吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (9): 2620-2630.doi: 10.13229/j.cnki.jdxbgxb.20240015

• 交通运输工程·土木工程 • 上一篇

水稻秸秆灰对混凝土抗压性能及微观结构的影响

- 1.黑龙江八一农垦大学 工程学院,黑龙江 大庆 163319

2.黑龙江八一农垦大学 土木水利学院,黑龙江 大庆 163319

3.吉林大学 机械与航空航天工程学院,长春 130022

Influence of rice straw ash on compressive properties and microstructure of concrete

Fu-cheng WANG1( ),Xin-rong ZHAO2,Jia-bing TIAN2,Guo-liang XIE2,Li-ming ZHOU3(

),Xin-rong ZHAO2,Jia-bing TIAN2,Guo-liang XIE2,Li-ming ZHOU3( )

)

- 1.College of Engineering,Heilongjiang Bayi Agricultural University,Daqing 163319,China

2.College of Civil Engineering and Water Conservancy,Heilongjiang Bayi Agricultural University,Daqing 163319,China

3.College of Mechanical and Aerospace Engineering,Jilin University,Changchun 130022,China

摘要:

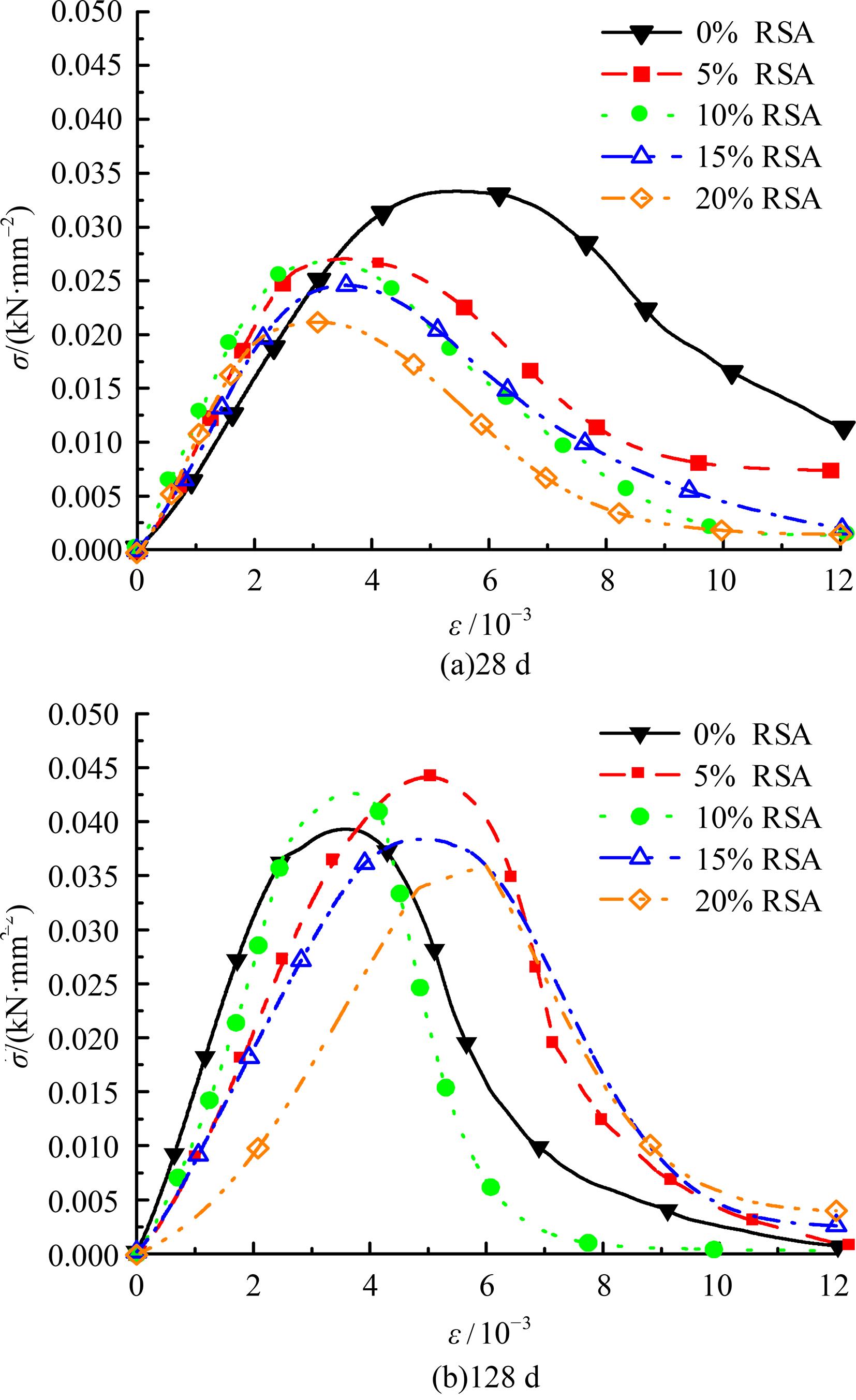

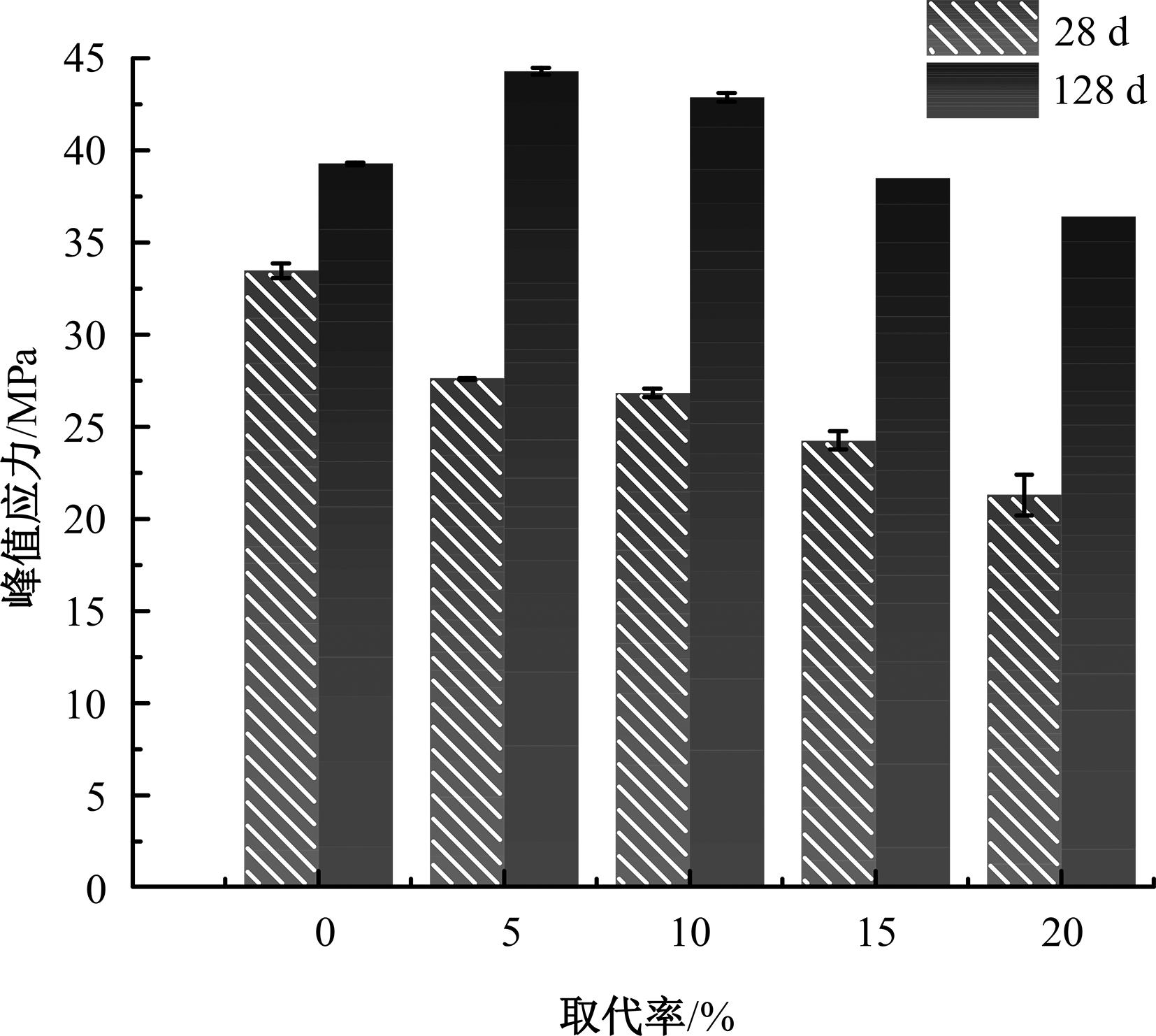

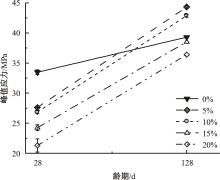

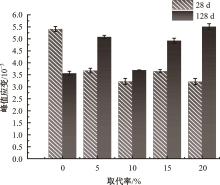

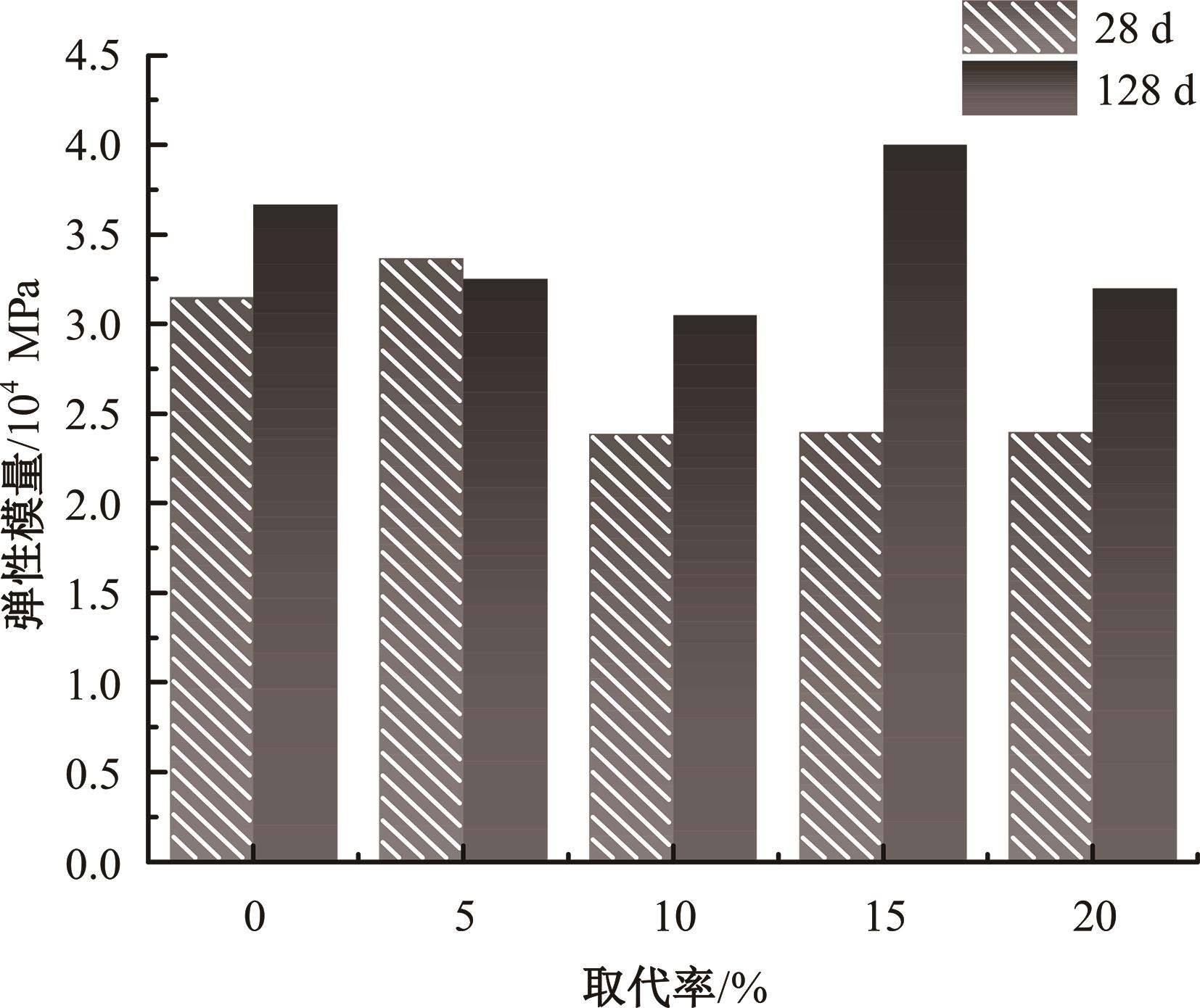

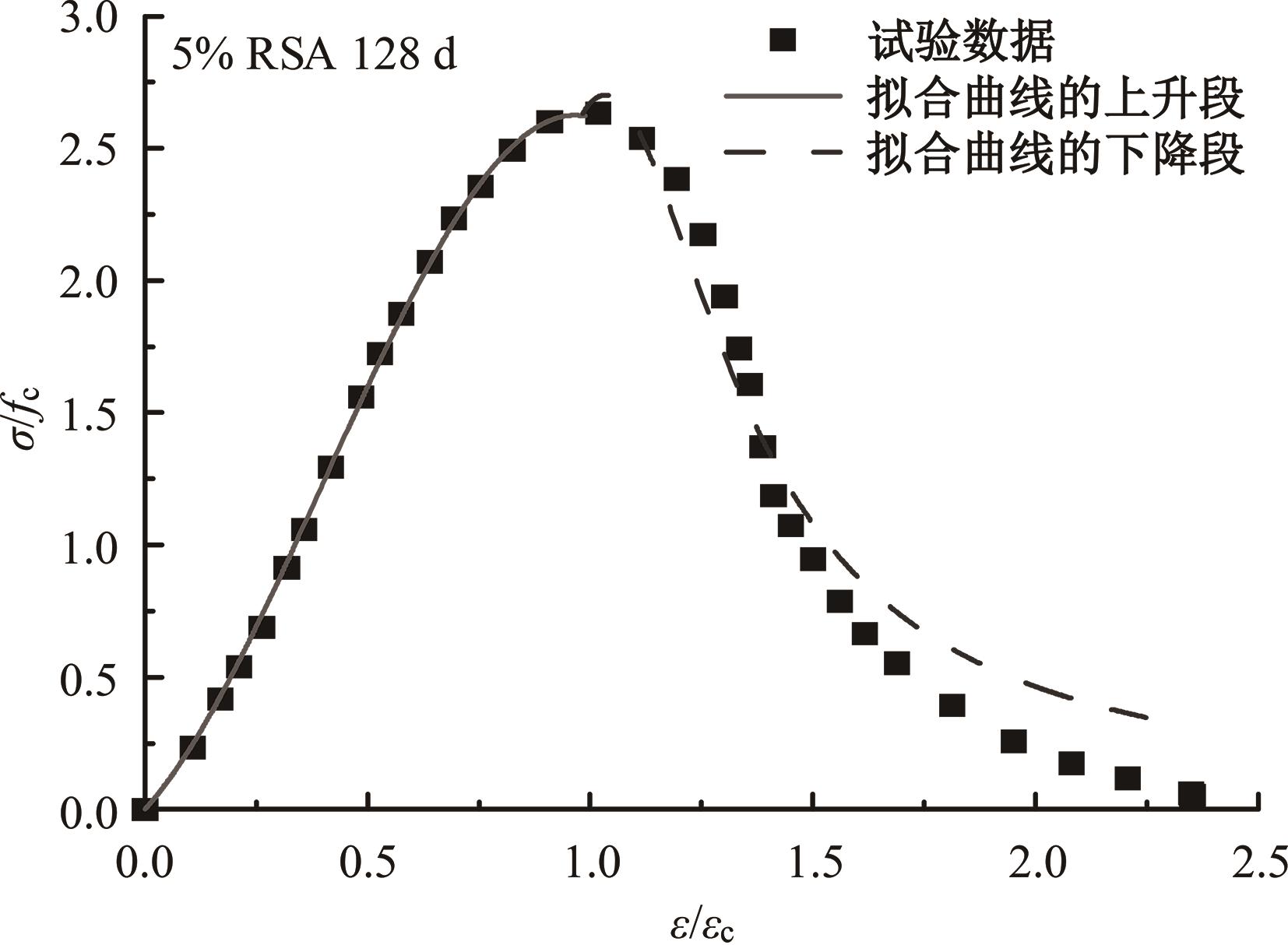

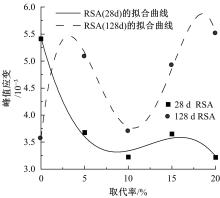

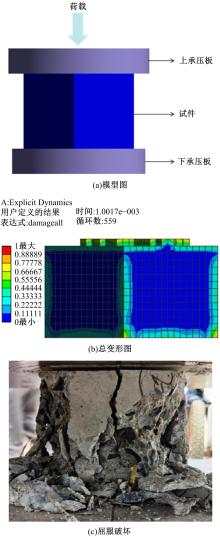

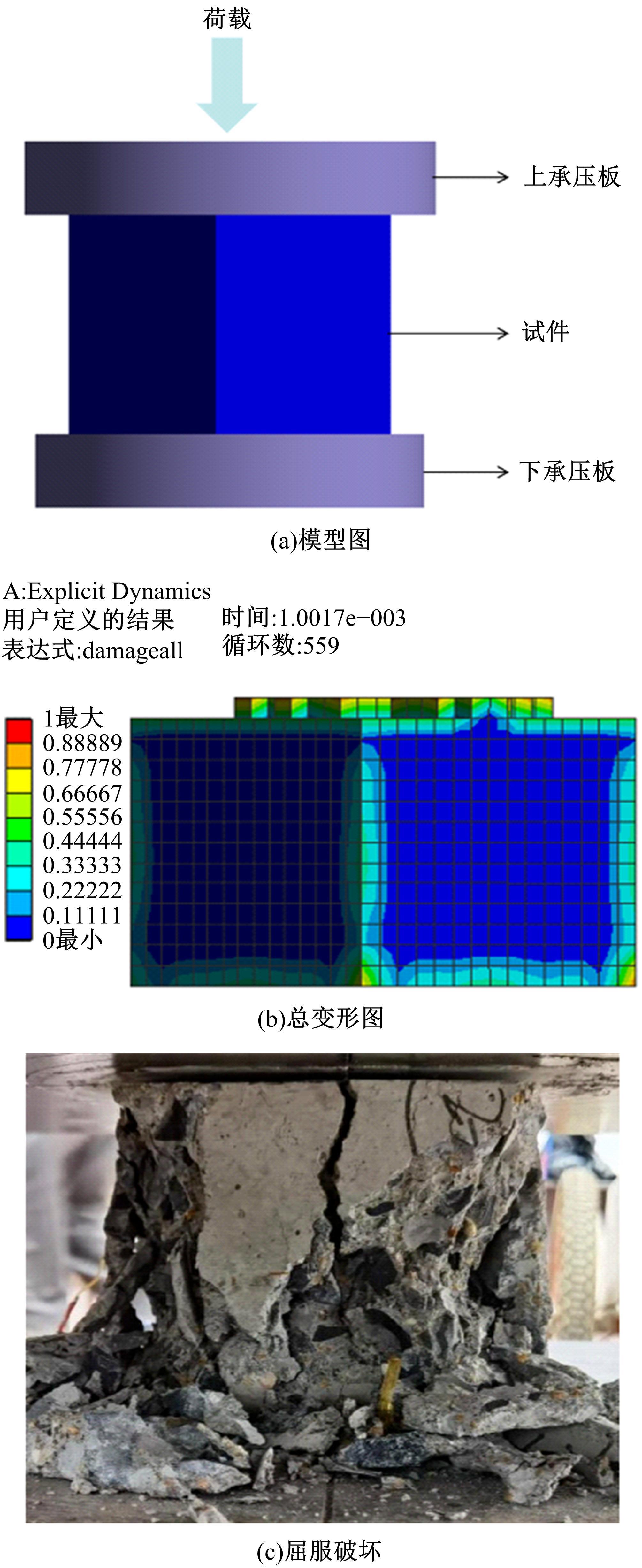

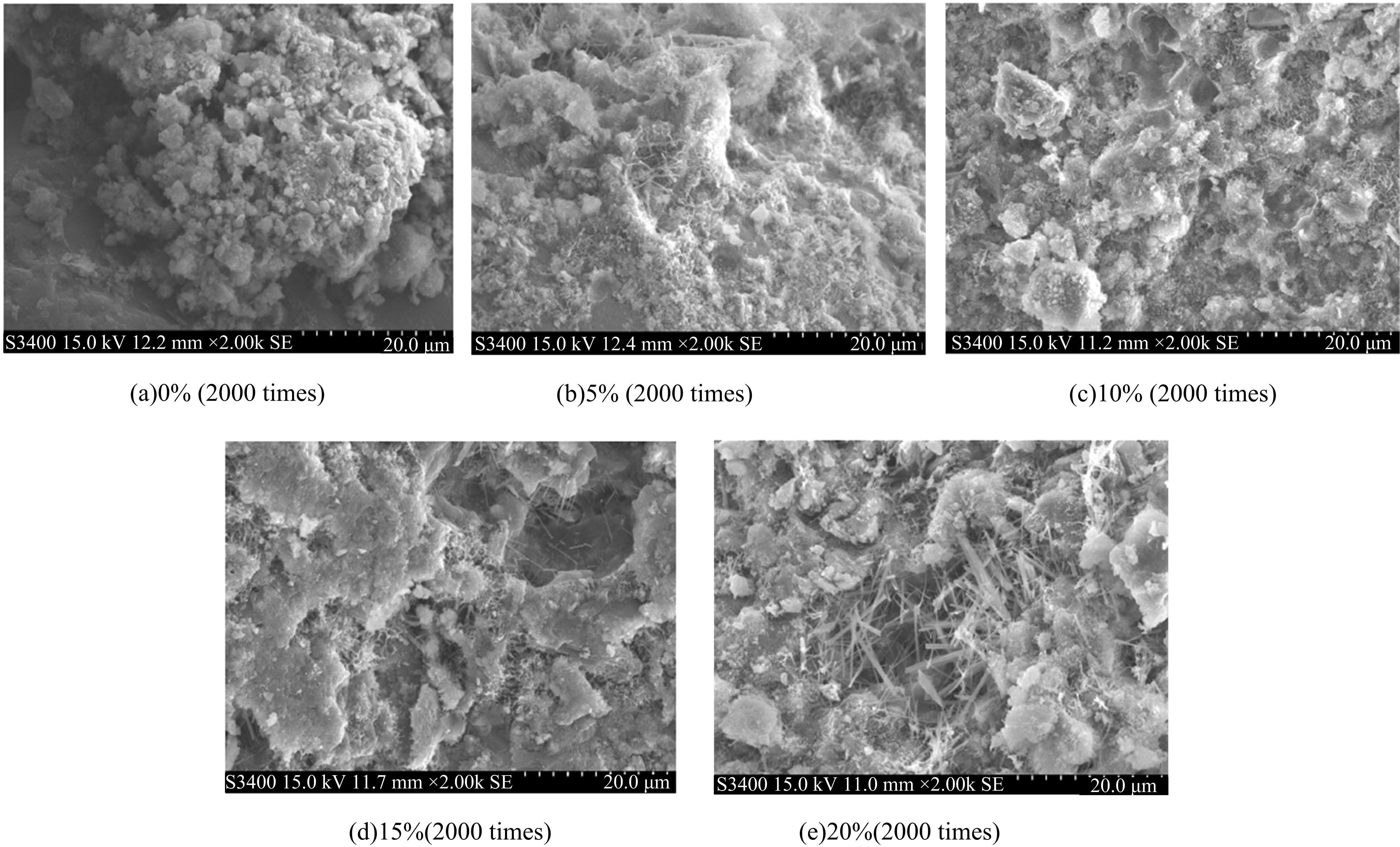

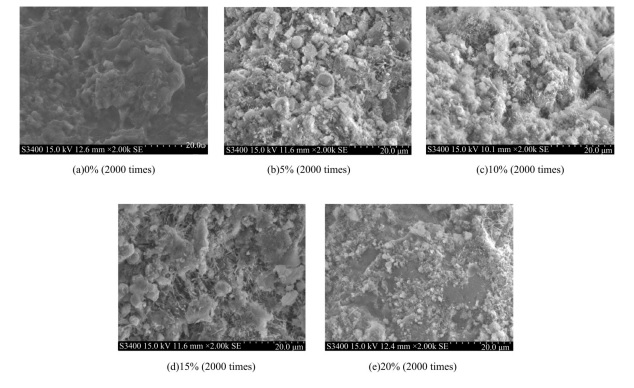

为探究水稻秸秆灰对普通混凝土性能的影响规律,以不同养护天数和不同取代率(0%、5%、10%、15%、20%)的水稻秸秆灰混凝土为研究对象进行受压试验,以本构关系、峰值应力、峰值应变、弹性模量、泊松比为评价指标,揭示水稻秸秆灰对混凝土性能的影响规律,提出并建立了水稻秸秆灰混凝土本构模型,利用有限元法分析水稻秸秆灰混凝土试件受压破坏形态,通过扫描电子显微镜进行微观分析,结果表明:对比普通混凝土,随着取代率的增加,养护28 