吉林大学学报(工学版) ›› 2023, Vol. 53 ›› Issue (12): 3388-3396.doi: 10.13229/j.cnki.jdxbgxb.20220084

• 材料科学与工程 • 上一篇

考虑各向异性的铝合金型材辊弯断裂预测

- 1.吉林大学 辊锻工艺研究所,长春 130022

2.吉林大学 材料科学与工程学院,长春 130022

3.中车长春轨道客车股份有限公司 工程规划发展部,长春 130051

Prediction of fracture of aluminum alloy profiles in roll bending considering anisotropy

Chun-guo LIU1,2( ),Zi-tong LI1,2,Xue-guang ZHANG3,Ming LI1,2

),Zi-tong LI1,2,Xue-guang ZHANG3,Ming LI1,2

- 1.Roll-forging Research Institute,Jilin University,Changchun 130022,China

2.School of Materials Science and Engineering,Jilin University,Changchun 130022,China

3.Engineering Planning and Development Department,CRRC Changchun Railway Vehicles Co. ,Ltd. ,Changchun 130051,China

摘要:

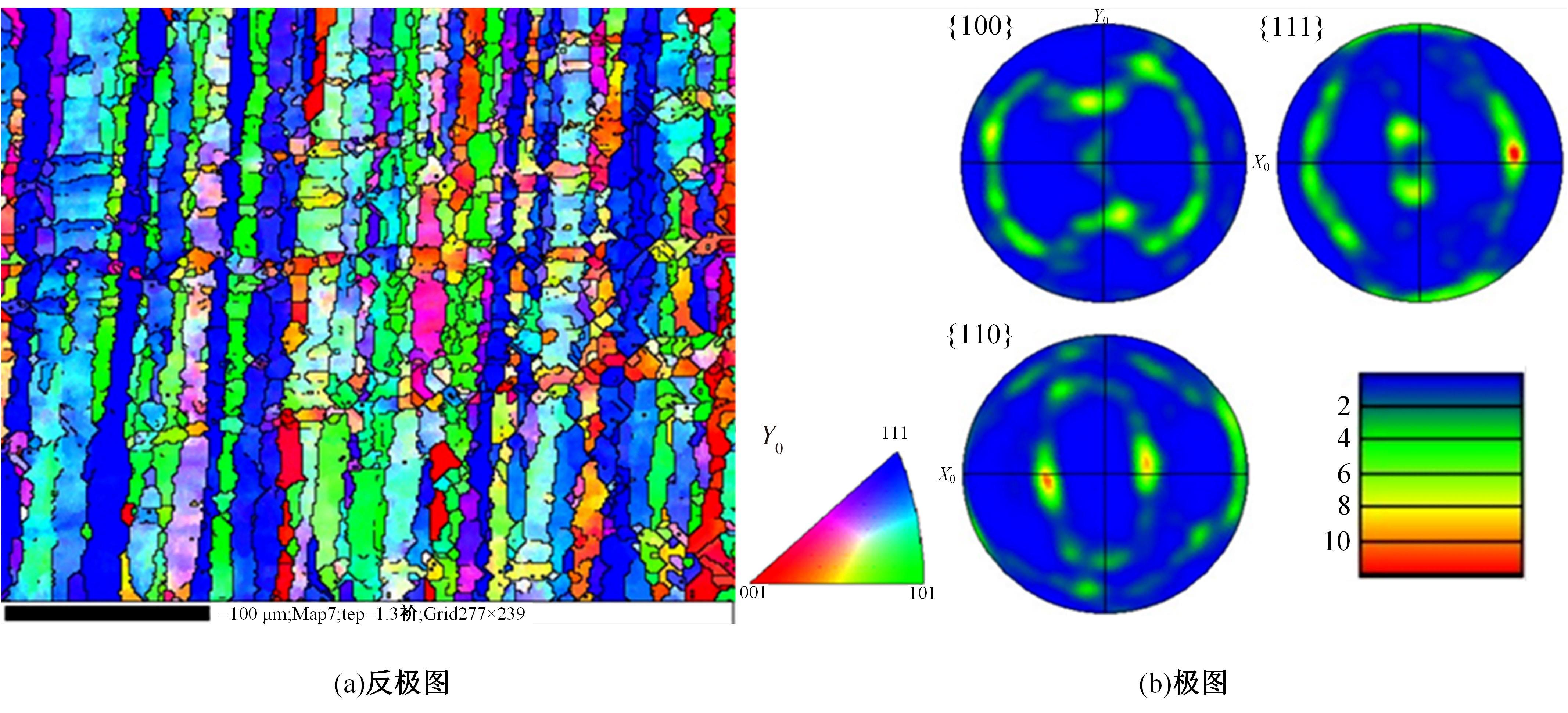

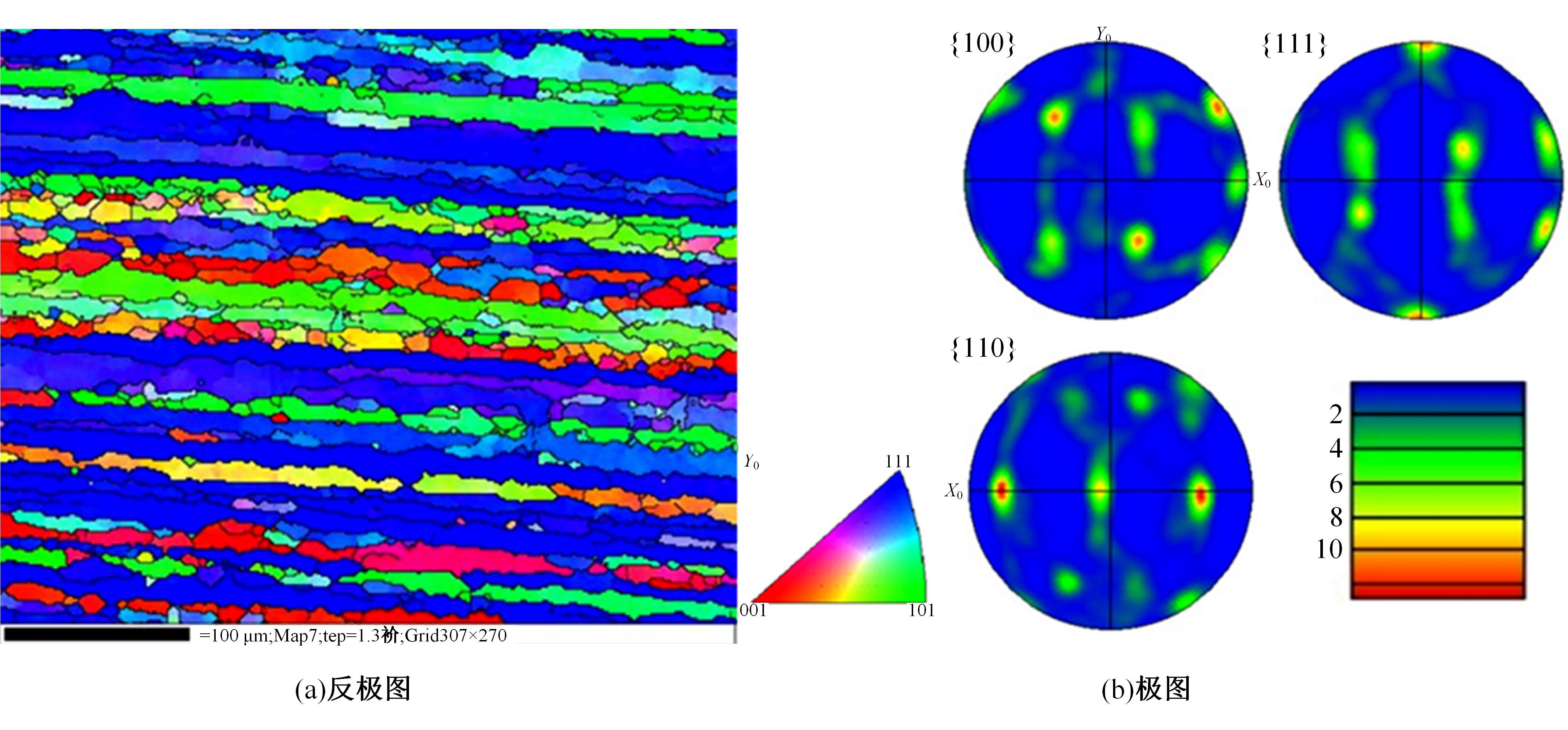

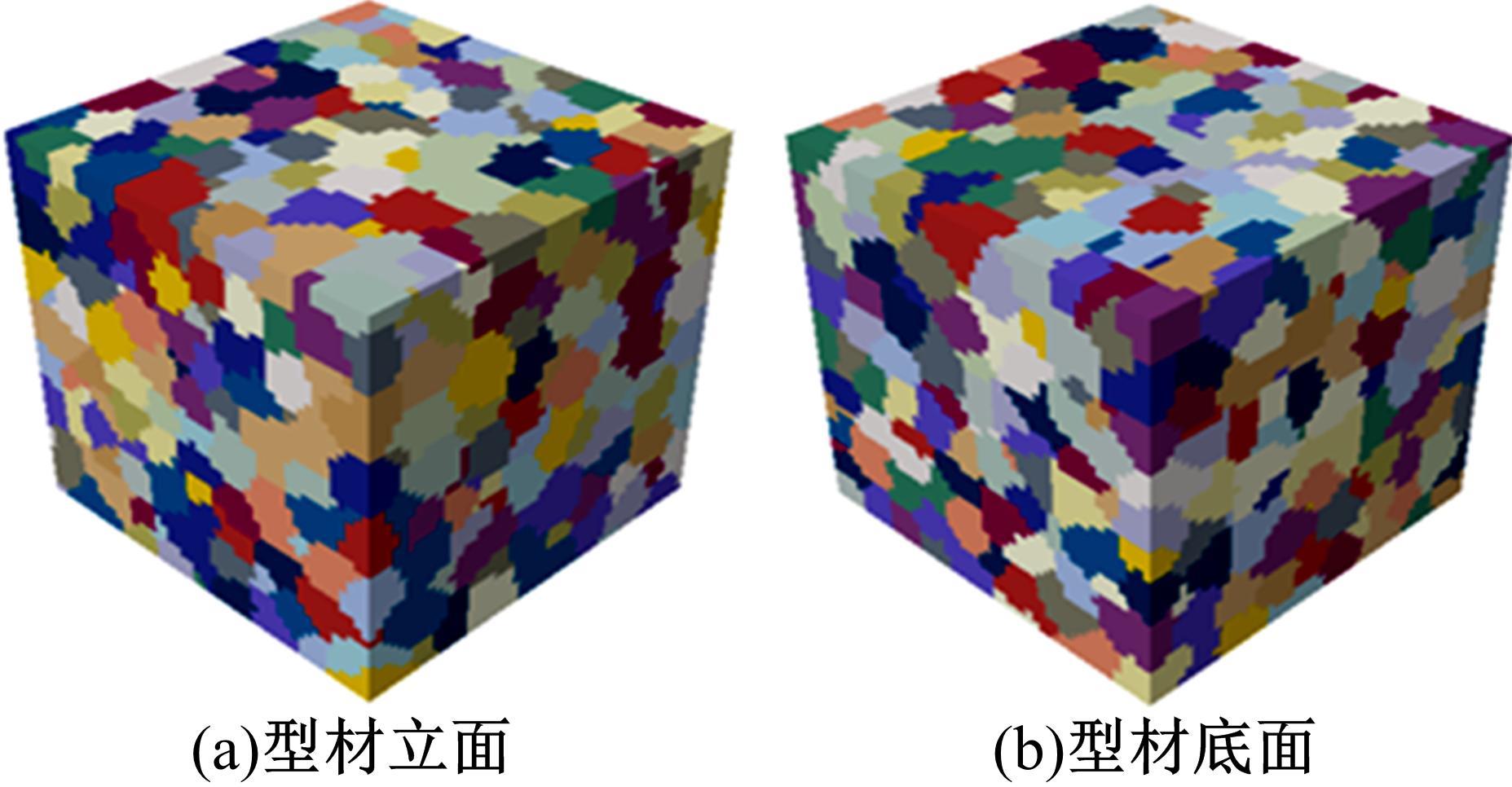

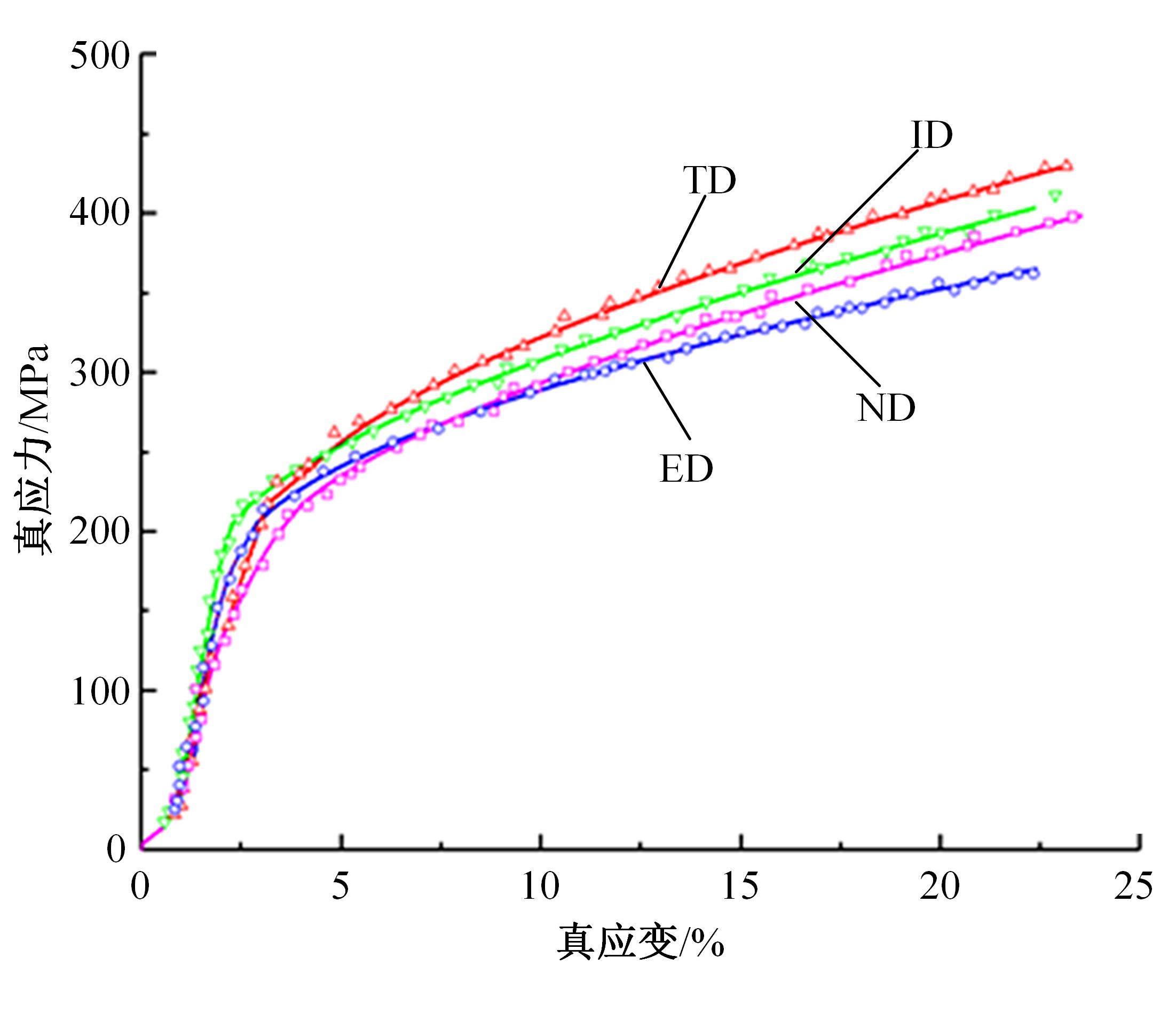

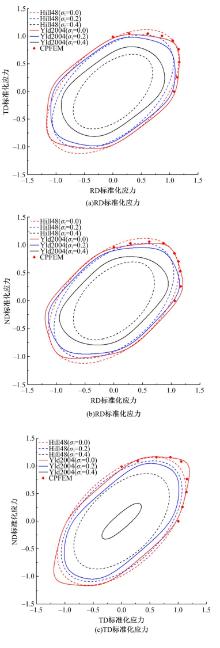

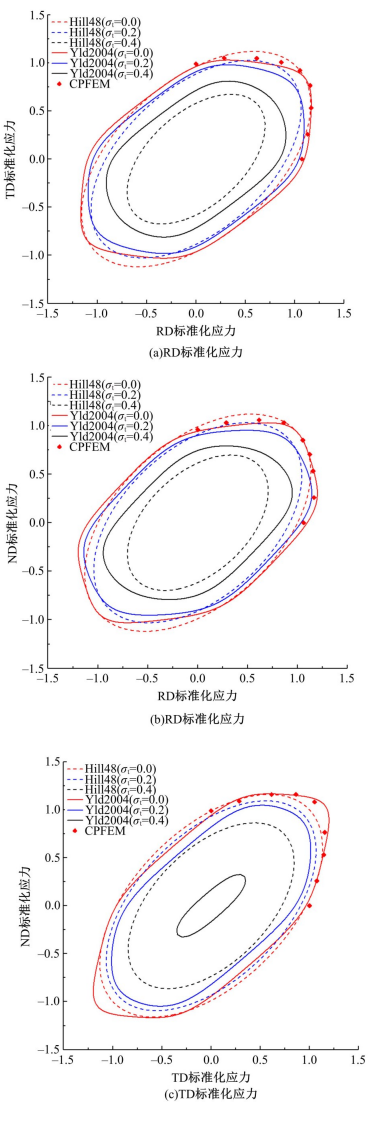

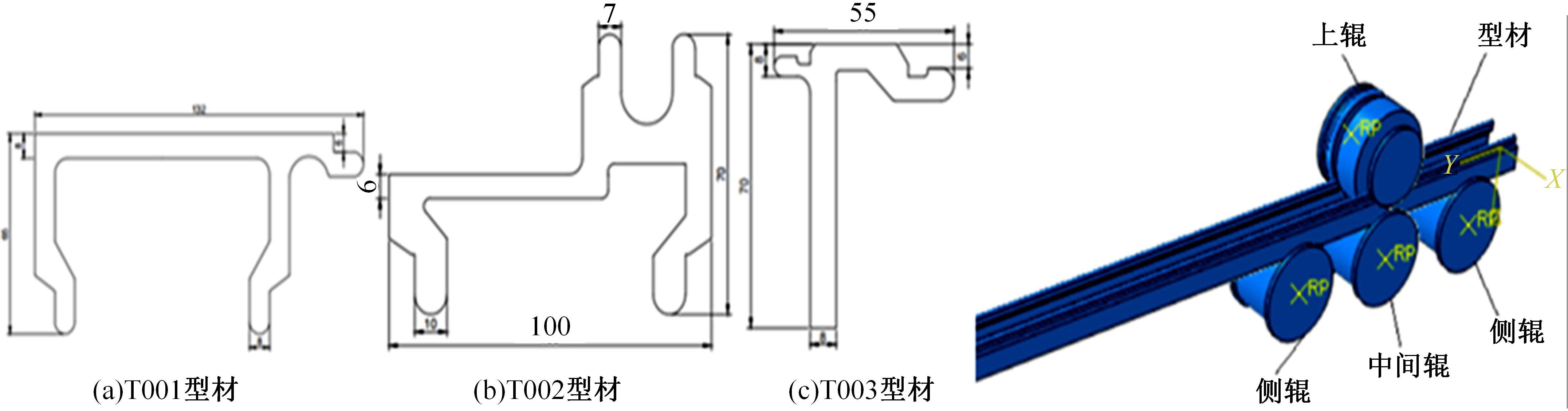

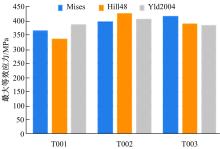

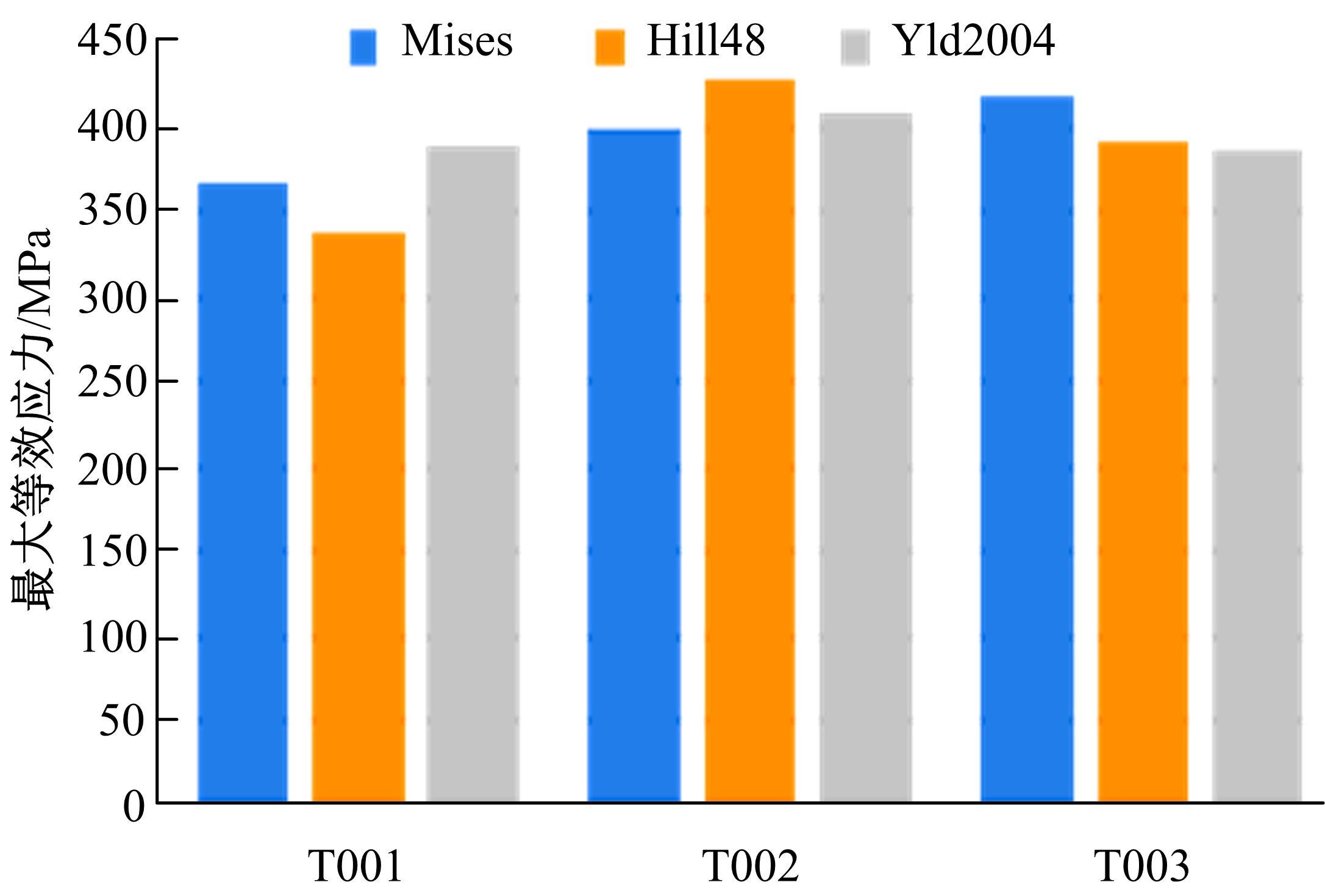

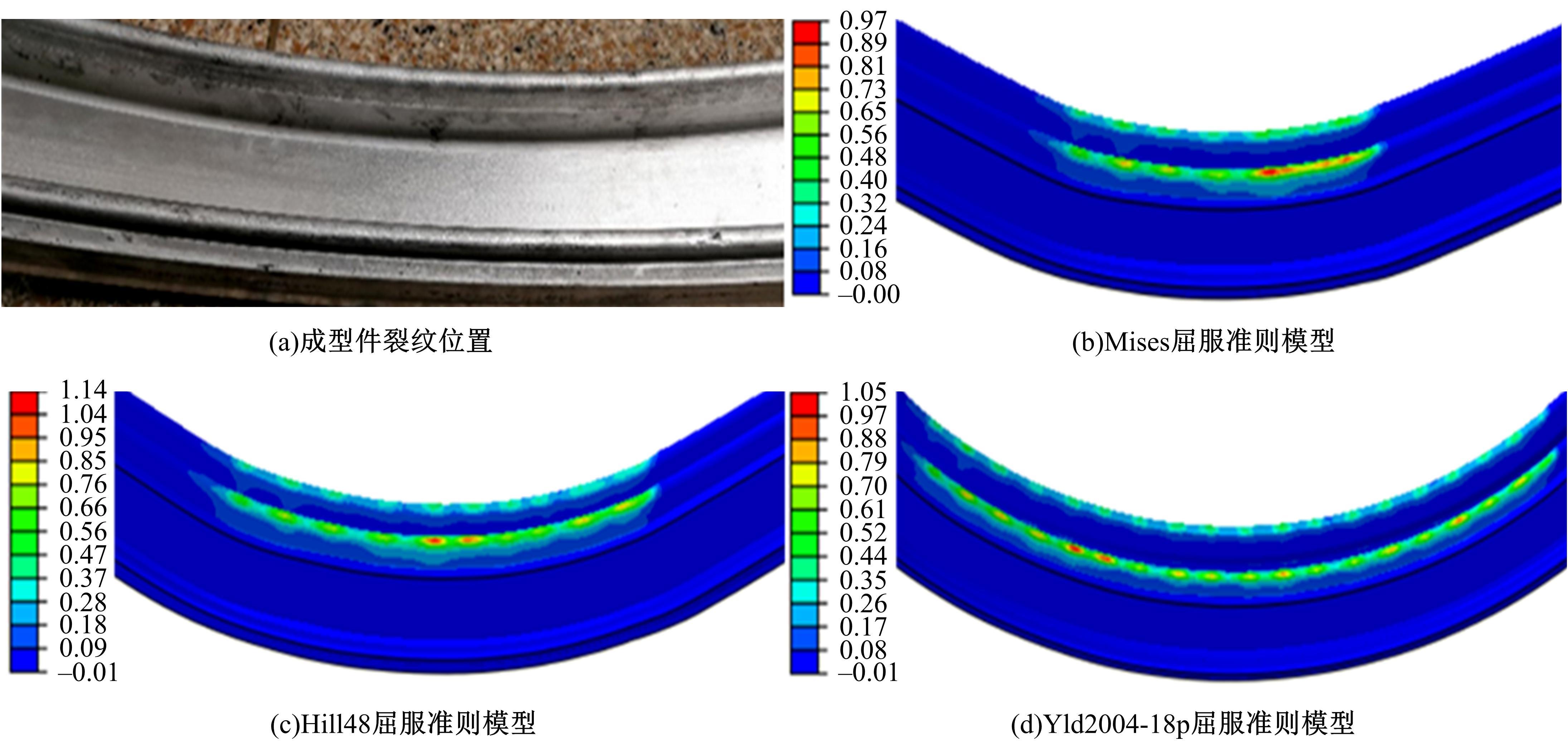

