吉林大学学报(工学版) ›› 2025, Vol. 55 ›› Issue (3): 811-819.doi: 10.13229/j.cnki.jdxbgxb.20230592

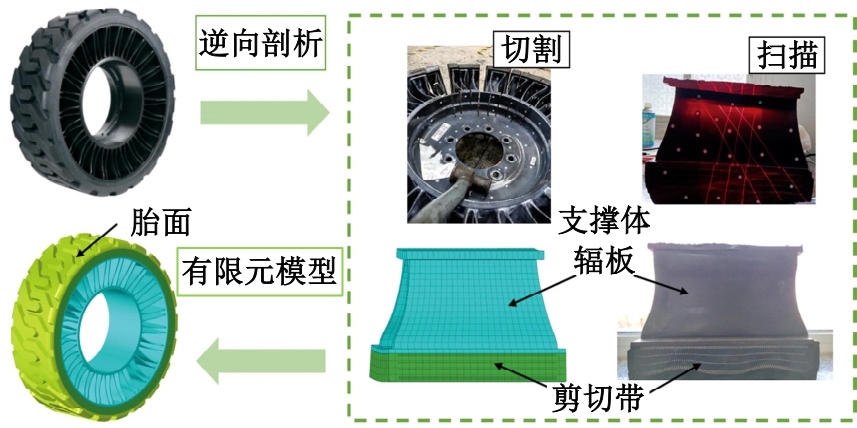

TWEEL轮胎接地压力均布特性分析

- 吉林大学 汽车工程学院,长春 130022

Analysis of uniform distribution characteristics of contact pressure of TWEEL tires

Dang LU( ),Xiao-fan WANG,Hai-dong WU(

),Xiao-fan WANG,Hai-dong WU( )

)

- College of Automotive Engineering,Jilin University,Changchun 130022,China

摘要:

