Journal of Jilin University(Engineering and Technology Edition) ›› 2024, Vol. 54 ›› Issue (9): 2723-2732.doi: 10.13229/j.cnki.jdxbgxb.20221431

Flow field simulation and test of air delivery system for orchard multi⁃duct sprayer

Xin YANG( ),Yu-xiao LIU,Yang WANG,Chun-hao CHEN,Lin-shuo LYU

),Yu-xiao LIU,Yang WANG,Chun-hao CHEN,Lin-shuo LYU

- College of Mechanical and Electrical Engineering,Hebei Agricultural University,Baoding 071001,China

CLC Number:

- S491

| 1 | 郑永军, 陈炳太, 吕昊暾, 等. 中国果园植保机械化技术与装备研究进展[J]. 农业工程学报, 2020, 36(20): 110-124. |

| Zheng Yong-jun, Chen Bing-tai, Lv Hao-tun, et al. Research progress of orchard plant protection mechanization technology[J]. Transactions of the Chinese Society of Agricultural Engineering, 2020, 36(20): 110-124. | |

| 2 | Yue S, Heping Z, Hui L, et al. Development of a laser-guided, embedded-computer-controlled, air-assisted precision sprayer[J]. Transactions of the ASABE, 2017, 60(6): 1827-1838. |

| 3 | 王震涛, 牛浩, 唐玉荣, 等. 果园喷雾机械及技术的研究现状[J]. 塔里木大学学报, 2019, 31(3): 83-91. |

| Wang Zhen-tao, Niu Hao, Tang Yu-rong, et al. Research status of orchard spray machinery and technology [J]. Journal of Tarim University, 2019, 31(3): 83-91. | |

| 4 | Kasner E J, Fenske R A, Hoheisel G A, et al. Spray drift from a conventional axial fan airblast sprayer in a modern orchard work environment[J]. Annals of Work Exposures and Health, 2018,62(9): 1134-1146. |

| 5 | 王杰, 陶振洋, 茹煜, 等. 风机在农林植保机械中的应用研究现状及展望[J]. 中国农机化学报, 2016, 37(9): 67-74. |

| Wang Jie, Tao Zhen-yang, Ru Yu, et al. Research progress and outlook on application of fan in plant protection machinery of agriculture and forestry[J].Journal of Chinese Agricultural Mechanization, 2016, 37(9): 67-74. | |

| 6 | Ade G, Molari G, Rondelli V. Recycling tunnel sprayer for poesticide dose adjustment to the crop environment[J]. Transactions of the ASABE, 2007, 50(2): 409-413. |

| 7 | Salcedo R, Ariane V, Granell R,et al. Eulerian-lagrangian model of the behaviour of droplets produced by an air-assisted sprayer in a citrus orchard[J]. Biosystems Engineering, 2017, 154: 76-91. |

| 8 | 姜红花, 牛成强, 刘理民, 等. 果园多风管风送喷雾机风量调控系统设计与试验[J]. 农业机械学报, 2020, 51(): 298-307. |

| Jiang Hon-ghua, Niu Cheng-qiang, Liu Li-min, et al. Design and experiment of air volume control system of orchard multi-pipe air sprayer[J]. Journal of Luoyang Institute of Technology, 2020, 51(Sup.2): 298-307. | |

| 9 | 李建平, 边永亮, 霍鹏, 等.喷雾机风送式环形喷管喷雾装置设计与试验优化[J].农业机械学报, 2021, 52(9): 79-88. |

| Li Jian-ping, Bian Yong-liang, Huo Peng,et al. Design and experimental optimization of spray air supply annular nozzle spray device[J]. Journal of Agricultural Machinery, 2021,52 (9): 79-88. | |

| 10 | Delele M A, De M A, Sonck B, et al.Modelling andvalidation of the air flow generated by a cross flow air sprayer as affected by travel speed and fan speed[J]. Biosystems Engineering, 2005, 92(2): 165-174. |

| 11 | 翟长远, 张燕妮, 窦汉杰, 等. 果园风送喷雾机出风口风场CFD建模与试验[J]. 智慧农业:中英文, 2021, 3(3): 70-81. |

| Zhai Chang-yuan, Zhang Yan-ni, Dou Han-jie, et al. CFD modeling and experiment of airflow at the air outlet of orchard air-assisted sprayer[J]. Smart Agriculture (English and Chinese), 2021, 3(3): 70-81. | |

| 12 | Endalew A M, Debaerb C, Rutten N, et al. A new integrated CFD modelling approach towards air-assisted orchard spraying-Part I: model development and effect of wind speed and direction on sprayer airflow[J]. Computers and Electronics in Agriculture, 2010, 71(1): 128-136. |