d的水稻秸秆灰混凝土应力-应变曲线有明显区别,峰值应力、峰值应变均有不同程度下降;养护128 d时曲线稍有变化,峰值应力、峰值应变均有不同程度增加,取代率5%时峰值应变提高12.24%,且长期强度最好。扫描电子显微镜图像分析表明:水稻秸秆灰中的二氧化硅可与水化产物反应,促进后期强度。研究结果可为水稻秸秆灰混凝土工业化应用提供技术支持,为生物质发电厂生产的水稻秸秆灰副产物利用以促进农业循环、增加农业收入提供了理论依据。

中图分类号:

- TB332

| 1 | Evi Aprianti S. A huge number of artificial waste material can be supplementary cementitious material (SCM) for concrete production-a review part II[J]. Journal of Cleaner Production,2017,142:4178-4194. |

| 2 | 许鹏,许昌东,王正君,等. 生物质秸秆灰活性分析及对混凝土力学特性的影响[J]. 混凝土,2020(3):108-112, 116. |

| Xu Peng, Xu Chang-dong, Wang Zheng-jun, et al.Analysis of biomass straw ash activity and its influence on the mechanical characteristics of concre-te[J]. Concrete, 2020 (3): 108-112, 116. | |

| 3 | 刘先南,王珂,李学军.双掺纳米二氧化钛和秸秆灰对混凝土力学及微观特性试验研究[J].混凝土,2023(6):125-129, 133. |

| Liu Xian-nan, Wang Ke, Li Xue-jun. Experimentalstudy on the mechanics and microscopic characteristics of concrete with double nanodoped titanium dioxide and straw ash[J]. Concrete, 2023 (6):125-129, 133. | |

| 4 | 张韦,刘超,刘化威,等. 基于孔体积分形维数的稻壳灰混凝土冻融损伤劣化机制[J]. 复合材料学报,2023,40(8):4733-4744. |

| Zhang Wei, Liu Chao, Liu Hua-wei, et al. The d-eterioration mechanism of rice husk ash concreteb-ased on hole volume fractal dimension[J]. Journaof Composite Materials, 2023,40(8):4733-4744. | |

