吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (7): 1887-1893.doi: 10.13229/j.cnki.jdxbgxb.20221323

• 材料科学与工程 • 上一篇

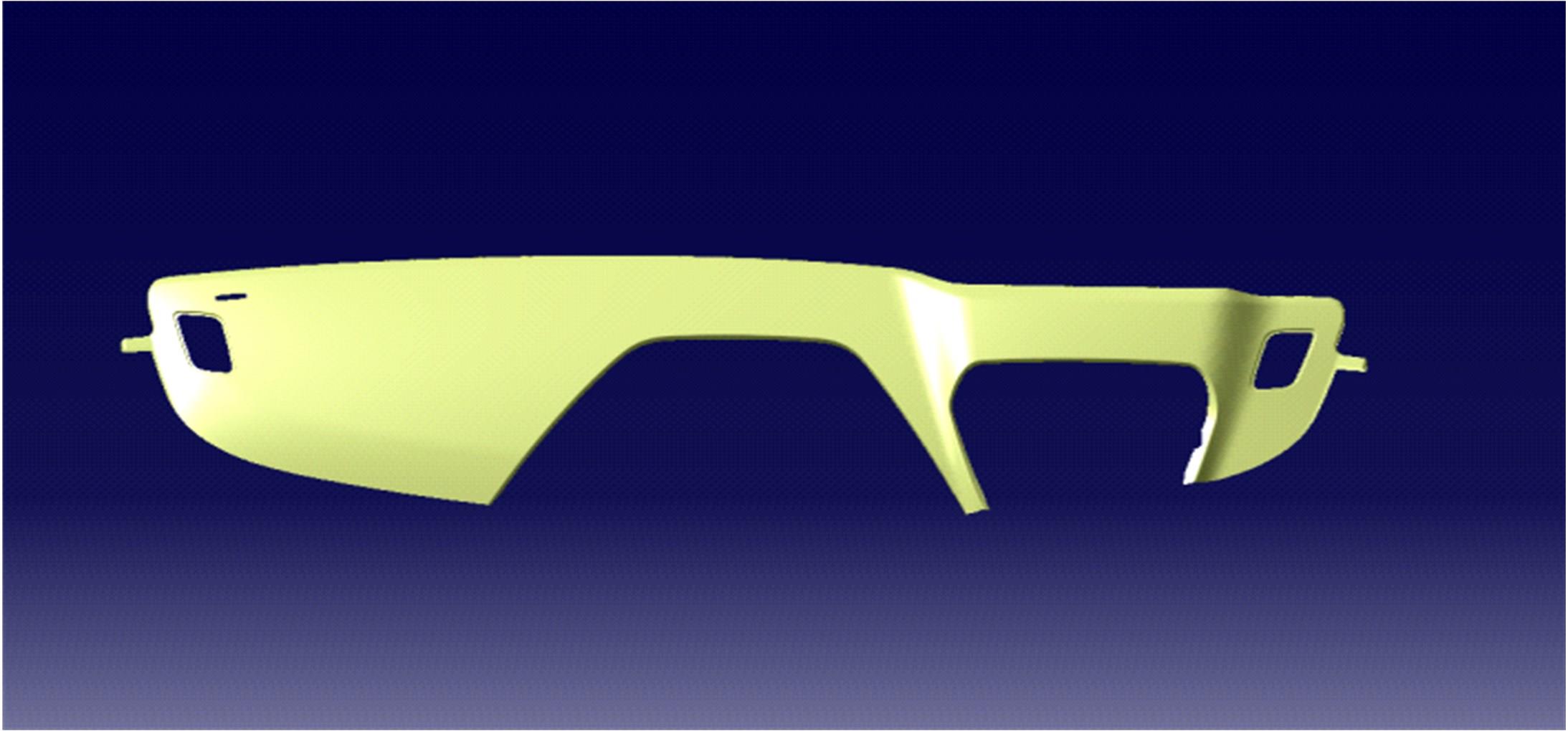

轿车内饰件包覆成型过程温度场变化对制件成型质量的影响

- 1.吉林大学 材料科学与工程学院,长春 130022

2.吉林大学 辊锻工艺研究所,长春 130022

Simulation on influence of temperature field on composite glued structure of car interior

