Journal of Jilin University(Engineering and Technology Edition) ›› 2024, Vol. 54 ›› Issue (5): 1482-1492.doi: 10.13229/j.cnki.jdxbgxb.20230666

Design and experiment of biomimetic sliding plate for rice direct seeding machine based on loach body surface

Guo-zhong ZHANG1,2( ),Kai-quan DING1,2,Zheng-bo LI1,2,Long CHEN1,2,Nan-rui TANG1,2,Wan-ru LIU1,2,Hai-dong HUANG1,2,Yong ZHOU1,2,Hong-chang WANG1,2(

),Kai-quan DING1,2,Zheng-bo LI1,2,Long CHEN1,2,Nan-rui TANG1,2,Wan-ru LIU1,2,Hai-dong HUANG1,2,Yong ZHOU1,2,Hong-chang WANG1,2( )

)

- 1.College of Engneering,Huazhong Agricultural University,Wuhan 430070,China

2.Key Laboratory of Agricultural Equipment in Mid-lower Yangtze River,Ministry of Agriculture and Rural Affairs,Wuhan 430070,China

CLC Number:

- S233.71

| 1 | 曹明. 水田土壤承载特性与物理参数相关性研究[D]. 杭州:浙江大学生物系统工程与食品科学学院,2019. |

| Cao Ming. Studies on correlation between soil carrying capacity and physical parameters of paddy soil[D]. Hangzhou: College of Biosystems Engineering and Food Science, Zhejiang University, 2019. | |

| 2 | Gao Y, Zhang G, Wang H, et al. Measuring system design and experiment for ground pressure on seeding skateboard of rice direct seeding machine[J]. Applied Sciences, 2021, 11(21): 10024. |

| 3 | 陈青春,石勇,丁启朔,等. 正反转旋耕作业的秸秆混埋效果比较[J]. 农业工程学报,2015,31(9):13-18. |

| Chen Qing-chun, Shi Yong, Ding Qi-shuo, et al. Comparison of straw incorporation effect with down-cut and up-cut rotary tillage[J]. Transactions of the Chinese Society of Agricultural Engineering, 2015, 31(9): 13-18. | |

| 4 | 王金武,尹大庆,韩永俊,等. 水稻秸秆整株还田机的设计与试验[J]. 农业机械学报,2007,38(10):54-56. |

| Wang Jin-wu, Yin Da-qing, Han Yong-jun . et al. Design and experiment of a rice straw whole plant returning machine[J]. Transactions of the Chinese Society for Agricultural Machinery, 2007, 38(10): 54-56. | |

| 5 | Zhang Guo-zhong, Wang Hong-chang, Du Jun, et al. Prominent problems and thoughts of paddy soil-terrain machine system based on disturbed saturated paddy soil conditions in South China[C]∥ 11th Asia-Pacific Regional Conference of the ISTVS, Harbin, China,2022. |

| 6 | 任露泉,佟金,李建桥,等. 松软地面机械仿生理论与技术[J]. 农业机械学报,2000(1):5-9. |

| Ren Lu-quan, Tong Jin, Li Jian-qiao, et al. Biomimetics of machinery for soft terrain[J]. Transactions of the Chinese Society for Agricultural Machinery, 2000(1): 5-9. | |

| 7 | 李建桥,黄晗,王颖,等. 松软地面机器系统研究进展[J]. 农业机械学报,2015,46(5):306-320. |

| Li Jian-qiao, Huang Han, Wang Ying, et al. Development on research of soft-terrain machine systems[J]. Transactions of the Chinese Society for Agricultural Machinery, 2015, 46(5): 306-320. | |

| 8 | Abouelnadar El Salem, Zhang Guo-zhong, Wang Hong-chang, et al. The effect of integrating a bio-inspired convex structure with a low-surface energy polymer on soil adhesion and friction[J]. Journal of Terramechanics, 2023, 109: 93-100. |

