吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (9): 2432-2440.doi: 10.13229/j.cnki.jdxbgxb.20221411

• 车辆工程·机械工程 • 上一篇

高速电主轴系统振动特性和精度可靠性分析

- 1.东北大学 机械工程与自动化学院,沈阳 110819

2.大连海洋大学 应用技术学院,辽宁 大连 116399

Vibration characteristics and precision reliability analysis of high-speed motorized spindle system

Xian-zhen HUANG1( ),Bin GUO1,Zhi-yuan JIANG1,Ji-wu TANG2

),Bin GUO1,Zhi-yuan JIANG1,Ji-wu TANG2

- 1.School of Mechanical Engineering and Automation,Northeastern University,Shenyang 110819,China

2.School of Applied Technology,Dalian Ocean University,Dalian 116399,China

摘要:

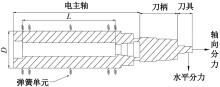

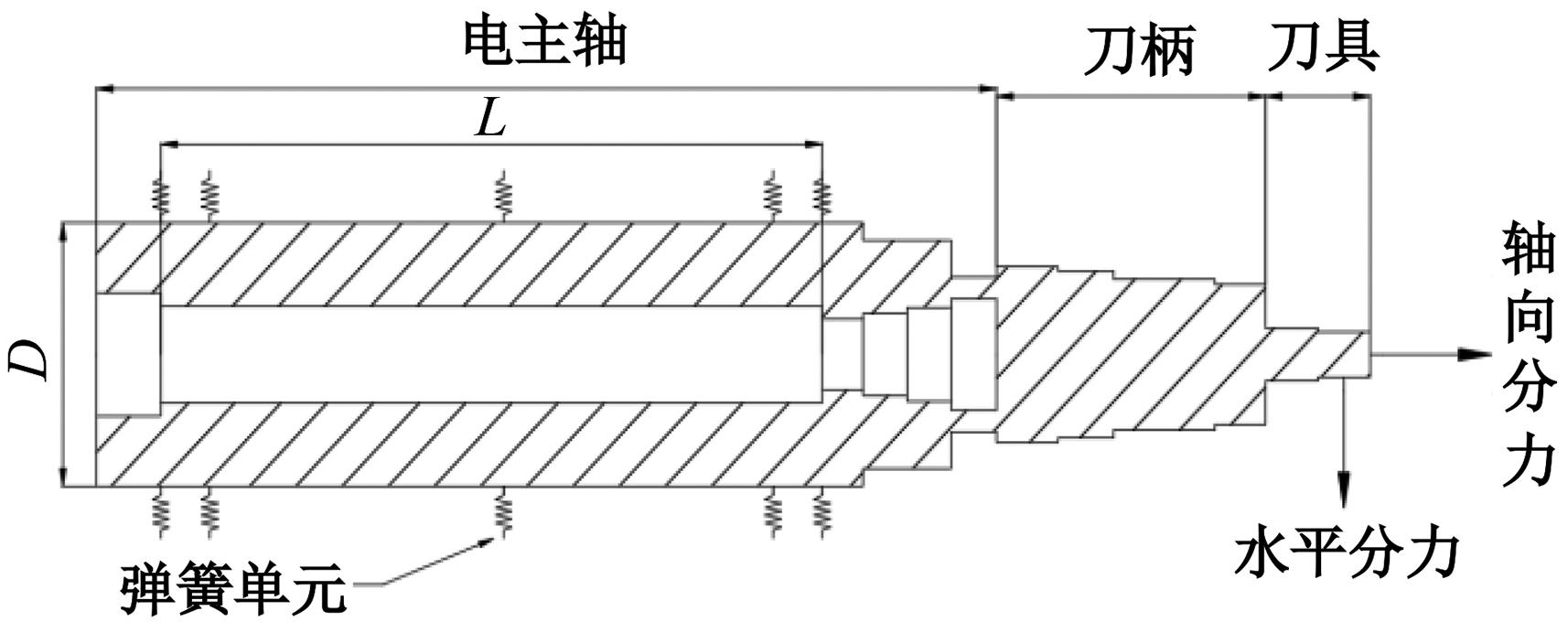

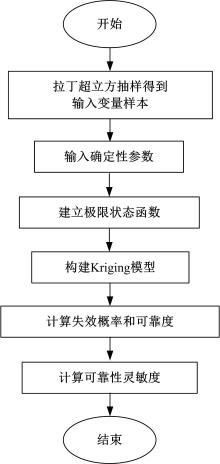

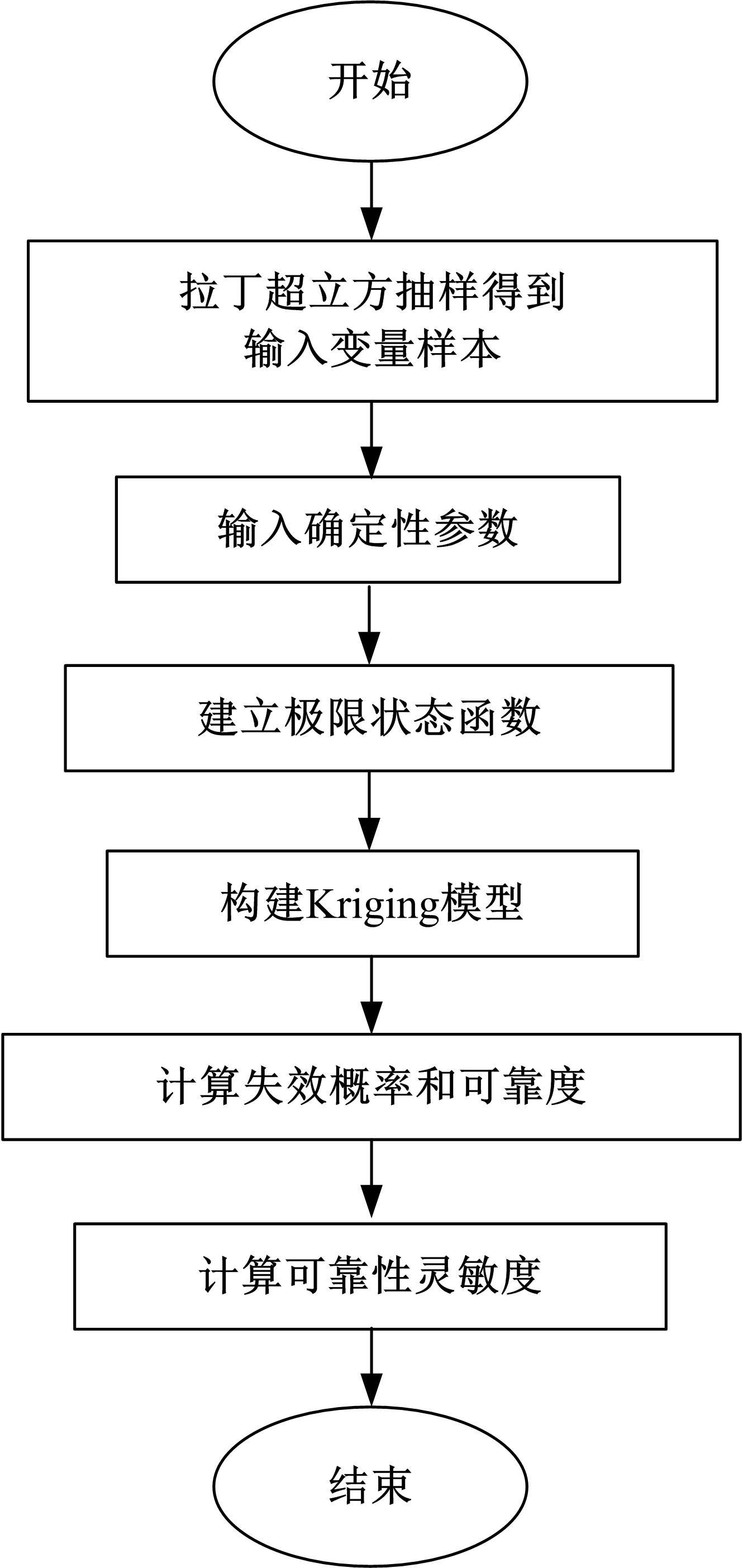

