南昌 330013

2.中车戚墅堰机车有限公司,常州 213011

Gearbox fault diagnosis baed on convolutional gated recurrent network

Long ZHANG1( ),Tian-peng XU1,Chao-bing WANG1,2,Jian-yu YI1,Can-zhuang ZHEN1

),Tian-peng XU1,Chao-bing WANG1,2,Jian-yu YI1,Can-zhuang ZHEN1

- 1.School of Mechatronics and Vehicle Engineering,East China Jiaotong University,Nanchang 330013,China

2.CRRC Qishuyan Co. ,Ltd. ,Changzhou 213011,China

摘要:

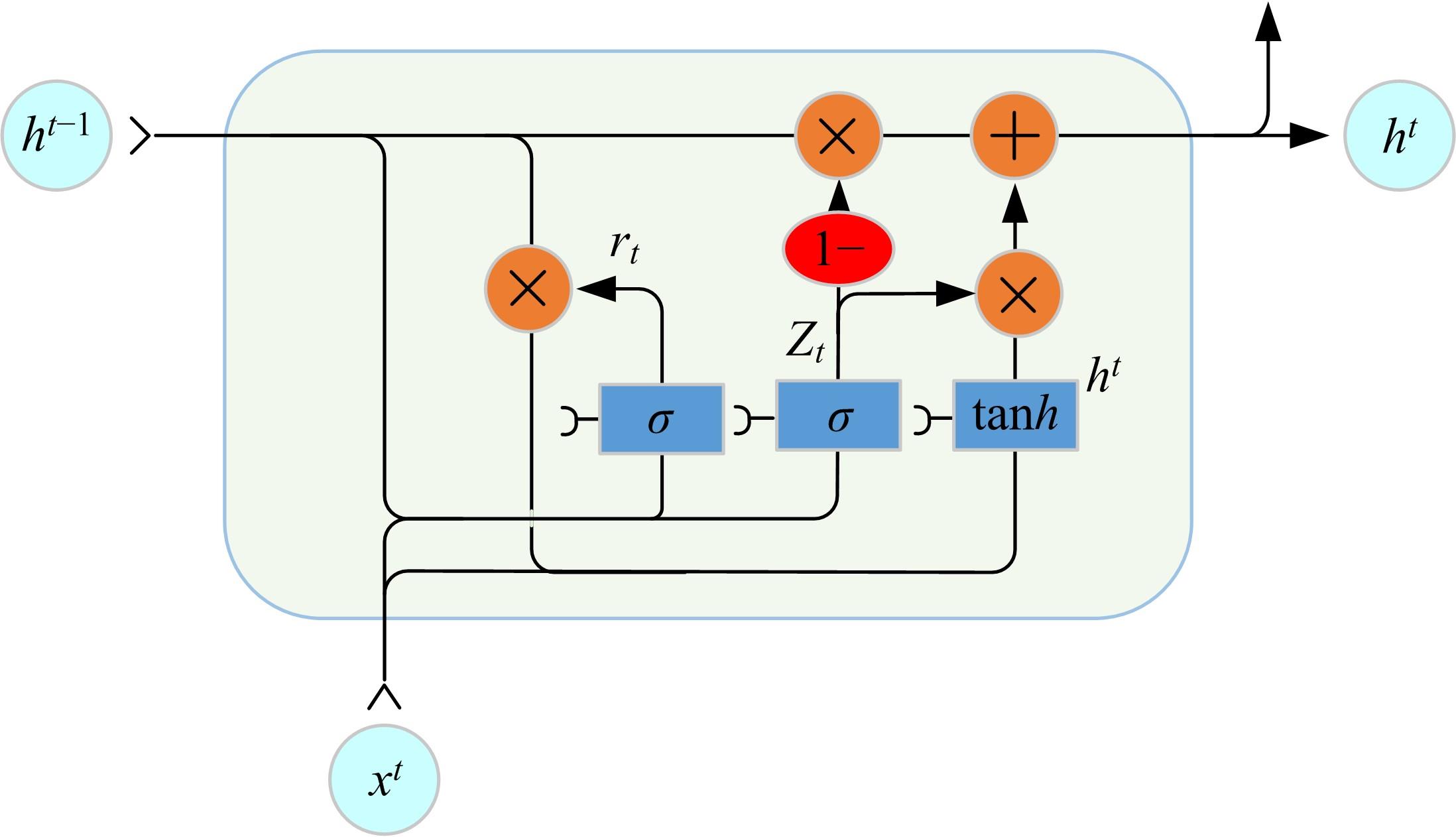

