吉林大学学报(工学版) ›› 2021, Vol. 51 ›› Issue (3): 925-935.doi: 10.13229/j.cnki.jdxbgxb20200350

基于灰色关联度的矿料对沥青混合料力学性能的影响分析

- 吉林大学 交通学院,长春 130022

Analysis of mechanical properties of asphalt mixture affected by aggregate based on grey relational degree

Yong-chun CHENG( ),He LI,Li-ding LI,Hai-tao WANG,Yun-shuo BAI,Chao CHAI

),He LI,Li-ding LI,Hai-tao WANG,Yun-shuo BAI,Chao CHAI

- College of Transportation,Jilin University,Changchun 130022,China

摘要:

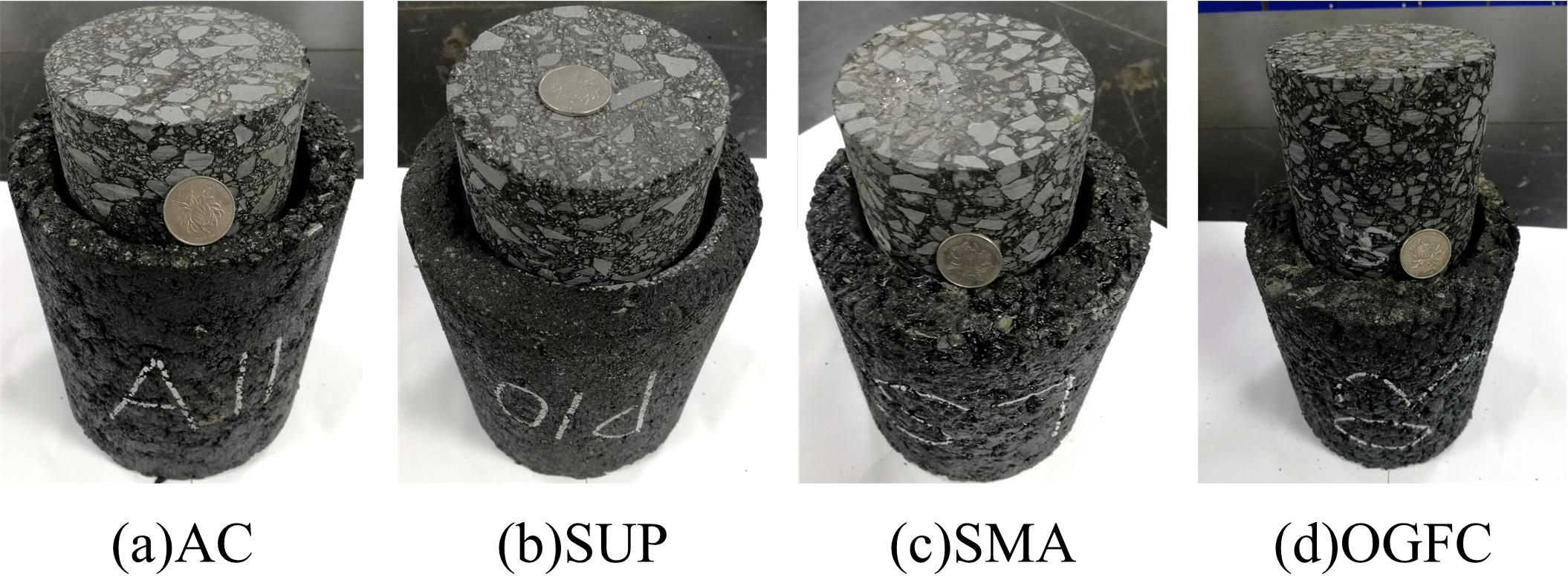

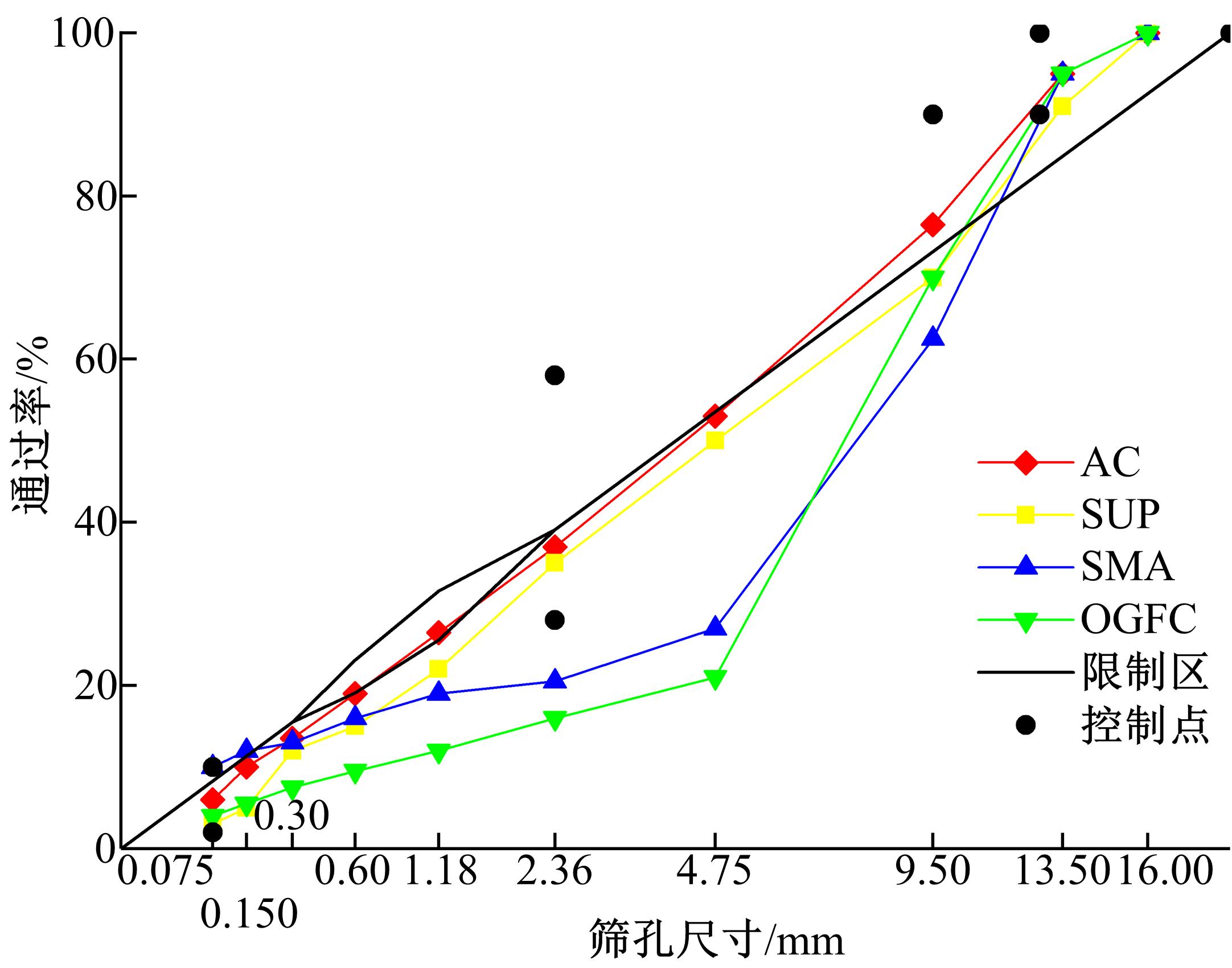

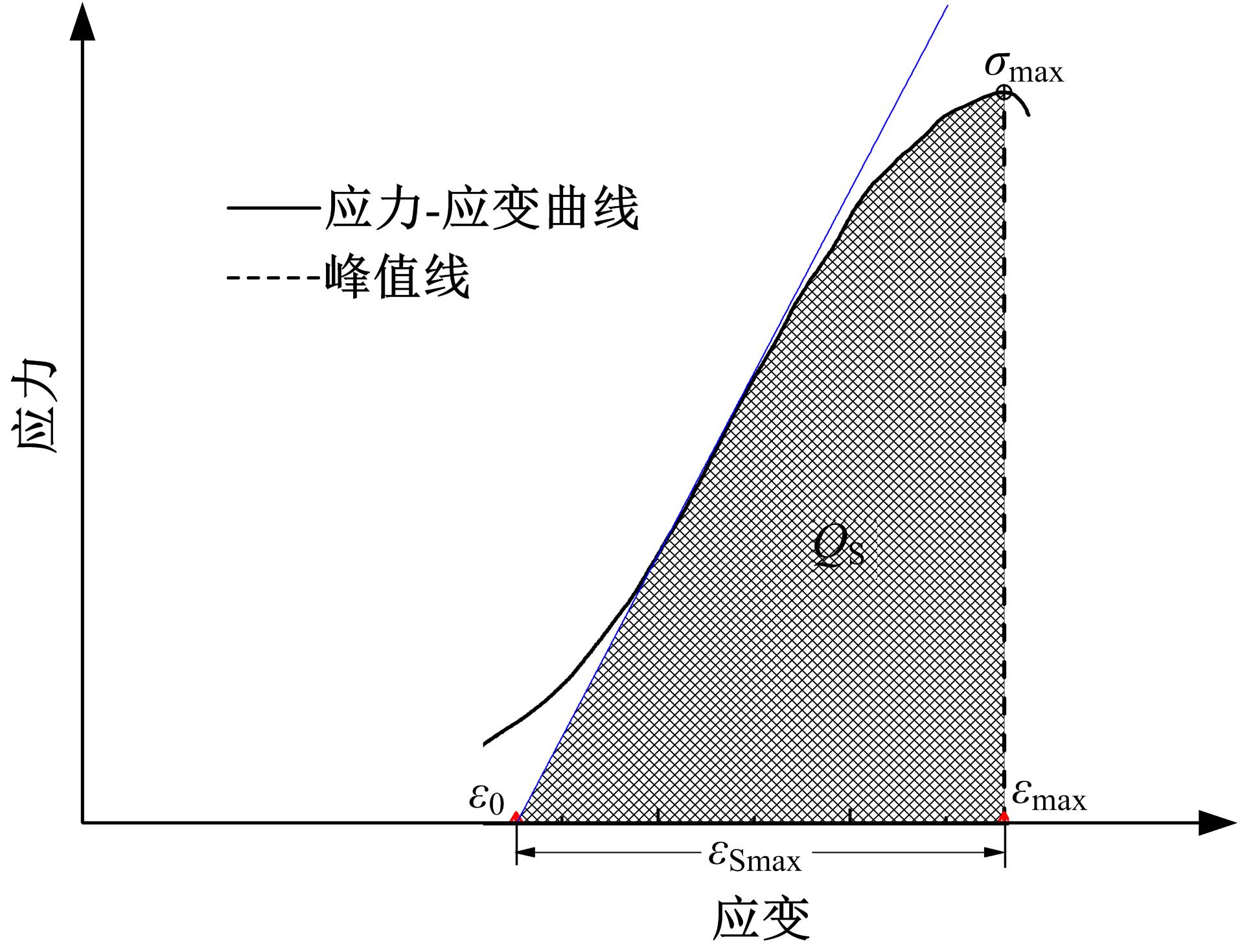

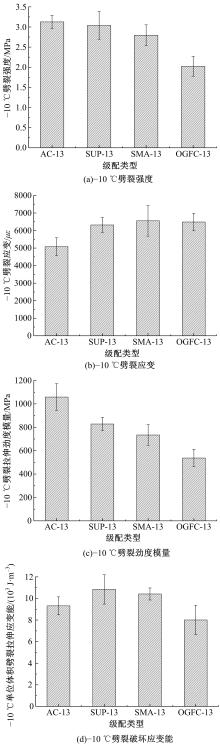

