吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (1): 198-208.doi: 10.13229/j.cnki.jdxbgxb.20220268

• 交通运输工程·土木工程 • 上一篇

低温环境下栓钉环焊缝焊接残余应力场数值模拟

- 西南交通大学 土木工程学院,成都 610031

Numerical simulation of residual stress field of stud girth weld in low temperature environment

Xing WEI( ),Ya-jie GAO,Zhi-rui KANG,Yu-chen LIU,Jun-ming ZHAO,Lin XIAO(

),Ya-jie GAO,Zhi-rui KANG,Yu-chen LIU,Jun-ming ZHAO,Lin XIAO( )

)

- School of Civil Engineering,Southwest Jiaotong University,Chengdu 610031,China

摘要:

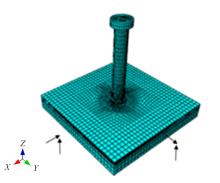

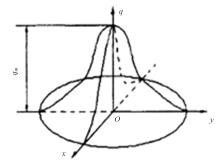

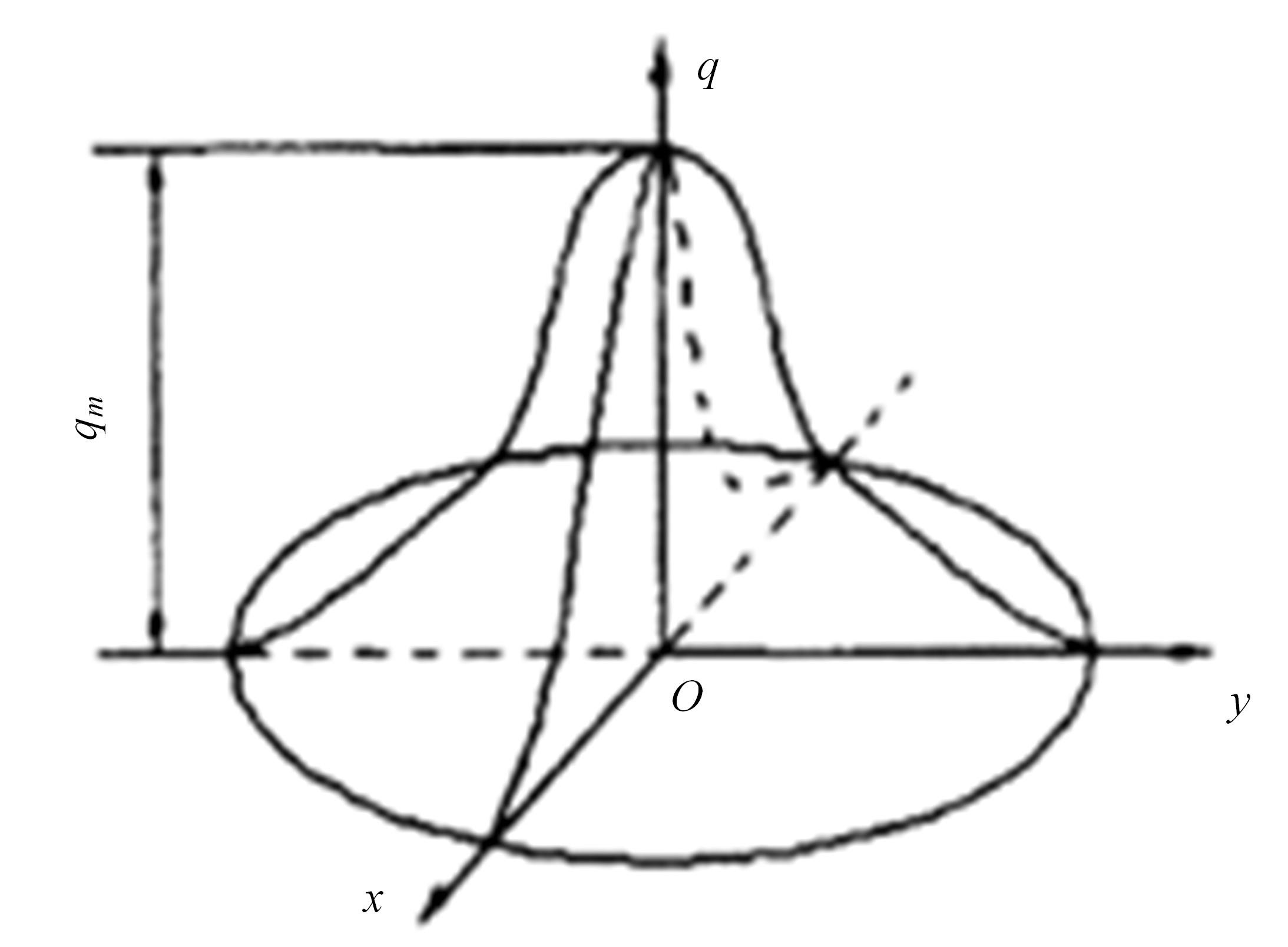

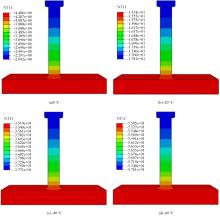

