Journal of Jilin University(Engineering and Technology Edition) ›› 2024, Vol. 54 ›› Issue (3): 842-851.doi: 10.13229/j.cnki.jdxbgxb.20220605

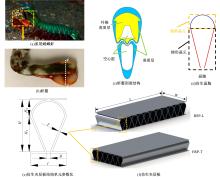

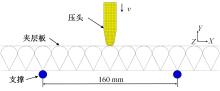

Design and numerical simulation of bionic sandwich panel based on a shrimp chela structure

Xin YANG1( ),Yang WANG1,2,Jia-feng SONG3,4,Yong ZHU2,Bin-bing HUANG2,Shu-cai XU3,5(

),Yang WANG1,2,Jia-feng SONG3,4,Yong ZHU2,Bin-bing HUANG2,Shu-cai XU3,5( )

)

- 1.College of Mechanical and Electrical Engineering,Hebei Agricultural University,Baoding 071001,China

2.Tsinghua University Suzhou Automobile Research Institute,Suzhou 215134,China

3.State Key Laboratory of intelligent Green Vehicle and Mobility,Tsinghua University,Beijing 100084

4.Key Laboratory of Transportation Industry for Transport Vehicle Detection,Diagnosis and Maintenance Technology,Jinan 250357,China

5.School of Vehicle and Mobility,Tsinghua University,Beijing 100084,China

CLC Number:

- TB17

| 1 | Zheng T, Li S, Wang G, et al. Mechanical and energy absorption properties of the composite XX-type lattice sandwich structure[J]. European Journal of Mechanics-A/Solids, 2022, 91: No. 104410. |

| 2 | Jeddi M, Yazdani M, Hasan-nezhad H. Energy absorption characteristics of aluminum sandwich panels with Shear Thickening Fluid (STF) filled 3Dfabric cores under dynamic loading conditions[J]. Thin-Walled Structures, 2021, 168: No. 108254. |

| 3 | Liu P, Liu Y, Zhang X. Simulation of hyper-velocity impact on double honeycomb sandwich panel and its staggered improvement with internal-structure model[J]. International Journal of mechanics and Materials in Design, 2016, 12(2): 241-254. |

| 4 | Sun G, Wang E, Zhang J, et al. Experimental study on the dynamic responses of foam sandwich panels with different facesheets and core gradients subjected to blast impulse[J]. International Journal of Impact Engineering, 2020, 135: No. 103327. |

| 5 | Huo X, Liu H, Luo Q, et al. On low-velocity impact response of foam-core sandwich panels[J]. International Journal of Mechanical Sciences, 2020, 181: No. 105681. |

| 6 | Liu T, Hou S, Nguyen X, et al. Energy absorption characteristics of sandwich structures with composite sheets and bio coconut core[J]. Composites Part B: Engineering, 2017, 114: 328-338. |

| 7 | Flores-Johnson E A, Shen L, Guiamatsia I, et al. A numerical study of bioinspired nacre-like composite plates under blast loading[J]. Composite Structures, 2015, 126: 329-336. |

| 8 | 葛东云, 莫与明, 何柏灵, 等. 复合材料帽型加筋板轴压试验及承载能力预测[J]. 复合材料学报, 2016, 33(7): 1531-1539. |

| Ge Dong-yun, Mo Yu-ming, He Bo-ling, et al. Test and ultimate load capacity prediction of hat-stiffened composite panel under axial compression[J]. Acta Materiae Compositae Sinica, 2016, 33(7): 1531-1539. | |

| 9 | 张保成, 刘晓婷, 杨贵春, 等. 折板截面特征对结构刚度的影响[J]. 机械设计, 2019, 36(4): 27-31. |

| Zhang Bao-cheng, Liu Xiao-ting, Yang Gui-chun, et al. Effect of cross-section characteristics of folded plate on structural stiffness[J]. Journal of Machine Design, 2019,36(4): 27-31. | |

| 10 | 秦勤, 王建伟, 刘星岩, 等. 复合蛋盒型夹层结构动态压缩的力学性能研究[J]. 稀有金属材料与工程, 2021, 50(11): 4103-4112. |