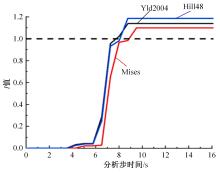

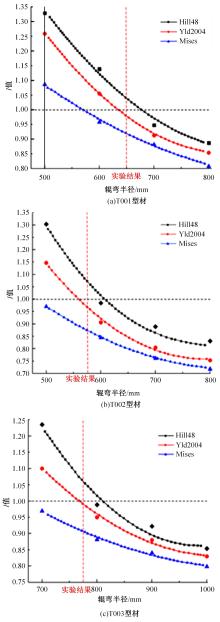

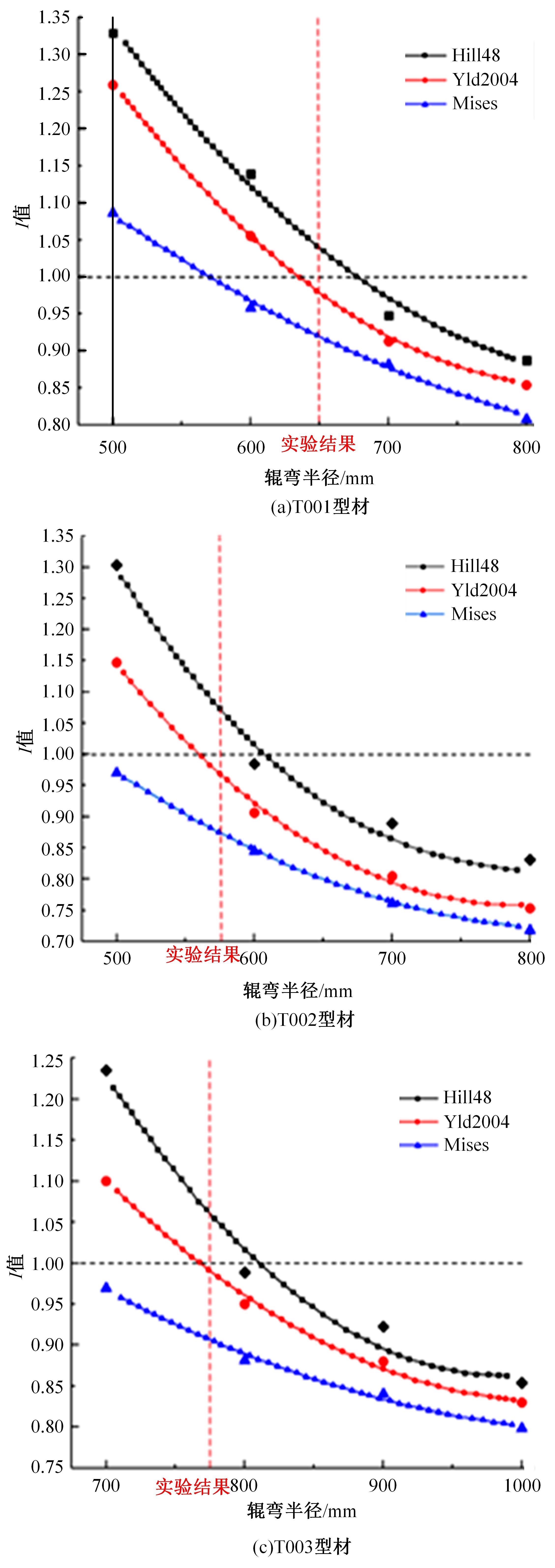

以6005A铝合金型材为例,提出了一种考虑各向异性的铝合金型材辊弯断裂预测方法,分别采用von Mises、Hill48和Yld2004-18p屈服准则描述铝合金的各向异性,通过实验和晶体有限元模拟确定了模型参数。模拟结果与辊弯实验结果对比表明:采用Mises屈服准则的预测误差大于15%;采用Hill48屈服准则的预测误差小于5%;采用Yld2004-18p屈服准则的预测误差小于3%。说明使用各向异性屈服准则与连续损伤准则耦合的有限元模型,比各向同性模型能更准确地预测铝合金型材辊弯成形中的断裂行为。

中图分类号:

- TG386

| 1 | Shi L, Wen J B, Ren C. The prediction of microstructure evolution of 6005A aluminum alloy in a P-ECAP extrusion study[J]. Journal of Materials Engineering and Performance, 2018, 27(5): 2566-2575. |

