Journal of Jilin University(Engineering and Technology Edition) ›› 2022, Vol. 52 ›› Issue (8): 1943-1950.doi: 10.13229/j.cnki.jdxbgxb20210205

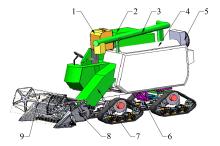

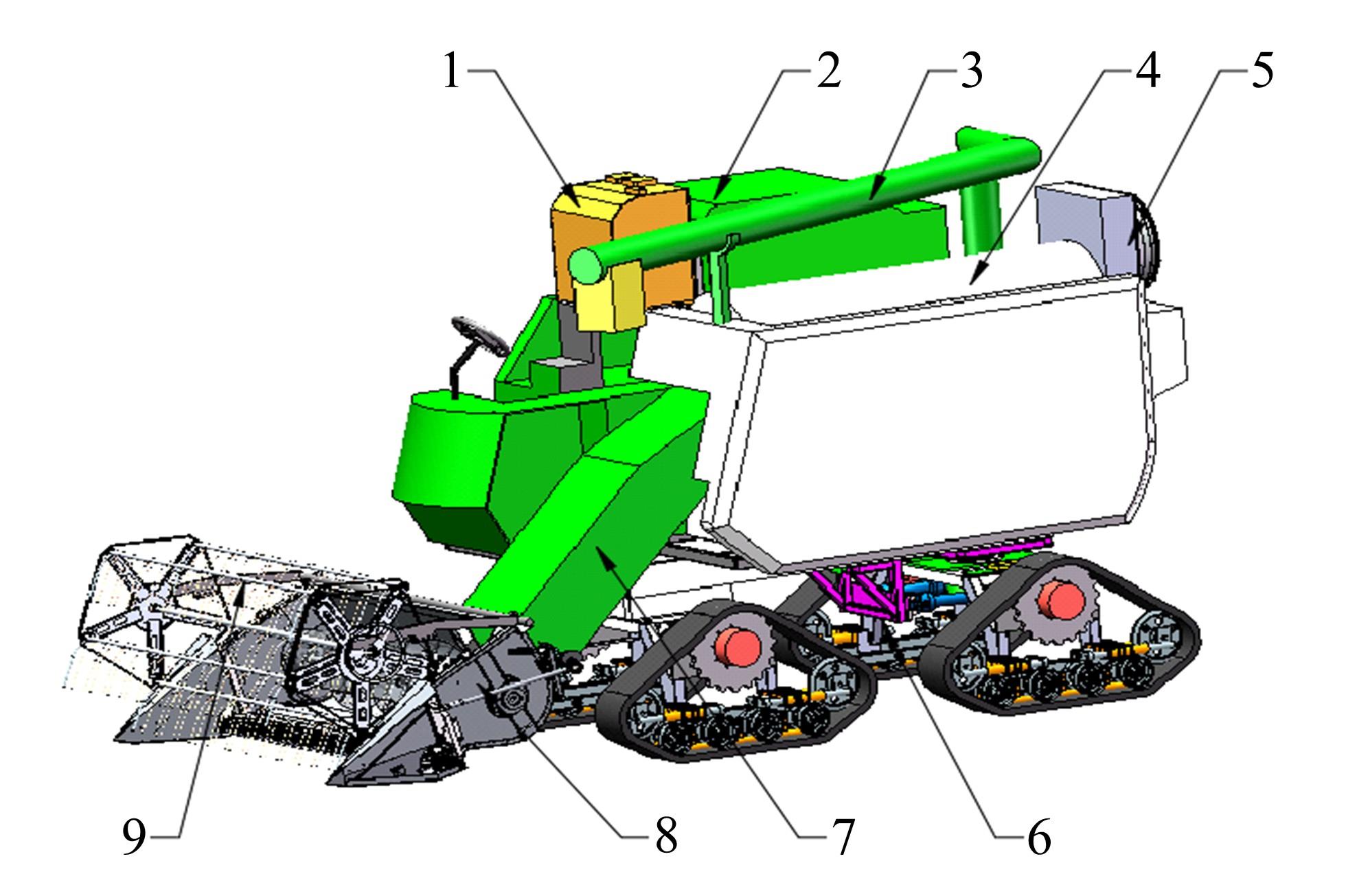

Design and test of the chassis of triangular crawler reclaiming rice harvester

Shan ZENG1,2( ),Deng-pan HUANG1,2,Wen-wu YANG1,2(

),Deng-pan HUANG1,2,Wen-wu YANG1,2( ),Wei-jian LIU1,2,Zhi-qiang WEN1,2,Li ZENG1,2

),Wei-jian LIU1,2,Zhi-qiang WEN1,2,Li ZENG1,2

- 1.College of Engineering,South China Agricultural University,Guangzhou 510642,China