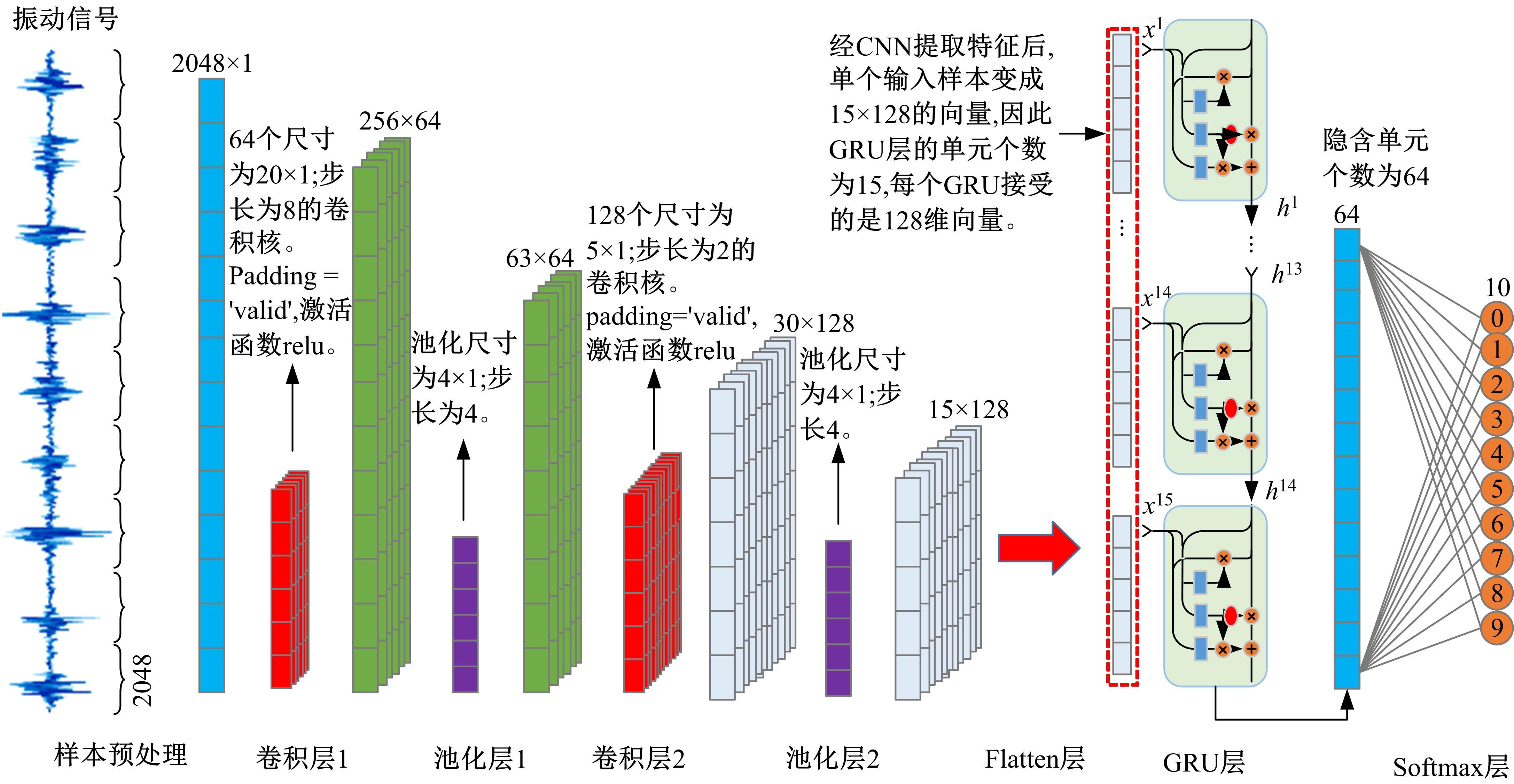

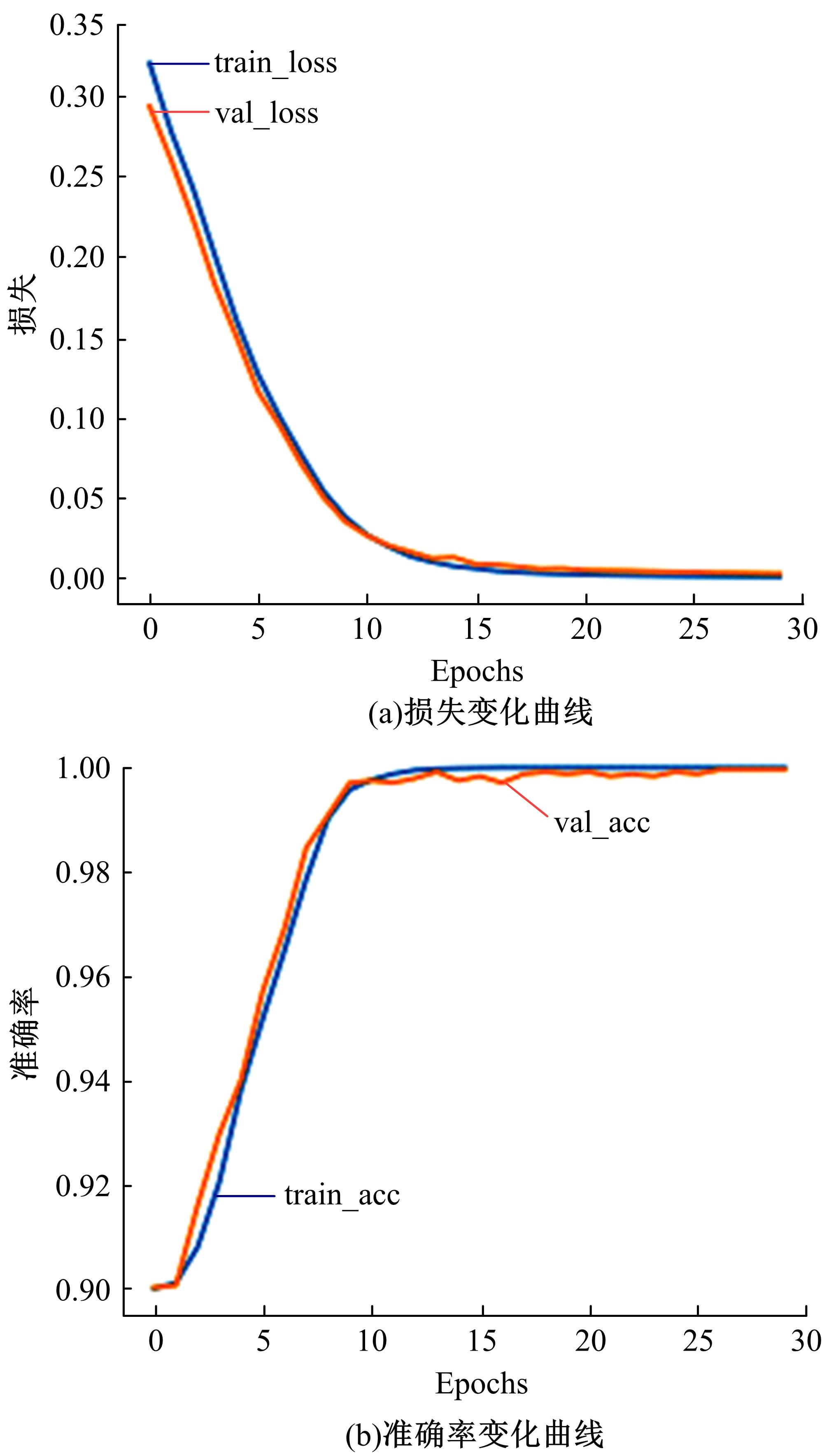

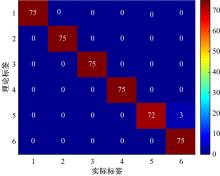

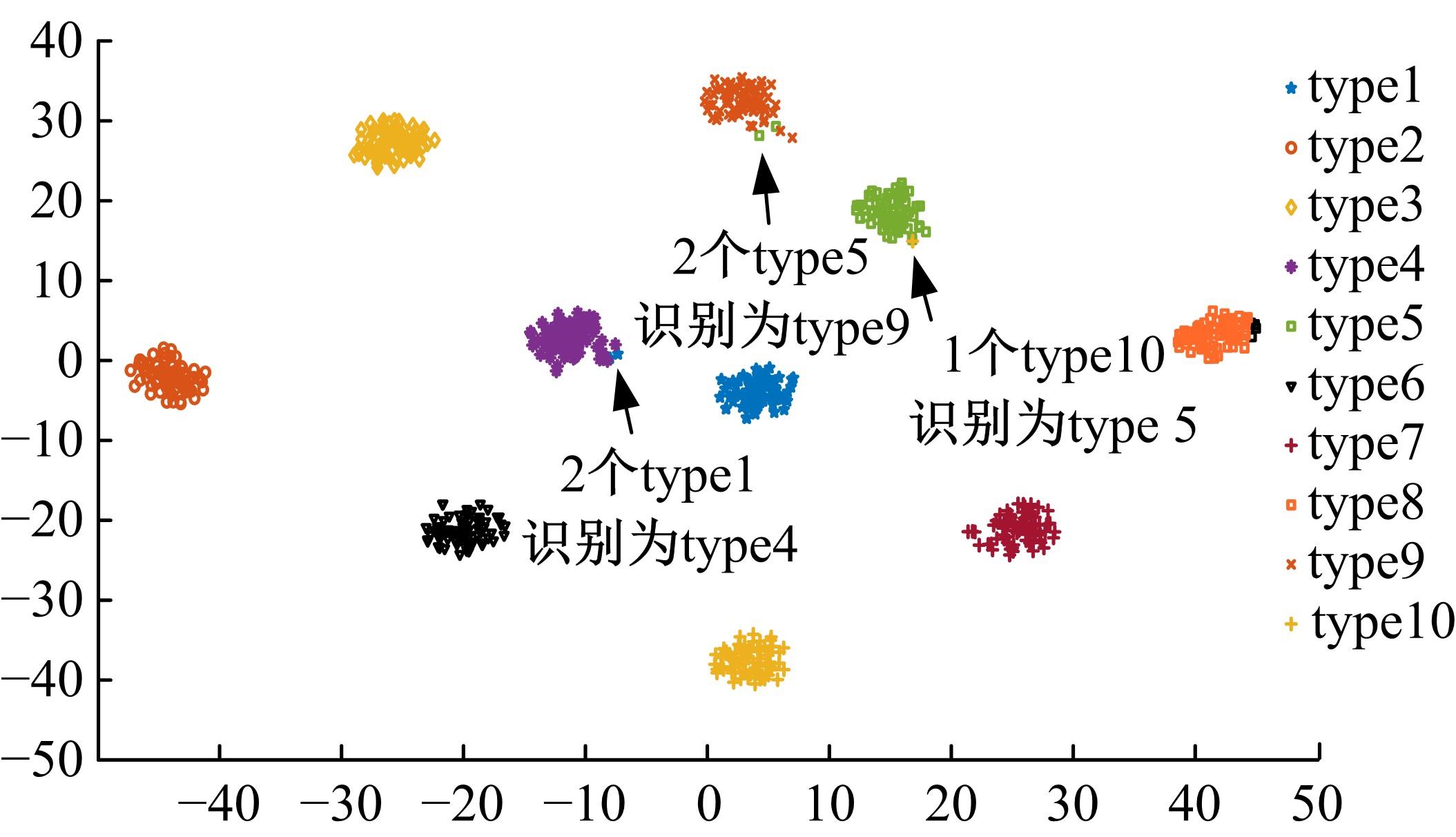

为充分利用信号的时序相关性特征,增强模型对数据信息的全面挖掘能力,以进一步提高卷积神经网络(CNN)诊断精度,本文将CNN与善于处理数据时序相关性特征的门控循环单元(GRU)相结合,提出了一种新的齿轮箱故障诊断模型。CNN通过端对端的方式提取数据空间特征,并将提取的特征作为GRU的输入进一步提取时空特征,最后将GRU提取的时空特征作为SoftMax的输入进行故障识别。两组齿轮箱实验数据分析结果显示:平均故障诊断精度分别可达99.86%和99.85%,与其它现有模型的结果对比体现了本文模型的有效性和优越性。

中图分类号:

