Journal of Jilin University(Engineering and Technology Edition) ›› 2023, Vol. 53 ›› Issue (2): 346-354.doi: 10.13229/j.cnki.jdxbgxb20210087

Previous Articles Next Articles

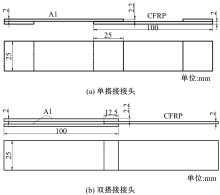

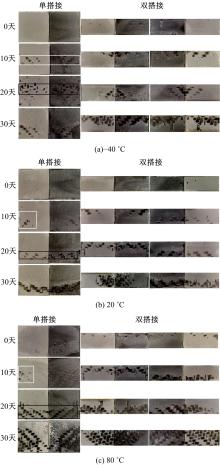

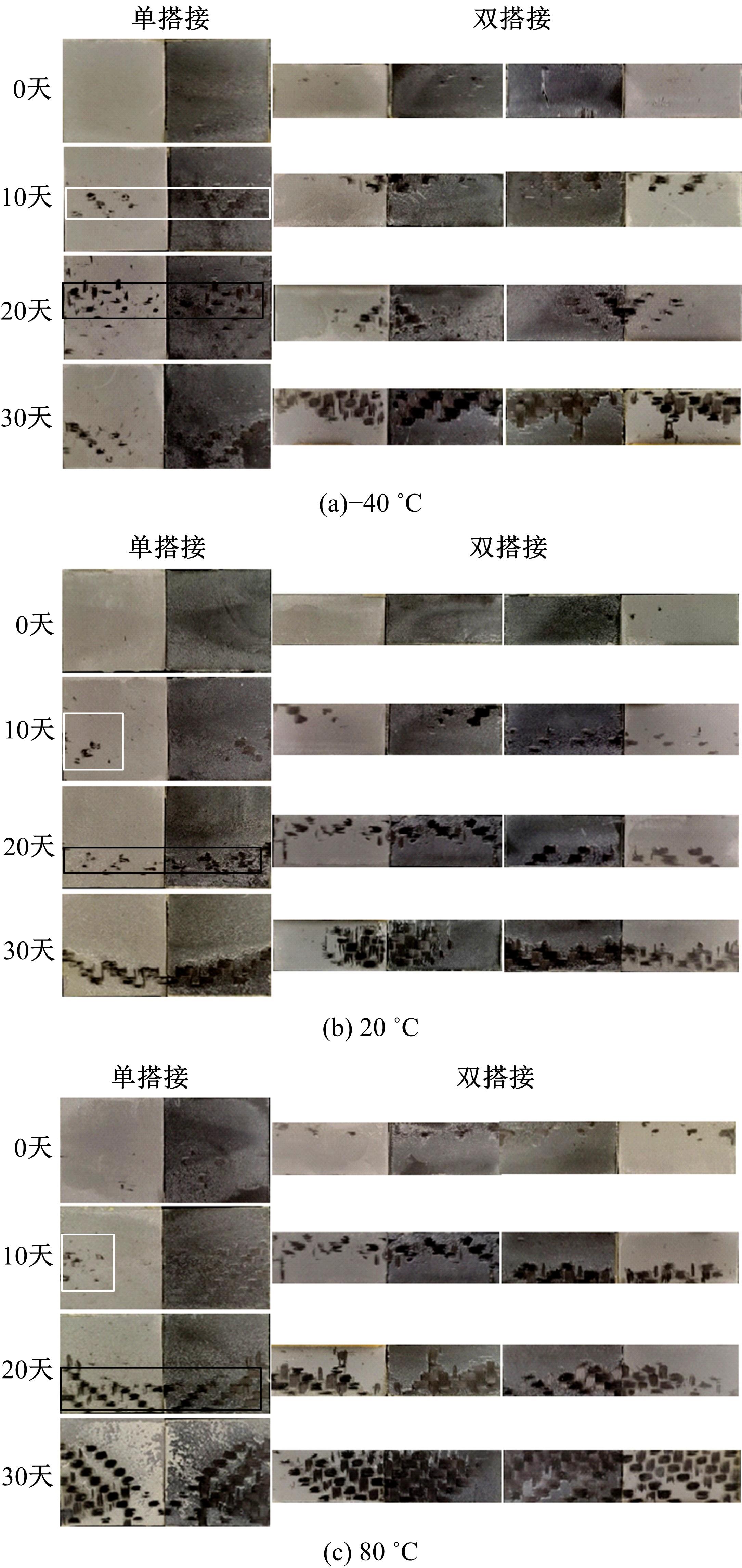

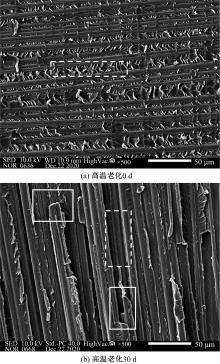

Failure comparison of single and double lap joints after high temperature aging

Deng-feng WANG( ),Hong-li CHEN,Jing-xin NA,Xin CHEN(

),Hong-li CHEN,Jing-xin NA,Xin CHEN( )

)