| Qin Qin, Wang Jian-wei, Liu Xing-yan, et al. Study on dynamic compression properties of egg-box sandwich structure[J]. Rare Metal Materials and Engineering, 2021, 50(11): 4103-4112. | |

| 11 | 邓云飞, 周楠, 田锐, 等. S型碳纤维褶皱夹芯结构低速冲击响应特性实验研究[J]. 航空学报, 2022, 43(6): 469-480. |

| Deng Yun-fei, Zhou Nan, Tian Rui, et al. Research on the response characteristics of sandwich structure with S-shaped CFRP folded core under low velocity impact[J]. Acta Aeronautica et Astronautica Sinica, 2022, 43(6): 469-480. | |

| 12 | Mohammadabadi M, Jarvis J, Yadama V, et al. Predictive models for elastic bending behavior of a wood composite sandwich panel[J]. Forests, 2020, 11(6): No. 624. |

| 13 | Khan M S, Abdul-Latif A, Koloor S S R, et al. Representat-ive cell analysis for damage-based failure model of polymer hexagonal honeycomb structure under the out-of-plane loadings[J]. Polymers, 2020, 13(1): No. 52. |

| 14 | Chen J, Hao N, Pan L, et al. Characteristics of compressive mechanical properties and strengthening mechanism of 3D-printed grid beetle elytron plates[J]. Journal of Materials Science, 2020, 55(20): 8541-8552. |

| 15 | Ha N S, Lu G, Xiang X. Energy absorption of a bio-inspired honeycomb sandwich panel[J]. Journal of Materials Science, 2019, 54(8): 6286-6300. |

| 16 | Song J F, Xu S C, Wang H X, et al. Bionic design and multi-objective optimization for variable wall thickness tube inspired bamboo structures[J]. Thin-Walled Structures, 2018, 125: 76-88. |

| 17 | Song J, Xu S, Liu S, et al. Design and numerical study on bionic columns with grooves under lateral impact[J]. Thin-Walled Structures, 2020, 148: No. 106546. |

| 18 | 霍鹏, 许述财, 范晓文, 等. 鹿角骨单位仿生薄壁管斜向冲击耐撞性研究[J]. 爆炸与冲击, 2020, 40(11): 127-138. |

| Huo Peng, Xu Shu-cai, Fan Xiao-wen, et al. Oblique impact resistance of a bionic thin-walled tube based on antles osteon[J]. Explosion and Shock Waves, 2020, 40(11): 127-138. | |

| 19 | Suksangpanya N, Yaraghi N A, Kisailus D, et al. Twisting cracks in Bouligand structures[J]. Journal of the Mechanical Behavior of Biomedical Materials, 2017, 76: 38-57. |

| 20 | Suksangpanya N, Yaraghi N A, Pipes R B, et al. Crack twisting and toughening strategies in Bouligand architectures[J]. International Journal of Solids and Structures, 2018, 150: 83-106. |