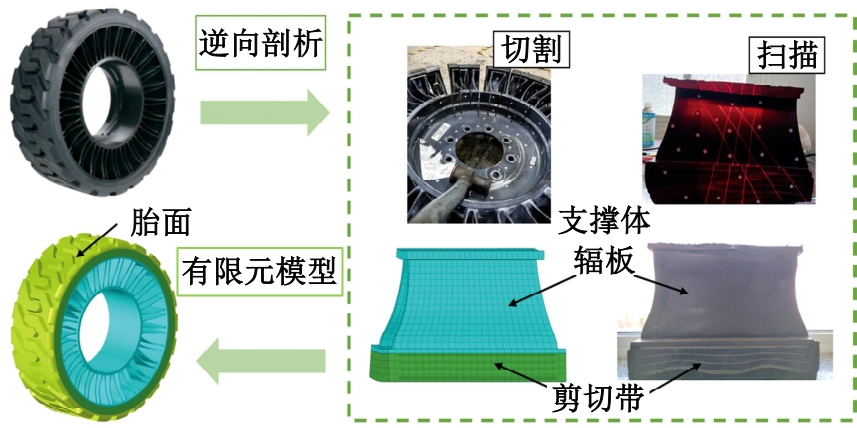

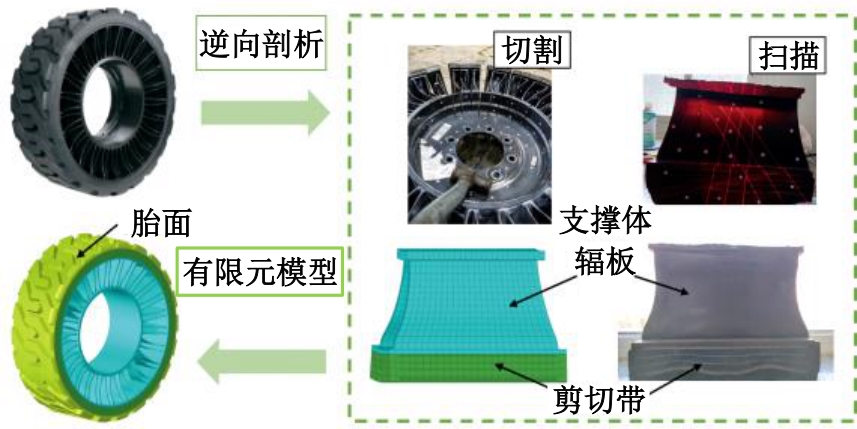

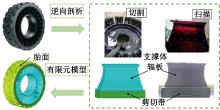

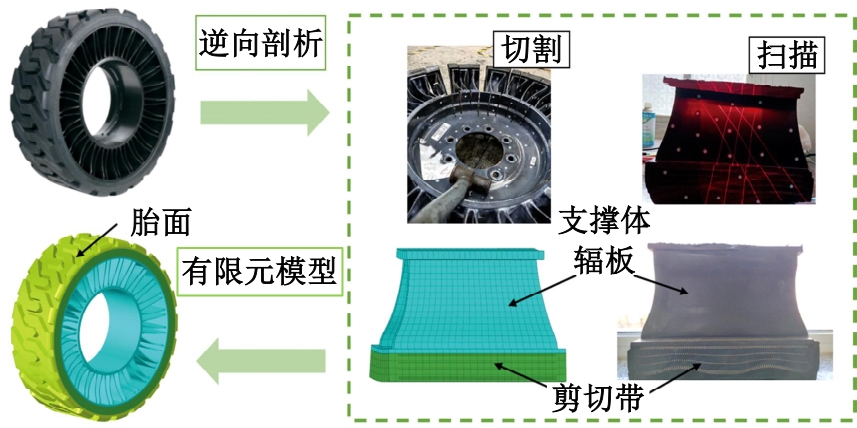

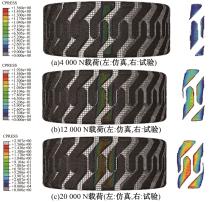

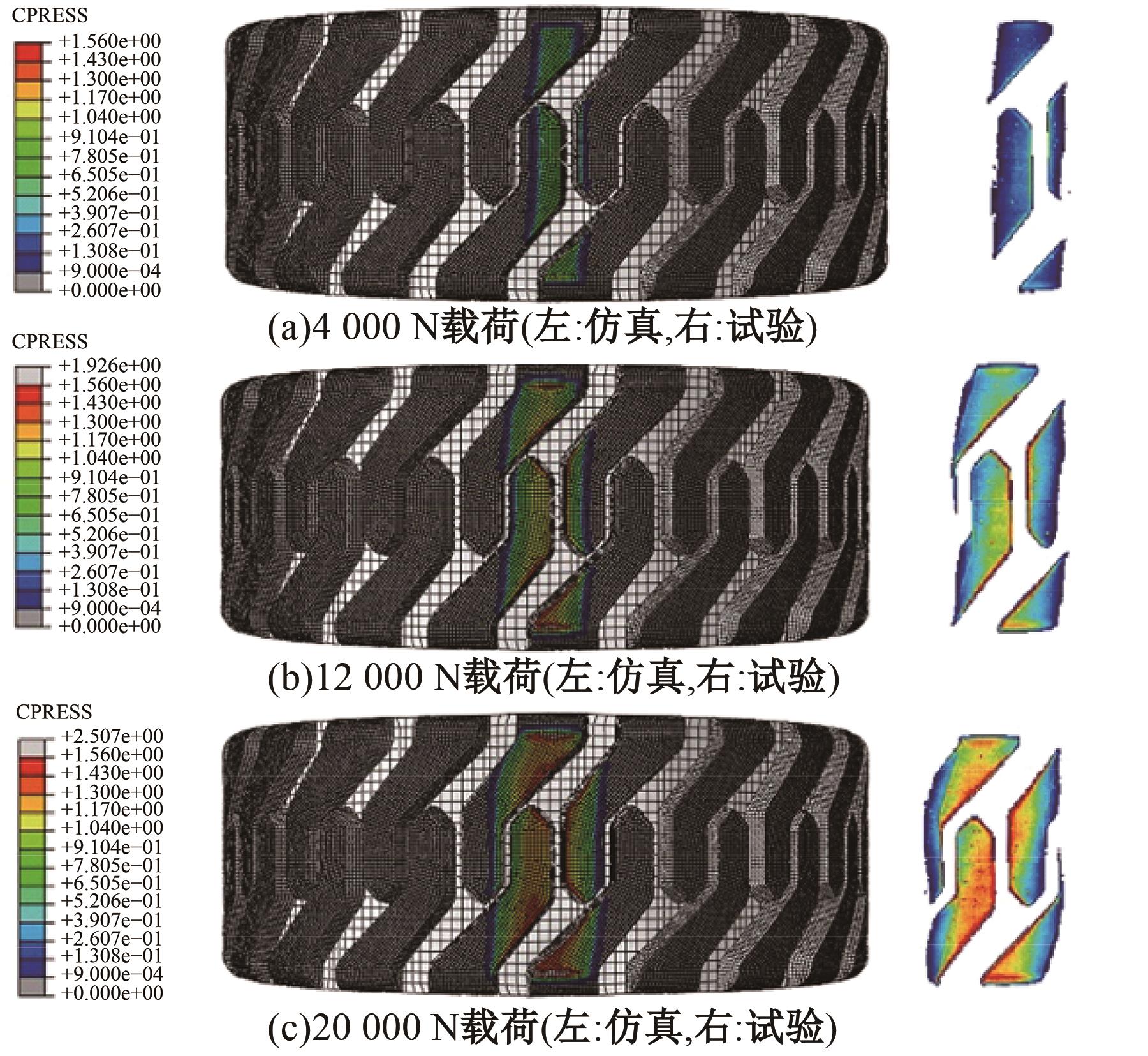

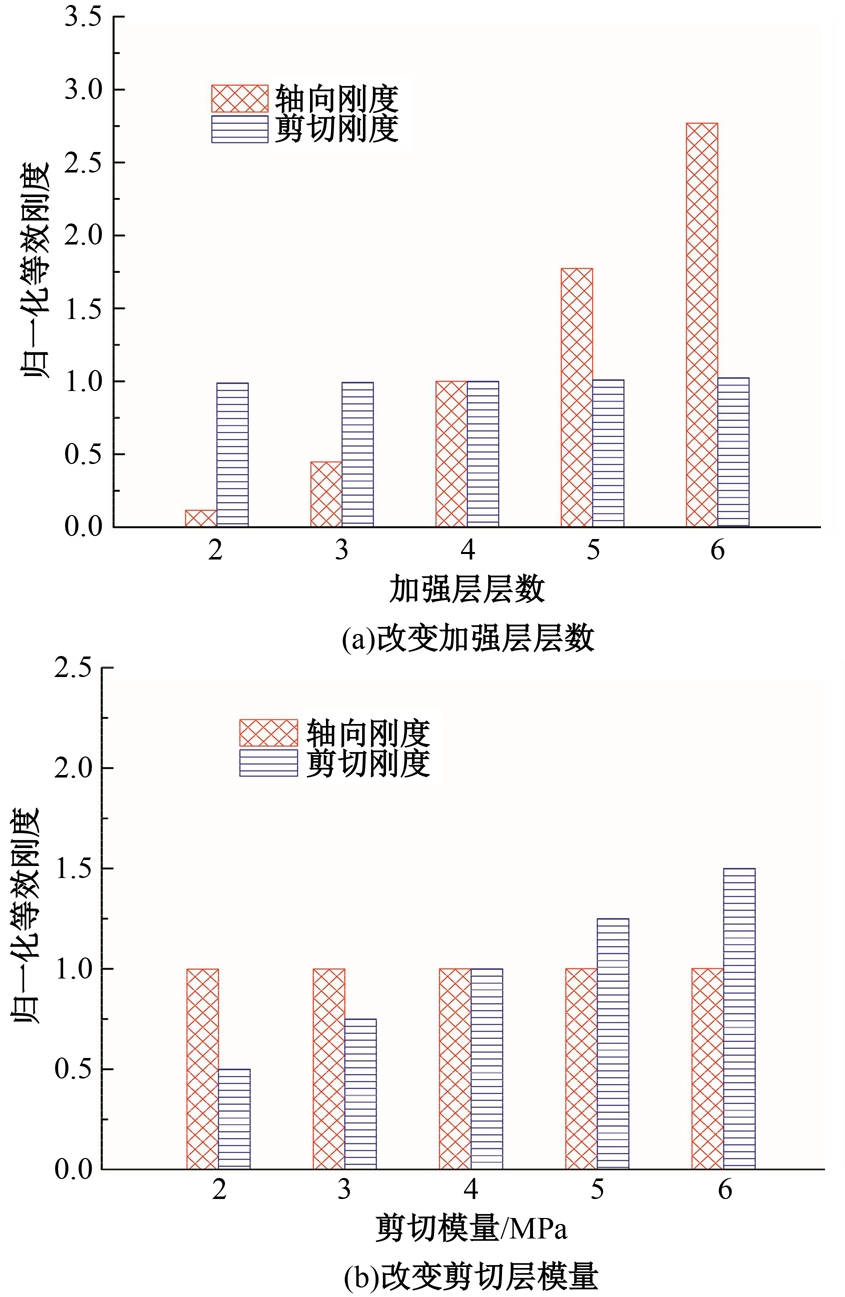

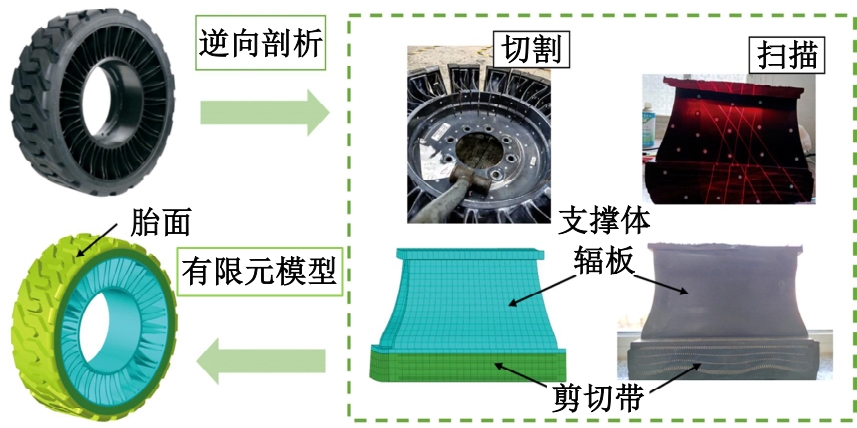

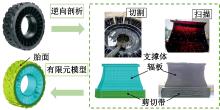

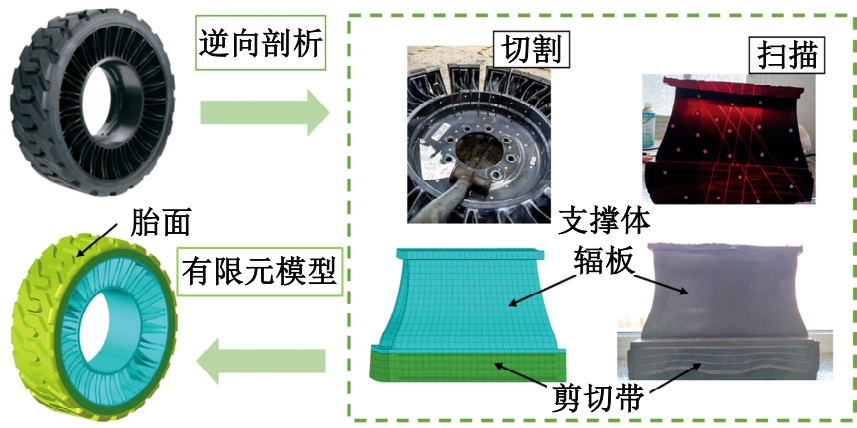

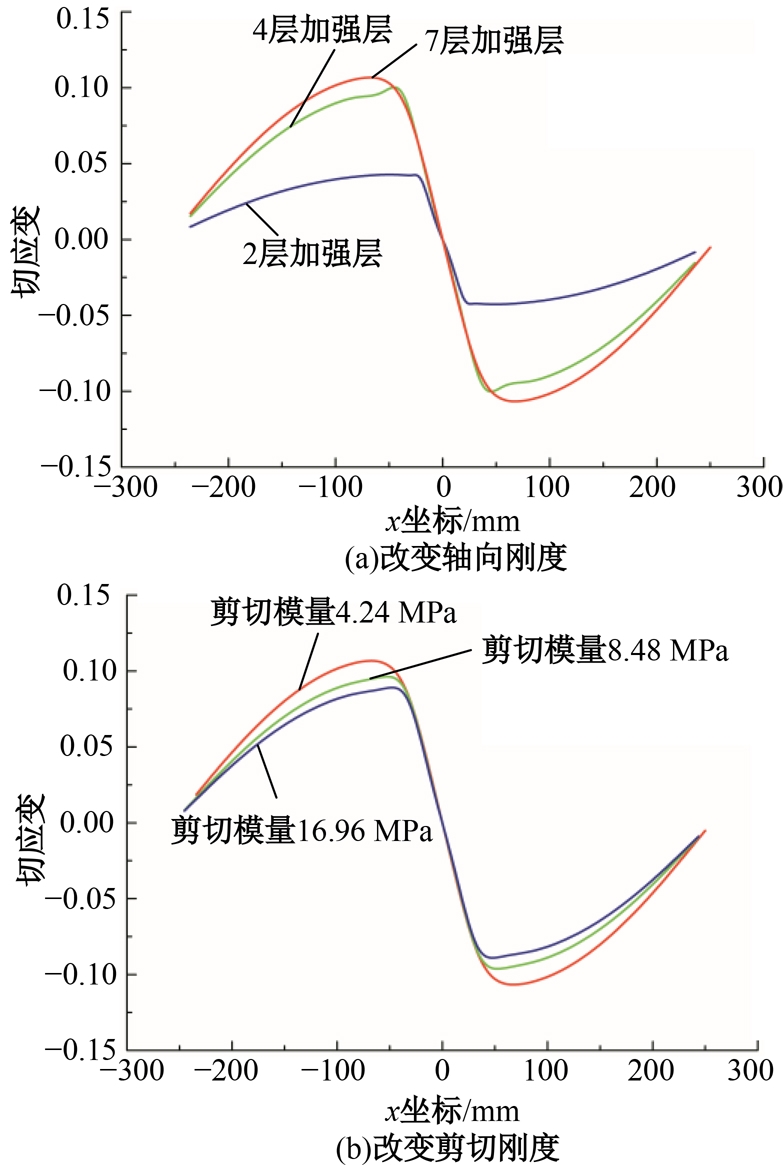

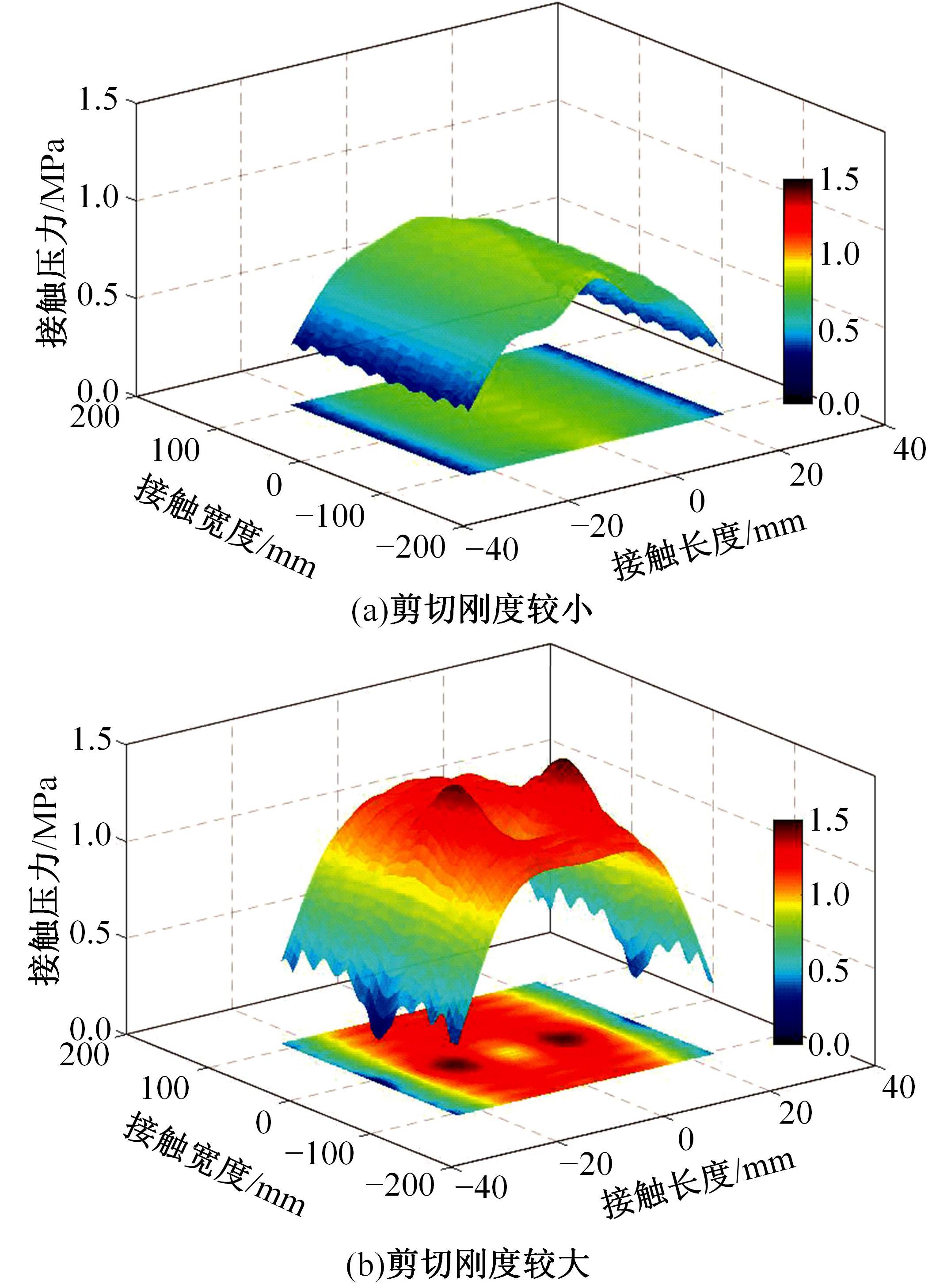

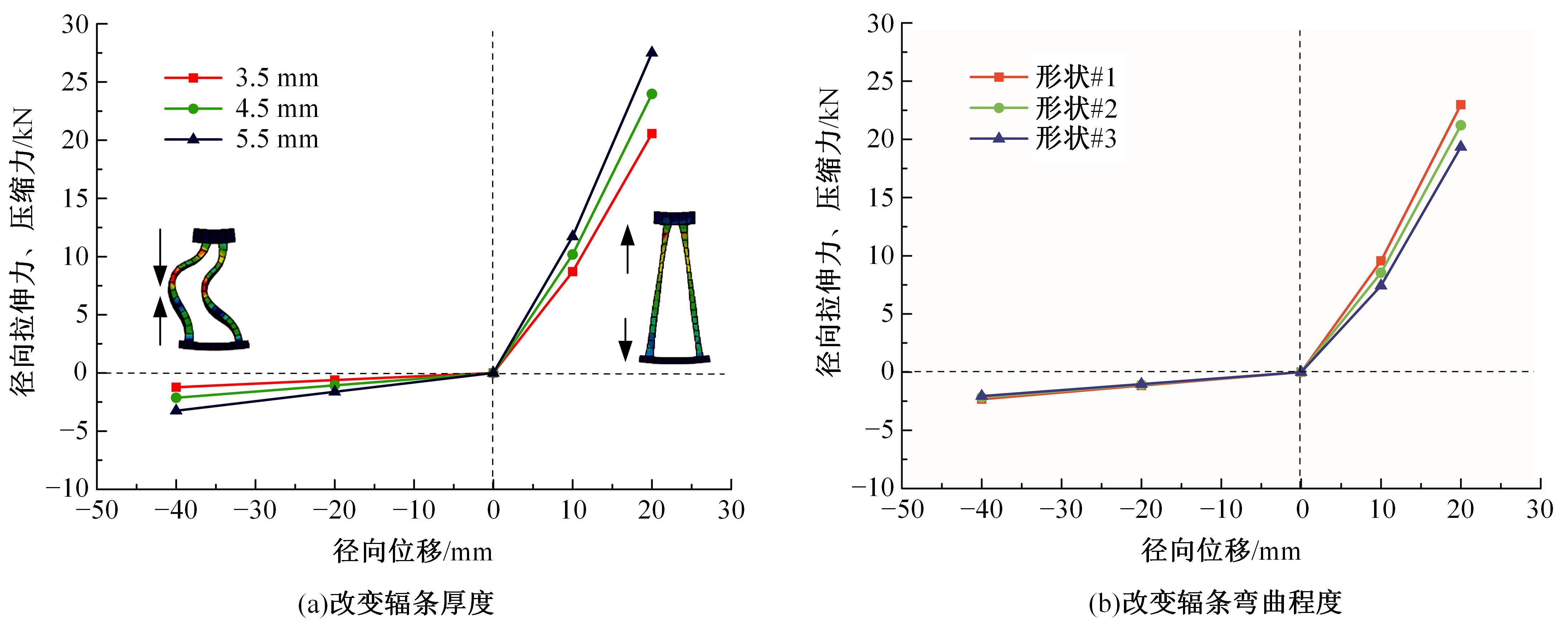

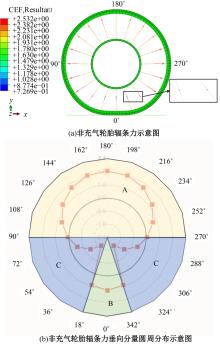