2.Key Laboratory of Key Technology on Agricultural Machine and Equipment,Ministry of Education,South China Agricultural University,Guangzhou 510642,China

CLC Number:

- S225.4

| 1 | 谢华安. 超级稻再生栽培高产特征及示范效果[C]∥2007中国科协年会专题论坛“红莲型杂交水稻学术专题研讨会”论文汇编, 武汉, 湖北, 中国, 2007: 189-195. |

| 2 | 郭文韬. 略论中国再生稻的历史发展[J]. 中国农史, 1993(4): 1-6. |

| Guo Wen-tao. On the historical development of ratooning rice in china[J]. Chinese Agricultural History, 1993(4): 1-6. | |

| 3 | 张桂莲,屠乃美,袁菊红,等. 播种期对再生稻腋芽萌发和产量的影响[J]. 湖南农业大学学报:自然科学版, 2005(3): 229-232. |

| Zhang Gui-lian, Tu Nai-mei, Yuan Ju-hong, et al. Effects of sowing stage on the sprouting of axillary bud and yield of ratooning rice[J]. Journal of Hunan Agricultural University(Natural Sciences), 2005(3): 229-232. | |

| 4 | 朱永川, 熊洪, 徐富贤, 等. 再生稻栽培技术的研究进展[J]. 中国农学通报, 2013, 29(36): 1-8. |

| Zhu Yong-chuan, Xiong Hong, Xu Fu-xian, et al. Progress on research of ratoon rice cultivation technology[J]. Chinese Agricultural Science Bulletin, 2013, 29(36): 1-8. | |

| 5 | 农业部关于印发《全国种植业结构调整规划(2016~2020年)》的通知[J]. 中华人民共和国农业部公报, 2016(5): 47-55. |

| Notice of ministry of agriculture on the issuance of national planting industry structure adjustment plan (2016~2020)[J]. Bulletin of the Ministry of Agriculture of the People's Republic of China, 2016(5): 47-55. | |

| 6 | 刘正忠. 再生稻头季机收关键技术分析[J]. 农业科技通讯, 2013(4): 118-120. |

| Liu Zheng-zhong. Analysis on key technology of mechanical harvesting of ratoon rice[J]. Agricultural Science and Technology Communication, 2013(4): 118-120. | |

| 7 | 郭翰林, 林建, 施火结, 等. 再生稻头季收获机械化的现状与发展趋势[J]. 福建农机, 2016(1): 16-18. |

| Guo Han-lin, Lin Jian, Shi Huo-jie, et al. Current situation and development trend of first harvest mechanization of ratoon rice[J]. Fujian Agricultural Machinery, 2016(1): 16-18. | |

| 8 | 马晓春. 中稻蓄留再生稻品种筛选与头季收获方式对再生季产量的影响[D]. 武汉: 华中农业大学植物科学技术学院, 2015. |

| Ma Xiao-chun. Studies on variety screening ratoon rice and the effect of main crop harvesting model on ratoon crop yield[D]. Wuhan: College of Plant Science and Technology, Huazhong Agricultural University, 2015. | |

| 9 | 肖森. 再生稻头季机收对再生季产量和品质的影响[D]. 武汉: 华中农业大学植物科学技术学院, 2018. |

| Xiao Sen. Effect of mechanical harvesting of main crop on the grain yield and quality of ratoon crop on ratooned rice[D]. Wuhan: College of Plant Science and Technology, Huazhong Agricultural University, 2018. | |

| 10 | 张国忠,张翼翔,黄见良,等. 再生稻割穗机的设计与性能试验[J]. 华中农业大学学报, 2016, 35(1): 131-136. |

| Zhang Guo-zhong, Zhang Yi-xiang, Huang Jian-liang, et al. Design and performance test of ratoon rice cutting machine[J]. Journal of Huazhong Agricultural University, 2016, 35(1): 131-136. | |

| 11 | 刘竣. 高地隙轮式再生稻收割机的设计与试验[D]. 广州: 华南农业大学工程学院, 2019. |

| Liu Jun. Design and experiment of high clearance wheeled ratoon rice harvester[D]. Guangzhou: College of Engineering, South China Agricultural University, 2019. | |

| 12 | 付建伟,张国忠,谢干,等. 双通道喂入式再生稻收获机研制[J]. 农业工程学报, 2020, 36(3): 11-20. |

| Fu Jian-wei, Zhang Guo-zhong, Xie Gan, et al. Development of double-channel feeding harvester for ratoon rice[J]. Transactions of the Chinese Society of Agricultural Engineering, 2020, 36(3): 11-20. | |

| 13 | 施国标,林逸,张昕. 动力转向技术及其发展[J]. 农业机械学报, 2006(10): 173-176. |

| Shi Guo-biao, Lin Yi, Zhang Xin. Power steering of car and its development [J]. Transactions of the Chinese Society for Agricultural Machinery, 2006(10): 173-176. | |