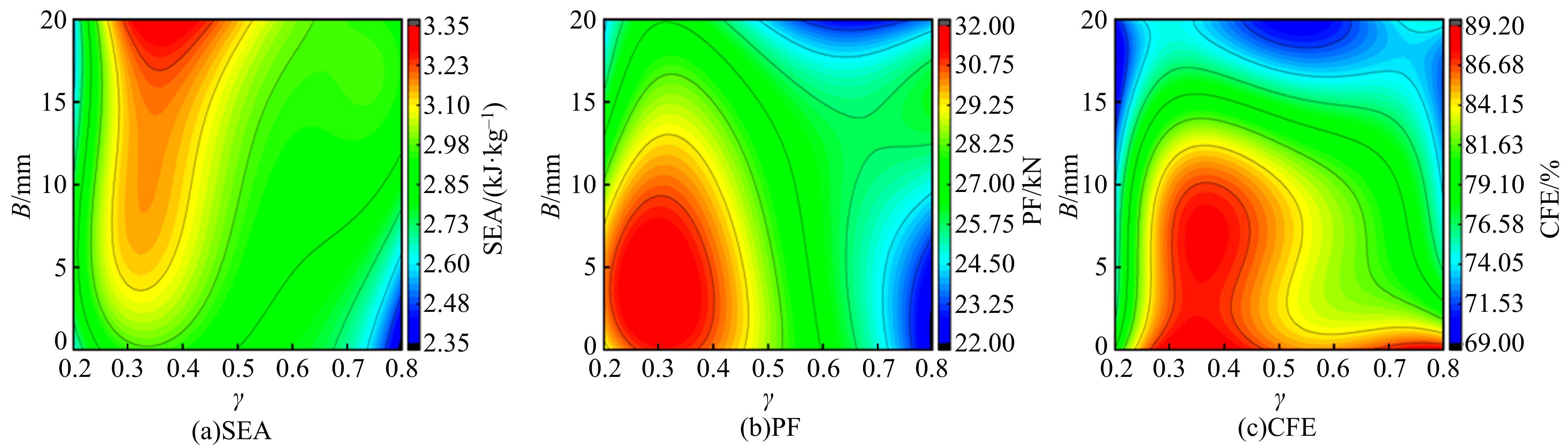

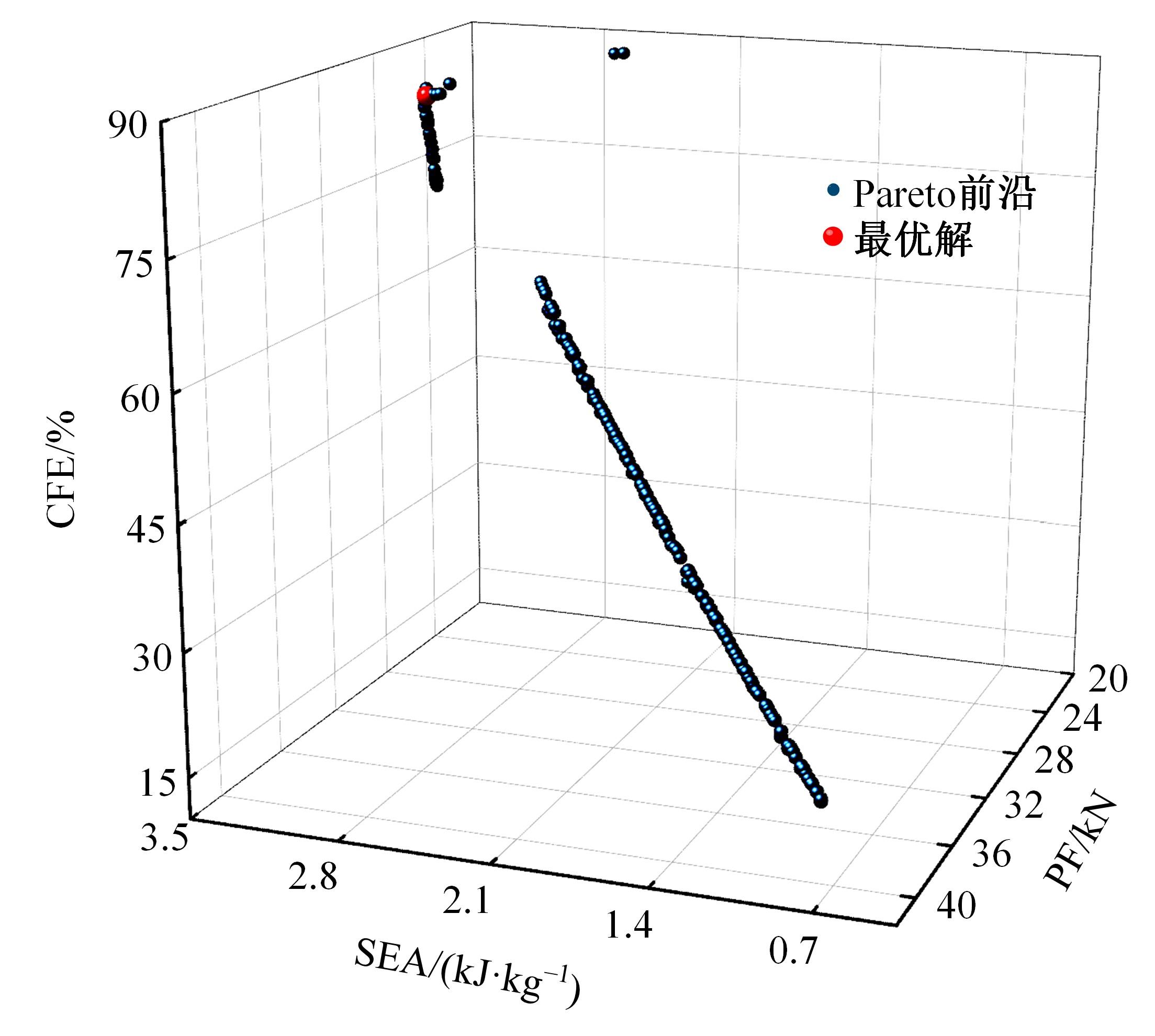

| 21 | Huang H, Yang X, Yan Q, et al. Crashworthiness analysis and multiobjective optimization of bio-inspired sandwich structure under impact load[J]. Thin-Walled Structures, 2022, 172: No. 108840. |

| 22 | 黄晗, 许述财, 陈姮. 仿生波纹夹层结构耐撞性分析及优化[J]. 爆炸与冲击, 2021, 41(8): 36-46. |

| Huang Han, Xu Shu-cai, Chen Heng. Crashworthiness analysis and optimization of bionic corrugated sandwich structures[J]. Explosion and Shock Waves, 2021, 41(8): 36-46. | |

| 23 | 黄晗, 闫庆昊, 向枳昕, 等. 基于虾螯的仿生多胞薄壁管耐撞性分析及优化[J]. 吉林大学学报: 工学版, 2022, 52(3): 716-724. |

| Huang Han, Yan Qing-hao, Xiang Zhi-xin, et al. Crashworthi-ness investigation and optimization of bionic multi-cell tube based on shrimp chela[J]. Journal of Jilin University (Engineering and Technology Edition), 2022, 52(3): 716-724. | |

| 24 | 杨欣, 范晓文, 许述财, 等. 仿虾螯结构薄壁管设计及耐撞性分析[J]. 爆炸与冲击, 2020, 40(4): 62-72. |

| Yang Xin, Fan Xiao-wen, Xu Shu-cai, et al. Design and crashworthiness analysis of thin-walled tubes based on a shrimp chela structure[J]. Explosion and Shock Waves, 2020, 40(4): 62-72. | |