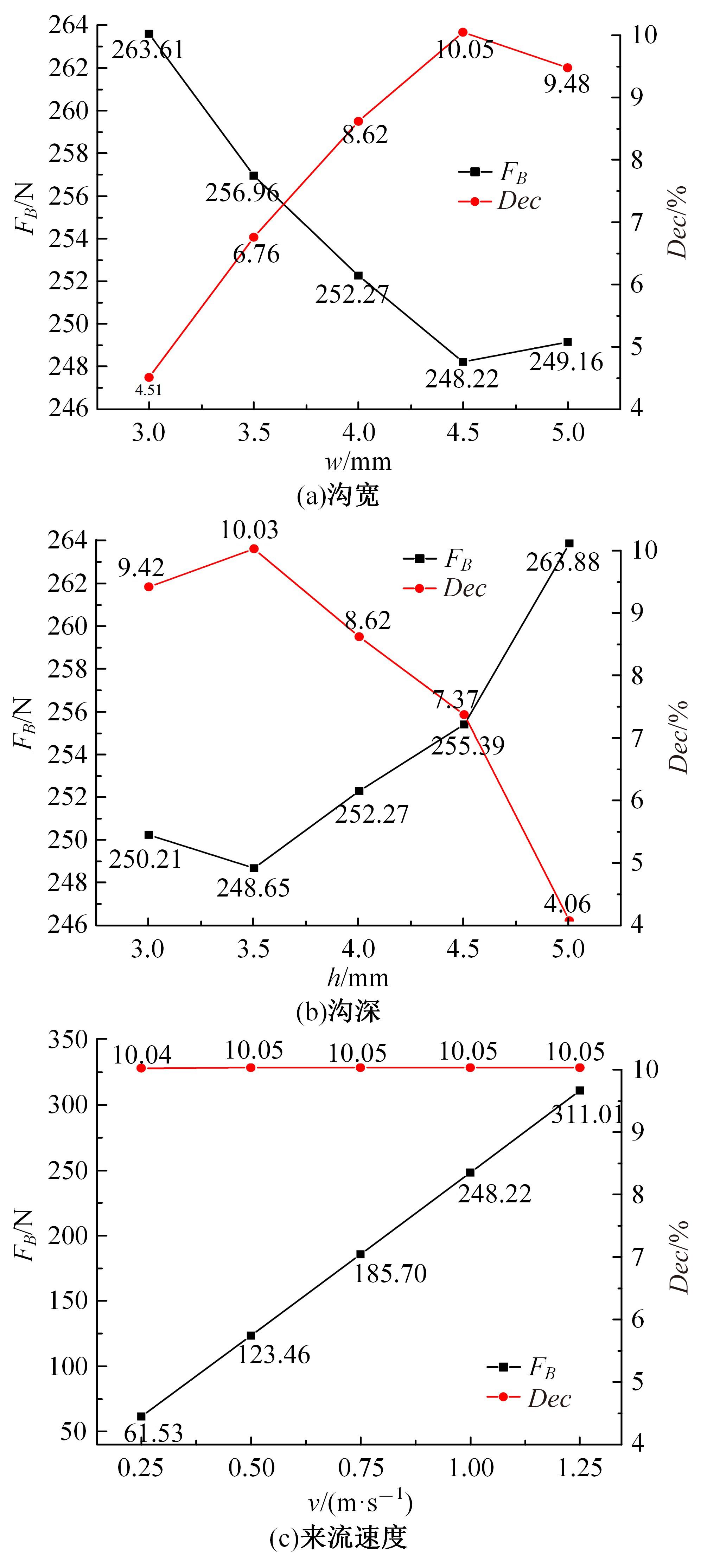

| 9 | Wang Hong-chang, Ding Kai-quan, Zhang Guo-zhong, et al. Research on drag reduction performance of sliding plate of rice direct seeding machine based on non-smooth structure of loach surface[J]. Journal of Terramechanics, 2023, 110:79-85. |

| 10 | 隗海林,王海洲,倪伟新,等. 仿生非光滑表面对车用柴油机螺旋进气道流通特性的影响[J]. 吉林大学学报:工学版,2014,44(3):668-674. |

| Kui Hai-lin, Wang Hai-zhou, Ni Wei-xin, et al. Flow characteristics in diesel helical intake port bionic with non-smooth surface[J]. Journal of Jilin University (Engineering and Technology Edition), 2014, 44(3): 668-674. | |