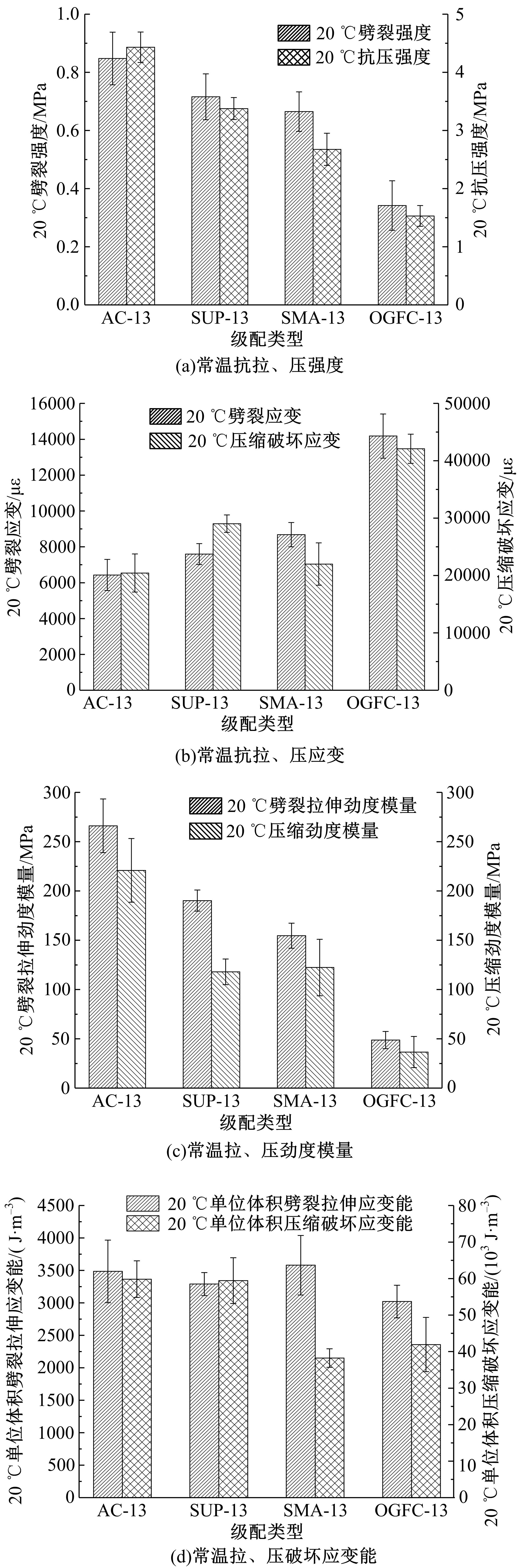

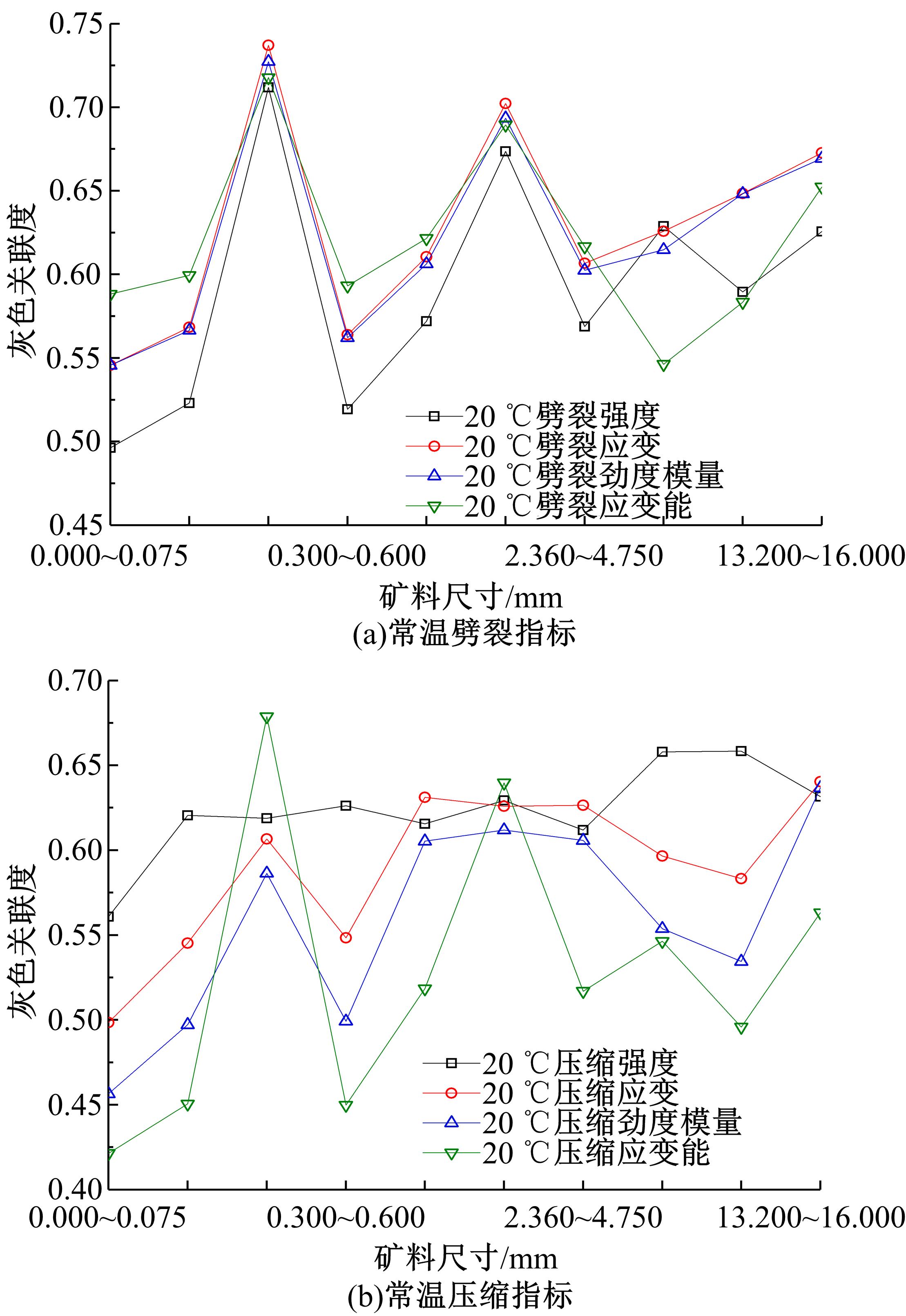

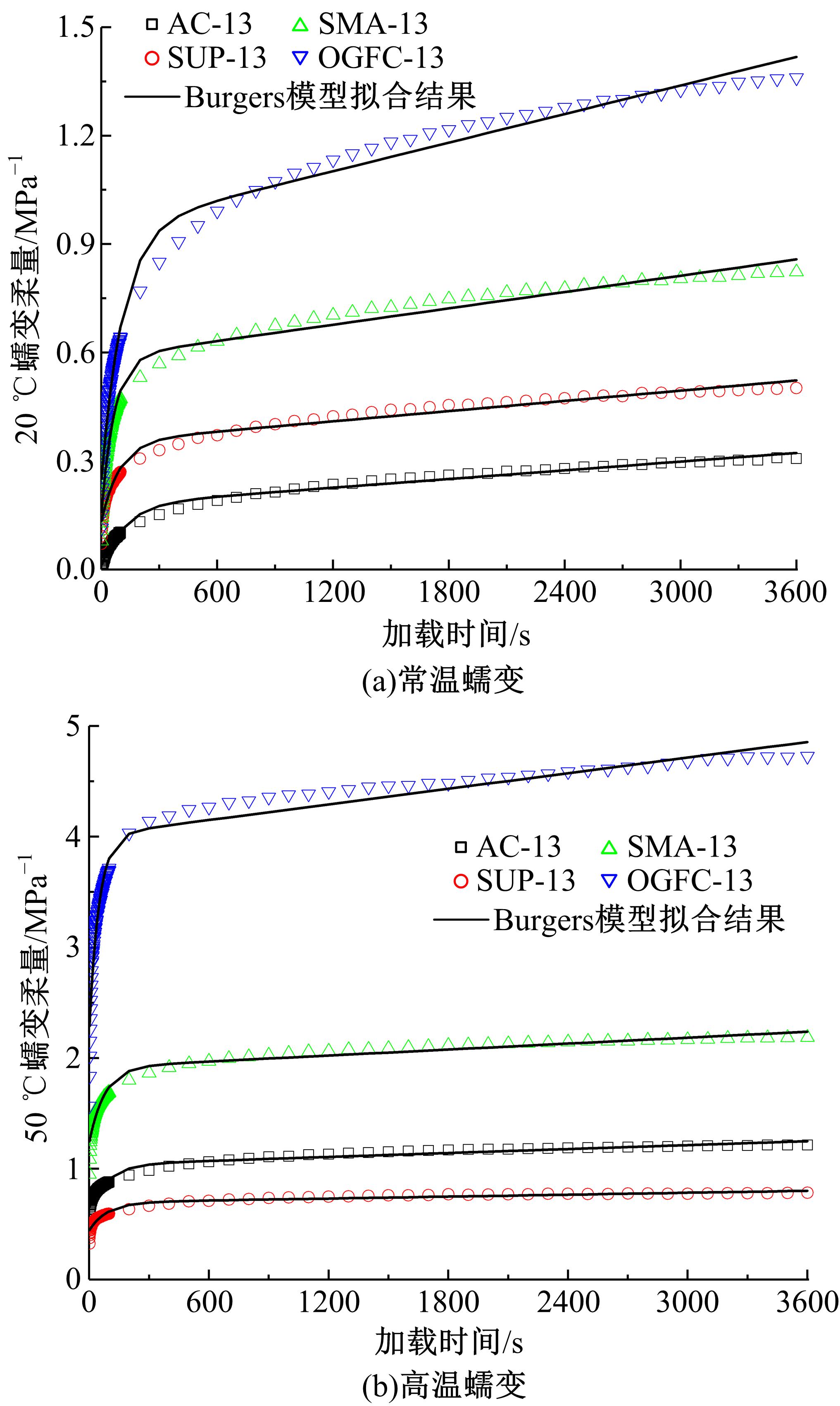

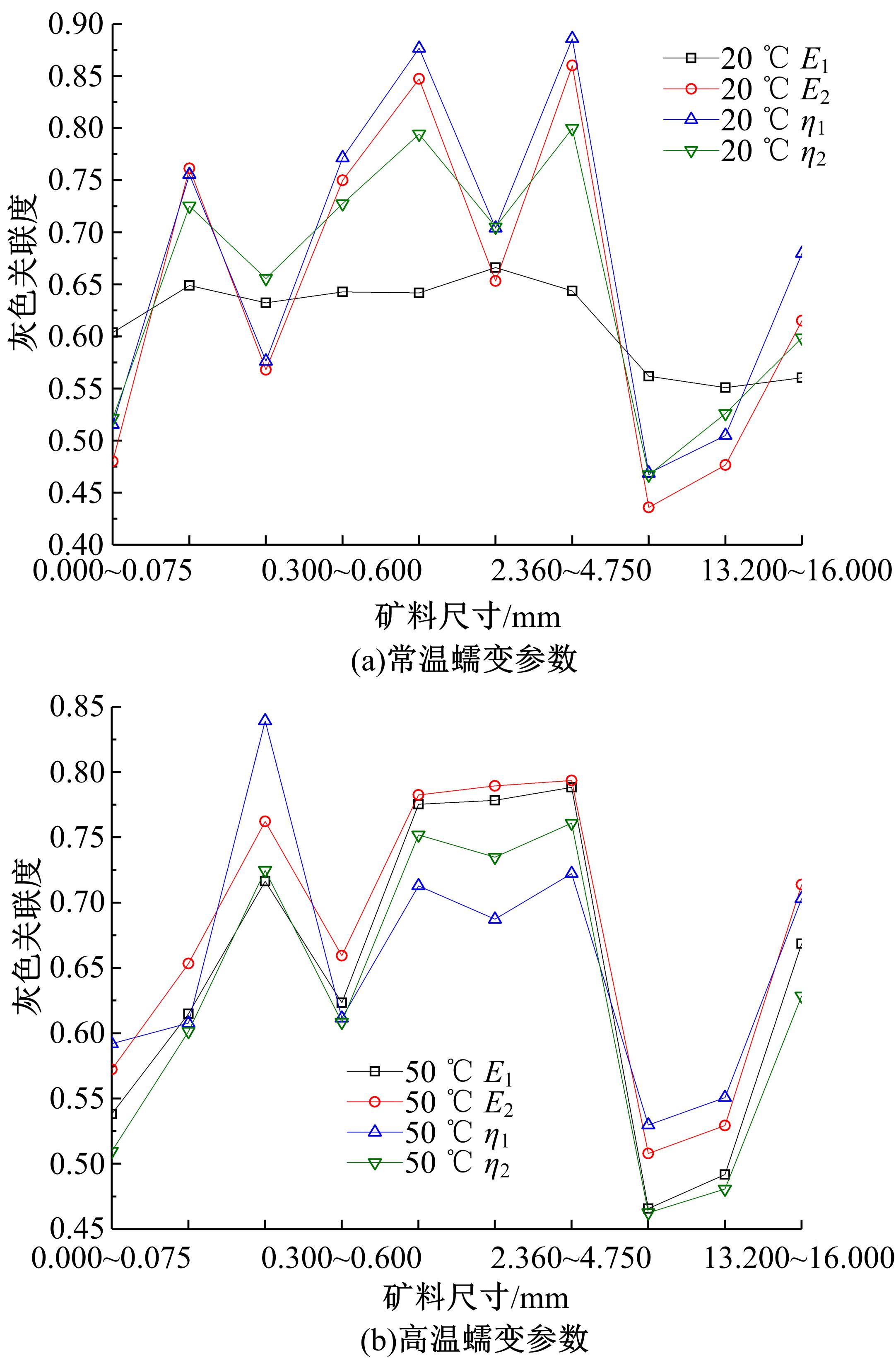

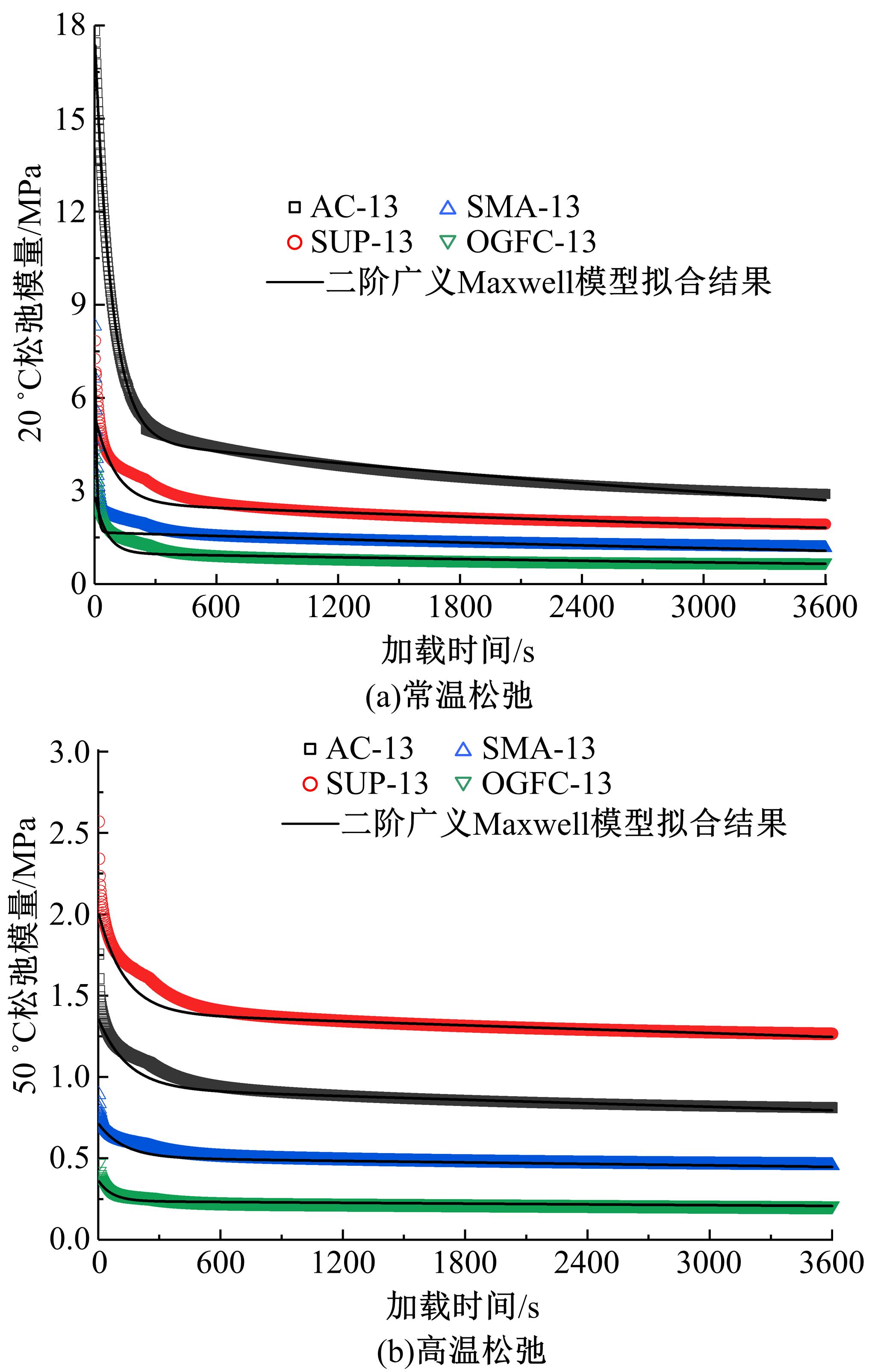

为分析矿料含量对沥青混合料力学性能的影响,利用旋转压实方法制备了4种级配沥青混合料,并通过劈裂试验、压缩试验以及蠕变试验研究了4种级配沥青混合料的低温抗开裂能力、常温抗拉/压破坏能力以及蠕变性能。随后,利用卷积积分和Laplace变换推导了4种沥青混合料的松弛模量随加载时间的变化趋势,并结合Burgers模型和二阶广义Maxwell模型对蠕变和松弛特性进行了拟合分析。最后,根据灰色关联度算法计算了矿料含量与沥青混合料力学性能的关联度,分析了矿料含量对混合料力学性能的影响。结果表明:沥青混合料的低温抗开裂、常温抗拉/压性能主要与0.15~0.3 mm和1.18~2.36 mm两档矿料的含量具有较高的相关度;而常温抗蠕变能力主要受0.6~1.18 mm和2.36~4.75 mm两档矿料的影响;温度升高后,抗蠕变能力受矿料含量变化的影响程度增加;松弛强度受细集料含量影响较大,而松弛时间主要受较大粒径矿料含量的影响。