- State Key Laboratory of Automotive Simulation and Control,Jilin University,Changchun 130022,China

CLC Number:

- U463.82

| 1 | , 轻型汽车污染物排放限值及测量方法(中国第六阶段) [S]. |

| 2 | 谭伟, 那景新, 任俊铭, 等. 高低温老化对碳纤维增强复合材料层间力学性能的影响[J]. 吉林大学学报:工学版, 2020, 50(4): 1324-1332. |

| Tan Wei, Na Jing-xin, Ren Jun-ming, et al. Effect of high and low temperature aging on interlaminar mechanical properties of carbon fiber reinforced composites[J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(4): 1324-1332. | |

| 3 | Witik R A, Payet J, Michaud V, et al. Assessing the life cycle costs and environmental performance of lightweight materials in automobile applications[J]. Composites Part A: Applied Science and Manufacturing, 2011, 42(11): 1694-1709. |

| 4 | 慕文龙,那景新,谭伟,等.基于FTIR分析的CFRP-铝合金粘接接头剩余强度预测[J].吉林大学学报:工学版, 2021, 51(1): 139-146. |

| Mu Wen-long, Na Jing-xin, Tan Wei, et al. Residual strength prediction of adhesive CFRP-aluminum alloy adhesively bonded joint based on FTIR analysis[J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(1): 139-146. | |

| 5 | Liu Q, Lin Y, Zong Z, et al. Lightweight design of carbon twill weave fabric composite body structure for electric vehicle[J]. Composite Structures, 2013, 97: 231-238. |

| 6 | Budhe S, Banea M D, De Barros S, et al. An updated review of adhesively bonded joints in composite materials[J]. International Journal of Adhesion and Adhesives, 2017, 72: 30-42. |

| 7 | Groche P, Wohletz S, Brenneis M, et al. Joining by forming—a review on joint mechanisms, applications and future trends[J]. Journal of Materials Processing Technology, 2014, 214(10): 1972-1994. |

| 8 | Costa M, Viana G, da Silva L F M, et al. Environmental effect on the fatigue degradation of adhesive joints: a review[J]. The Journal of Adhesion, 2017, 93(1/2): 127-146. |

| 9 | 秦国锋,那景新,慕文龙,等.高温老化对CFRP/铝合金粘接接头失效的影响[J]. 吉林大学学报:工学版, 2019, 49(4): 1063-1071. |

| Qin Guo-feng, Na Jing-xin, Mu Wen-long,et al.Degradation failure of adhesively bonded CFRP/ aluminum alloy subjected to high temperature environment[J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1063-1071. | |

| 10 | Pecora M, Pannier Y, Lafarie-Frenot M C, et al. Effect of thermo-oxidation on the failure properties of an epoxy resin[J]. Polymer Testing, 2016, 52: 209-217. |

| 11 | Wolfrum J, Eibl S, Lietch L. Rapid evaluation of long-term thermal degradation of carbon fibre epoxy composites [J]. Composites Science and Technology, 2009, 69(3/4): 523-530. |

| 12 | Yao M, Zhu D, Yao Y, et al. Experimental study on basalt FRP/steel single-lap joints under different loading rates and temperatures[J]. Composite Structures, 2016, 145: 68-79. |

| 13 | Qin G F, Na J X, Mu W L, et al. Effect of continuous high temperature exposure on the adhesive strength of epoxy adhesive, CFRP and adhesively bonded CFRP-aluminum alloy joints[J]. Composites Part B:Engineering, 2018, 154: 43-55. |

| 14 | Cassidy P E, Johnson J M, Locke C E. The relationship of glass transition temperature to adhesive strength[J]. The Journal of Adhesion, 1972, 4(3): 183-191. |

| 15 | Zhang Y, Adams R D, da Silva L F M. Effects of curing cycle and thermal history on the glass transition temperature of adhesives[J]. The Journal of Adhesion, 2014, 90(4): 327-345. |

| 16 | Banea M D, de Sousa F S M, da Silva L F M,et al. Effects of temperature and loading rate on the mechanical properties of a high temperature epoxy adhesive[J]. Journal of Adhesion Science and Technology, 2011, 25(18): 2461-2474. |

| 17 | Firmo J P, Roquette M G, Correia J R, et al. Influence of elevated temperatures on epoxy adhesive used in CFRP strengthening systems for civil engineering applications[J]. International Journal of Adhesion and Adhesives, 2019, 93: 102333. |

| 18 | 孙靖先,葛美周,赵香国,等.粘接在轨道交通车辆上的应用进展[J]. 机车车辆工艺, 2020(2): 15-16, 23. |

| Sun Jing-xian, Ge Mei-zhou, Zhao Xiang-guo,et al. Application progress of adhesive bonding in rail transit vehicles[J]. Locomotive & Rolling Stock Technology, 2020(2): 15-16, 23. | |

| 19 | Zamani P, Jaamialahmadi A, da Silva L F M. The influence of GNP and nano-silica additives on fatigue life and crack initiation phase of Al-GFRP bonded lap joints subjected to four-point bending[J]. Composites Part B: Engineering, 2021, 207: 108589. |