| 2 | 韩飞, 刘继英, 艾正青, 等. 辊弯成型技术理论及应用研究现状[J]. 塑性工程学报, 2010, 17(5): 53-60. |

| Han Fei, Liu Ji-ying, Ai Zheng-qing, et al. Research status of roll forming technology theory and application[J]. Chinese Journal of Plastic Engineering, 2010, 17(5): 53-60. | |

| 3 | Yan Y, Wang H B, Li Q. The inverse parameter identification of Hill 48 yield criterion and its verification in press bending and roll forming process simulations[J]. Journal of Manufacturing Processes, 2015, 20(1): 46-53. |

| 4 | Li S, Engler O, Houtte P V. Plastic anisotropy and texture evolution during tensile testing of extruded aluminium profiles[J]. Modelling and Simulation in Materials Science and Engineering, 2005, 13(5): 783-795. |

| 5 | Lian J, Shen F, Jia X, et al. An evolving non-associated Hill48 plasticity model accounting for anisotropic hardening and r-value evolution and its application to forming limit prediction[J]. International Journal of Solids and Structures, 2018, 151: 20-44. |

| 6 | Basak S, Panda S K, Lee M-G. Formability and fracture in deep drawing sheet metals: Extended studies for pre-strained anisotropic thin sheets[J]. International Journal of Mechanical Sciences, 2020, 170: No. 105346. |

| 7 | Achani D, Hopperstad O S, Lademo O G. Influence of advanced yield criteria on predictions of plastic anisotropy for aluminium alloy sheets[J]. International Journal of Material Forming, 2009, 2(Sup.1): 487-490. |

| 8 | Dick R E, Yoon J W. Plastic anisotropy and failure in thin metal: Material characterization and fracture prediction with an advanced constitutive model and polar EPS (effective plastic strain) fracture diagram for AA 3014-H19[J]. International Journal of Solids and Structures, 2018, 151: 195-213. |

| 9 | Lou Y, Yoon J W. Alternative approach to model ductile fracture by incorporating anisotropic yield function[J]. International Journal of Solids and Structures, 2019, 164: 12-24. |

| 10 | Grytten F, Holmedal B, Hopperstad O S, et al. Evaluation of identification methods for YLD2004-18p[J]. International Journal of Plasticity, 2008, 24(12): 2248-2277. |

| 11 | Bate P, An Y. Plastic anisotropy in AA5005 Al-1Mg: predictions using crystal plasticity finite element analysis[J]. Scripta Materialia, 2004, 51(10): 973-977. |

