吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (7): 1851-1861.doi: 10.13229/j.cnki.jdxbgxb.20221178

• 车辆工程·机械工程 • 上一篇

基于改进麻雀搜索算法的平行行排序问题

- 1.西南交通大学 机械工程学院,成都 610031

2.西南交通大学 轨道交通运维技术与装备四川省重点实验室,成都 610031

Parallel row ordering problem based on improved sparrow search algorithm

Ze-qiang ZHANG( ),Can WANG,Jun-qi LIU,Dan JI,Si-lu LIU

),Can WANG,Jun-qi LIU,Dan JI,Si-lu LIU

- 1.School of Mechanical Engineering,Southwest Jiaotong University,Chengdu 610031,China

2.Technology and Equipment of Rail Transit Operation and Maintenance Key Laboratory of Sichuan Province,Southwest Jiaotong University,Chengdu 610031,China

摘要:

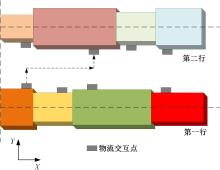

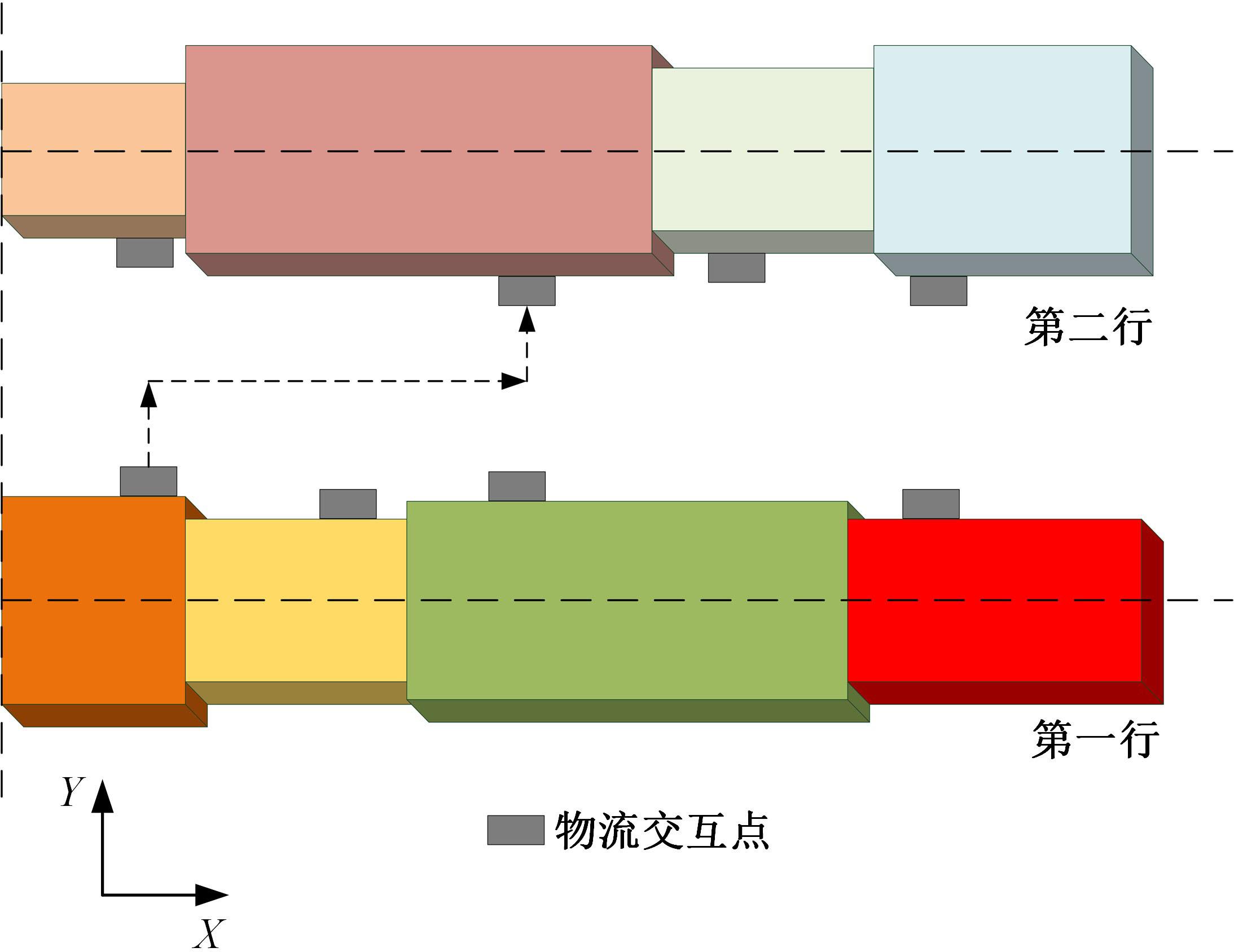

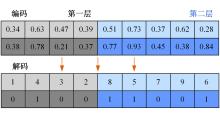

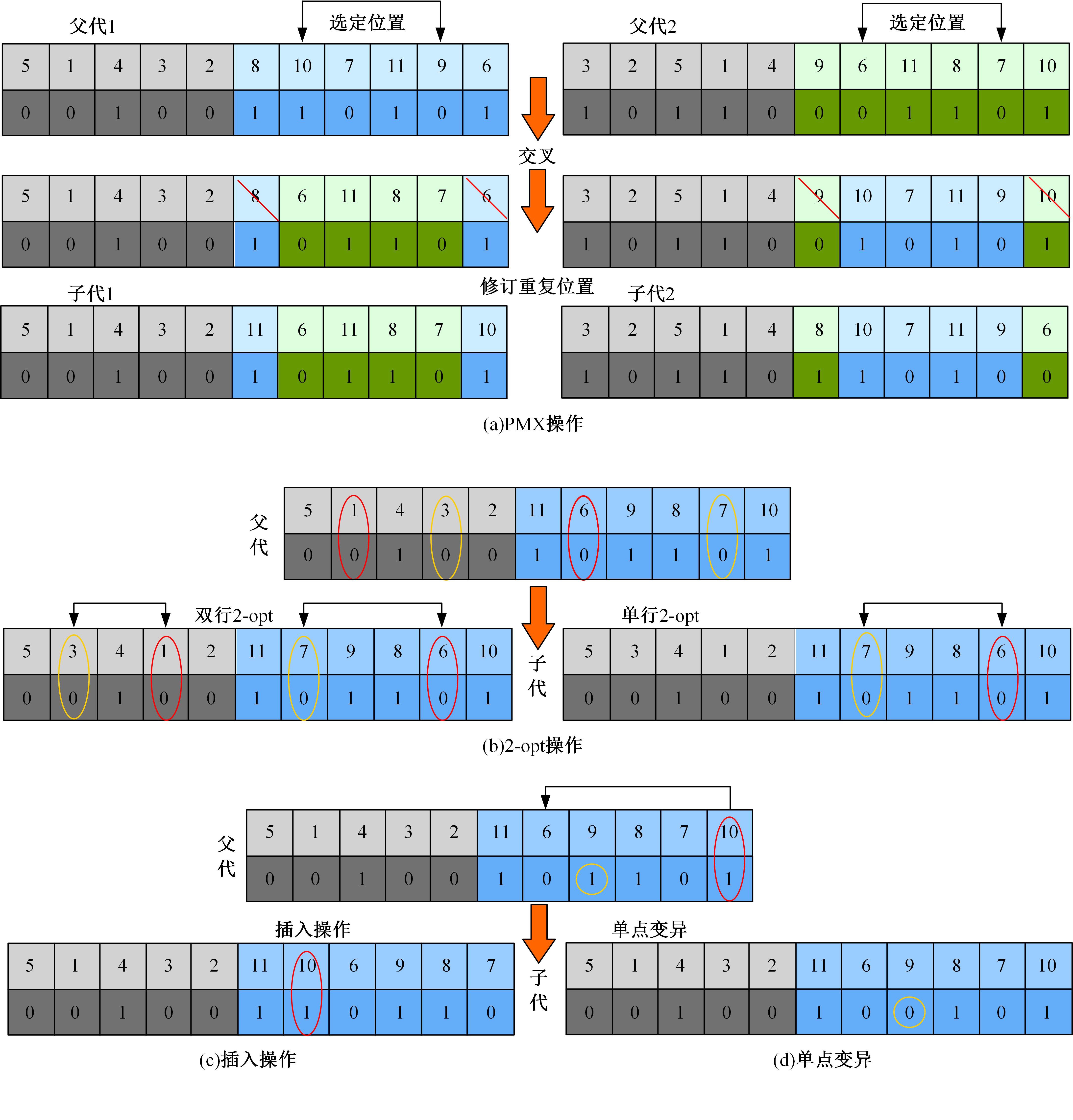