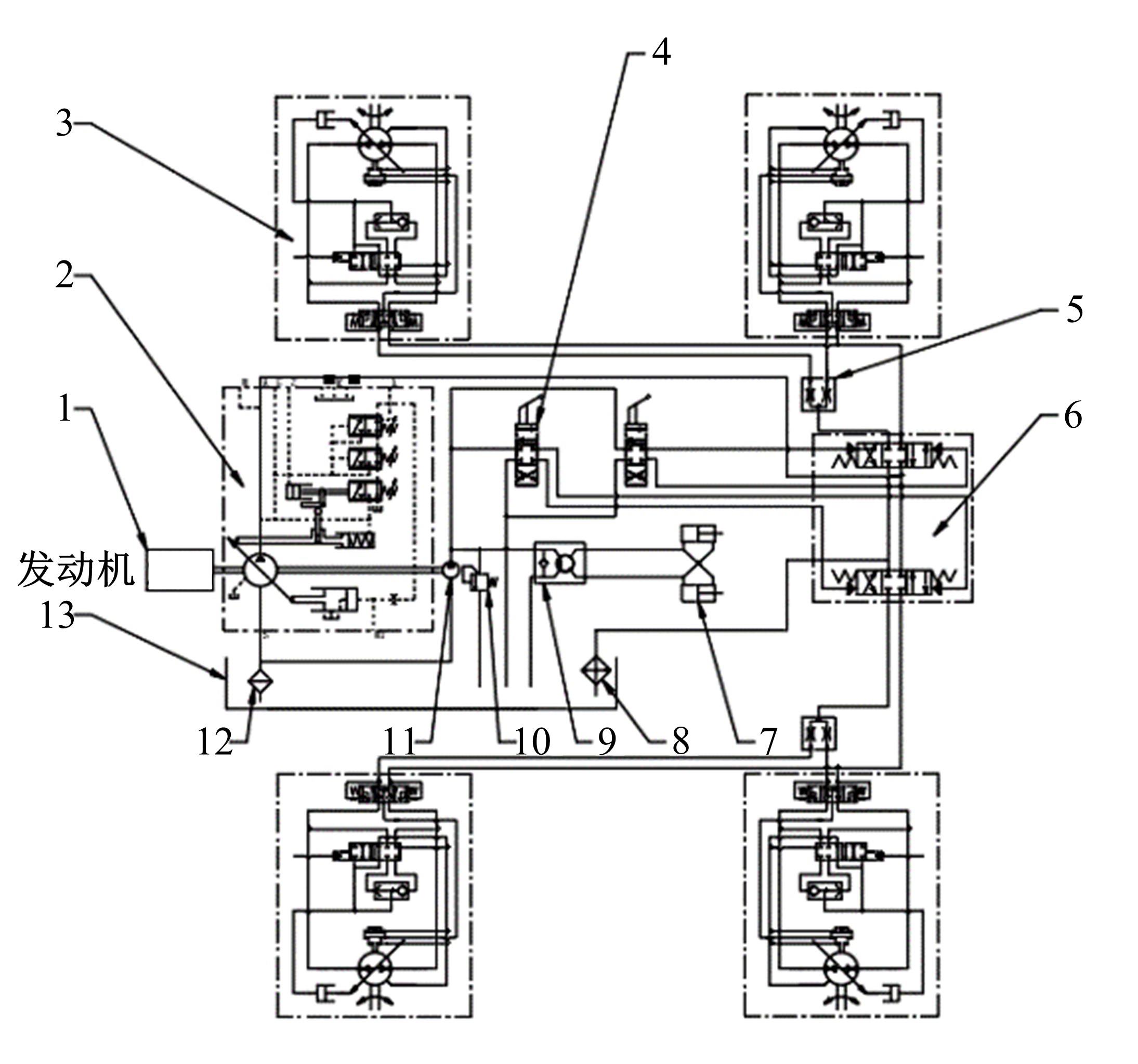

| 14 | 时元玲. 全液压顶驱电液比例容积调速系统研究[D]. 长春: 吉林大学建设工程学院, 2018. |

| Shi Yuan-ling. Development and investigation of electro-hydraulic proportional volumetric speed control system of hydraulic top drive[D]. Changchun: College of Construction Engineering, Jilin University, 2018. | |

| 15 | Li Y, He L. Counterbalancing speed control for hydrostatic drive heavy vehicle under long down-slope[J]. IEEE/ASME Transactions on Mechatronics, 2015, 20(4): 1533-1542. |