| 11 | 杨晓东,任露泉. 形体减阻类型、减阻机理与仿生[J]. 农业机械学报,2003(1):130-133. |

| Yang Xiao-dong, Ren Lu-quan. Types and mechanisms of shape drag reduction[J]. Transactions of the Chinese Society for Agricultural Machinery, 2003(1): 130-133. | |

| 12 | Fu Y F, Yuan C Q, Bai X Q. Marine drag reduction of shark skin inspired riblet surfaces[J]. Biosurface and Biotribology, 2017, 3(1): 11-24. |

| 13 | 孙久荣,程红,丛茜,等. 蜣螂(Copris ochus Motschulsky)减粘脱附的仿生学研究[J]. 生物物理学报,2001(4):785-793. |

| Sun Jiu-rong, Cheng Hong, Cong Qian, et al. Bionic study on the dung beetle copris ochus motschulsky for reduction of soil adhesion[J]. Acta Biophysica Sinica, 2001(4): 785-793. | |

| 14 | 张璇,白秀琴,袁成清,等. 防污贝壳表面纹理特征减阻效应仿真分析[J]. 中国造船,2013,54(4):146-154. |

| Zhang Xuan, Bai Xiu-qin, Yuan Cheng-qing, et al. Simulation analysis on drag reduction effect of shell surface texture with function of anti-fouling[J]. Shipbuilding of China, 2013, 54(4): 146-154. | |

| 15 | 任露泉,张成春,田丽梅. 仿生非光滑用于旋成体减阻的试验研究[J]. 吉林大学学报:工学版,2005(4):431-436. |

| Ren Lu-quan, Zhang Cheng-chun, Tian Li-mei. Experimental study on drag reduction for bodies of revolution using bionic non-smoothness[J]. Journal of Jilin University (Engineering and Technology Edition), 2005, 35(4): 431-436. | |

| 16 | 王政,李田,李明,等. 仿生表面微结构减阻优化及机理研究综述[J]. 河北科技大学学报,2017,38(4):325-334. |

| Wang Zheng, Li Tian, Li Ming, et al. Review of mechanical research and aerodynamic drag reduction of bionic surfaces micro-structures[J]. Journal of Hebei University of Science and Technology, 2017, 38(4): 325-334. | |

| 17 | Gu Y, Zhao G, Zheng J, et al. Experimental and numerical investigation on drag reduction of non-smooth bionic jet surface[J]. Ocean Engineering, 2014, 81: 50-57. |

| 18 | Heidarian A, Ghassemi H, Liu P. Numerical analysis of the effects of riblets on drag reduction of a flat plate[J]. Journal of Applied Fluid Mechanics, 2018, 11(3): 679-688. |

| 19 | Walsh M J. Riblets as a viscous drag reduction technique[J]. AIAA Journal, 1983, 21(4): 485-486. |

| 20 | Bechert D W, Bruse M, Hage W, et al. Experiments on drag-reducing surfaces and their optimization with an adjustable geometry[J]. Journal of Fluid Mechanics, 1997, 338: 59-87. |

| 21 | Martin S, Bhushan B. Modeling and optimization of shark-inspired riblet geometries for low drag applications[J]. Journal of Colloid and Interface Science, 2016, 474: 206-215. |

| 22 | 唐俊,刘岩岩,闫一天. 水下航行器仿生非光滑表面减阻特性[J]. 兵工学报,2022,43(5):1135-1143. |

| Tang Jun, Liu Yan-yan, Yan Yi-tian. Drag reduction characteristics of bionic non-smooth surface for underwater vehicle[J]. ActaArmamentarii, 2022, 43(5): 1135-1143. | |

| 23 | Qaisrani R, LI J, Khan M A, et al. Soil adhesion preventing mechanism of bionic bulldozing plates and mouldboard ploughs[J]. Advances in Natural Science, 2010, 3(2): 100-107. |