| 13 | Duga A T, Delele M A, Rysen K, et al. Development and validation of a 3D CFD model of drift and its application to air-assisted orchard sprayers[J]. Biosystems Engineering, 2016, 154: 62-75. |

| 14 | 宋淑然, 夏侯炳, 卢玉华, 等. 风送式喷雾机导流器结构优化及试验研究[J]. 农业工程学报, 2012, 28(6): 7-12. |

| Song Shu-ran, Xia Hou-bing, Lu Yu-hua, et al. Structural optimization and experiment on fluid director of air-assisted sprayer[J]. Transactions of the Chinese Society of Agricultural Engineering, 2012, 28(6): 7-12. | |

| 15 | 徐奕蒙. 基于CFD技术的喷雾机风场研究与风送喷雾机控制系统研制[D]. 杨凌: 西北农林科技大学水利与建筑工程学院, 2019. |

| Xu Yi-meng. Research on wind farm of sprayer based on CFD technology and control system of air sprayer[D]. Yangling:College of Water Resources and Building Engineering, Northwest Agriculture and Forestry University, 2019. | |

| 16 | 臧帅. 果园喷雾机风送喷雾系统设计仿真与试验研究[D]. 镇江: 江苏大学农业工程学院, 2020. |

| Zang Shuai. Design, simulation and experimental study of an air-assisted spraying system of orchard sprayer[D]. Zhenjiang: College of Agricultural Engineering, Jiangsu University, 2020. | |

| 17 | 向浩, 兰兴欣, 于磊. 基于Solidworks软件的风扇自然风模拟仿真分析的研究[J]. 中国机械, 2014(17): No.218. |

| Xiang Hao, Lan Xing-xin, Yu Lei. Research on simulation analysis of natural wind simulation of fan based on Solidworks software[J]. China Machinery, 2014(17): No.218. | |

| 18 | 王平. 基于Flow Simulation 的直埋供热管道热损失模拟分析[J]. 区域供热, 2021, 210(1): 29-33, 43. |

| Wang Ping. Simulation of heat loss in direct buried heating pipes based on Flow Simulation[J]. District Heating, 2021, 210(1): 29-33, 43. | |

| 19 | 张燕妮. 果园喷药空间风场及风树交互作用CFD建模研究[D]. 杨凌: 西北农林科技大学机械与电子工程学院, 2021. |

| Zhang Yan-ni. CFD modeling research on orchard spatial airflow field and interaction between airflow and tree for orchard spraying[D]. Yangling: College of Mechanical and Electronic Engineering,Northwest Agriculture and Forestry University, 2021. | |

| 20 | Wang H Q, Zou Z Y, Chen S Q, et al. Numerical simulation investigation on pressure loss of diffusion tank of axial main fan[J]. Journal of Coal Science & Engineering, 2011, 17(4): 447-449. |