Yi LI1( ),Ya-sai BAI1,Ji-cai LIANG1,2,Wei-guo YAO1,Ce LIANG1(

),Ya-sai BAI1,Ji-cai LIANG1,2,Wei-guo YAO1,Ce LIANG1( )

)

- 1.College of Materials Science and Engineering,Jilin University,Changchun 130022,China

2.Roll Forging Institute,Jilin University,Changchun 130022,China

摘要:

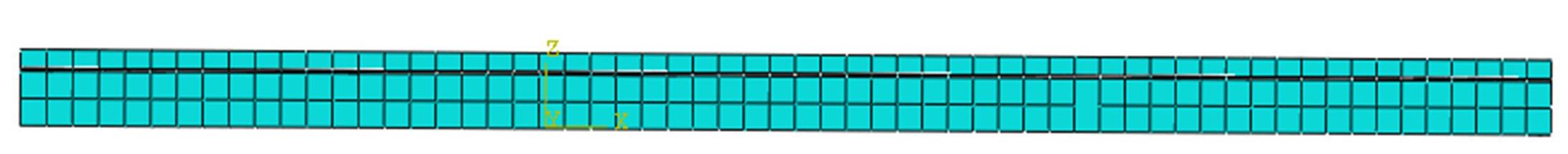

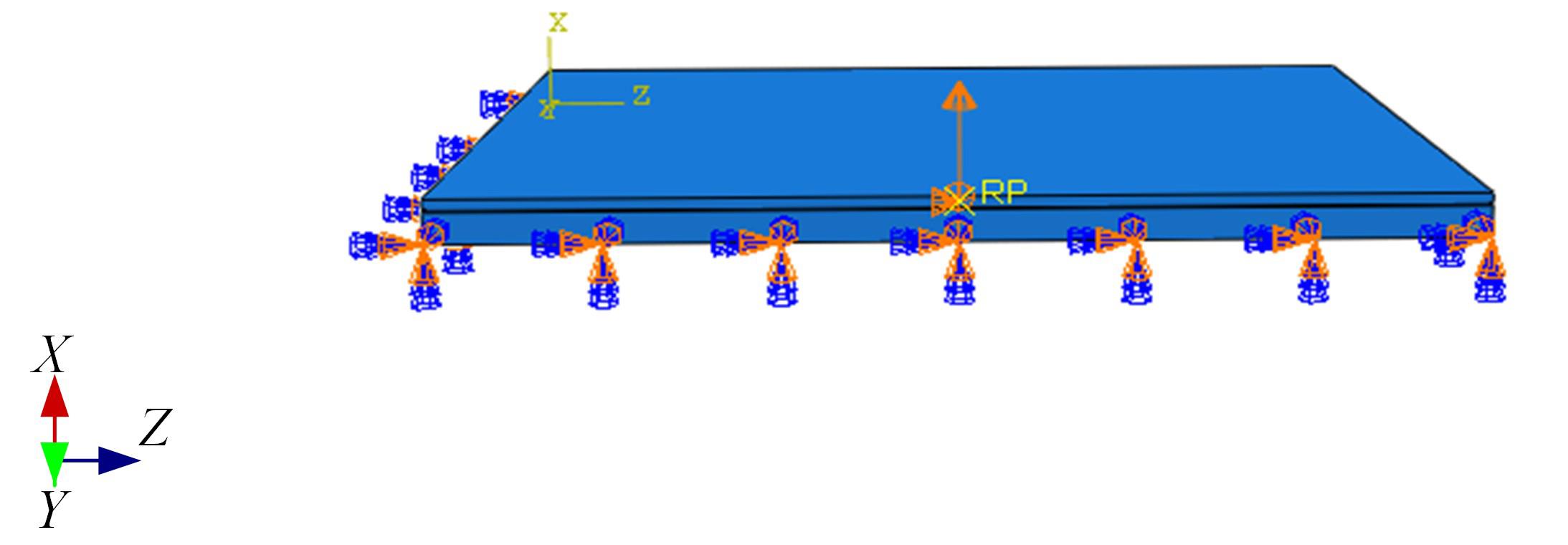

