吉林大学学报(工学版) ›› 2023, Vol. 53 ›› Issue (12): 3501-3507.doi: 10.13229/j.cnki.jdxbgxb.20220916

• 交通运输工程·土木工程 • 上一篇

砂浆碱集料反应细观数值模拟

- 1.南昌大学 工程建设学院,南昌 330031

2.赤峰学院 资源环境与建筑工程学院,内蒙古 赤峰 024000

Meso numerical simulation of alkali aggregate reaction in mortar

- 1.School of Infrastructure Engineering,Nanchang University,Nanchang 330031,China

2.School of Resources Environment and Architectural Engineering,Chifeng University,Chifeng 024000,China

摘要:

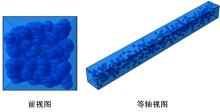

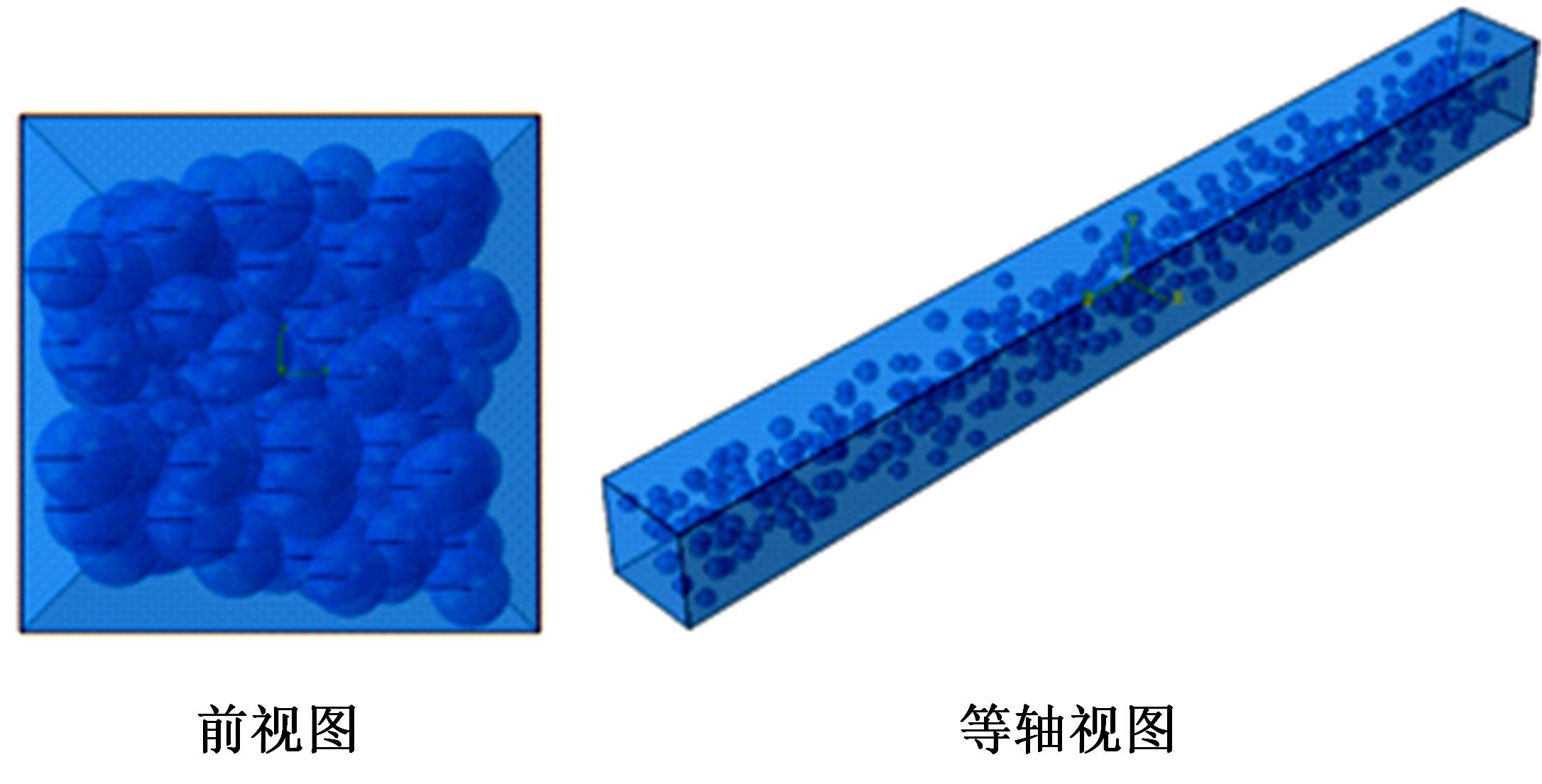

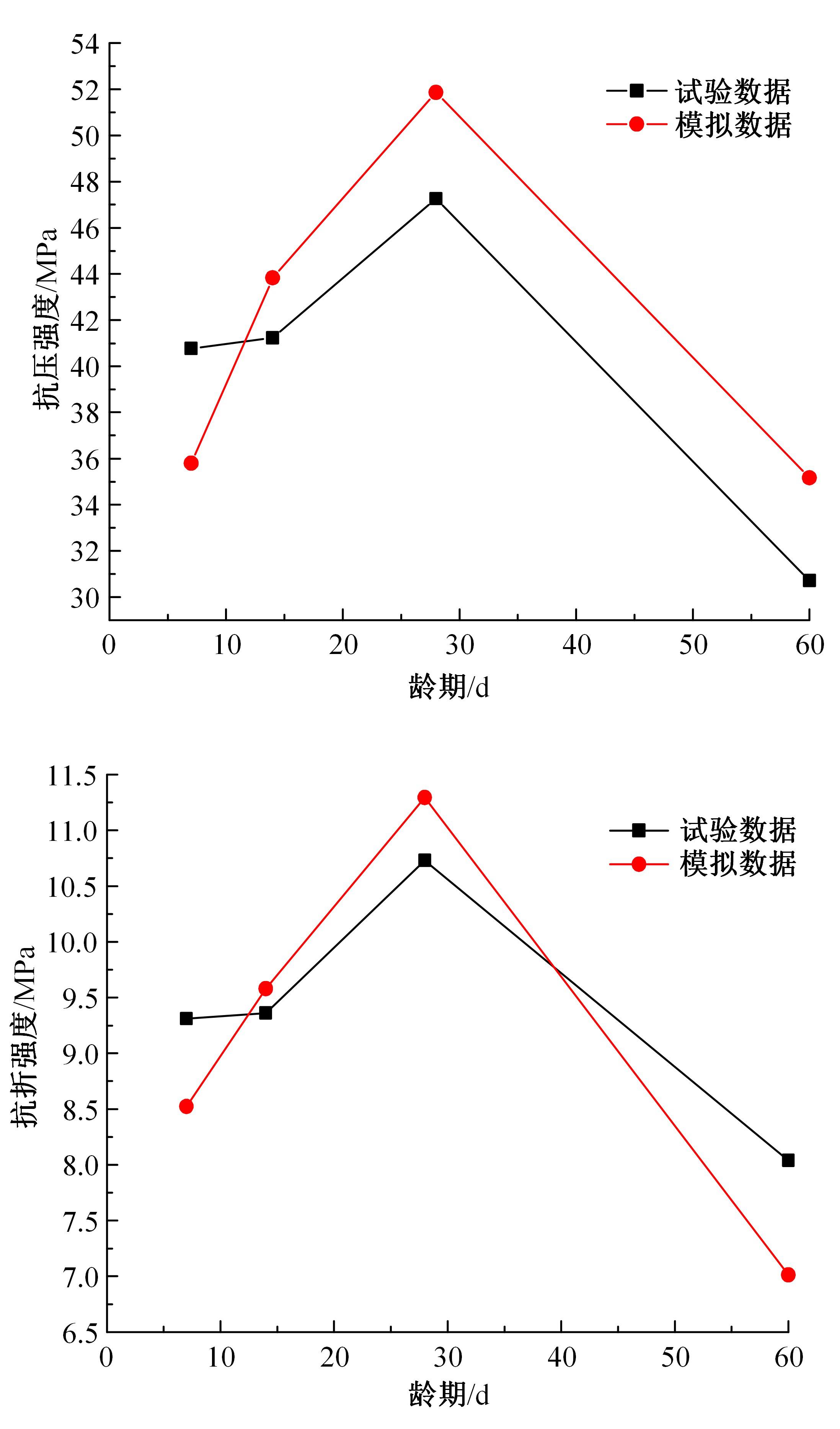

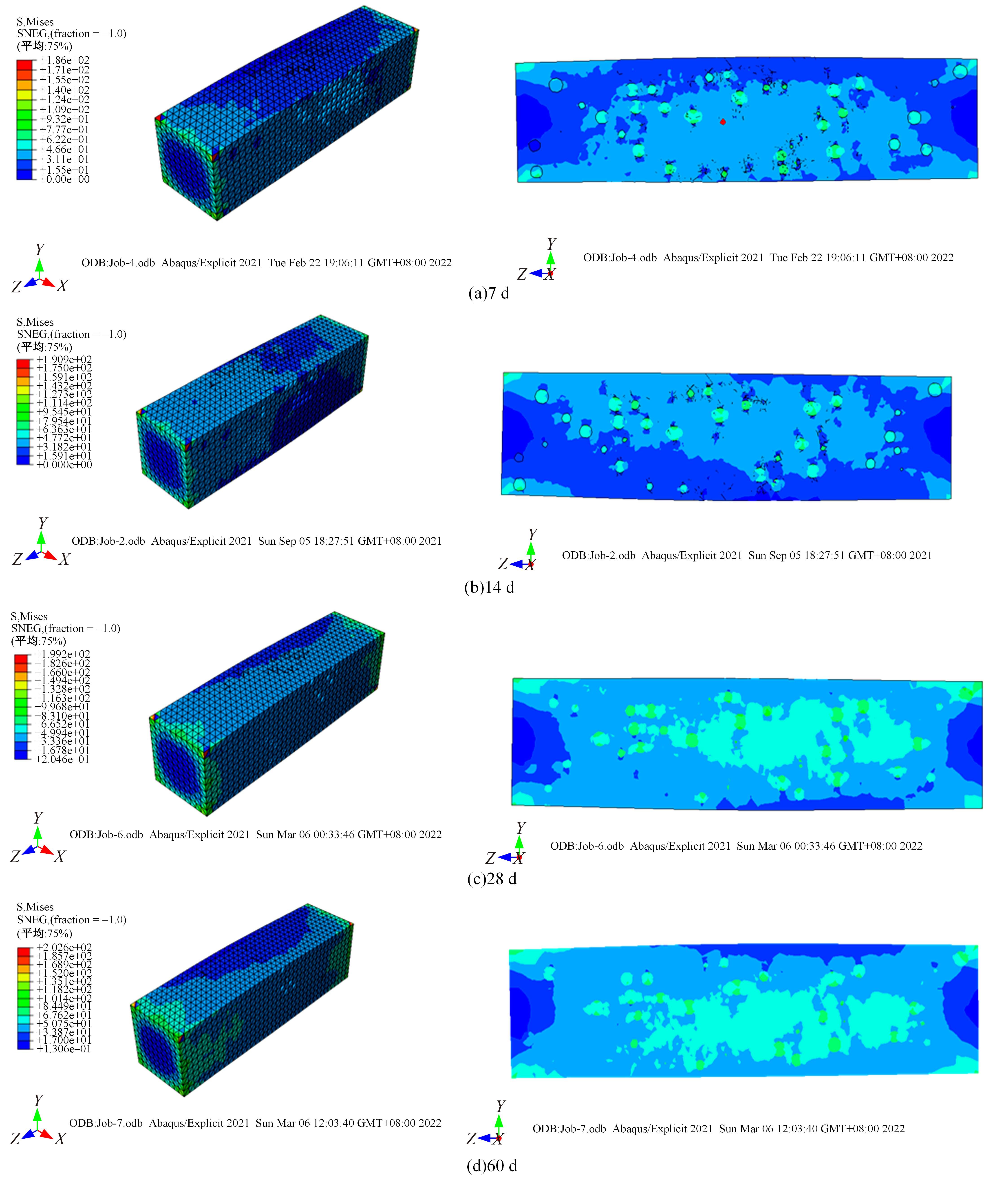

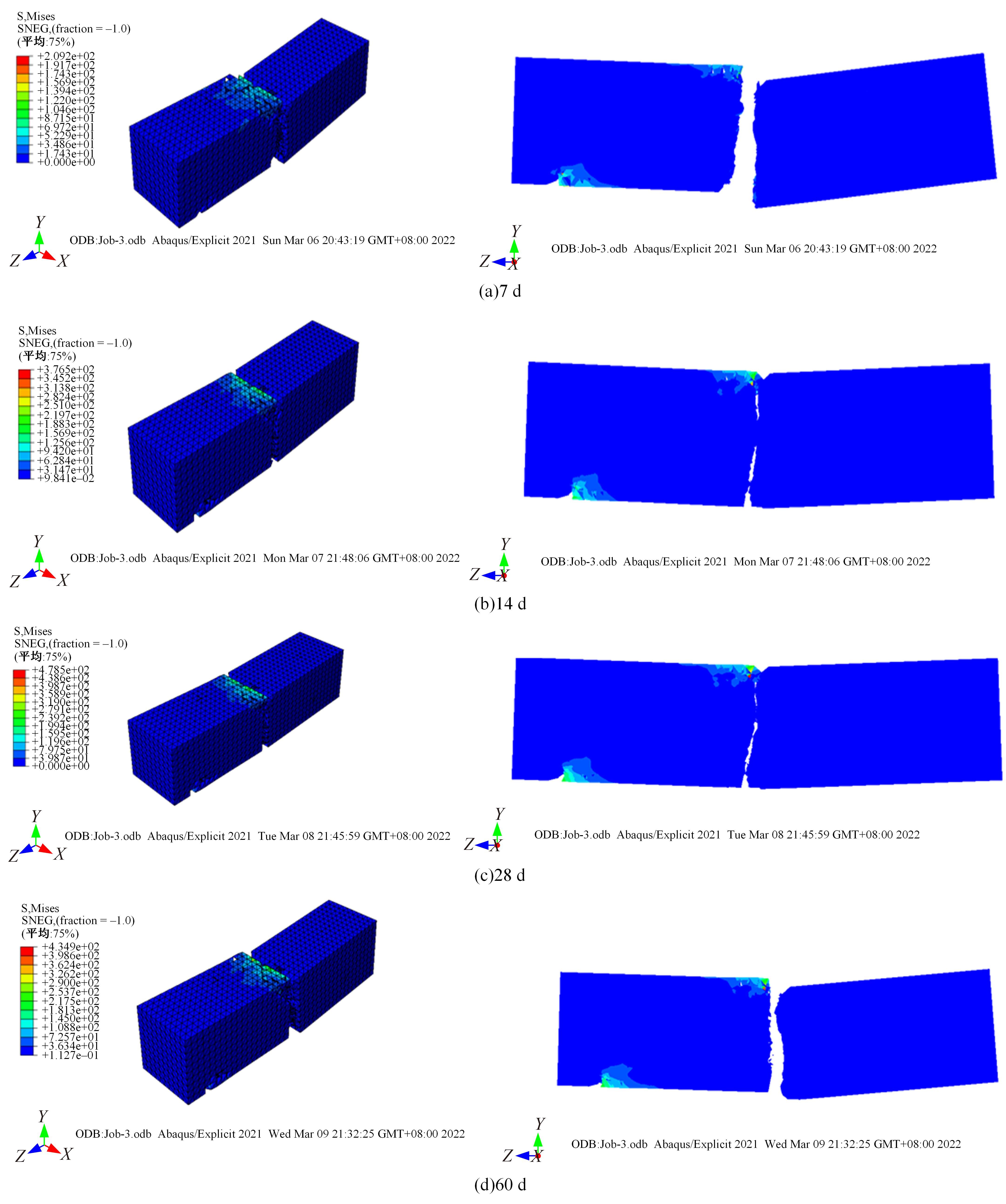

由于局部砂浆碱集料现场测试中存在着对上部竖向的压力,为研究砂浆碱集料反应的力学性能,进行了砂浆碱集料反应细观数值模拟。用砂浆棒快速法制备了试样,进行了砂浆试样膨胀率、抗压强度、抗折强度测定;将砂浆试样看作由骨料、界面过渡区(ITZ)和砂浆基体组成的三相复合材料,建立了碱集料反应膨胀模型和碱集料反应强度模型,模拟了不同尺寸规格试样在不同龄期的抗压和抗折性能,解决了砂浆抗压强度和抗折强度较高的问题,仿真结果与测试结果基本一致,证明该模拟仿真具有较好的实用性。

中图分类号:

- TU528.56

| 1 | 王耀, 纵岗, 付佳佳,等. 再生骨料取代率及老砂浆强度对混凝土细观性能的影响[J]. 混凝土, 2020(5): 64-68. |

| Wang Yao, Zong Gang, Fu Jia-jia, et al. Effect of recycled aggregate replacement ratio and old mortar strength on mesoscopic properties of concrete[J]. Concrete, 2020(5): 64-68. | |

| 2 | 金浏, 杨旺贤, 余文轩,等. 基于细观模拟的轻骨料混凝土动态压缩破坏及尺寸效应分析[J]. 工程力学, 2020, 37(3): 56-65. |

| Jin Liu, Yang Wang-xian, Yu Wen-xuan, et al. Dynamic compressive failure and size effect in lightweight aggregate concrete based on meso-scale simulation[J]. Engineering Mechanics, 2020, 37(3): 56-65. | |

| 3 | 朱华胜, 曾晓辉, 刘海川,等. 水泥乳化沥青砂浆静态力学性能与组成的关系[J]. 硅酸盐学报, 2020, 48(5): 644-651. |

| Zhu Hua-sheng, Zeng Xiao-hui, Liu Hai-chuan, et al. Relationship between static mechanical properties and composition of cement and emulsified asphalt mortar[J]. Journal of the Chinese Ceramic Society, 2020, 48(5): 644-651. | |

| 4 | 朱愿愿, 王爱国, 孙道胜, 等. 煅烧煤矸石细骨料特性及其对砂浆性能的提升作用[J]. 煤炭学报, 2021, 46(11): 3657-3669. |

| Zhu Yuan-yuan, Wang Ai-guo, Sun Dao-sheng, et al. Characteristics of coal gangue fine aggregates after calcination and its effects on the improvement of mortar properties[J]. Journal of China Coal Society, 2021, 46(11): 3657-3669. | |

| 5 | 张彩虹, 宋志刚, 毛敏, 等. 水泥砂浆受硫酸溶蚀的试验研究和数值模拟[J]. 自然灾害学报, 2021, 3(1):112-121. |

| Zhang Cai-hong, Song Zhi-gang, Mao Min, et al. Experimental study and numerical simulation on cement mortar corroded by sulfuric acid[J]. Journal of Natural Disasters, 2021, 3(1): 112-121. | |

| 6 | 王昊, 王文杰. 全长砂浆锚固玻璃钢锚杆动力响应数值模拟分析[J]. 化工矿物与加工, 2020, 49(9): 10-14. |

| Wang Hao, Wang Wen-jie. Numerical simulation analysis of dynamic response to the FRP bolt anchored with full length of mortar[J]. Industrial Minerals & Processing, 2020, 49(9): 10-14. | |

| 7 | 陈聪, 柯国军, 谭天戈, 等. 蒸压养护对废玻璃粉复合砂浆力学性能的改善[J]. 中国粉体技术, 2020, 26(4): 46-51. |

| Chen Cong, Ke Guo-jun, Tan Tian-ge, et al. Improvement of mechanical properties of waste glass powder composite mortar by autoclave curing[J]. China Powder Science and Technology, 2020, 26(4): 46-51. | |

| 8 | 钱达友, 杨建明. 水冻融和硫酸盐溶液冻融环境下MKPC砂浆的耐久性评价[J]. 硅酸盐通报, 2020, 39(2): 359-366. |

| Qian Da-you, Yang Jian-ming. Durability evaluation of MKPC mortar under water-freeze-thaw and sulfate solution freeze-thaw environment[J]. Bulletin of the Chinese Ceramic Society, 2020, 39(2): 359-366. | |

| 9 | 李黎, 陶佳诚, 曹明莉, 等. 混杂纤维增强砂浆高温后单轴受压本构关系[J]. 复合材料学报, 2022, 39(11):5375-5385. |

| Li Li, Tao Jia-cheng, Cao Ming-li, et al. Constitutive relation of uniaxial compression of hybrid fiber reinforced mortar after high temperature[J]. Acta Materiae Compositae Sinica, 2022, 39(11): 5375-5385. | |

| 10 | 王宁, 马涛, 陈丰, 等. 影响智能骨料感知的关键因素及数据分析方法[J]. 吉林大学学报: 工学版, 2023, 53(6): 1799-1808. |