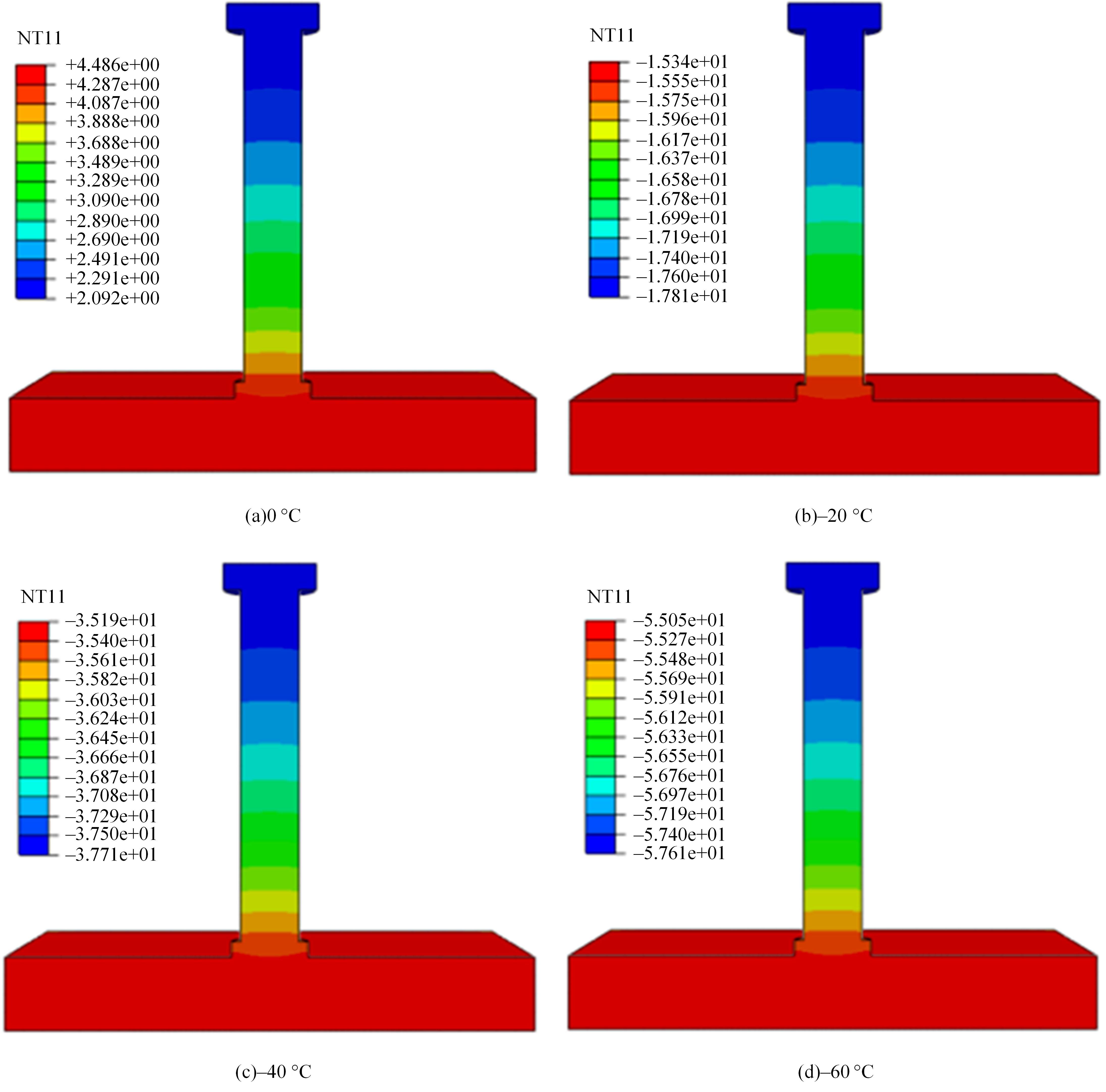

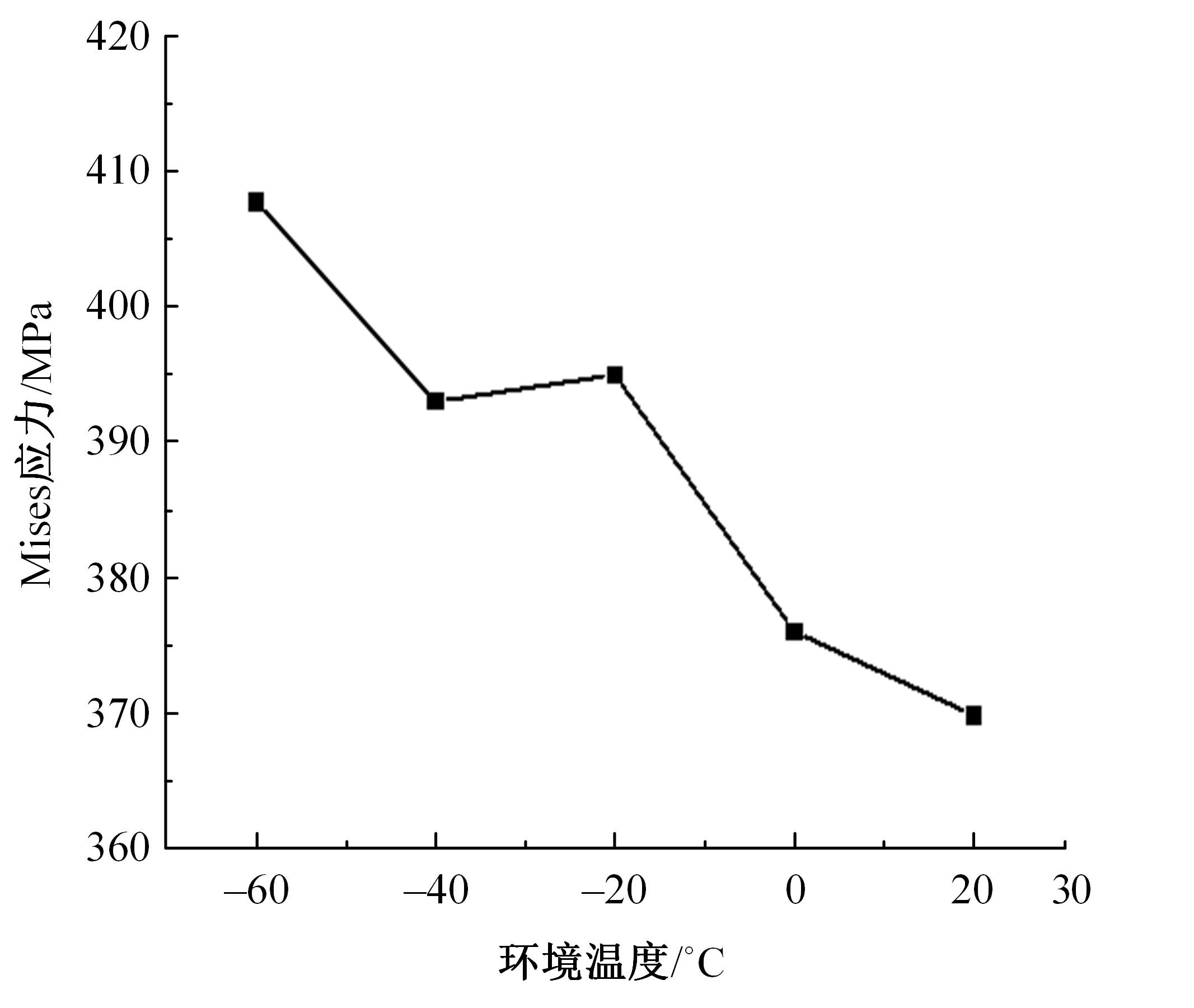

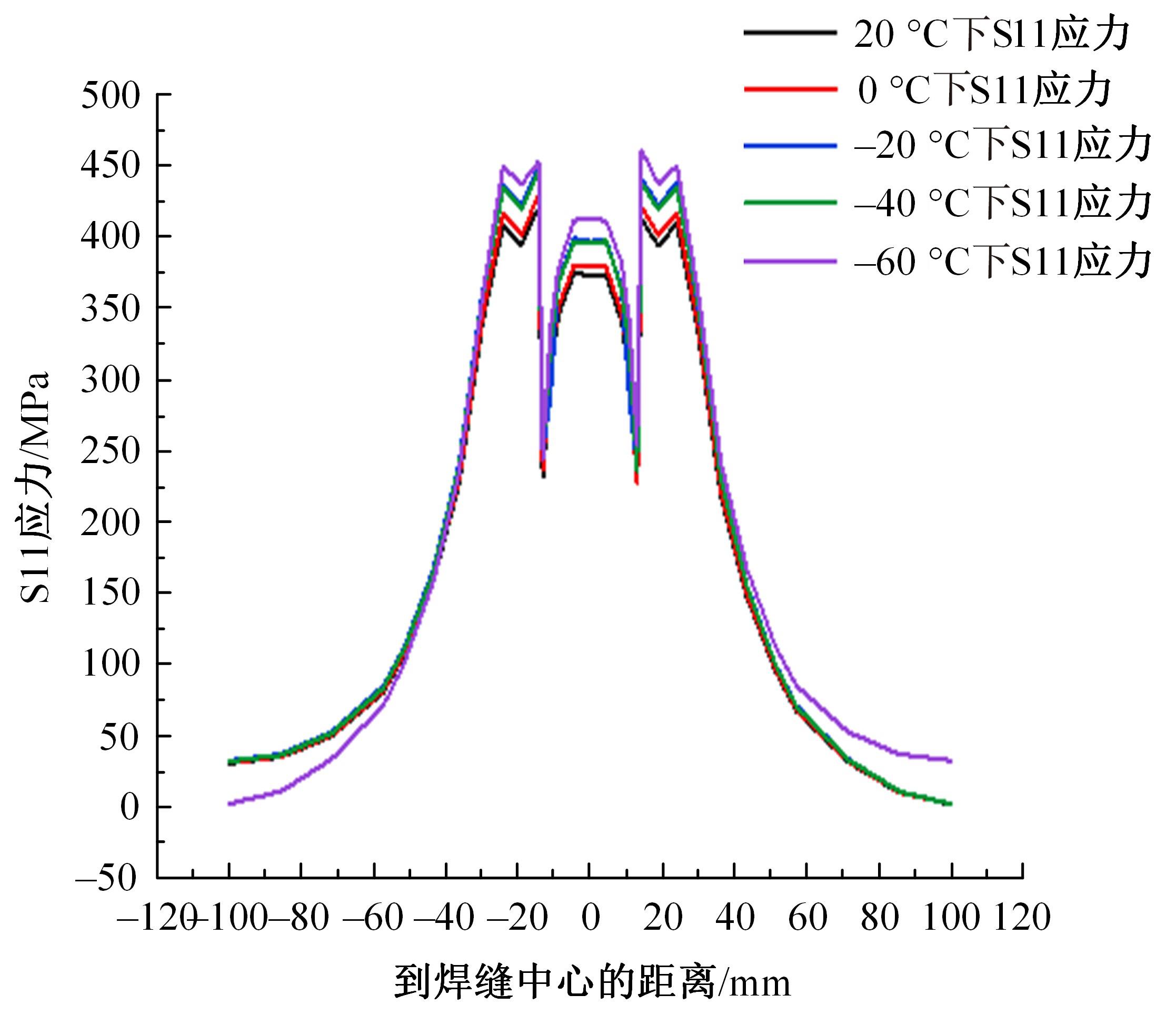

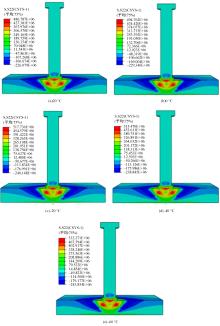

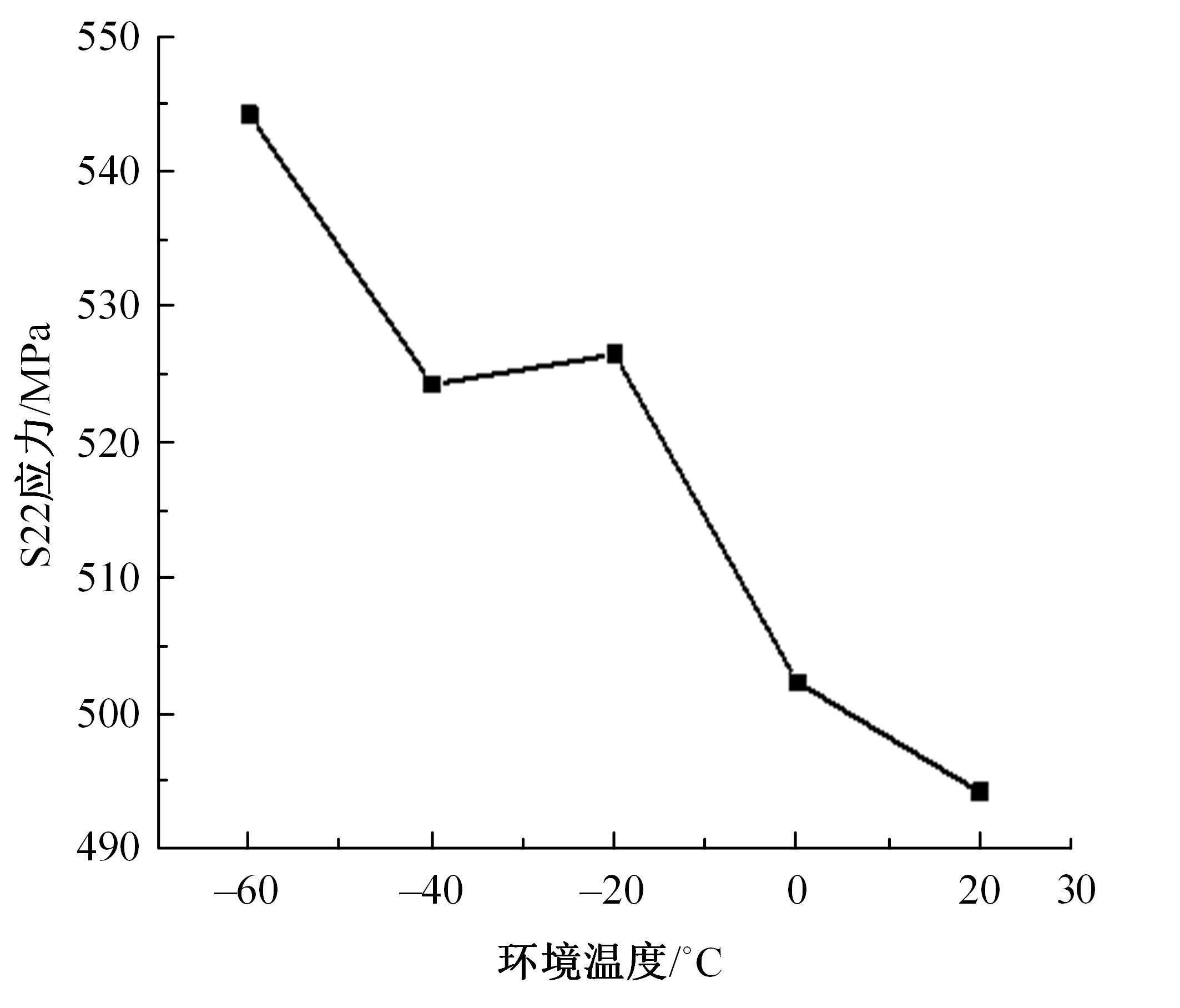

为了研究低温环境对栓钉焊接残余应力分布规律的影响,通过ABAQUS建立栓钉模型进行数值模拟,考虑了5个不同的温度进行有限元热-固耦合分析。结果表明:Mises应力、径向残余应力最大值均位于焊缝附近10 mm处,随着距离的增加迅速衰减;环向残余应力在焊缝附近为残余拉应力,远离焊缝处为残余压应力,最大值位于焊缝中心;低温会提高焊接残余应力,Mises应力集中表现在焊缝中心,环向残余应力集中表现在焊缝附近,径向残余应力在焊缝中心及焊缝附近均有所增加。低温对提高焊接残余拉应力影响明显,对残余压应力影响不大。