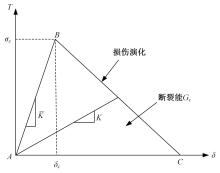

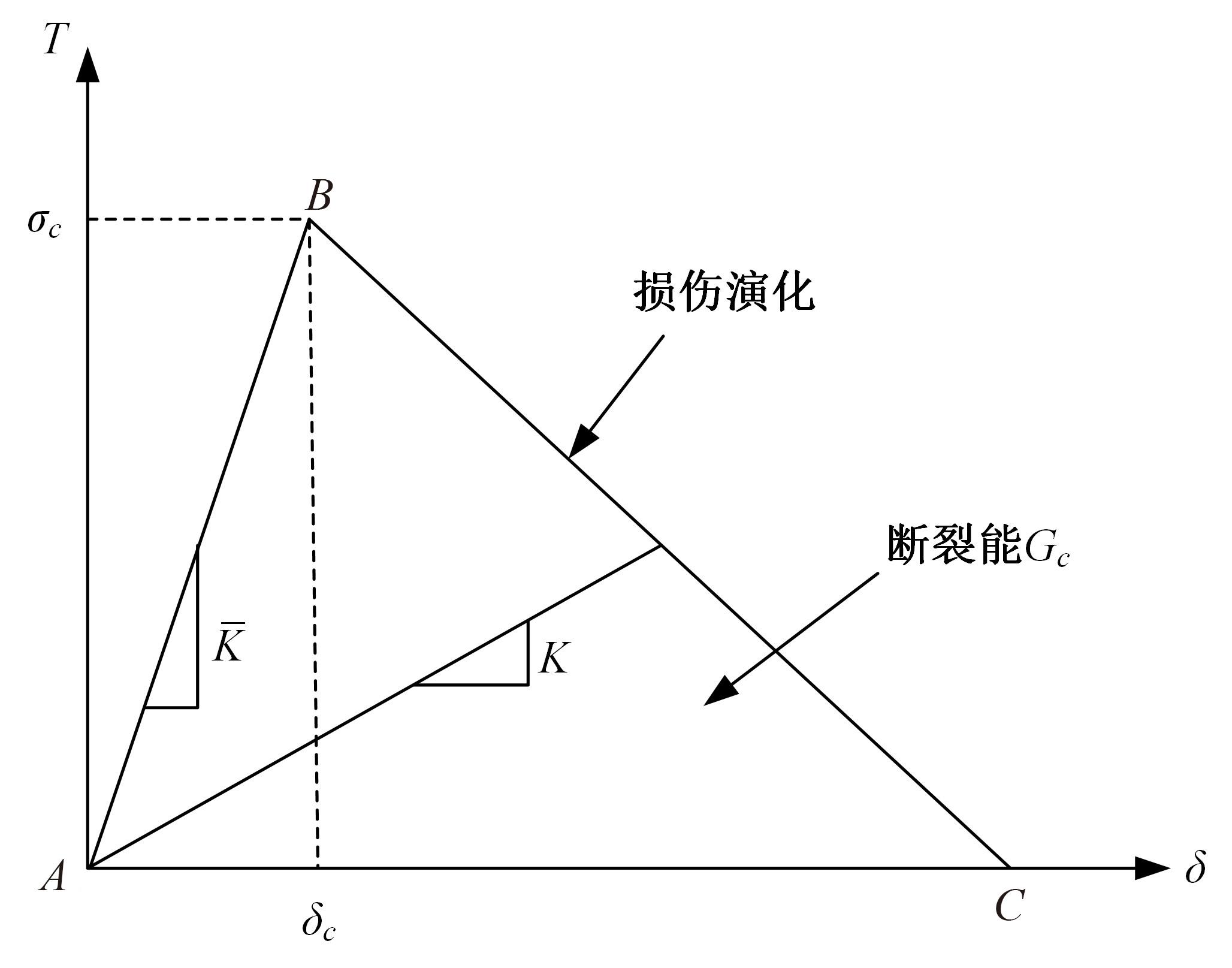

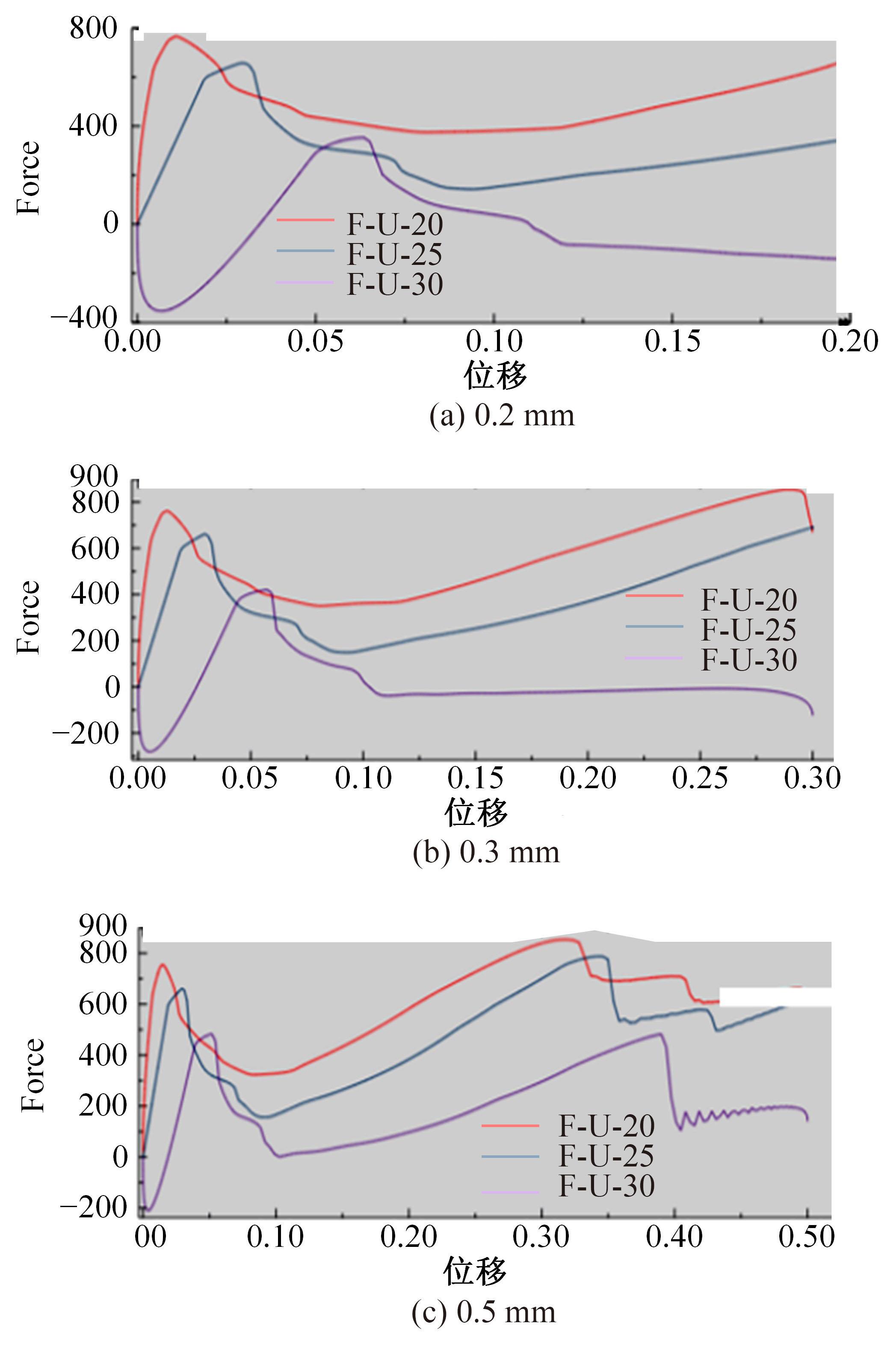

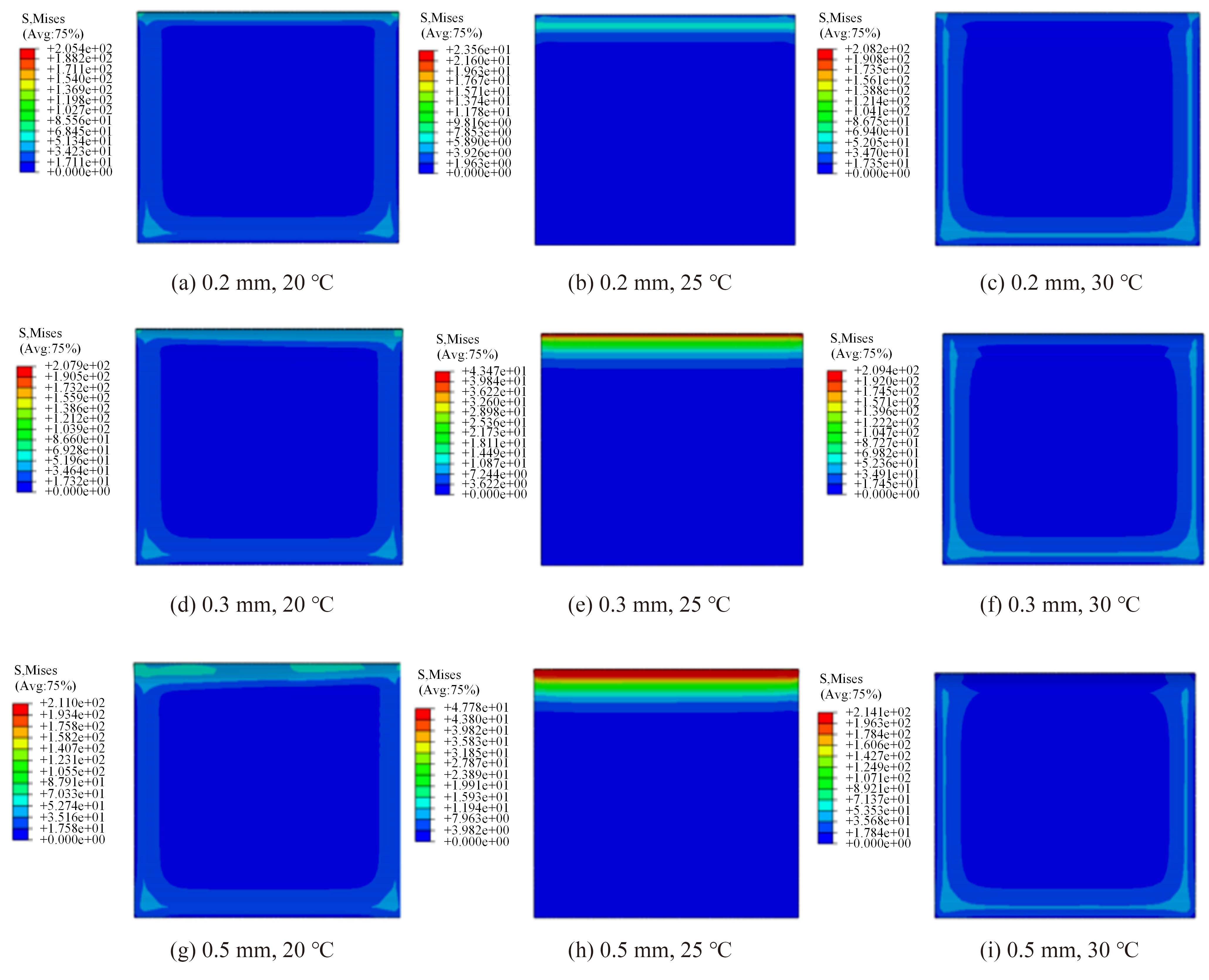

利用仿真模拟软件,在分析制件表皮施加位移对包覆成型制品质量影响的基础上,考察表皮温度对接触面强度的影响。研究过程中,对模型进行温度-位移耦合,加载方式不变,改变温度和加载位移。研究结果表明,在相同的温度变化差下,不同位移的模拟结果特征相似。温度降低会加快胶层的损伤和失效,使失效载荷的值增大;温度升高会促进胶层起始损伤,但延缓胶层失效,使失效载荷的值降低。温度升高和降低均会引起应力变化,且变化的趋势为由内向外逐渐增大,加载过程中剥离力由位移载荷和应力共同提供。