| 25 | Patek S N, Caldwell R L. Extreme impact and cavitation forces of a biological hammer: strike forces of the peacock mantis shrimp Odontodactylus scyllarus[J]. Journal of Experimental Biology, 2005, 208(19): 3655-3664. |

| 26 | Grunenfelder L K, Milliron G, Herrera S, et al. Ecologically driven ultrastructural and hydrodynamic designs in stomatopod cuticles[J]. Advanced Materials, 2018, 30(9): No. 1705295. |

| 27 | Nia A A, Chahardoli S. Optimizing the layout of nested three-tube structures in quasi-static axial collapse[J]. Thin-Walled Structures, 2016, 107: 169-181. |

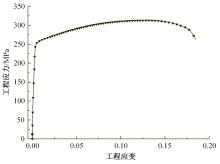

| 28 | Manes A, Peroni L, Scapin M, et al. Analysis of strain rate behavior of an Al 6061 T6 alloy[J]. Procedia Engineering, 2011, 10: 3477-3482. |

| 29 | Gong C, Bai Z, Lv J, et al. Crashworthiness analysis of bionic thin-walled tubes inspired by the evolution laws of plant stems[J]. Thin-Walled Structures, 2020, 157: No. 107081. |

| 30 | 马芳武, 梁鸿宇, 赵颖, 等. 内凹三角形负泊松比结构耐撞性多目标优化设计[J]. 吉林大学学报: 工学版, 2020, 50(1): 29-35. |