| 5 | 汪知文,李碧雄.稻壳灰应用于水泥混凝土的研究进展[J].材料导报,2020,34(9):9003-9011. |

| Wang Zhi-wen, Li Bi-xiong. Progress of the application of rice husk ash to cement concrete [J]. Materials Reports, 2020,34(9):9003-9011. | |

| 6 | 王淑娟,金玉杰.秸秆灰理化特性及作为混凝土掺和料可行性[J].非金属矿,2020,43(2):30-33. |

| Wang Shu-juan, Jin Yu-jie. Physicochemical characteristics of straw ash and its feasibility as a concrete admixture [J]. Non-Metallic Mines, 2020,43 (2): 30-33. | |

| 7 | 韦京利,李舒阳,钟福文,等.生物质灰混凝土抗压强度的多因素计算模型[J].混凝土,2021(9):63-68, 72. |

| Wei Jing-li, Li Shu-yang, Zhong Fu-wen, et al. Multifactor calculation model of the compressive strength of biomass ash concrete[J]. Concrete, 2021(9): 63-68, 72. | |

| 8 | 许鹏,王正君,魏凌傲,等.玉米秸秆灰生态多孔混凝土抗冻性能试验研究[J].水利科学与寒区工程,2018,1(8):6-10. |

| Xu Peng, Wang Zheng-jun, Wei Ling-ao,et al. Study on the resistance of ash-born porous concrete in corn year after year[J]. Hydro Science and Cold Zone Engineering, 2018,1 (8): 6-10. | |

| 9 | Amin M N, Murtaza T, Shahzada K,et al. Pozzolanic potential and mechanical performance of wheat straw ash incorporated sustainable concrete[J]. Sustainability,2019,11(2) :1-20. |

| 10 | .通用硅酸盐水泥 [S]. |

| 11 | 白兆兴,曹建峰,林鹏云,等.秸秆类生物质燃烧动力学特性实验研究[J].能源研究与信息,2009,25(3):130-137. |

| Bai Zhao-xing, Cao Jian-feng, Lin Peng-yun, et al. Experimental study on the combustion kinetics of straw biomass[J]. Energy Research and Information, 2009,25 (3): 130-137. | |