中图分类号:

- TG356

| 1 | 蒋志军, 张志刚, 吕崇建,等. 汽车内饰包覆零件设计与工艺研究[J]. 汽车实用技术, 2018,44(7):131-134. |

| Jiang Zhi-jun, Zhang Zhi-gang, Chong-jian Lyu. Research on the design and process of automotive interior coating parts[J]. Automobile Applied Technology,2018,44(7):131-134. | |

| 2 | Hu P, Han X, Li W D, et al. Research on the static strength performance of adhesive single lap joints subjected to extreme temperature environment for automotive industry[J]. International Journal of Adhesion & Adhesives, 2013, 41:119-126. |

| 3 | Sayman O, Arikan V, Dogan A, et al. Failure analysis of adhesively bonded composite joints under transverse impact and different temperatures[J]. Composites Part B: Engineering, 2013, 54(11):409-414. |

| 4 | Vaidya U K, Gautam A, Hosur M, et al. Experimental-numerical studies of transverse impact response of adhesively bonded lap joints in composite structures[J]. International Journal of Adhesion & Adhesives, 2006, 26(3):184-198. |

| 5 | Huang W, Sun L, Li L, et al. Investigations on low-energy impact and post-impact fatigue of adhesively bonded single-lap joints using composites substrates[J]. The Journal of Adhesion, 2019:1-29. |

| 6 | Oz De Mir O, Oztoprak N. An investigation into the effects of fabric reinforcements in the bonding surface on failure response and transverse impact behavior of adhesively bonded dissimilar joints[J]. Composites Part B: Engineering, 2017, 126(10):72-80. |

| 7 | Machado J, Marques E, Lucas F M, et al. The journal of adhesion adhesives and adhesive joints under impact loadings: an overview[J] .The Journal of Adhesion,2018,94(5/7):421-452 . |

| 8 | Soykok I F, Sayman O, Ozen M, et al. Failure analysis of mechanically fastened glass fiber/epoxy composite joints under thermal effects[J]. Composites Part B: Engineering, 2013, 45(1):192-199. |

| 9 | Kemiklioglu U, Sayman O, Batar T.Strength comparison of ductile and brittle adhesives under single and repeated impacts[J]. Applied Adhesion Science, 2015, 3(1):1-9. |

| 10 | Kumagai S, Shindo Y. Experimental and analytical evaluation of the notched tensile fracture of CFRP-woven laminates at low temperatures[J]. Journal of Composite Materials, 2004, 38(13):1151-1164. |

| 11 | Shindo Y, Takahashi S, Takeda T, et al. Mixed-mode interlaminar fracture and damage characterization in woven fabric-reinforced glass/epoxy composite laminates at cryogenic temperatures using the finite element and improved test methods[J]. Engineering Fracture Mechanics, 2008, 75(18):5101-5112. |

| 12 | Tserpes K I, Labeas G, Papanikos P, et al. Strength prediction of bolted joints in graphite/epoxy composite laminates[J]. Composites Part B: Engineering, 2002, 33(7):521-529. |

| 13 | Mi Y, Crisfield M A, Davies G A O, et al. Progressive delamination using interface elements[J]. Journal of Composite Matrerials, 1998, 32(14):1246-1272. |

| 14 | 徐庚. 基于率相关粘接界面模型的夹芯复合材料结构极限强度研究[D]. 武汉:武汉理工大学交通与物流工程学院, 2018. |

| Xu Geng. Study of ultimate strength of sandwich composite structures based on rate dependence adhesive interface model[D]. Wuhan: School of Transportation and Logistics Engineering, Wuhan University of Technology, 2018. | |

| 15 | Benzeggagh M L, Kenane M. Measurement of mixed-mode delamination fracture toughness of unidirectional glass/epoxy composites with mixed-mode bending apparatus[J]. Composites Science and Technology, 1996, 56(4):439-449. |