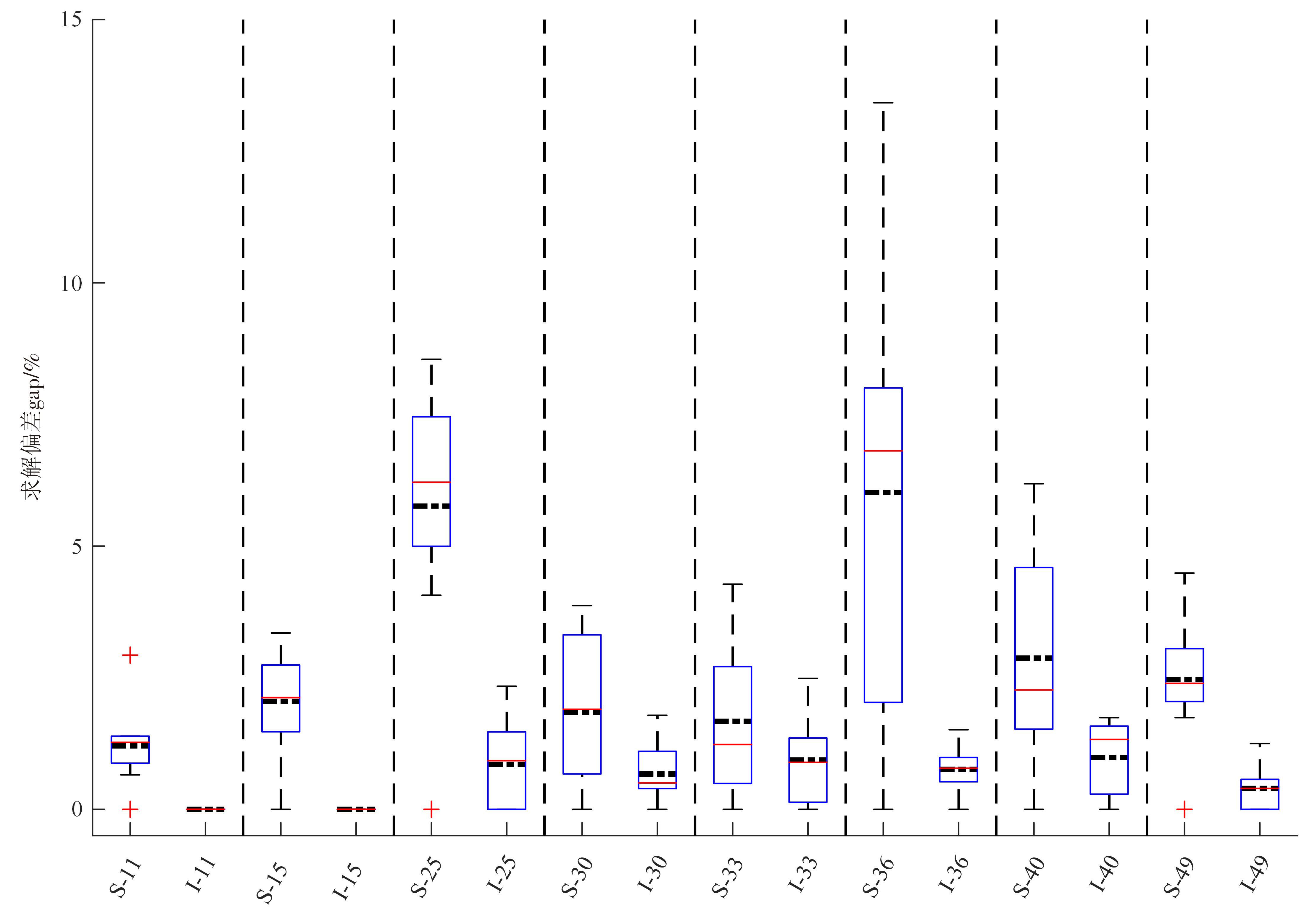

针对平行行排序问题中的物流交互点位置问题,以车间布局为研究背景,提出了具备物流交互点及两行间距的平行行排序问题。以最小物流成本为目标,构建了混合整数规划模型,并运用Lingo求解器对小规模算例进行求解验证。结合问题特性,提出了一种改进的麻雀搜索算法。该算法采用佳点集初始化种群,使种群更具多样性,同时对警惕者数量动态变化,结合PMX交叉算子、连续2-opt算子、插入算子等操作加快求解速度,加入提前终止规则,减少冗余迭代次数。将本文算法与麻雀搜索算法、模拟退火算法、遗传算法等进行对比验证,用于求解25~49不同规模算例,结果表明本文算法在求解质量和求解速度上均具有一定优势。将本文算法应用在某生产车间布局中,对车间布局进行优化,改进后的布局降低了32.40%的物流成本,表明了本文模型及算法的有效性。

中图分类号:

- TH181

| 1 | Salam Q D A, Gualtiero F, Franco F. Analysis of drivers for solving facility layout problems: a literature review[J]. Journal of Industrial Information Integration, 2021, 21: 100187. |

| 2 | Mojtaba K, Vahid M D, Sajjad A. A new intelligent algorithm for dynamic facility layout problem in state of fuzzy constraints[J]. Neural Computing and Applications, 2014, 24(5): 1179-1190. |

| 3 | Hosseini-Nasab H, Fereidouni S, Fatemi G S M T, et al. Classification of facility layout problems: a review study[J]. The International Journal of Advanced Manufacturing Technology,2018,94(1-4): 957-977. |

| 4 | 查珊珊, 郭宇, 黄少华, 等. 不确定需求下的车间设施动态布局[J]. 吉林大学学报:工学版, 2017, 47(6): 1811-1821. |

| Shan-shan Cha, Guo Yu, Huang Shao-hua, et al. Dynamic facility layout for workshop under uncertain product demands[J]. Journal of Jilin University (Engineering and Technology Edition), 2017, 47(6): 1811-1821. | |

| 5 | Guan C, Zhang Z Q, Zhu L X, et al. Mathematical formulation and a hybrid evolution algorithm for solving an extended row facility layout problem of a dynamic manufacturing system[J]. Robotics and Computer-Integrated Manufacturing, 2022,78: 102379. |

| 6 | Liu J Q, Zhang Z Q, Chen F, et al. A novel hybrid immune clonal selection algorithm for the constrained corridor allocation problem[J]. Journal of Intelligent Manufacturing, 2022, 33(4): 953-972. |

| 7 | Zhang Z, Gong J, Liu J, et al. A fast two-stage hybrid meta-heuristic algorithm for robust corridor allocation problem[J]. Advanced Engineering Informatics, 2022, 53: 101700. |

| 8 | André R S A. A parallel ordering problem in facilities layout[J]. Computers & Operations Research,2013, 40(12): 2930-2939. |

| 9 | Hungerländer P. A semidefinite optimization approach to the parallel row ordering problem[R]. Technical Report, Alpen-Adria-Universität Klagenfurt,2015. |

| 10 | Maadi M, Javidnia M, Jamshidi R. Two strategies based on meta-heuristic algorithms for parallel row ordering problem[J]. Iranian Journal of Management Studies, 2017, 10(2): 467-498. |

| 11 | Yang X H, Cheng W M, Alice E S, et al. An improved model for the parallel row ordering problem[J]. The Journal of the Operational Research Society, 2020, 71(3): 475-490. |

| 12 | Gong J H, Zhang Z Q, Liu J Q, et al. Hybrid algorithm of harmony search for dynamic parallel row ordering problem[J]. Journal of Manufacturing Systems, 2021, 58: 159-175. |

| 13 | Cravo G L, Amaral A R S. Adaptive iterated local search for the parallel row ordering problem[J]. Expert Systems with Applications, 2022, 208: 118033. |

| 14 | 计丹, 张则强, 刘俊琦,等. 具有安全间隙及物料装卸点的多行布局问题建模与优化[J]. 计算机集成制造系统, 2023, 29(9): 3074-3085. |

| Ji Dan, Zhang Ze-qiang, Liu Jun-qi, et al. Modeling and optimization of multi-row layout problem with safety clearance and material handling points[J]. Computer Integrated Manufacturing Systems, 2023,29(9): 3074-3085. | |

| 15 | Karateke H, Şahin R, Niroomand S. A hybrid Dantzig-Wolfe decomposition algorithm for the multi-floor facility layout problem[J]. Expert Systems with Applications, 2022, 206: 117845. |

| 16 | 刘俊琦, 张则强, 王沙沙, 等. 考虑不规则物流交互点的过道布置问题建模与优化[J]. 计算机集成制造系统, 2021, 27(4): 1155-1166. |

| Liu Jun-qi, Zhang Ze-qiang, Wang Sha-sha, et al. Modeling and optimization of corridor problem considering irregular logistics interaction points[J]. Computer Integrated Manufacturing Systems, 2021, 27(4): 1155-1166. | |

| 17 | 董舒豪, 徐志刚, 常艳茹, 等. 考虑物料装卸点与搬运通道的多行设施布局[J]. 计算机集成制造系统, 2021, 27(5): 1269-1280. |

| Dong Shu-hao, Xu Zhi-gang, Chang Yan-ru, et al. Multi-row facility layout considering material loading/unloading points and handling passages[J]. Computer Integrated Manufacturing Systems, 2021, 27(5): 1269-1280. | |

| 18 | Xue J K, Shen B. A novel swarm intelligence optimization approach: sparrow search algorithm[J]. Systems Science & Control Engineering, 2020, 8(1): 22-34. |