| Ma Fang-wu, Liang Hong-yu, Zhao Ying, et al. Multi-objective crashworthiness optimization design of concave triangles cell structure with negative Poisson′s ratio[J]. Journal of Jilin University (Engineering and Technology Edition), 2020,50(1): 29-35. | |

| 31 | 马超, 高云凯, 刘哲, 等. 骨架式车身多材料及梁截面形状和尺寸优化[J]. 吉林大学学报: 工学版, 2021, 51(5): 1583-1592. |

| Ma Chao, Gao Yun-kai, Liu Zhe, et al. Optimization of multi-material and beam cross-sectional shape and dimension of skeleton-type body[J]. Journal of Jilin University (Engineering and Technology Edition), 2021, 51(5): 1583-1592. |

| [1] | Xiao-lin DENG,Fu-mo YANG,Shan-gan QIN. Comparative analysis on crashworthiness of a novel bamboo⁃like hexagonal gradient hierarchical multicellular tube [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(2): 333-345. |

| [2] | Xiao WU,Wen-ku SHI,Nian-cheng GUO,Yan-yan ZHAO,Zhi-yong CHEN,Xin-peng LI,Zhuo SUN,Jian LIU. Multi-objective optimization of hypoid gears based on Ease off [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(1): 76-85. |

| [3] | Xiao ZHOU,Yi-jie LIANG,Zhong-xuan XI,Yu-tao WANG. Welding deformation and compensation method of B-pillar in body-in-white [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(8): 2212-2218. |

| [4] | Chang-jiang ZHENG,Huan HU,Mu-qing DU. Design of multimodal express delivery network structure considering hub failure [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(8): 2304-2311. |

| [5] | Guo-hong TIAN,Peng-jie DAI. Active collision avoidance method of driverless vehicle based on partheno genetic algorithm [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(8): 2404-2409. |

| [6] | Ying-xin HUI,Jia-wei CHEN. Squeezed branch pile groups optimization method based on improved genetic algorithm [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(7): 2089-2098. |

| [7] | Xin CHEN,Guan-chen ZHANG,Kang-ming ZHAO,Jia-ning WANG,Li-fei YANG,De-rong SITU. Influence of lap welds on the lightweight design of welded aluminum structures [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(5): 1282-1288. |

| [8] | Yan-bo LI,Bai-song LIU,Bo-bin YAO,Jun-shuo CHEN,Kai-fa QU,Qi-sheng WU,Jie-ning CAO. Location of electrical changing station of expressway considering stochastic characteristics of road network [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(5): 1364-1371. |

| [9] | Hong-bo YANG,Wen-ku SHI,Zhi-yong CHEN,Nian-cheng GUO,Yan-yan ZHAO. Multi⁃objective optimization of macro parameters of helical gear based on NSGA⁃Ⅱ [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(4): 1007-1018. |

| [10] | Hai-bo LONG,Jia-qi YANG,Liang YIN,Xue-yu ZHAO,Zi-quan XIANG. Multi-objective decision-making on emergency material distribution under uncertain demand based on robust optimization [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(4): 1078-1084. |

| [11] | Ying HE,Jun-song FAN,Wei WANG,Geng SUN,Yan-heng LIU. Joint optimization of secure communication and trajectory planning in unmanned aerial vehicle air⁃to⁃ground [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(3): 913-922. |

| [12] | Min MA,Da-wei HU,Lan SHU,Zhuang-lin MA. Resilience assessment and recovery strategy on urban rail transit network [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(2): 396-404. |

| [13] | Pei-ran YING,Xiao-qing ZENG,Tuo SHEN,Teng-fei YUAN,Hai-feng SONG,Yi-zeng WANG. Redundant operation code-based intelligent algorithm for energy⁃efficient driving of high-speed train [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(12): 3404-3414. |

| [14] | Jin-song ZHU,Ya-ting QIN,Zhou-qiang LIU. Section optimization design of prestressed UHPC-NC composite beams [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(11): 3151-3159. |

| [15] | Han-wu LIU,Yu-long LEI,Xiao-feng YIN,Yao FU,Xing-zhong LI. Multi⁃point control strategy optimization for auxiliary power unit of range⁃extended electric vehicle [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(8): 1741-1750. |

|

||