| 24 | Chirende B, Li J Q, Wen L G, et al. Effects of bionic non-smooth surface on reducing soil resistance to disc ploughing[J]. Science China Technological Sciences, 2010, 53: 2960-2965. |

| 25 | 邬立岩,齐胜,宋玉秋,等. 水田作业机械仿生表面减阻机理的离散元研究[J]. 沈阳农业大学学报,2017,48(1):55-62. |

| Wu Li-yan, Qi Sheng, Song Yu-qiu, et al. A DEM analysis on drag reduction characteristics of paddy field machinery surface with bionic microarchitectures[J]. Journal of Shenyang Agricultural University, 2017, 48(1): 55-62. | |

| 26 | 焦志彬. 插秧机船板表面微观结构仿生减阻研究[D]. 沈阳:沈阳农业大学工程学院,2017. |

| Jiao Zhi-bin. Research on drag reduction of transplanter float with bionic microstructures[D].Shenyang: Engineering College, Shenyang Agricultural University, 2017. | |

| 27 | Yan G, Tian P, Mo J, et al. Low-velocity resistance distortion and bionic drag reduction for ship-type paddy field machinery[J]. International Journal of Agricultural and Biological Engineering, 2020, 13(2): 7-14. |

| 28 | Wang Y, Li N, Ma Y, et al. Field experiments evaluating a biomimetic shark-inspired (BioS) subsoiler for tillage resistance reduction[J]. Soil and Tillage Research, 2020, 196: 104432. |

| 29 | 孙朋朋. 泥鳅粘液中凝集素的提取、分离、纯化及性质研究[D]. 天津:天津科技大学食品科学与工程学院,2019. |

| Sun Peng-peng. Study on extraction, isolation purification and characterization of lection from loach skin mucus[D]. Tianjin: College of Food Science and Engineering, Tianjin University of Science&Technology, 2019. | |