| 12 | .固体生物质燃料灰成分测定方法 [S]. |

| 13 | .混凝土物理力学性能试验方法标准 [S]. |

| 14 | 李静,王哲.真三轴加载条件下混凝土的力学特性[J].吉林大学学报:工学版,2017,47(3):771-777. |

| Li Jing, Wang Zhe. Mechanical characteristics of concrete under true triaxial loading condition[J]. Journal of Jilin University(Engineering and Technology Edition), 2017,47(3):771-777. | |

| 15 | 柳艳杰,金明山,张晓东,等.再生混凝土冻融作用下强度损伤研究[J].黑龙江大学工程学报,2020,11(3):23-27. |

| Liu Yan-jie, Jin Ming-shan, Zhang Xiao-dong, et al. Study on strength damage under freezing and thawing of reclaimed concrete[J]. Journal of Engineering of Heilongjiang University, 2020,11(3):23-27. | |

| 16 | 林强,刘赞群,禹雷,等.乳化沥青橡胶混凝土的力学性能[J].复合材料学报,2023,40(3):1560-1568. |

| Lin Qiang, Liu Zan-qun, Yu Lei, et al. Mechanical properties of emulsified asphalt rubber concrete[J]. Journal of Composite Materials, 2023,40(3):1560-1568. | |

| 17 | 李舒阳,陈正,韦京利,等.三乙醇胺助磨剂对蔗渣灰颗粒特性及蔗渣灰砂浆性能的影响[J].硅酸盐通报,2022,41(3):931-939. |

| Li Shu-yang, Chen Zheng, Wei Jing-li, et al.Characteristics of triethanolamine-assisted grinding slag ash and film of sugarcane ash performance[J]. Bulletin of the Chinese Ceramic Society, 2022, 41 (3): 931-939. | |

| 18 | Kazmi S M S, Munir M J, Patnaikuni I,et al. Pozzolanic reaction of sugarcane bagasse ash and its role in controlling alkali silica reaction[J]. Construction and Building Materials,2017,153(30):1010. |

| 19 | Jagadesh P, Ramachandramurthy A, Murugesan R. Evaluation of mechanical properties of sugar cane bagasse ash concrete[J]. Construction and Building Materials,2018,176(10):608-617. |

| 20 | 刘勇,冯竟竟,于雷,等.生物质灰对水泥硬化浆体抗压强度影响的试验研究[J].硅酸盐通报,2017,36(5):1718-1722. |

| Liu Yong, Feng Jing-jing, Yu Lei, et al.Study on the influence of hardening body resistance of bio-ash cement slurry[J]. Bulletin of the Chinese Ceramic Society,2017, 36(5): 1718-1722. | |

| 21 | 于本田,李彦宵,张占旭,等.不同石粉及掺量对高延性工程水泥基复合材料的性能影响[J/OL].[2024-10-22]. |

| 22 | Hakeem I Y, Amin M, Agwa I S, et al. Ultra-high-performance concrete properties containing rice straw ash and nano eggshell powder[J]. Case Studies in Construction Materials,2023,19: No.e02291. |

| 23 | Fadi A, Osama Z, Rebeca M, et al. Ultra-high-performance fiber-reinforced sustainable concrete modified with silica fume and wheat straw ash[J]. Journal of Materials Research and Technology,2023,24: 6118-6139. |

| 24 | 潘素明. 混凝土抗冻耐久性的数值计算研究[J].水利与建筑工程学报, 2022, 20(5): 68-74. |

| Pan Su-ming. The value calculation of the durability of concrete[J]. Journal of Water Conservancy and Construction Engineering, 2022,20(5): 68-74. | |

| 25 | 许鹏, 王正君, 康浩. 秸秆灰基混凝土抗压强度及净水特性试验研究[J]. 森林工程, 2019, 35(1): 107-112. |

| Xu Peng, Wang Zheng-jun, Kang Hao.Study on resistance andwater characteristics of hot ash-based concrete[J].Forest Engineering, 2019, 35(1): 107-112. | |

| 26 | Carreira D J, Chu K H. Stress-strain relationship for plain concrete in compression[J]. Journal Proceedings, 1985, 82(6): 797-804. |

| 27 | Wee T H, Chin M S, Mansur M A. Stress-strain relationship of high-strength concrete in compression[J]. Journal of Materials in Civil Engineering, 1996, 8(2): 70-76. |

| 28 | 过镇海, 张秀琴, 张达成, 等. 混凝土应力-应变全曲线的试验研究[J].建筑结构学报, 1982(1): 1-12. |

| Guo Zhen-hai, Zhang Xiu-qin, Zhang Da-cheng, et al. Experimental study on the full stress-strain curve of concrete [J].Journal of Building Structures,1982(1): 1-12. | |

| 29 | 刘海峰, 陶仁光, 车佳玲, 等. 荷载和高温对沙漠砂混凝土单轴抗压性能影响[J/OL]. [2024-10-22]. |

| 30 | Wang F C, Wang C, Yi S J. Strength and performance of straw ash cement mortar[J]. Revue des Composites et des Matériaux Avancés-Journal of Composite and Advanced Materials, 2019, 29(1): 15-20. |