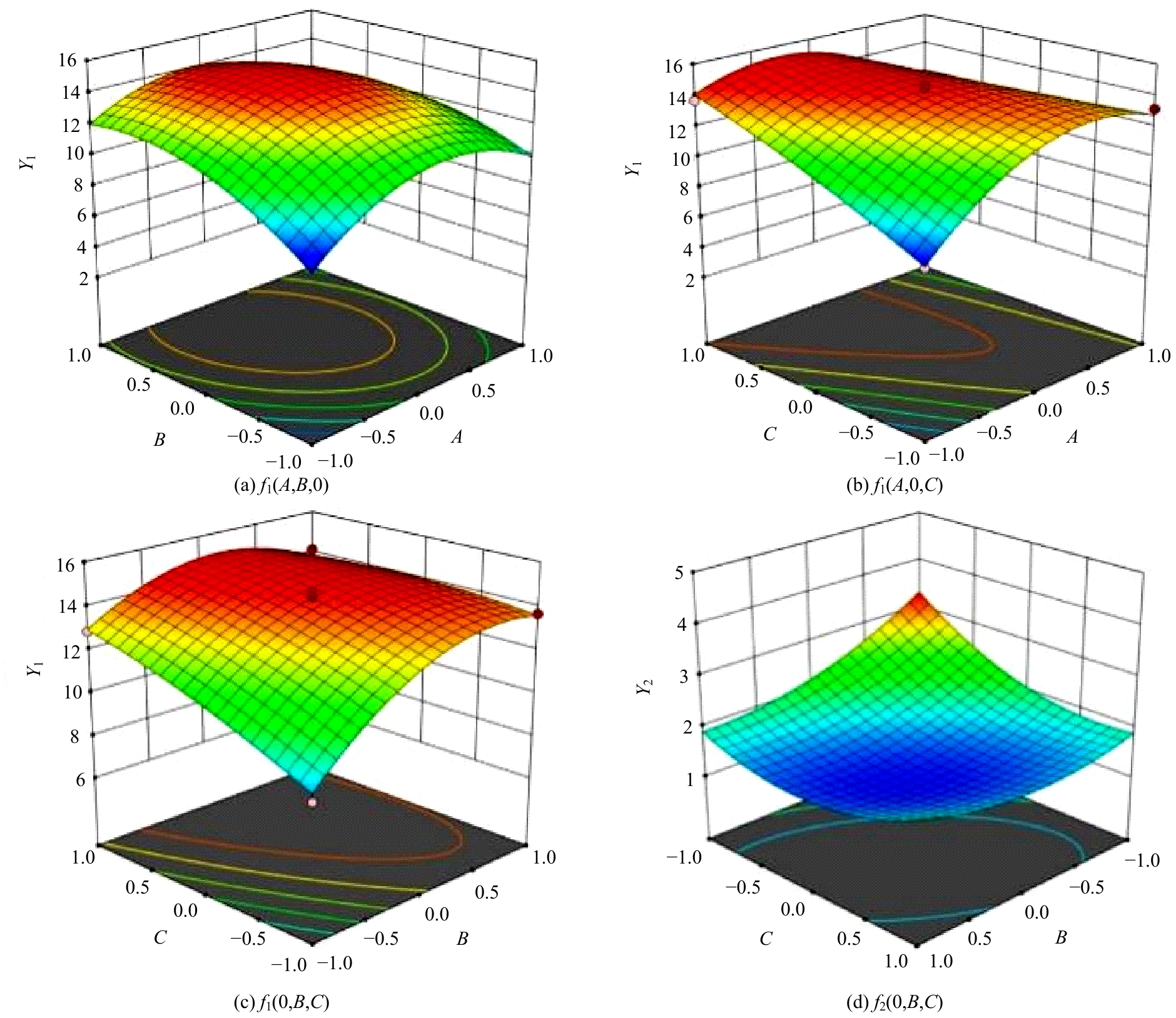

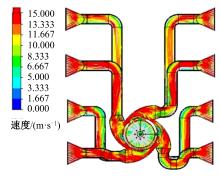

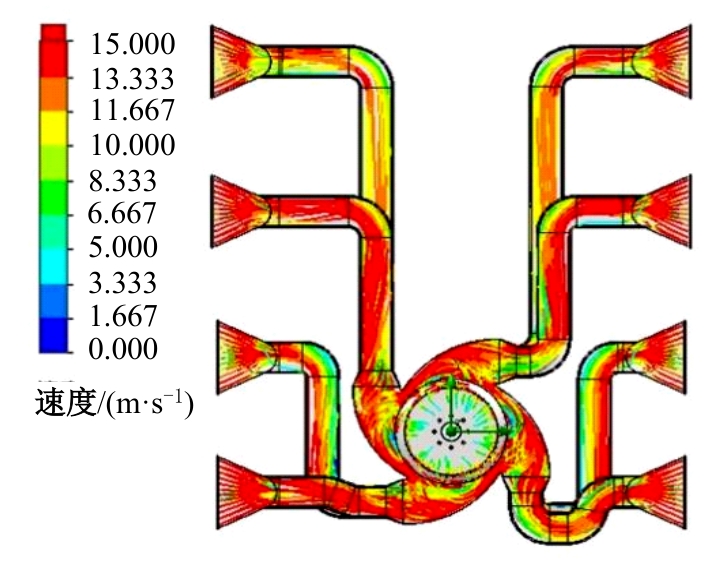

| 21 | 李建平, 边永亮, 杨欣, 等. 果园多风机风送喷雾机作业参数优化与试验[J]. 吉林大学学报: 工学版, 2022, 52(10): 2474-2485. |

| Li Jian-ping, Bian Yong-liang, Yang Xin,et al. Operational parameter optimization and testing of an air-assisted multi-fan orchard sprayer [J]. Journal of Jilin University (Engineering and Technology Edition), 2022, 52(10): 2474-2485. | |

| 22 | 戴奋奋. 风送喷雾机风量的选择与计算[J]. 植物保护, 2008(6): 124-127. |

| Dai Fen-fen. Selection and calculation of the blowing rate of air-assisted sprayers [J]. Plant Protection, 2008(6): 124-127. | |