- TH132.4

| 1 | Liu Y B, Qian Q, Liu F, et al. Wayside bearing fault diagnosis based on envelope analysis paved with time-domain interpolation resampling and weighted-correlation-coefficient-guided stochastic resonance[J]. Shock and Vibration, 2017(1): 1-17. |

| 2 | McKee K K, Forbes G L, Mazhar I, et al. A vibration cavitation sensitivity parameter based on spectral and statistical methods[J]. Expert Systems with Applications, 2015, 42(1): 67-78. |

| 3 | 胡茑庆, 陈徽鹏, 程哲, 等. 基于经验模态分解和深度卷积神经网络的行星齿轮箱故障诊断方法[J]. 机械工程学报, 2019, 55(7): 9-18. |

| Hu Niao-qing, Chen Hui-peng, Cheng Zhe, et al. Fault diagnosis for planetary gearbox based on EMD and deep convolutional neural networks[J]. Journal of Mechanical Engineering, 2019, 55(7): 9-18. | |

| 4 | 黄海松, 魏建安, 任竹鹏, 等. 基于失衡样本特性过采样算法与SVM的滚动轴承故障诊断[J]. 振动与冲击, 2020, 39(10): 65-74, 132. |

| Huang Hai-song, Wei Jian-an, Ren Zhu-peng, et al. Rolling bearing fault diagnosis based on imbanced sample characteristics oversampling algorithm and SVM[J]. Journal of Mechanical Engineering, 2020. 39(10): 65-74, 132. | |

| 5 | 谭刚, 李军. 机械设备故障诊断系统中决策树算法的应用研究[J]. 自动化与仪器仪表, 2016(12): 90-91. |

| Tan Gang, Li Jun. Application of decision tree algorithm in mechanical equipment fault diagnosis system[J].Automation & Instrumentation, 2016(12): 90-91. | |

| 6 | 何雷, 刘溯奇, 蒋婷, 等. 基于改进LMD与BP神经网络的变速箱故障诊断[J]. 机械传动, 2020, 44(1): 171-176. |

| He Lei, Liu Su-qi, Jiang Ting, et al. Gearbox fault diagnosis based on improved LMD and BP neural network[J]. Journal of Mechanical Transmission, 2020, 44(1): 171-176. | |

| 7 | Boudiaf A, Moussaoui A, Dahane A, et al. A comparative study of various methods of bearing faults diagnosis using the case western reserve university data[J]. Journal of Failure Analysis and Prevention, 2016, 16(2): 271-284. |

| 8 | Li P, Chen Z K, Yang L T, et al. An incremental deep convolutional computation model for feature learning on industrial big data[J]. IEEE Transactions on Industrial Informatics, 2019, 15(3): 1341-1349. |

| 9 | Mao S B, Rajan D, Chia L T, et al. Deep residual learning for image recognition[J]. IEEE Computer Society, 2016: 770-778. |

| 10 | Hinton G, Deng L, Yu D, et al. Deep neural networks for acoustic modeling in speech recognition: the shared views of four research groups[J]. IEEE Signal Processing Magazine, 2012, 29(6): 82-97. |

| 11 | Tran Q T, Nguyen S D, Seo Tae-ll.Algorithm for estimating online bearing fault upon the ability to extract meaningful information from big data of intelligent structures[J]. IEEE Transactions on Industrial Electronics, 2019, 66(5): 3804-3813. |

| 12 | Sun W F, Yao B,Zeng N Y, et al. An intelligent gear fault diagnosis methodology using a complex wavelet enhanced convolutional neural network[J]. Materials, 2017, 10(7): 790-807. |

| 13 | He J, Yang S, Gan C. Unsupervised fault diagnosis of a gear transmission chain using a deep belief network[J]. Sensors, 2017, 10(7): 1564-1583. |

| 14 | Eren L. Bearing fault detection by one-dimensional convolutional neural networks[J]. Mathematical Problems in Engineering, 2017(7): 8617315. |

| 15 | Hochreiter S, Schmidhuber J. Long short-term memory[J]. Neural Computation, 1997, 9(8): 1735-1780. |

| 16 | 李琳辉, 伦智梅, 连静, 等. 基于卷积神经网络的道路车辆检测方法[J]. 吉林大学学报: 工学版, 2017, 47(2): 384-391. |