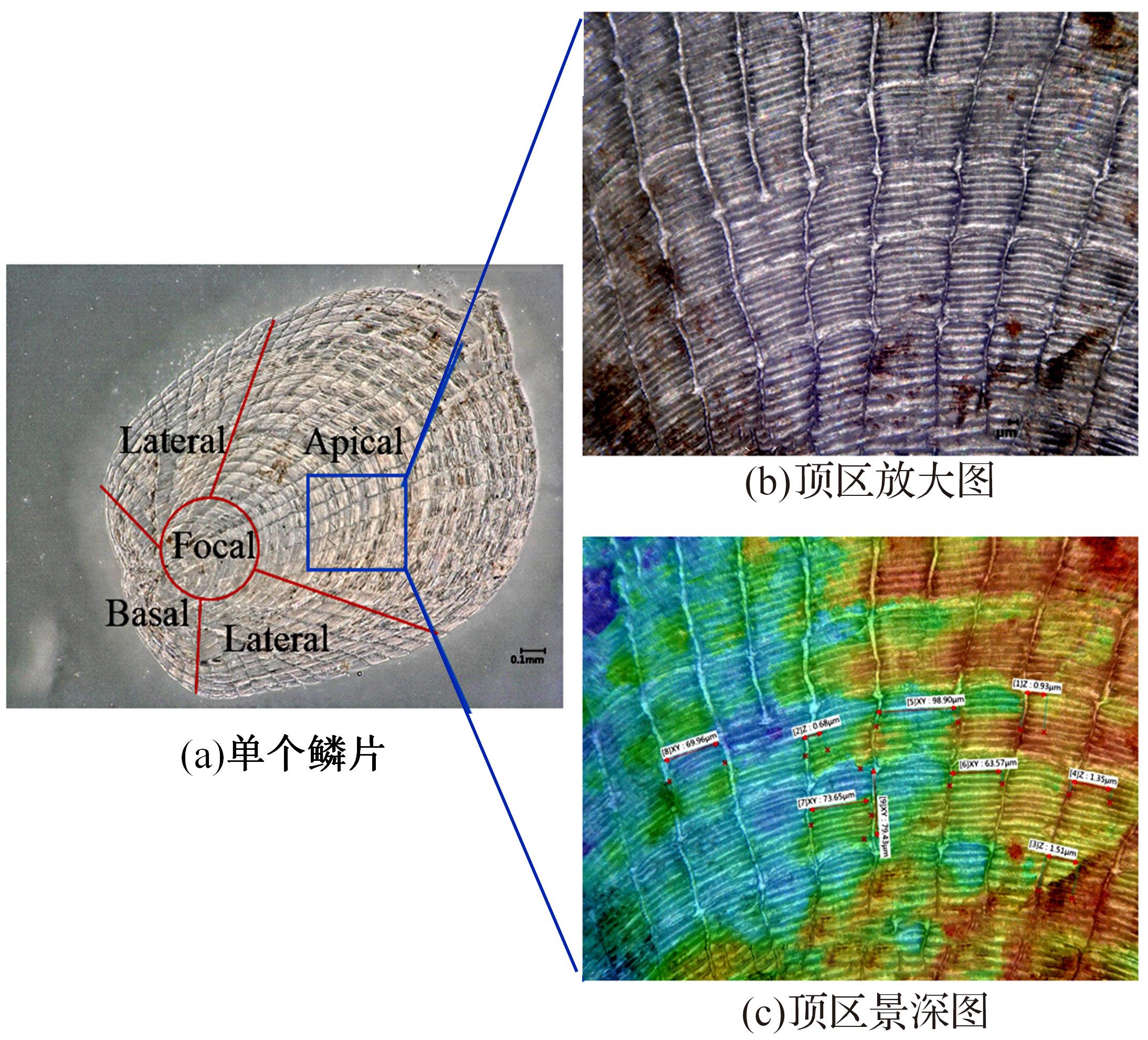

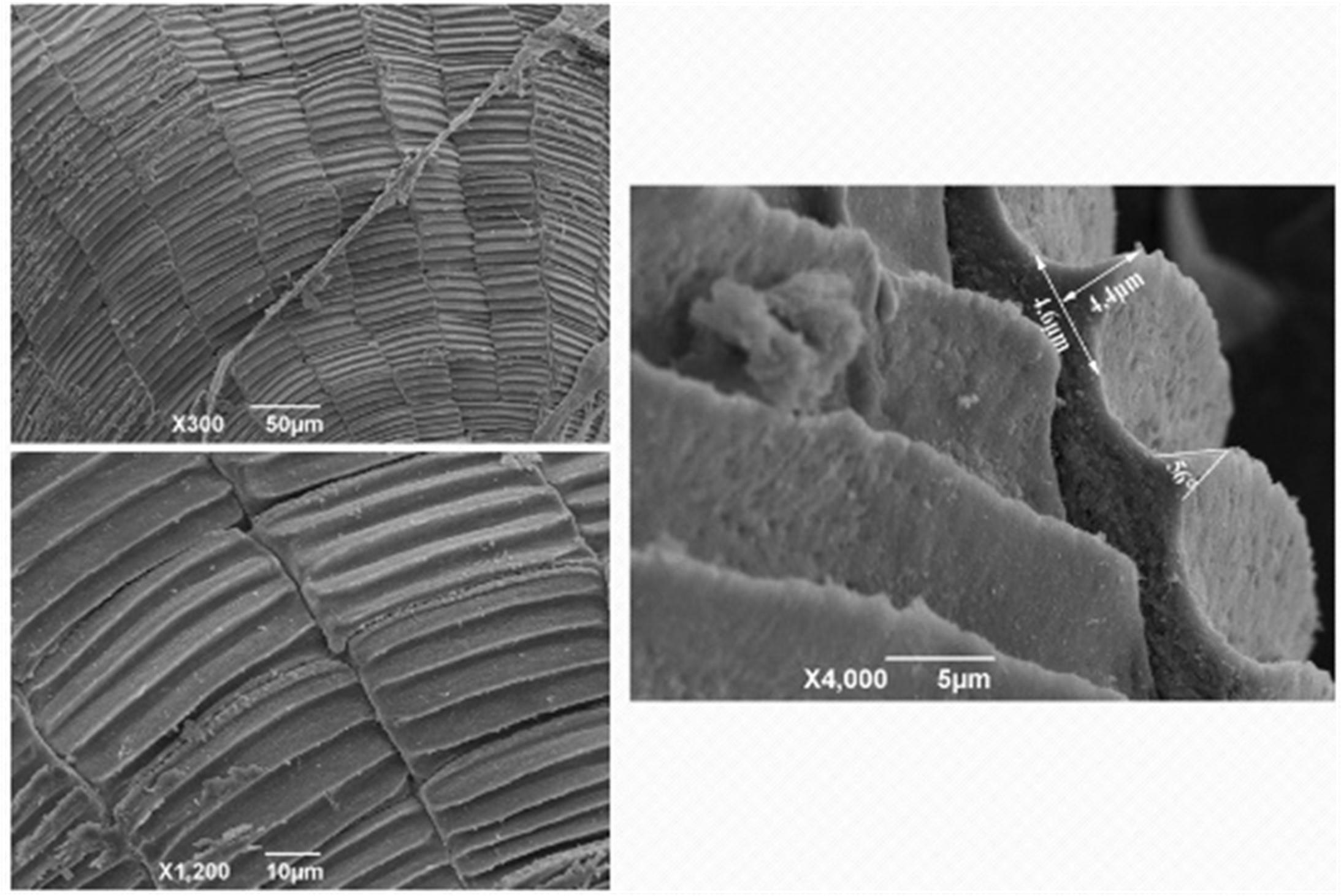

| 30 | 温健. 大鳞副泥鳅(P.Dabryanus)体表柔性微形貌减阻特性仿生研究[D]. 沈阳:沈阳农业大学工程学院,2020. |

| Wen Jian. Study on drag reduction characteristics of P. Dabryanus loach surface flexible micro-morphology[D]. Shenyang: Engineering College, Shenyang Agricultural University, 2020. | |

| 31 | Seo E, Yoon G Y, Kim H N, et al. Morphological features of mucous secretory organ and mucous secretion of loach misgurnus anguillicaudatus skin for friction drag reduction[J]. Journal of Fish Biology, 2020, 96(1): 83-91. |

| 32 | Wu L, Wang H, Song Y, et al. Drag reduction mechanism of paramisgurnus dabryanus loach with self-lubricating and flexible micro-morphology[J]. Scientific Reports, 2020, 10(1): 12873. |

| 33 | Wu L, Wang J, Luo G, et al. Study on the drag reduction characteristics of the surface morphology of paramisgurnus dabryanus loach[J]. Coatings, 2021, 11(11): No. 1357. |

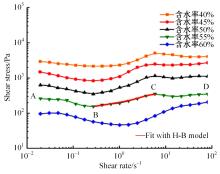