| 16 | Huang J, Dong Z, Quan L, et al. Development of a dual displacement controlled circuit for hydraulic shovel swing motion[J]. Automation in Construction, 2015, 57: 166-174. |

| 17 | 王宝山. 全液压驱动高地隙履带作业车设计研究[D]. 郑州: 河南农业大学机电工程学院, 2017. |

| Wang Bao-shan. Design and research of full hydraulic drive high clearance tracked vehicle[D]. Zhengzhou: College of Mechanical and Electrical Engineering, Henan Agricultural University, 2017. | |

| 18 | 蔡岗础. 油茶果采摘机三角橡胶履带轮底盘的设计与力学分析[D]. 长沙: 中南林业科技大学机电工程学院, 2014. |

| Cai Gang-chu. The design and mechanical analysis of oil camellia fruit picking machines rubber track system chassis[D]. Changsha: College of Mechanical and Electrical Engineering, Central South University of Forestry and Technology, 2014. | |

| 19 | . 农业机械试验条件测定方法的一般规定 [S]. |

| 20 | . 农业机械生产试验方法 [S]. |

| 21 | . 水稻联合收割机作业质量 [S]. |

| [1] | Guo-liang WEI,Qing-song ZHANG,Biao WANG,Kun HE,Qing-xi LIAO. Analysis and experiment on parameters of plough body of rapeseed direct seeder [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(7): 1709-1718. |

| [2] | Zhao-hui JIN,Le-qi GU,Wei HONG,Fang-xi XIE,Tian YOU. Analysis on pressure fluctuation of hydraulic variable valve actuation [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(4): 773-780. |

| [3] | Tong-jian WANG,Shu-wei YANG,Xiao-dan TAN,Jin-shi CHEN,Tong-wen LIU,Zhen-ling ZHI. Performance analysis of hydraulic excavator based on DEM-MBD co-simulation [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(4): 811-818. |

| [4] | Jian-jun NIE,Xiu-peng YAN,Zong-zheng MA,Xiao-lin XIE,Jia-jie GUO,Ya-lei LYU. Design and trafficability analysis of new bow waist mobile chassis [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(3): 515-524. |

| [5] | Duan-yang GENG,Xiao-dong MU,Guo-dong ZHANG,Zong-yuan WANG,Jun-ke ZHU,Hai-gang XU. Analysis and optimization of cleaning mechanism of wheat combine harvester [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(1): 219-230. |

| [6] | Zun-ling DU,Yi-min ZHANG. Reliability analysis of piston pump under random flow rate [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(6): 1967-1974. |

| [7] | Xing-jun HU,Jing-long ZHANG,Yu-fei LUO,Li XIN,Sheng LI,Jin-rui HU,Wei LAN. Influence investigation of cooling tube structure and airflow direction on thermal⁃hydraulic performance of air⁃cooled charge air cooler [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(6): 1933-1942. |

| [8] | Rong-qing LIANG,Bo ZHONG,He-wei MENG,Zhi-min SUN,Za KAN. Design of 4QJ⁃3 type pickup header of silage oat [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(5): 1887-1896. |

| [9] | Xing-jun HU,Jing-long ZHANG,Li XIN,Yu-fei LUO,Jing-yu WANG,Tian-ming YU. Investigation on influence of cooling tube structure and airflow speed on cold side performance of air⁃cooled charge air cooler [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(5): 1557-1564. |

| [10] | Jia-cheng YUAN,Chang WANG,Kun HE,Xing-yu WAN,Qing-xi LIAO. Effect of components mass ratio under sieve on cleaning system performance for rape combine harvester [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(5): 1897-1907. |

| [11] | Wei LI,Huai-liang ZHANG,Wei QU. Design method of hydraulic straight pipe under random vibration [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(4): 1222-1229. |

| [12] | Zhen SONG,Jun-liang LI,Gui-qiang LIU. Constant flow prediction method of variable speed hydraulic power source based on deep learning and limitation fuzzy [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(3): 1106-1110. |

| [13] | Ji-cheng HUANG,Cheng SHEN,Ai-min JI,Xian-wang LI,Bin ZHANG,Kun-peng TIAN,Hao-lu LIU. Optimization of cutting⁃conveying key working parameters of hemp harvester [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(2): 772-780. |

| [14] | Wei-da WANG,Yan-jie WU,Jia-lei SHI,Liang LI. Electronic hydraulic brake power system control strategy based on driver intention recognition [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(2): 406-413. |

| [15] | Qian CONG,Jin XU,Bo-shuai MA,Xiao-chao ZHANG,Ting-kun CHEN. Design and test of tractor hydraulic suspension system testing device based on virtual simulation [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(2): 754-760. |

|

||