| Li Lin-hui, Zhi-mei Lun, Lian Jing, et al. Convolution neural network-based vehicle detection method[J]. Journal of Jilin University(Engineering and Technology Edition), 2017, 47(2): 384-391. | |

| 17 | 钟辉, 李红, 李振建, 等. 基于卷积神经网络的图像拼接篡改检测算法[J]. 吉林大学学报: 工学版, 2020, 50(4): 1428-1434. |

| Zhong Hui, Li Hong, Li Zhen-jian, et al. Image manipulation detection based on convolutional neural networks[J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(4): 1428-1434. | |

| 18 | 何俊. 齿轮箱振动特性分析与智能故障诊断方法研究[D]. 杭州: 浙江大学机械工程学院, 2018. |

| He Jun. Vibration charcteristic analysis and intelligent fault diagnosis of gearboxes[D]. Hangzhou: School of Mechanical Engineering , Zhejiang University, 2018. | |

| 19 | Vibroacoustic gear signatures with time-frequency spectrograms[EB/OL]. [202-12-03]. |

| [1] | 王进花,胡佳伟,曹洁,黄涛. 基于自适应变分模态分解和集成极限学习机的滚动轴承多故障诊断[J]. 吉林大学学报(工学版), 2022, 52(2): 318-328. |

| [2] | 董绍江,朱朋,裴雪武,李洋,胡小林. 基于子领域自适应的变工况下滚动轴承故障诊断[J]. 吉林大学学报(工学版), 2022, 52(2): 288-295. |

| [3] | 陈晓雷,孙永峰,李策,林冬梅. 基于卷积神经网络和双向长短期记忆的稳定抗噪声滚动轴承故障诊断[J]. 吉林大学学报(工学版), 2022, 52(2): 296-309. |

| [4] | 段亮,宋春元,刘超,魏苇,吕成吉. 基于机器学习的高速列车轴承温度状态识别[J]. 吉林大学学报(工学版), 2022, 52(1): 53-62. |

| [5] | 欧阳丹彤,张必歌,田乃予,张立明. 结合格局检测与局部搜索的故障数据缩减方法[J]. 吉林大学学报(工学版), 2021, 51(6): 2144-2153. |

| [6] | 钟辉,康恒,吕颖达,李振建,李红,欧阳若川. 基于注意力卷积神经网络的图像篡改定位算法[J]. 吉林大学学报(工学版), 2021, 51(5): 1838-1844. |

| [7] | 胡晶,李聪,张邦成,乔晓利,张心明,周笑平. 考虑离心膨胀的双级串联轴承油膜刚度和阻尼[J]. 吉林大学学报(工学版), 2021, 51(5): 1601-1611. |

| [8] | 院老虎,连冬杉,张亮,刘义. 基于密集连接卷积网络和支持向量机的飞行器机械部件故障诊断[J]. 吉林大学学报(工学版), 2021, 51(5): 1635-1641. |

| [9] | 王德兴,吴若有,袁红春,宫鹏,王越. 基于多尺度注意力融合和卷积神经网络的水下图像恢复[J]. 吉林大学学报(工学版), 2021, 51(4): 1396-1404. |

| [10] | 李伟,陈剑,陶善勇. 自适应耦合周期势系统随机共振信号增强方法[J]. 吉林大学学报(工学版), 2021, 51(3): 1091-1096. |

| [11] | 欧阳丹彤,刘扬,刘杰. 故障响应指导下基于测试集的故障诊断方法[J]. 吉林大学学报(工学版), 2021, 51(3): 1017-1025. |

| [12] | 潘凤文,弓栋梁,高莹,徐明伟,麻斌. 基于锂离子电池线性化模型的电流传感器故障诊断[J]. 吉林大学学报(工学版), 2021, 51(2): 435-441. |

| [13] | 王柯俨,王迪,赵熹,陈静怡,李云松. 基于卷积神经网络的联合估计图像去雾算法[J]. 吉林大学学报(工学版), 2020, 50(5): 1771-1777. |

| [14] | 李志军,杨楚皙,刘丹,孙大洋. 基于深度卷积神经网络的信息流增强图像压缩方法[J]. 吉林大学学报(工学版), 2020, 50(5): 1788-1795. |

| [15] | 刘国华,周文斌. 基于卷积神经网络的脉搏波时频域特征混叠分类[J]. 吉林大学学报(工学版), 2020, 50(5): 1818-1825. |

|

||