中图分类号:

- TU398.9

| 1 | 卫星, 肖林, 温宗意, 等. 钢混组合结构桥梁2020年度研究进展[J]. 土木与环境工程学报, 2021, 43(): 107-119. |

| Wei Xing, Xiao Lin, Wen Zong-yi, et al. Research progress of steel-concrete composite bridges in 2020[J]. Journal of Civil and Environmental Engineering, 2021, 43(Sup.1): 107-119. | |

| 2 | 王天鹏, 张建仁, 肖宏彬. 低温环境下桥梁用结构钢疲劳寿命估算方法[J]. 自然灾害学报, 2020, 29(1): 64-71. |

| Wang Tian-peng, Zhang Jian-ren, Xiao Hong-bin. Estimation method of fatigue life of bridge struct-ural steel in low temperature environment[J]. Journal of Natural Disasters, 2020, 29(1): 64-71. | |

| 3 | 王元清, 廖小伟, 贾单锋, 等. 钢结构的低温疲劳性能研究进展综述[J]. 建筑钢结构进展, 2018, 20(1): 1-11. |

| Wang Yuan-qing, Liao Xiao-wei, Jia Shan-feng, et al. A review of research progress on low temperature fatigue properties of steel structures [J]. Progress in Building Steel Structures, 2018, 20(1): 1-11. | |

| 4 | 张玉玲. 低温环境下铁路钢桥疲劳断裂性能研究[J]. 中国铁道科学, 2008(1): 22-25. |

| Zhang Yu-ling. Research on fatigue fracture performance of railway steel bridge under low temperature environment[J]. China Railway Science, 2008(1): 22-25. | |

| 5 | 刘昱含. 钢板混凝土组合结构中栓钉焊接残余应力测定与影响分析[D]. 上海:上海交通大学船舶海洋与建筑工程学院, 2019. |

| Liu Yu-han. Determination and influence analysis of stud welding residual stress in steel plate-concrete composite structure[D]. Shanghai: School of Ship, Ocean and Architectural Engineerring, Shanghai Jiaotong University, 2019. | |

| 6 | 焦晋峰, 贾朋朋, 贾玥, 等. 钢管-焊接空心球节点焊接残余应力数值模拟及试验研究[J]. 广西大学学报:自然科学版, 2020, 45(6): 1259-1266. |

| Jiao Jin-feng, Jia Peng-peng, Jia Yue, et al. Numerical simulation and experimental research on welding residual stress of steel pipe-welded hollow sphere joints[J]. Journal of Guangxi University(Natural Science Edition), 2020, 45(6): 1259-1266. | |

| 7 | Barsoum Z, Barsoum I. Residual stress effects on fatigue life of welded structures using LEFM[J]. Engineering Failure Analysis, 2009, 16: 449-467. |

| 8 | Barsoum Zuheir. Residual stress analysis and fatigue assessment of welded steel structures[D]. Stockholm,Sweden: KungligaTekniska Högskolan, 2008. |

| 9 | Obeid O, Alfano G, Bahai H, et al. Numerical simulation of thermal and residual stress fields induced by lined pipe welding[J]. Thermal Science and Engineering Progress, 2018, 5: 1-14. |

| 10 | 廖小伟. 低温环境下桥梁钢材与焊接细节的疲劳性能研究[D]. 北京: 清华大学土木工程学院, 2018. |

| Liao Xiao-wei. Research on fatigue properties of bridge steel and welding details in low temperature environment[D]. Beijing: School of Civil Engineering, Tsinghua University, 2018. | |

| 11 | 卫星, 刘茂坤, 肖林, 等. 斜十字接头三维焊接残余应力的数值模拟[J]. 焊接学报, 2019, 40(5): 48-53,78, 163. |

| Wei Xing, Liu Mao-kun, Xiao Lin, et al. Numerical simulation of three-dimensional welding residual stress of inclined cross joints [J]. Chinese Journal of Welding, 2019, 40(5): 48-53, 78,163. | |