| 34 | 诸葛茜,冉天麟,罗大海. 水田土壤的切变速率与剪切应力关系的试验研究[J]. 武汉工学院学报,1984(3):65-79. |

| Zhuge Qian, Ran Tian-lin, Luo Da-hai. Researches on relation between shear strain rate and shear stress of paddy soils[J]. Journal of Wuhan Institute of Technology, 1984(3): 65-79. | |

| 35 | 杨益,李兴高,李兴春,等. 基于Herschel-Bulkley流变模型的盾构螺旋输送机保压性能[J]. 湖南大学学报:自然科学版,2021,48(11):195-204. |

| Yang Yi, Li Xing-gao, Li Xing-chun, et al. Pressure maintaining performance of shield screw conveyor based on herschel-bulkley rheological model[J]. Journal of Hunan University(Natural Sciences), 2021, 48(11): 195-204. | |

| 36 | Yang Y, Li X G, Su W L. Experimental Investigation on rheological behaviors of bentonite-and CMC-conditioned sands[J]. KSCE Journal of Civil Engineering, 2020, 24(6): 1914-1923. |

| 37 | Jeong S W, Locat J, Leroueil S, et al. Rheological properties of fine-grained sediment: the roles of texture and mineralogy[J]. Canadian Geotechnical Journal, 2010, 47(10): 1085-1100. |