| 31 | Naraindas B, Wan I M H, Kennedy Charles A,et al. Mechanical performance of concrete incorporating wheat straw ash as partialreplacement of cement[J]. Journal of Building Pathology and Rehabilitation,2021, 6(1): No.4. |

| 32 | 解伟, 司先洋, 李树山, 等.均布荷载作用下高强钢筋混凝土深梁受剪性能研究及有限元分析[J].混凝土,2022(11): 1-5, 10. |

| Xie Wei, Si Xian-yang, Li Shu-shan, et al. Study on shear performance and finite element analysis of high strength reinforced concrete deep beam under uniform cloth load[J]. Concrete, 2022(11): 1-5, 10. | |

| 33 | 张梦琳, 张纪刚, 马哲昊, 等. 基于ANSYS/LS-DYNA的人防墙抗冲击性能研究[J]. 青岛理工大学学报, 2023, 44(2): 67-76. |

| Zhang Meng-lin, Zhang Ji-gang, Ma Zhe-hao, et al. Study on impact resistance of civil air defense wall based on ANSYS / LS-DYNA[J]. Journal of Qingdao University of Technology, 2023,44(2): 67-76. | |

| 34 | 狄胜同, 贾超, 乔卫国, 等. 橡胶集料混凝土细观损伤特性的加载速率效应[J].吉林大学学报: 工学版,2019, 49(6): 1900-1910. |

| Di Sheng-tong, Jia Chao, Qiao Wei-guo,et al. Loading rate effect of meso-damage characteristics of crumb rubber concrete[J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6):1900-1910. |

| [1] | 冯琼,田浩正,乔宏霞,念腾飞,韩文文. 自然暴露与盐雾加速环境下钢筋混凝土劣化规律及等效关系[J]. 吉林大学学报(工学版), 2024, 54(2): 494-505. |

| [2] | 闫清峰,张纪刚,王涛,陈德刚,郁有升,杨迎春. 预制预装修模块化建筑连接节点抗震性能[J]. 吉林大学学报(工学版), 2023, 53(2): 505-514. |

| [3] | 陈伟宏,陈艳,洪秋榕,崔双双,颜学渊. BRBs加固震损装配式混凝土框架结构抗震性能试验[J]. 吉林大学学报(工学版), 2022, 52(8): 1817-1825. |

| [4] | 何兆益,李金凤,周文,官志桃. 多孔沥青混合料的动态模量及其预估模型[J]. 吉林大学学报(工学版), 2022, 52(6): 1375-1385. |

| [5] | 谷拴成,聂红宾. 极温冻融-荷载作用下碳纤维复合材料修复试件损伤分析[J]. 吉林大学学报(工学版), 2021, 51(6): 2108-2120. |

| [6] | 周靖,黎亚军,赵卫锋,罗宗健,补国斌. 胶合竹板-钢管约束收尘石粉混凝土柱的偏压性能[J]. 吉林大学学报(工学版), 2021, 51(6): 2096-2107. |

| [7] | 文畅平,任睆遐. 基于Lade模型的生物酶改良膨胀土双屈服面本构关系[J]. 吉林大学学报(工学版), 2021, 51(5): 1716-1723. |

| [8] | 张广泰,张路杨,邢国华,曹银龙,易宝. 钢-聚丙烯混杂纤维混凝土剪力墙抗震性能[J]. 吉林大学学报(工学版), 2021, 51(3): 946-955. |

| [9] | 杜瑞锋,裴向军,贾俊,张晓超,陈俊宇,张国华. 多次冲击下砂岩粘弹性损伤本构关系[J]. 吉林大学学报(工学版), 2021, 51(2): 638-649. |

| [10] | 许卫晓,程扬,杨伟松,鞠佳昌,于德湖. RC框架⁃抗震墙并联结构体系拟静力试验[J]. 吉林大学学报(工学版), 2021, 51(1): 268-277. |

| [11] | 单德山,张潇,顾晓宇,李乔. 斜拉索悬链线构形的伸长量解析计算方法[J]. 吉林大学学报(工学版), 2021, 51(1): 217-224. |

| [12] | 刘柳,冯卫星. 基于NNBR模型的隧道盾构施工地表沉降实测与计算分析[J]. 吉林大学学报(工学版), 2021, 51(1): 245-251. |

| [13] | 薛素铎,鲁建,李雄彦,刘人杰. 跳格布置对环形交叉索桁结构静动力性能的影响[J]. 吉林大学学报(工学版), 2020, 50(5): 1687-1697. |

| [14] | 王勃,董元正,董丽欣. 基于短期风速资料的基本风压计算方法[J]. 吉林大学学报(工学版), 2020, 50(5): 1739-1746. |

| [15] | 李明,王浩然,赵唯坚. 单向带抗剪键叠合板的受力性能试验[J]. 吉林大学学报(工学版), 2020, 50(2): 654-667. |

|

||