| Wang Ning, Ma Tao, Chen Feng, et al. Key factors affecting smart aggregate perception and data analysis methods[J]. Journal of Jilin University (Engineering and Technology Edition), 2023, 53(6): 1799-1808. | |

| 11 | 杜修力,金浏. 混凝土材料宏观力学特性分析的细观单元等效化模型[J]. 计算力学学报, 2012, 29(5): 654-661. |

| Du Xiu-li, Jin Liu. Meso-element equivalent model for macro-scopic mechanical properties analysis of concrete materials[J]. Chinese Journal of Computational Mechanics, 2012,29(5): 654-661. | |

| 12 | 杜修力,金浏. 非匀质混凝土材料破坏的三维细观数值模拟[J]. 工程力学, 2013, 30(2): 82-88. |

| Du Xiu-li, Jin Liu. Numerical simulation of three-dimensional meso-mechanical model for damage process of heterogeneous concrete[J]. Engineering Mechanics, 2013, 30(2): 82-88. |

| [1] | 许良,边钰博,周松,肖景厚. 高温水浸对T800/环氧树脂基复合材料性能的影响[J]. 吉林大学学报(工学版), 2023, 53(7): 1943-1950. |

| [2] | 匡亚川,宋哲轩,刘胤虎,莫小飞,伏亮明,罗时权. 新型装配式双舱综合管廊力学性能试验[J]. 吉林大学学报(工学版), 2022, 52(3): 596-603. |

| [3] | 魏海斌,王相焱,王富玉,张勇. 基于振动成型AC-25沥青混合料力学性能及细观分析[J]. 吉林大学学报(工学版), 2021, 51(4): 1269-1276. |

| [4] | 程永春,李赫,李立顶,王海涛,白云硕,柴潮. 基于灰色关联度的矿料对沥青混合料力学性能的影响分析[J]. 吉林大学学报(工学版), 2021, 51(3): 925-935. |

| [5] | 刘寒冰,高鑫,宫亚峰,刘诗琪,李文俊. 表面处理对玄武岩纤维活性粉末混凝土力学性能的影响及断裂特性[J]. 吉林大学学报(工学版), 2021, 51(3): 936-945. |

| [6] | 王金国,王志强,任帅,闫瑞芳,黄恺,郭劲. Ti添加量对球墨铸铁组织及力学性能的影响[J]. 吉林大学学报(工学版), 2020, 50(5): 1653-1662. |

| [7] | 向红亮,陈盛涛,邓丽萍,张伟,詹土生. 微合金化2205双相不锈钢组织及性能[J]. 吉林大学学报(工学版), 2020, 50(5): 1645-1652. |

| [8] | 李明,王浩然,赵唯坚. 单向带抗剪键叠合板的受力性能试验[J]. 吉林大学学报(工学版), 2020, 50(2): 654-667. |

| [9] | 修文翠,吴化,韩英,刘云旭. 等温热处理温度对超级贝氏体组织与性能的影响[J]. 吉林大学学报(工学版), 2020, 50(2): 520-525. |

| [10] | 佟鑫,张雅娇,黄玉山,胡正正,王庆,张志辉. 选区激光熔化304L不锈钢的组织结构及力学性能分析[J]. 吉林大学学报(工学版), 2019, 49(5): 1615-1621. |

| [11] | 李明,王浩然,赵唯坚. 带抗剪键叠合板的力学性能[J]. 吉林大学学报(工学版), 2019, 49(5): 1509-1520. |

| [12] | 姜秋月,杨海峰,檀财旺. 22MnB5超高强钢焊接接头强化性能[J]. 吉林大学学报(工学版), 2018, 48(6): 1806-1810. |

| [13] | 庄蔚敏, 赵文增, 解东旋, 李兵. 超高强钢/铝合金热铆连接接头性能[J]. 吉林大学学报(工学版), 2018, 48(4): 1016-1022. |

| [14] | 刘晓波, 周德坤, 赵宇光. 不同等温热处理条件下半固态挤压Mg2Si/Al复合材料的组织和性能[J]. 吉林大学学报(工学版), 2016, 46(5): 1577-1582. |

| [15] | 李春玲, 樊丁, 王斌, 余淑荣. 5A06铝合金/镀锌钢预置涂粉对接激光熔钎焊组织与性能[J]. 吉林大学学报(工学版), 2016, 46(2): 516-521. |

|

||