中图分类号:

- U414

| 1 | Mirzababaei P. Effect of zycotherm on moisture susceptibility of warm mix asphalt mixtures prepared with different aggregate types and gradations[J]. Construction and Building Materials, 2016, 116:403-412. |

| 2 | Sun Z, Wang S, Zhu G. The design method of aggregate gradation of GAC-20 modified asphalt mixture based on road performance[J]. IOP Conference Series: Materials Science and Engineering, 2018, 381:No.012060. |

| 3 | Fang M, Park D, Singuranayo J L, et al. Aggregate gradation theory, design and its impact on asphalt pavement performance: a review[J]. International Journal of Pavement Engineering,2018,20(12):1408-1424. |

| 4 | 董泽蛟, 肖桂清, 龚湘兵. 级配及抗车辙剂对沥青混合料抗车辙性能的影响分析[J]. 公路交通科技, 2014, 31(2), 27-31, 46. |

| Dong Ze-jiao, Xiao Gui-qing, Gong Xiang-bing. Analysis on impact of gradaton and anti-rutting additive on rutting resistance of asphalt mixture[J]. Journal of Highway and Transportation Research and Development, 2014, 31(2):27-31, 46. | |

| 5 | 刘正伟, 郭瑞, 李萍, 等. 沥青混合料抗车辙性能的灰色理论分析[J]. 公路, 2020, 65(3):36-42. |

| Liu Zheng-wei, Guo Rui, Li Ping, et al. Grey theory analysis on anti-rutting property of asphalt mixture[J]. Highway, 2020, 65(3):36-42. | |

| 6 | Cai X, Wu K H, Huang W K, et al. Study on the correlation between aggregate skeleton characteristics and rutting performance of asphalt mixture[J]. Construction and Building Materials, 2018, 179:294-301. |

| 7 | Garcia-Gil L,Miró R, Pérez-Jiménez F. Evaluating the role of aggregate gradation on cracking performance of asphalt concrete for thin overlays[J]. Applied Sciences, 2019, 9(4):1-13. |

| 8 | 刘贵应, 毛中川, 郭泽宇, 等. 级配对结构层沥青混合料路用性能影响试验研究[J]. 公路, 2019, 64(5):219-225. |

| Liu Gui-ying, Mao Zhong-chuan, Guo Ze-yu, et al. Experimental study on aggregate gradation influence on the performance-related properties of structural-layer asphalt mixtures[J]. Highway, 2019, 64(5):219-225. | |

| 9 | Sreedhar S, Coleri E. Effects of binder content, density, gradation, and polymer modification on cracking and rutting resistance of asphalt mixtures used in oregon[J]. Journal of Materials in Civil Engineering, 2018, 30(11):No.04018298. |

| 10 | Kuity A, Das A. Effect of filler gradation on creep response of asphalt mix[J]. Road Materials and Pavement Design, 2017, 18(4):913-928. |

| 11 | Wang X, Gu X, Jiang J, et al. Experimental analysis of skeleton strength of porous asphalt mixtures[J]. Construction and Building Materials, 2018, 171:13-21. |

| 12 | Zhang Y, Luo X, Onifade I, al et, Mechanical evaluation of aggregate gradation to characterize load carrying capacity and rutting resistance of asphalt mixtures[J]. Construction and Building Materials, 2019, 205:499-510. |

| 13 | ―2011. 公路工程沥青及沥青混合料试验规程[S]. |

| 14 | Al-Khateeb G G, Khedaywi T S, Obaidat T I A S, et al. Laboratory study for comparing rutting performance of limestone and basalt superpave asphalt mixtures[J]. Journal of Materials in Civil Engineering, 2013, 25(1):21-29. |

| 15 | 朱春凤, 程永春, 梁春雨, 等. 硅藻土-玄武岩纤维复合改性沥青混合料路用性能试验[J]. 吉林大学学报:工学版, 2020, 50(1):165-173. |

| Zhu Chun-feng, Cheng Yong-chun, Liang Chun-yu, et al. Road performance experiment of diatomite-basalt fiber composite modified asphalt mixture[J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(1):165-173. | |

| 16 | Al-Omari A A, Khasawneh M A, Al-Rousan T M, et al. Static creep of modified superpave asphalt concrete mixtures using crumb tire rubber, microcrystalline synthetic wax, and nano-silica[J]. International Journal of Pavement Engineering, 2019,22:No.1646913. |

| 17 | 栗培龙, 张争奇, 王秉纲. 沥青混合料高温蠕变变形行为及机理[J]. 建筑材料学报, 2012, 15(3):422-426. |

| Li Pei-long, Zhang Zheng-qi, Wang Bing-gang. High-temperature creep deformation behavior and its mechanism of asphalt mixture[J]. Journal of Building Materials, 2012, 15(3):422-426. | |