| 19 | 吕鑫, 慕晓冬, 张钧,等. 混沌麻雀搜索优化算法[J]. 北京航空航天大学学报, 2021, 47(8): 1712-1720. |

| Xin Lyu, Mu Xiao-dong, Zhang Jun, et al. Chaos sparrow search optimization algorithm[J]. Journal of Beijing University of Aeronautics and Astronautics, 2021, 47(8): 1712-1720. | |

| 20 | 国强,朱国会,李万臣. 基于混沌麻雀搜索算法的TDOA/FDOA定位[J]. 吉林大学学报:工学版, 2023,53(2):593-600. |

| Guo Qiang, Zhu Guo-hui, Li Wan-chen. TDOA/FDOA localization based on chaotic sparrow search algorithm[J]. Journal of Jilin University (Engineering and Technology Edition), 2023,53(2):593-600. | |

| 21 | 段锦, 姚安妮, 王震, 等. 改进的麻雀搜索算法优化无线传感器网络覆盖[J]. 吉林大学学报: 工学版,2024, 54(3): 761-770. |

| Duan Jin, Yao An-ni, Wang Zhen, et al. An improved sparrow search algorithm optimizes coverage in wireless sensor networks[J]. Journal of Jilin University (Engineering and Technology Edition), 2024, 54(3): 761-770. |

| [1] | 回丽,金磊,宋万万,周松,安金岚. 转向架用SMA490BW钢不同焊接区域裂纹扩展速率[J]. 吉林大学学报(工学版), 2024, 54(3): 650-656. |

| [2] | 段锦,姚安妮,王震,于林韬. 改进的麻雀搜索算法优化无线传感器网络覆盖[J]. 吉林大学学报(工学版), 2024, 54(3): 761-770. |

| [3] | 段中兴,刘瑞兴,刘冲. 多策略改进麻雀搜索算法优化三维DV-Hop节点定位[J]. 吉林大学学报(工学版), 2024, 54(3): 771-784. |

| [4] | 杨志军,张驰,黄观新. 基于浮动坐标法的刚柔耦合定位平台力学模型[J]. 吉林大学学报(工学版), 2024, 54(2): 385-393. |

| [5] | 石林榕,赵武云. 西北寒旱农区胡麻滚勺式精量穴播器的设计及试验[J]. 吉林大学学报(工学版), 2023, 53(9): 2706-2717. |

| [6] | 柴博森,王广义,闫东,朱国仁,张进,吕恒升. 液力变矩器空化数值模拟及对性能的影响[J]. 吉林大学学报(工学版), 2023, 53(8): 2236-2244. |

| [7] | 陈国辉,徐业银,焦映厚. 考虑偏转的斜齿轮啮合刚度及其振动分析[J]. 吉林大学学报(工学版), 2023, 53(7): 1902-1910. |

| [8] | 陈贵升,罗国焱,李靓雪,黄震,李一. 柴油机颗粒捕集器孔道流场及其高原环境下噪声特性分析[J]. 吉林大学学报(工学版), 2023, 53(7): 1892-1901. |

| [9] | 于立娟,安阳,何佳龙,李国发,王升旭. 机电装备载荷谱外推技术研究进展及发展趋势[J]. 吉林大学学报(工学版), 2023, 53(4): 941-953. |

| [10] | 李胜,朱佳,黄德惠,陈存福,费洪庆,丰伟,胡兴军. 空冷中冷器百叶窗翅片结构参数优化[J]. 吉林大学学报(工学版), 2023, 53(4): 998-1006. |

| [11] | 王建,于威,王斌. 高原状态下甲醇替代率对柴油机燃烧与排放的影响[J]. 吉林大学学报(工学版), 2023, 53(4): 954-963. |

| [12] | 国强,朱国会,李万臣. 基于混沌麻雀搜索算法的TDOA/FDOA定位[J]. 吉林大学学报(工学版), 2023, 53(2): 593-600. |

| [13] | 柴博森,闫东,王广义,左文杰. 制动工况桃腔偶合器三维涡特征分析及仿真评价[J]. 吉林大学学报(工学版), 2023, 53(11): 3045-3055. |

| [14] | 朱凌,王秋成. 空间几何约束下新能源汽车驱动系统协调控制方法[J]. 吉林大学学报(工学版), 2022, 52(7): 1509-1514. |

| [15] | 金兆辉,谷乐祺,洪伟,解方喜,尤田. 液压可变气门系统压力波动的影响分析[J]. 吉林大学学报(工学版), 2022, 52(4): 773-780. |

|

||