| 38 | 杨闻宇. 剪切载荷作用下高浓度粘性泥沙流变特性的实验研究[D]. 上海:上海交通大学船舶海洋与建筑工程学院,2014. |

| Yang Wen-yu. Experimental study on the rheological properties of dense cohesive sediments under shear loadings[D].Shanghai: School of Naval Architecture, Ocean & Civil Engineering, Shanghai Jiao Tong University, 2014. | |

| 39 | Scholle M, Rund A, Aksel N. Drag reduction and improvement of material transport in creeping films[J]. Archive of Applied Mechanics, 2006, 75: 93-112. |

| [1] | Fu ZHANG,Li-min LOU,Dan QIAN,Shi-qiang WANG,Chun-ling FENG,Yi-rong ZHAO. Optimum design and test of compression mechanism of big square baler [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(4): 1166-1174. |

| [2] | Peng-fei ZHOU,Xue-geng CHEN,He-wei MENG,Rong-qing LIANG,Bing-cheng ZHANG,Za KAN. Design and experiment of trommel with function of separating soil from residual film mixture [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(9): 2718-2731. |

| [3] | Wei-jian LIU,Xi-wen LUO,Shan ZENG,Zhi-qiang WEN,Li ZENG. Field turning mechanism and performance test of crawler reclaimed rice harvester [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(9): 2695-2705. |

| [4] | Mao-jian ZHANG,Jing-fu JIN,Yi-ying CHEN,Ting-kun CHEN. Vibration symmetry characteristics of wheeled tractor structure [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(7): 2136-2142. |

| [5] | Guang-qiang ZHU,Tian-yu LI,Fu-jun ZHOU,Wen-ming WANG. Design and experiment of bionic ear picking device for fresh corn [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(4): 1231-1244. |

| [6] | Guo-qiang DUN,Wen-hui LIU,Ning MAO,Xing-peng WU,Wen-yi JI,Hong-yan MA. Optimization design and experiment of alternate post changing seed metering device for soybean plot breeding [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(1): 285-296. |

| [7] | Shan ZENG,Deng-pan HUANG,Wen-wu YANG,Wei-jian LIU,Zhi-qiang WEN,Li ZENG. Design and test of the chassis of triangular crawler reclaiming rice harvester [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(8): 1943-1950. |

| [8] | Guo-liang WEI,Qing-song ZHANG,Biao WANG,Kun HE,Qing-xi LIAO. Analysis and experiment on parameters of plough body of rapeseed direct seeder [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(7): 1709-1718. |

| [9] | Jia-jie LIU,Lan MA,Wei XIANG,Bo YAN,Qing-hua WEN,Jiang-nan LYU. Design of 4QM⁃4.0 fibre crops green fodder combine harvester [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(12): 3039-3048. |

| [10] | Bai-gong ZENG,Kui-liang LI,Jin YE,Li-li REN,Jaloliddin Rashidov,Ming ZHANG. Design and experiment of harvesting device for industrialized production line of Shanghaiqing [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(11): 2756-2764. |

| [11] | Xing-yu WAN,Qing-xi LIAO,Ya-jun JIANG,Yi-yin SHAN,Yu ZHOU,Yi-tao LIAO. Discrete element simulation and experiment of mechanized harve- sting and chopping process for fodder rape crop harvest [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(11): 2735-2745. |

| [12] | Guang-qiang ZHU,Tian-yu LI,Fu-jun ZHOU. Design and experiment of flexible clamping and conveying device for bionic ear picking of fresh corn [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(10): 2486-2500. |

| [13] | Rong-qing LIANG,Bo ZHONG,He-wei MENG,Zhi-min SUN,Za KAN. Design of 4QJ⁃3 type pickup header of silage oat [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(5): 1887-1896. |

| [14] | Jia-cheng YUAN,Chang WANG,Kun HE,Xing-yu WAN,Qing-xi LIAO. Effect of components mass ratio under sieve on cleaning system performance for rape combine harvester [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(5): 1897-1907. |

| [15] | Zhao XUE,Jun FU,Zhi CHEN,Feng-de WANG,Shao-ping HAN,Lu-quan REN. Optimization experiment on parameters of chopping device of forage maize harvester [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 739-748. |

|

||