| 20 | Lin Y C, Chen X, Zhang H J, et al. Effects of hygrothermal aging on epoxy-based anisotropic conductive film[J]. Materials Letters, 2006, 60(24): 2958-2963. |

| 21 | Lowe A, Fox B, Otieno-Alego V. Interfacial ageing of high temperature carbon/bismaleimide composites[J]. Composites Part A: Applied Science and Manufacturing, 2002, 33(10): 1289-1292. |

| 22 | Skourlis T P, McCullough R L. The effect of temperature on the behavior of the interphase in polymeric composites[J]. Composites Science and Technology, 1993, 49(4): 363-368. |

| 23 | 陈仲堂,赵德平,李彦平.数理统计[M].北京:化学工业出版社, 2014. |

| 24 | Buch X, Shanahan M E R. Influence of the gaseous environment on the thermal degradation of a structural epoxy adhesive[J]. Journal of Applied Polymer Science, 2000, 76(7): 987-992. |

| 25 | Na J, Mu W, Qin G, et al. Effect of temperature on the mechanical properties of adhesively bonded basalt FRP-aluminum alloy joints in the automotive industry [J]. International Journal of Adhesion and Adhesives, 2018, 85: 138-148. |

| 26 | Liu S, Cheng X, Zhang Q, et al. An investigation of hygrothermal effects on adhesive materials and double lap shear joints of CFRP composite laminates[J]. Composites Part B: Engineering, 2016, 91: 431-440. |

| [1] | Ke-yong WANG,Da-tong BAO,Su ZHOU. Data-driven online adaptive diagnosis algorithm towards vehicle fuel cell fault diagnosis [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(9): 2107-2118. |

| [2] | Qi-ming CAO,Hai-tao MIN,Wei-yi SUN,Yuan-bin YU,Jun-yu JIANG. Hydrothermal characteristics of proton exchange membrane fuel cell start⁃up at low temperature [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(9): 2139-2146. |

| [3] | Hai-lin KUI,Ze-zhao WANG,Jia-zhen ZHANG,Yang LIU. Transmission ratio and energy management strategy of fuel cell vehicle based on AVL⁃Cruise [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(9): 2119-2129. |

| [4] | Yan LIU,Tian-wei DING,Yu-peng WANG,Jing DU,Hong-hui ZHAO. Thermal management strategy of fuel cell engine based on adaptive control strategy [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(9): 2168-2174. |

| [5] | Cheng LI,Hao JING,Guang-di HU,Xiao-dong LIU,Biao FENG. High⁃order sliding mode observer for proton exchange membrane fuel cell system [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(9): 2203-2212. |

| [6] | Pei ZHANG,Zhi-wei WANG,Chang-qing DU,Fu-wu YAN,Chi-hua LU. Oxygen excess ratio control method of proton exchange membrane fuel cell air system for vehicle [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(9): 1996-2003. |

| [7] | Xun-cheng CHI,Zhong-jun HOU,Wei WEI,Zeng-gang XIA,Lin-lin ZHUANG,Rong GUO. Review of model⁃based anode gas concentration estimation techniques of proton exchange membrane fuel cell system [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(9): 1957-1970. |

| [8] | Yao-wang PEI,Feng-xiang CHEN,Zhe HU,Shuang ZHAI,Feng-lai PEI,Wei-dong ZHANG,Jie-ran JIAO. Temperature control of proton exchange membrane fuel cell thermal management system based on adaptive LQR control [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(9): 2014-2024. |

| [9] | Guang-di HU,Hao JING,Cheng LI,Biao FENG,Xiao-dong LIU. Multi⁃objective sliding mode control based on high⁃order fuel cell model [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(9): 2182-2191. |

| [10] | Feng-xiang CHEN,Qi WU,Yuan-song LI,Tian-de MO,Yu LI,Li-ping HUANG,Jian-hong SU,Wei-dong ZHANG. Matching,simulation and optimization for 2.5 ton fuel cell/battery hybrid forklift [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(9): 2044-2054. |

| [11] | Xiao-hua WU,Zhong-wei YU,Zhang-ling ZHU,Xin-mei GAO. Fuzzy energy management strategy of fuel cell buses [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(9): 2077-2084. |

| [12] | Qing GAO,Hao-dong WANG,Yu-bin LIU,Shi JIN,Yu CHEN. Experimental analysis on spray mode of power battery emergency cooling [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(8): 1733-1740. |

| [13] | Kui-yang WANG,Ren HE. Recognition method of braking intention based on support vector machine [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(8): 1770-1776. |

| [14] | Jun-cheng WANG,Lin-feng LYU,Jian-min LI,Jie-yu REN. Optimal sliding mode ABS control for electro⁃hydraulic composite braking of distributed driven electric vehicle [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(8): 1751-1758. |

| [15] | Han-wu LIU,Yu-long LEI,Xiao-feng YIN,Yao FU,Xing-zhong LI. Multi⁃point control strategy optimization for auxiliary power unit of range⁃extended electric vehicle [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(8): 1741-1750. |

|