| 18 | Cheng Y, Li H, Li L, et al. Viscoelastic properties of asphalt mixtures with different modifiers at different temperatures based on static creep tests[J]. Applied Sciences, 2019, 9(20):No.4246. |

| 19 | Chen S Q, Wang D S, Yi J. Y,et al. Implement the Laplace transform to convert viscoelastic functions of asphalt mixtures[J]. Construction and Building Materials, 2019, 203:633-641. |

| 20 | Cheng Y C, Li L D, Zhou P L, et al. Multi-objective optimization design and test of compound diatomite and basalt fiber asphalt mixture[J]. Materials, 2019, 12(9):No.1461. |

| 21 | 刘世豪, 叶文华, 陈蔚芳, 等. 基于正交试验法和灰色关联的机床主轴箱优化设计[J]. 振动与冲击, 2011, 30(7):127-132. |

| Liu Shi-hao, Ye Wen-hua, Chen Wei-fang, et al. Optimization design for headstock of machine tool based on orthogonal experimental method and grey relational analysis[J]. Journal of Vibration and Shock, 2011, 30(7):127-132. | |

| 22 | 田莉, 胡霞光, 刘玉, 等. 沥青玛蹄脂粘弹性模型参数分段线性拟合法[J]. 交通运输工程学报, 2007, 7(3):66-69. |

| Tian Li, Hu Xia-guang, Liu Yu, et al. Sectioned linear fitting method of parameters for asphalt mastics viscoelastic Burgers model[J]. Journal of Traffic and Transportation Engineering, 2007, 7(3):66-69. | |

| 23 | Huang W, Guo W, Wei Y. Thermal effect on rheological properties of epoxy asphalt mixture and stress prediction for bridge deck paving[J]. Journal of Materials in Civil Engineering, 2019, 31(10):No.04019222. |

| [1] | 朱伟刚,朱超,张亚球,魏海斌. 基于卷积格网曲面拟合滤波算法的数字高程模型构建及质量评价[J]. 吉林大学学报(工学版), 2021, 51(3): 1073-1080. |

| [2] | 宫亚峰,逄蕴泽,王博,谭国金,毕海鹏. 基于吉林省路况的新型预制装配式箱涵结构的力学性能[J]. 吉林大学学报(工学版), 2021, 51(3): 917-924. |

| [3] | 阳恩慧,徐加秋,唐由之,李奥,邱延峻. 温拌剂对沥青断裂和老化性能的影响[J]. 吉林大学学报(工学版), 2021, 51(2): 604-610. |

| [4] | 王金国,王志强,任帅,闫瑞芳,黄恺,郭劲. Ti添加量对球墨铸铁组织及力学性能的影响[J]. 吉林大学学报(工学版), 2020, 50(5): 1653-1662. |

| [5] | 向红亮,陈盛涛,邓丽萍,张伟,詹土生. 微合金化2205双相不锈钢组织及性能[J]. 吉林大学学报(工学版), 2020, 50(5): 1645-1652. |

| [6] | 李明,王浩然,赵唯坚. 单向带抗剪键叠合板的受力性能试验[J]. 吉林大学学报(工学版), 2020, 50(2): 654-667. |

| [7] | 修文翠,吴化,韩英,刘云旭. 等温热处理温度对超级贝氏体组织与性能的影响[J]. 吉林大学学报(工学版), 2020, 50(2): 520-525. |

| [8] | 戴文亭,司泽华,王振,王琦. 剑麻纤维水泥加固土的路用性能试验[J]. 吉林大学学报(工学版), 2020, 50(2): 589-593. |

| [9] | 方宇,孙立军. 基于生存分析的城市桥梁使用性能衰变模型[J]. 吉林大学学报(工学版), 2020, 50(2): 557-564. |

| [10] | 王芳,李晓光,郭慧,胡佳. 基于驾驶员视觉兴趣区的沙漠草原公路曲线间直线段线形指标优化[J]. 吉林大学学报(工学版), 2020, 50(1): 114-120. |

| [11] | 王英,李萍,念腾飞,姜继斌. 基于动水冲刷作用的沥青混合料短期水损害特性[J]. 吉林大学学报(工学版), 2020, 50(1): 174-182. |

| [12] | 朱春凤,程永春,梁春雨,肖波. 硅藻土⁃玄武岩纤维复合改性沥青混合料路用性能试验[J]. 吉林大学学报(工学版), 2020, 50(1): 165-173. |

| [13] | 万平,吴超仲,马晓凤. 基于ROC曲线和驾驶行为特征的驾驶愤怒强度判别阈值[J]. 吉林大学学报(工学版), 2020, 50(1): 121-131. |

| [14] | 熊锐,乔宁,褚辞,杨发,关博文,盛燕萍,牛冬瑜. 掺盐沥青胶浆低温流变及粘附特性[J]. 吉林大学学报(工学版), 2020, 50(1): 183-190. |

| [15] | 狄胜同,贾超,乔卫国,李康,童凯. 橡胶集料混凝土细观损伤特性的加载速率效应[J]. 吉林大学学报(工学版), 2019, 49(6): 1900-1910. |

|

||