| 16 | 欧阳林辉. 温度环境对复合材料力学性能影响研究[D]. 西安: 西北工业大学力学与土木建筑学院, 2016. |

| Ouyang Lin-hui. Effect analysis of temperature environment on composite structure mechanical properites[D]. Xi´an: School of Mechanics, Civil Engineering and Architecture, Northwestern Polytechnical University,2016. | |

| 17 | 田宇. SiCp/AlSi3复合材料热残余应力有限元分析[D]. 长春: 吉林大学物理学院, 2009. |

| Tian Yu. Finite element analysis of SiCp/AlSi3 composite thermal residual stress[D]. Chanchun: College of Physics, Jilin University, 2009. |

| [1] | 卫星,高亚杰,康志锐,刘宇辰,赵骏铭,肖林. 低温环境下栓钉环焊缝焊接残余应力场数值模拟[J]. 吉林大学学报(工学版), 2024, 54(1): 198-208. |

| [2] | 宫亚峰,吴树正,毕海鹏,谭国金. 基于现场监测技术的装配式箱涵温度场及冻胀分析[J]. 吉林大学学报(工学版), 2023, 53(8): 2321-2331. |

| [3] | 宋剑锋,黄鑫磊,仪帅,杨振熙,董永刚,李树林. 列车制动过程踏面温度场及应力⁃应变分布特性[J]. 吉林大学学报(工学版), 2023, 53(10): 2773-2784. |

| [4] | 卢晓红,乔金辉,周宇,马冲,隋国川,孙卓. 搅拌摩擦焊温度场研究进展[J]. 吉林大学学报(工学版), 2023, 53(1): 1-17. |

| [5] | 郭庆林,刘强,吴春利,李黎丽,李懿明,刘富春. 导电沥青及混合料裂缝局部温度场及愈合效果[J]. 吉林大学学报(工学版), 2022, 52(6): 1386-1393. |

| [6] | 惠迎新,孙晓荣,王红雨,高晨. 预制T梁早期水化热温度效应及梁端开裂机理[J]. 吉林大学学报(工学版), 2021, 51(5): 1734-1741. |

| [7] | 张艳芹,冯雅楠,孔鹏睿,于晓东,孔祥滨. 基于热油携带的静压支承油膜温度场及试验[J]. 吉林大学学报(工学版), 2019, 49(4): 1203-1211. |

| [8] | 李于朋,孙大千,宫文彪. 6082⁃T6铝合金薄板双轴肩搅拌摩擦焊温度场[J]. 吉林大学学报(工学版), 2019, 49(3): 836-841. |

| [9] | 刘志峰, 赵代红, 王语莫, 浑连明, 赵永胜, 董湘敏. 重载静压转台承载力与油垫温度场分布的关系[J]. 吉林大学学报(工学版), 2018, 48(3): 773-780. |

| [10] | 王国林, 孙砚田, 梁晨, 杨建, 周海超. 应用满应力理论的轮胎轮廓设计[J]. 吉林大学学报(工学版), 2017, 47(2): 365-372. |

| [11] | 邵晴, 徐涛, 徐从占, 郭昊添, 郭桂凯, 张海博. 基于聚醚醚酮保持架的角接触球轴承特性仿真[J]. 吉林大学学报(工学版), 2017, 47(1): 163-168. |

| [12] | 史栋勇1, 2, 盈亮3, 胡平1, 3, 申国哲3, 武文华2, 姜大鑫3. 高强度钢板热成形三维温度场数值模拟分析[J]. 吉林大学学报(工学版), 2014, 44(4): 946-952. |

| [13] | 姜封国, 赵景鲁, 郑重远. 基于荷载抗力设计法的受火钢柱可靠性分析[J]. 吉林大学学报(工学版), 2014, 44(4): 978-984. |

| [14] | 陈燕虹, 吴伟静, 刘宏伟, 沈帅, 李策园, 耿焕亮. 纯电动汽车电池箱的热特性[J]. 吉林大学学报(工学版), 2014, 44(4): 925-932. |

| [15] | 姜封国, 赵景鲁. 受火后钢筋混凝土构件的可靠性[J]. 吉林大学学报(工学版), 2013, 43(06): 1500-1503. |

|

||