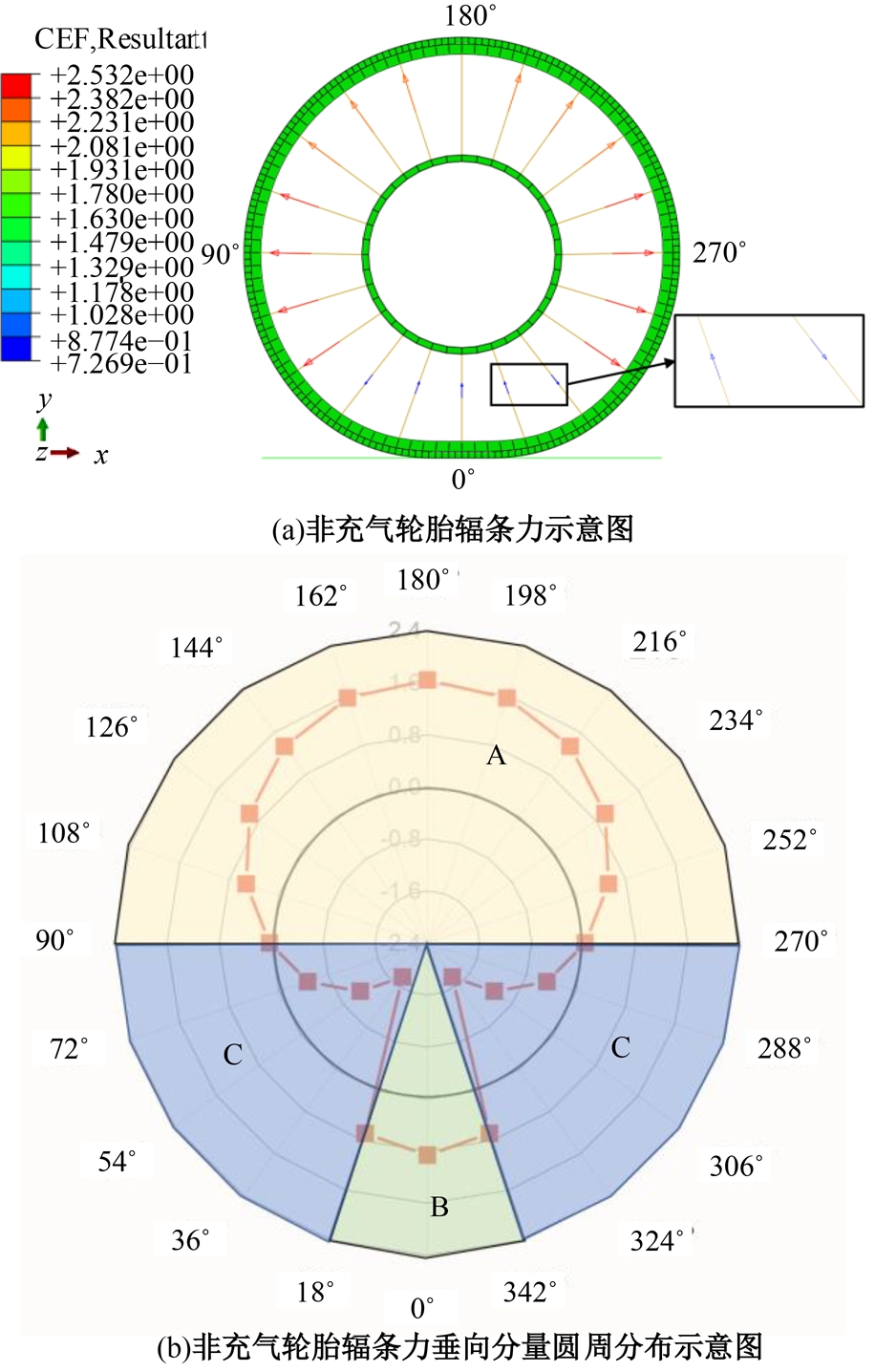

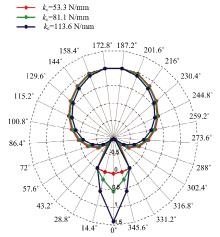

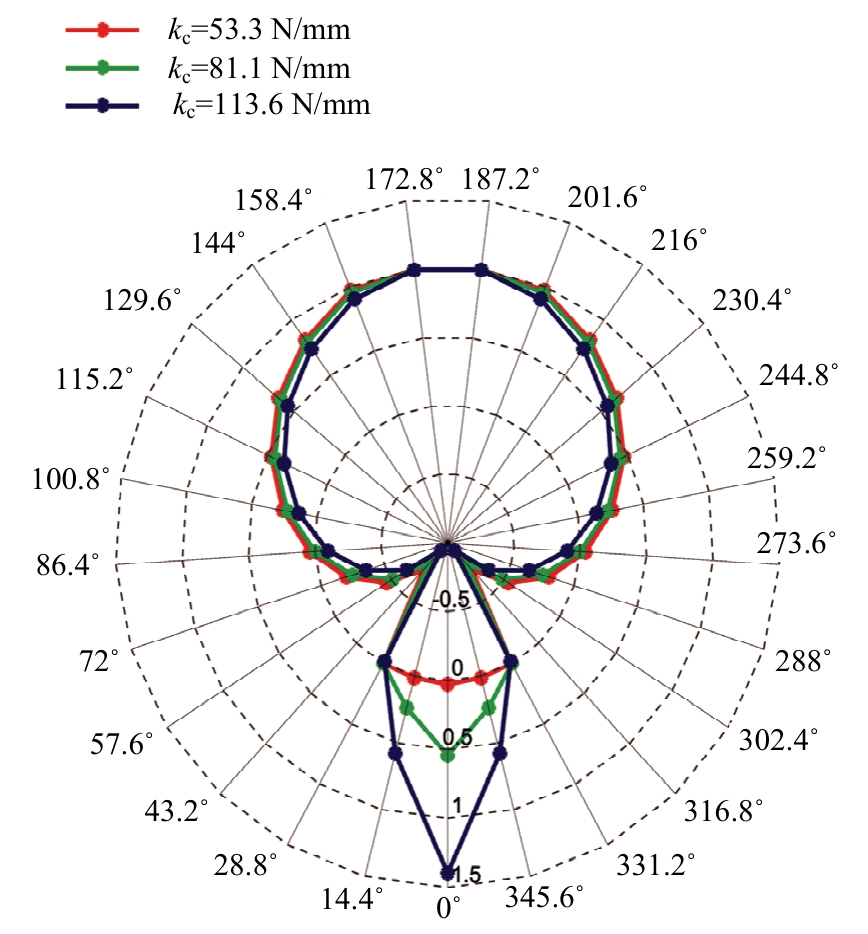

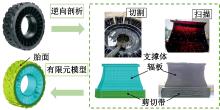

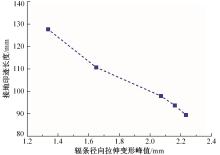

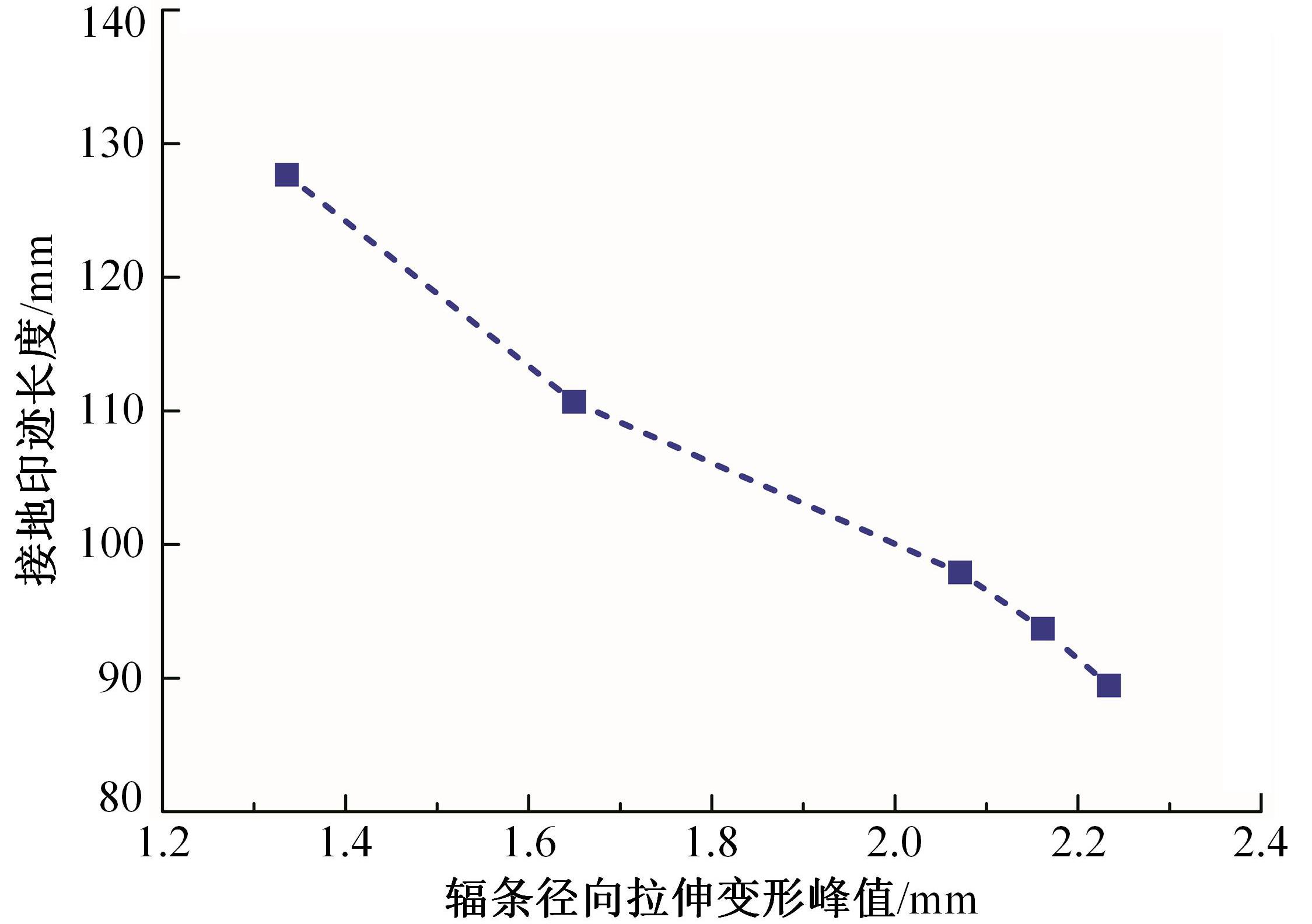

为了深入研究非充气轮胎的接地压力分布特性,对辐条式非充气轮胎——TWEEL进行了逆向剖析,建立了TWEEL有限元模型,并验证了模型精度。基于有限元模型,分析了TWEEL主要部件——剪切带及辐条对接地压力均布特性的影响。结果表明:TWEEL轮胎剪切带极大的等效轴向刚度和较小的剪切刚度可使剪切变形更容易产生,是TWEEL实现接地压力均布的设计要点;较小的辐条径向压缩刚度使TWEEL具备较强的顶部承载能力,减小了接地印迹内辐条传递载荷对压力均布的影响;较大的辐条拉伸刚度可以增大接地面积,保证TWEEL具有均布且较低的接地压力。研究结果为非充气轮胎结构设计和优化提供了重要参考。

中图分类号:

- U463.34

| 1 | Kim K, Kim D M. Contact pressure of non-pneumatic tires with hexagonal lattice spokes[C]∥SAE Technical Paper, 2011-0099. |

| 2 | Cesbron J, Anfosso-Ledee F, Duhamel D, et al. Experimental study of tyre/road contact forces in rolling conditions for noise prediction[J]. Journal of Sound and Vibration, 2009, 320(1-2): 125-144. |

| 3 | Rhyne T B, Thompson R H, Cron S M, et al. Non-pneumatic tire 4[P]. United States Patent :720119,2007-04-10. |

| 4 | Cron S M, Pompier J P, Rhyne T B, et al. Non-pneumatic tire[P]. United States Patent: 7418988, 2008-09-02. |

| 5 | Rhyne T B, Cron S M. Development of a non-pneumatic wheel[J]. Tire Science and Technology, 2006, 34(3): 150-169. |

| 6 | Manesh A, Tercha M, Anderson B, et al. Tension-based non-pneumatic tire[P]. United States:8176957, 2012-02-07. |

| 7 | Manesh A, Tercha M J, Meliska B, et al. Tension-based non-pneumatic tire[P]. United States: 8176957, 2012-05-15. |

| 8 | 赵又群, 付宏勋, 林棻, 等. 非充气车轮及其力学特性研究进展[J].江苏大学学报:自然科学版,2016,37(6): 621-627. |

| Zhao You-qun, Fu Hong-xun, Lin Fen, et al. Advancement of non-pneumatic wheels and mechanical characteristics[J]. Journal of Jiangsu University (Natural Science Edition), 2016, 37(6): 621-627. | |

| 9 | Corporation Bridgestone. Non-pneumatic tire [P]. Janpan: 078538, 2013-10-22. |

| 10 | 赵颖, 宋胜, 李建重, 等. 新型负泊松比非充气轮胎设计及性能分析[J].南京理工大学学报,2021, 45(6):751-760. |

| Zhao Ying, Song Sheng, Li Jian-chong, et al. Structural design and performance analysis on novel airless tire with negative Poisson´s ratio characteristic[J]. Journal of Nanjing University of Science and Technology, 2021, 45(6): 751-760. | |

| 11 | Gasmi A, Joseph P F, Rhyne T B, et al. Closed-form solution of a shear deformable, extensional ring in contact between two rigid surfaces[J]. International Journal of Solids and Structures, 2011, 48(5): 843-853. |

| 12 | Veeramurthy M. Modeling, finite element analysis, and optimization of non-pneumatic tire (NPT) for the minimization of rolling resistance[D]. Clemson: The Graduate School, Clemson University, 2011. |

| 13 | Veeramurthy M, Ju J, Thompson L L, et al. Optimisation of geometry and material properties of a non-pneumatic tyre for reducing rolling resistance[J]. International Journal of Vehicle Design, 2014, 66(2): 193-216. |