| 23 | .风送式果园喷雾机作业质量 [S]. |

| 24 | 曹军琳, 祁力钧, 杨知伦, 等. 基于图像处理的雾滴沉积分布试验研究[J]. 中国农业大学学报, 2019, 24(1): 130-137. |

| Cao Jun-lin, Qi Li-jun, Yang Zhi-lun, et al. Experimental study of droplet distribution based on image processing[J]. Journal of China Agricultural University, 2019, 24(1): 130-137. | |

| 25 | 陈奕璇. 喷雾药液性质与农药沉积利用率关系研究[D]. 北京: 中国农业科学院植物保护研宄所, 2021. |

| Chen Yi-xuan. Study on the relationship between the properties of spray liquid and the utilization rate of pesticide[D]. Beijing: Institute of Plant Protection,Chinese Academy of Agricultural Sciences, 2021. |

| [1] | Guo-qiang DUN,Xing-peng WU,Xin-xin JI,Fu-li ZHANG,Wen-yi JI,Li-gui ZHU. Design and experiment of corn strip swing tube fertilizer spreader [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(9): 2697-2707. |

| [2] | Guo-zhong ZHANG,Kai-quan DING,Zheng-bo LI,Long CHEN,Nan-rui TANG,Wan-ru LIU,Hai-dong HUANG,Yong ZHOU,Hong-chang WANG. Design and experiment of biomimetic sliding plate for rice direct seeding machine based on loach body surface [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(5): 1482-1492. |

| [3] | Fu ZHANG,Li-min LOU,Dan QIAN,Shi-qiang WANG,Chun-ling FENG,Yi-rong ZHAO. Optimum design and test of compression mechanism of big square baler [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(4): 1166-1174. |

| [4] | Peng-fei ZHOU,Xue-geng CHEN,He-wei MENG,Rong-qing LIANG,Bing-cheng ZHANG,Za KAN. Design and experiment of trommel with function of separating soil from residual film mixture [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(9): 2718-2731. |

| [5] | Wei-jian LIU,Xi-wen LUO,Shan ZENG,Zhi-qiang WEN,Li ZENG. Field turning mechanism and performance test of crawler reclaimed rice harvester [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(9): 2695-2705. |

| [6] | Mao-jian ZHANG,Jing-fu JIN,Yi-ying CHEN,Ting-kun CHEN. Vibration symmetry characteristics of wheeled tractor structure [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(7): 2136-2142. |

| [7] | Guang-qiang ZHU,Tian-yu LI,Fu-jun ZHOU,Wen-ming WANG. Design and experiment of bionic ear picking device for fresh corn [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(4): 1231-1244. |

| [8] | Guo-qiang DUN,Wen-hui LIU,Ning MAO,Xing-peng WU,Wen-yi JI,Hong-yan MA. Optimization design and experiment of alternate post changing seed metering device for soybean plot breeding [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(1): 285-296. |

| [9] | Shan ZENG,Deng-pan HUANG,Wen-wu YANG,Wei-jian LIU,Zhi-qiang WEN,Li ZENG. Design and test of the chassis of triangular crawler reclaiming rice harvester [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(8): 1943-1950. |

| [10] | Guo-liang WEI,Qing-song ZHANG,Biao WANG,Kun HE,Qing-xi LIAO. Analysis and experiment on parameters of plough body of rapeseed direct seeder [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(7): 1709-1718. |

| [11] | Jia-jie LIU,Lan MA,Wei XIANG,Bo YAN,Qing-hua WEN,Jiang-nan LYU. Design of 4QM⁃4.0 fibre crops green fodder combine harvester [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(12): 3039-3048. |

| [12] | Bai-gong ZENG,Kui-liang LI,Jin YE,Li-li REN,Jaloliddin Rashidov,Ming ZHANG. Design and experiment of harvesting device for industrialized production line of Shanghaiqing [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(11): 2756-2764. |

| [13] | Xing-yu WAN,Qing-xi LIAO,Ya-jun JIANG,Yi-yin SHAN,Yu ZHOU,Yi-tao LIAO. Discrete element simulation and experiment of mechanized harve- sting and chopping process for fodder rape crop harvest [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(11): 2735-2745. |

| [14] | Guang-qiang ZHU,Tian-yu LI,Fu-jun ZHOU. Design and experiment of flexible clamping and conveying device for bionic ear picking of fresh corn [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(10): 2486-2500. |

| [15] | Rong-qing LIANG,Bo ZHONG,He-wei MENG,Zhi-min SUN,Za KAN. Design of 4QJ⁃3 type pickup header of silage oat [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(5): 1887-1896. |

|

||