| 12 | Wei P, Lu C, Liu H, et al. Study of anisotropic plastic behavior in high pressure torsion of aluminum single crystal by crystal plasticity finite element method[J]. Crystals, 2017, 7(12): 362-372. |

| 13 | 黄建科. 金属成形过程的细观损伤力学模型及韧性断裂准则研究[D]. 上海:上海交通大学材料科学与工程学院, 2009. |

| Huang Jian-ke. Research on meso-scale damage mechanics model and ductile fracture criterion of metal forming process[D]. Shanghai: School of Materials Science and Engineering, Shanghai Jiaotong University, 2009. | |

| 14 | 高付海, 桂良进, 范子杰. 基于韧性准则的金属板料冲压成形断裂模拟[J]. 工程力学, 2010, 27(2): 204-208. |

| Gao Fu-hai, Gui Liang-jin, Fan Zi-jie. Fracture simulation of sheet metal stamping based on toughness criterion[J]. Engineering Mechanics, 2010, 27(2): 204-208. | |

| 15 | Rice J R, Tracey D M. On the ductile enlargement of voids in triaxial stress fields[J]. Journal of the Mechanics and Physics of Solids, 1969, 17(3): 201-217. |

| 16 | Liu C, Li M, Yue T. Thick anisotropy analysis for AA7B04 aluminum plate using CPFEM and its application for springback prediction in multi-point bending[J]. The International Journal of Advanced Manufacturing Technology, 2021, 115(4): 1139-1153. |

| [1] | 朱先勇,谢良稳,樊跃香,姜城,孙炜佳,王鹏,肖雄. 搅拌摩擦加工参数对镁合金表面改性层的影响[J]. 吉林大学学报(工学版), 2023, 53(8): 2263-2271. |

| [2] | 张恒,詹志刚,陈奔,隋邦杰,潘牧. 气体扩散层各向异性传输特性的孔尺度模拟[J]. 吉林大学学报(工学版), 2022, 52(9): 2055-2062. |

| [3] | 姬会爽,彭艳,刘洋,杨彦博,高鲲,尔立民. SCR生产线结晶腔铜液凝固行为及质量控制[J]. 吉林大学学报(工学版), 2021, 51(6): 2021-2030. |

| [4] | 向红亮,陈盛涛,邓丽萍,张伟,詹土生. 微合金化2205双相不锈钢组织及性能[J]. 吉林大学学报(工学版), 2020, 50(5): 1645-1652. |

| [5] | 谷晓燕,隋成龙,狄星,孟政宇,朱开轩,楚长春. 焊接能量对铜/钛超声波焊接接头性能的影响[J]. 吉林大学学报(工学版), 2020, 50(5): 1669-1676. |

| [6] | 李小雨,许男,仇韬,郭孔辉. 各向异性刚度对轮胎力学特性及车辆操纵性的影响[J]. 吉林大学学报(工学版), 2020, 50(2): 389-398. |

| [7] | 蔡中义,孟凡响,陈庆敏,赵轩. 复杂钩舌锻件近净成形的预锻形状优化设计[J]. 吉林大学学报(工学版), 2020, 50(1): 84-90. |

| [8] | 庄蔚敏,施宏达,解东旋,杨冠男. 钢铝异质无铆钉粘铆复合连接胶层厚度分布[J]. 吉林大学学报(工学版), 2020, 50(1): 100-106. |

| [9] | 关庆丰,姚欣雯,杨洋,张凌燕,刘迪,李晨,吕鹏. 强流脉冲电子束作用下TC4钛合金表面Cr合金层制备及性能[J]. 吉林大学学报(工学版), 2019, 49(6): 2002-2009. |

| [10] | 石舟,寇淑清. 36MnVS4裂解连杆性能分析及轻量化设计[J]. 吉林大学学报(工学版), 2019, 49(6): 1992-2001. |

| [11] | 依卓,付文智,李明哲. 双层剖分式超高压模具数值模拟及实验[J]. 吉林大学学报(工学版), 2019, 49(5): 1593-1599. |

| [12] | 谷晓燕,刘东锋,刘婧,孙大千,马会峰. 焊接能量对Cu/Al超声波焊接接头组织与性能的影响[J]. 吉林大学学报(工学版), 2019, 49(5): 1600-1607. |

| [13] | 李欣,孙延朋,王丹,陈军绪,谷诤巍,徐虹. 汽车前地板成形有限元数值模拟[J]. 吉林大学学报(工学版), 2019, 49(5): 1608-1614. |

| [14] | 李欣,王丹,陈军绪,孙延朋,谷诤巍,徐虹. 手刹固定板冲压成形数值模拟[J]. 吉林大学学报(工学版), 2019, 49(4): 1258-1265. |

| [15] | 刘文权,盈亮,荣海,胡平. 基于损伤修正M⁃K模型的高强度钢成形极限预测[J]. 吉林大学学报(工学版), 2019, 49(4): 1266-1271. |

|

||