| 14 | Aboul-Yazid A M, Emam M A A, Shaaban S, et al. Effect of spokes structures on characteristics performance of non-pneumatic tires[J]. International Journal of Automotive and Mechanical Engineering, 2015, 11(1):2212-2223. |

| 15 | Hryciow Z, Jackowski J, Żmuda M. The influence of non-pneumatic tyre structure on its operational properties[J]. International Journal of Automotive and Mechanical Engineering, 2020, 17(3): 8168-8178. |

| 16 | 付宏勋, 赵又群, 林棻, 等. 机械弹性车轮稳态侧偏特性的理论与试验分析[J].浙江大学学报:工学版,2017, 51(2): 344-349. |

| Fu Hong-xun, Zhao You-qun, Lin Fen, et al. Theoretical and experimental analysis on steady‑state cornering properties of mechanical elastic wheel[J]. Journal of Zhejiang University (Engineering Science), 2017, 51(2): 344-349. | |

| 17 | 臧利国, 赵又群, 李波, 等. 机械弹性车轮提高轮胎耐磨性和抓地性分析[J]. 农业工程学报, 2014, 30(12): 56-63. |

| Zang Li-guo, Zhao You-qun, Li Bo, et al. Mechanical elastic wheel improving road holding and wear resistance of tire[J]. Transactions of the Chinese Society of Agricultural Engineering, 2014, 30(12): 56-63. | |

| 18 | 赵又群, 杜现斌, 林棻, 等. 侧倾角对机械弹性车轮刚度及接地特性的影响[J]. 兵工学报, 2018, 39(3):444-450. |

| Zhao You-qun, Du Xian-bin, Lin Fen, et al. Influence of camber angle on stiffness and grounding characteristics of non-pneumatic mechanical elastic wheel[J]. Acta Armamentarii, 2018, 39(3): 444-450. | |

| 19 | 周勇, 王鑫伟, 孙亚飞,等. 压电复合材料层合板弯曲变形及脱粘损伤的有限元分析[J]. 吉林大学学报:工学版, 2004, 34(2): 180-184. |

| Zhou Yong, Wang Xin-wei, Sun Ya-fei, et al. Finite element analyses for piezoelectric laminated plate in bending and actuator debonding[J]. Journal of Jilin University (Engineering and Technology Edition), 2004, 34(2): 180-184. | |

| 20 | 沈观林, 胡更开, 刘彬. 复合材料力学[M]. 2版. 北京: 清华大学出版社, 2013. |

| [1] | 朱冰,范天昕,赵文博,李伟男,张培兴. 自动驾驶汽车连续测试场景复杂度评估方法[J]. 吉林大学学报(工学版), 2025, 55(2): 456-467. |

| [2] | 曲俊龙,史文库,玄圣夷,陈志勇. 面向汽车传动系统多挡共振的多级吸振器参数设计方法[J]. 吉林大学学报(工学版), 2025, 55(2): 444-455. |

| [3] | 陈鑫,张祥源,武子涛,于贵申,杨立飞. 工艺顺序对车用铝薄板胶-PFSSW接头拉剪性能的影响[J]. 吉林大学学报(工学版), 2025, 55(2): 468-475. |

| [4] | 胡宏宇,张争光,曲优,蔡沐雨,高菲,高镇海. 基于双分支和可变形卷积网络的驾驶员行为识别方法[J]. 吉林大学学报(工学版), 2025, 55(1): 93-104. |

| [5] | 王军年,曹宇靖,罗智仁,李凯旋,赵文伯,孟盈邑. 基于双目视觉的道路水深在线检测算法[J]. 吉林大学学报(工学版), 2025, 55(1): 175-184. |

| [6] | 谭草,任浩鑫,葛文庆,宋亚东,陆佳瑜. 直驱阀控液压振动平台改进自抗扰控制[J]. 吉林大学学报(工学版), 2025, 55(1): 84-92. |

| [7] | 李寿涛,杨路,屈如意,孙鹏鹏,于丁力. 基于模型预测控制的滑移率控制方法[J]. 吉林大学学报(工学版), 2024, 54(9): 2687-2696. |

| [8] | 刘化民,杨舒涵,李义,梁策,韩奇钢. 推力杆球铰仿生表面改进及有限元分析[J]. 吉林大学学报(工学版), 2024, 54(9): 2733-2740. |

| [9] | 吴量,顾义凡,邢彪,马芳武,倪利伟,贾微微. 基于线性二次型调节器的四轮转向与分布式集成控制方法[J]. 吉林大学学报(工学版), 2024, 54(9): 2414-2422. |

| [10] | 王玉海,李晓之,李兴坤. 面向高速工况的混合动力卡车预见性节能算法[J]. 吉林大学学报(工学版), 2024, 54(8): 2121-2129. |

| [11] | 常胜,刘宏飞,邹乃威. 汽车变曲率路径循迹H∞回路成形鲁棒控制[J]. 吉林大学学报(工学版), 2024, 54(8): 2141-2148. |

| [12] | 梁策,李敏,李义,梁继才,韩奇钢. 轿车前轴摇臂衬套仿生柔性接触表面摩擦特性数值模拟[J]. 吉林大学学报(工学版), 2024, 54(8): 2181-2186. |

| [13] | 刘建泽,柳江,李敏,章新杰. 基于最小二乘的车速解耦路面辨识方法[J]. 吉林大学学报(工学版), 2024, 54(7): 1821-1830. |

| [14] | 郑建校,王文博,刘金颂,周立明,李宇. 基于渐近均匀化的力-电-湿耦合光滑有限元法[J]. 吉林大学学报(工学版), 2024, 54(7): 1876-1886. |

| [15] | 谢宪毅,张明君,金立生,周彬,胡涛,白宇飞. 考虑舒适度的智能汽车人工蜂群轨迹规划方法[J]. 吉林大学学报(工学版), 2024, 54(6): 1570-1581. |

|

||