| 12 | 王瑞. 钢箱梁制造焊接过程温度场及应力场的数值分析[D]. 成都: 西南交通大学机械工程学院, 2016. |

| Wang Rui. Numerical analysis of temperature field and stress field during welding of steel box girder[D]. Chengdu: School of Mechanical Engineering, Southwest Jiaotong University, 2016. | |

| 13 | Eagar T W, Tsai N S. Temperature fields produced by traveling distributed heat sources[J]. Weld Res Suppl, 1983, 62(12): 346-355. |

| 14 | 贾单锋, 王元清, 崔佳, 等. 桥梁钢Q345qD低温力学性能及冲击韧性试验研究[J]. 钢结构, 2017, 32(5): 41-45. |

| Jia Shan-feng, Wang Yuan-qing, Cui Jia, et al. Experimental study on low temperature mechanical properties and impact toughness of bridge steel Q345qD[J]. Steel Structure, 2017, 32(5): 41-45. |

| [1] | 龙关旭,张修石,辛公锋,王涛,杨干. 融合机器视觉的桥梁动态称重方法[J]. 吉林大学学报(工学版), 2024, 54(1): 188-197. |

| [2] | 谭国金,欧吉,艾永明,杨润超. 基于改进DeepLabv3+模型的桥梁裂缝图像分割方法[J]. 吉林大学学报(工学版), 2024, 54(1): 173-179. |

| [3] | 左新黛,张劲泉,赵尚传. 在役混凝土T梁疲劳刚度退化及寿命预测方法[J]. 吉林大学学报(工学版), 2023, 53(9): 2563-2572. |

| [4] | 郑植,袁佩,金轩慧,魏思斯,耿波. 桥墩复合材料柔性防撞护舷试验[J]. 吉林大学学报(工学版), 2023, 53(9): 2581-2590. |

| [5] | 安然,王有志. 剪力钉连接件拉剪共同作用抗剪性能[J]. 吉林大学学报(工学版), 2023, 53(9): 2554-2562. |

| [6] | 宫亚峰,吴树正,毕海鹏,谭国金. 基于现场监测技术的装配式箱涵温度场及冻胀分析[J]. 吉林大学学报(工学版), 2023, 53(8): 2321-2331. |

| [7] | 王俊,李加武,王峰,张久鹏,黄晓明. 简化U形峡谷风速分布及其对悬索桥抖振响应的影响[J]. 吉林大学学报(工学版), 2023, 53(6): 1658-1668. |

| [8] | 王峰,刘双瑞,王佳盈,宋佳玲,王俊,张久鹏,黄晓明. 尺寸和形状效应对多孔结构风阻系数的影响[J]. 吉林大学学报(工学版), 2023, 53(6): 1677-1685. |

| [9] | 冯宇,郝键铭,王峰,张久鹏,黄晓明. 非平稳极端风作用下大跨桥梁瞬态风致效应分析[J]. 吉林大学学报(工学版), 2023, 53(6): 1638-1649. |

| [10] | 王华,王龙林,张子墨,何昕. 基于裂缝宽度变化的连续刚构桥安全性预警技术[J]. 吉林大学学报(工学版), 2023, 53(6): 1650-1657. |

| [11] | 吴春利,黄诗茗,李魁,顾正伟,黄晓明,张炳涛,杨润超. 基于数值仿真和统计分析的洪水作用下桥墩作用效应分析[J]. 吉林大学学报(工学版), 2023, 53(6): 1612-1620. |

| [12] | 顾正伟,张攀,吕东冶,吴春利,杨忠,谭国金,黄晓明. 基于数值仿真的简支梁桥震致残余位移分析[J]. 吉林大学学报(工学版), 2023, 53(6): 1711-1718. |

| [13] | 江辉,李新,白晓宇. 桥梁抗震结构体系发展述评:从延性到韧性[J]. 吉林大学学报(工学版), 2023, 53(6): 1550-1565. |

| [14] | 谭国金,孔庆雯,何昕,张攀,杨润超,朝阳军,杨忠. 基于动力特性和改进粒子群优化算法的桥梁冲刷深度识别[J]. 吉林大学学报(工学版), 2023, 53(6): 1592-1600. |

| [15] | 刘子玉,陈士通,支墨墨,黄晓明,陈哲心. 可“临-永”转换抢修钢墩应急使用极限承载力[J]. 吉林大学学报(工学版), 2023, 53(6): 1601-1611. |

|

||