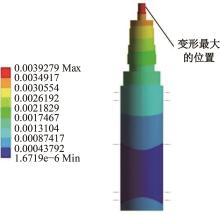

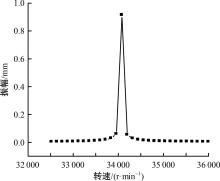

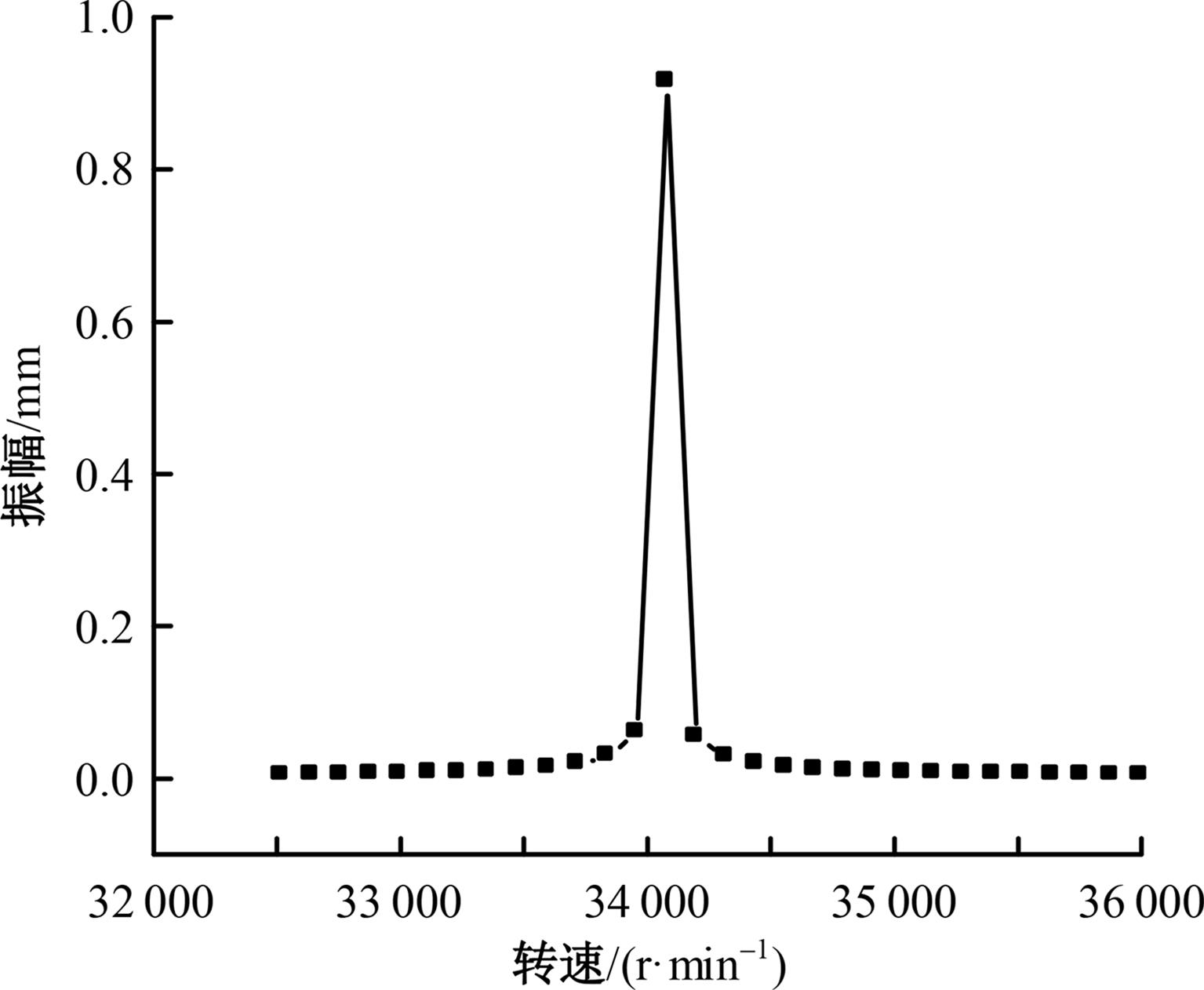

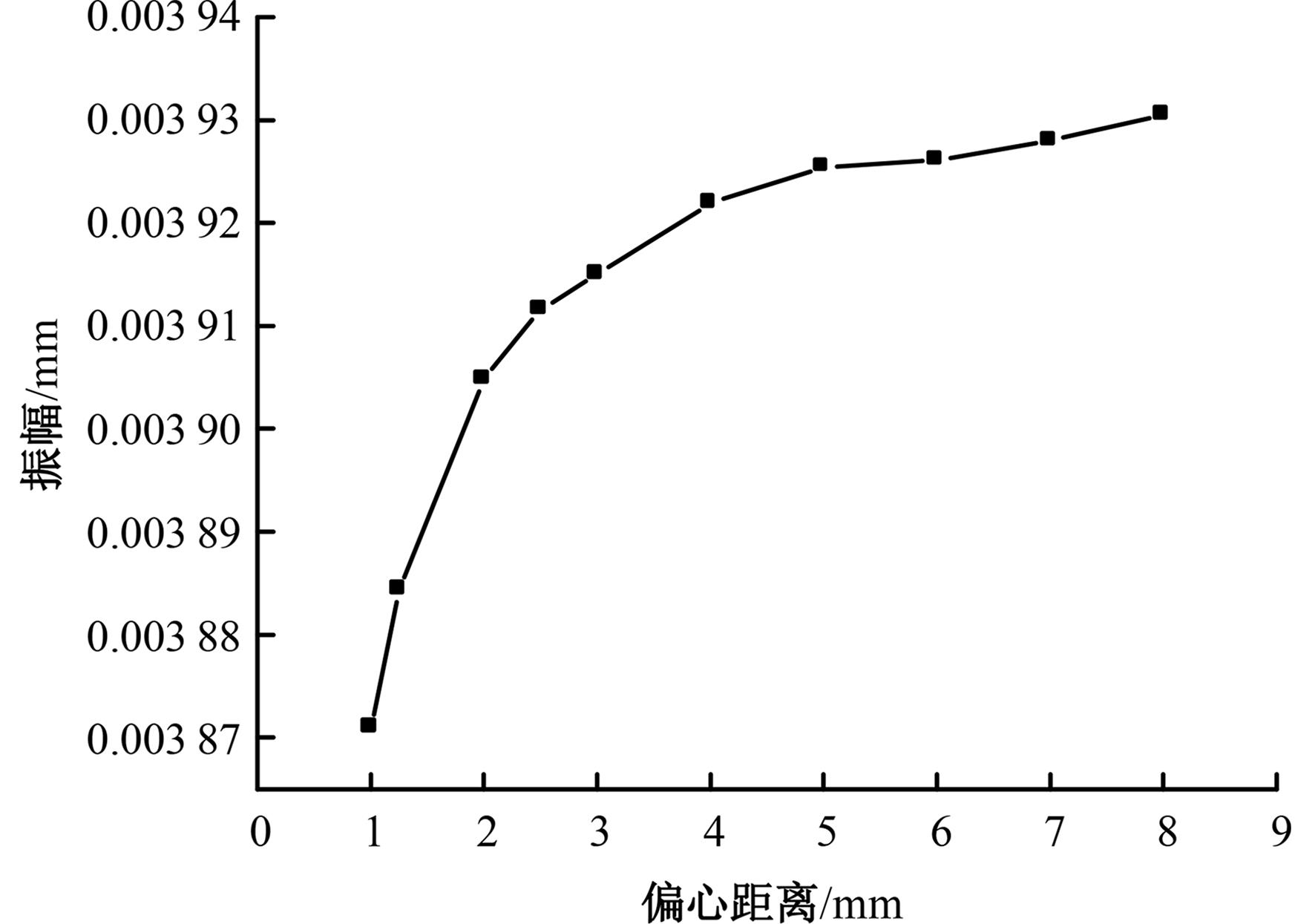

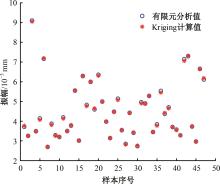

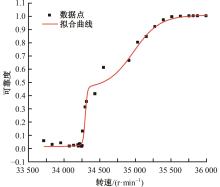

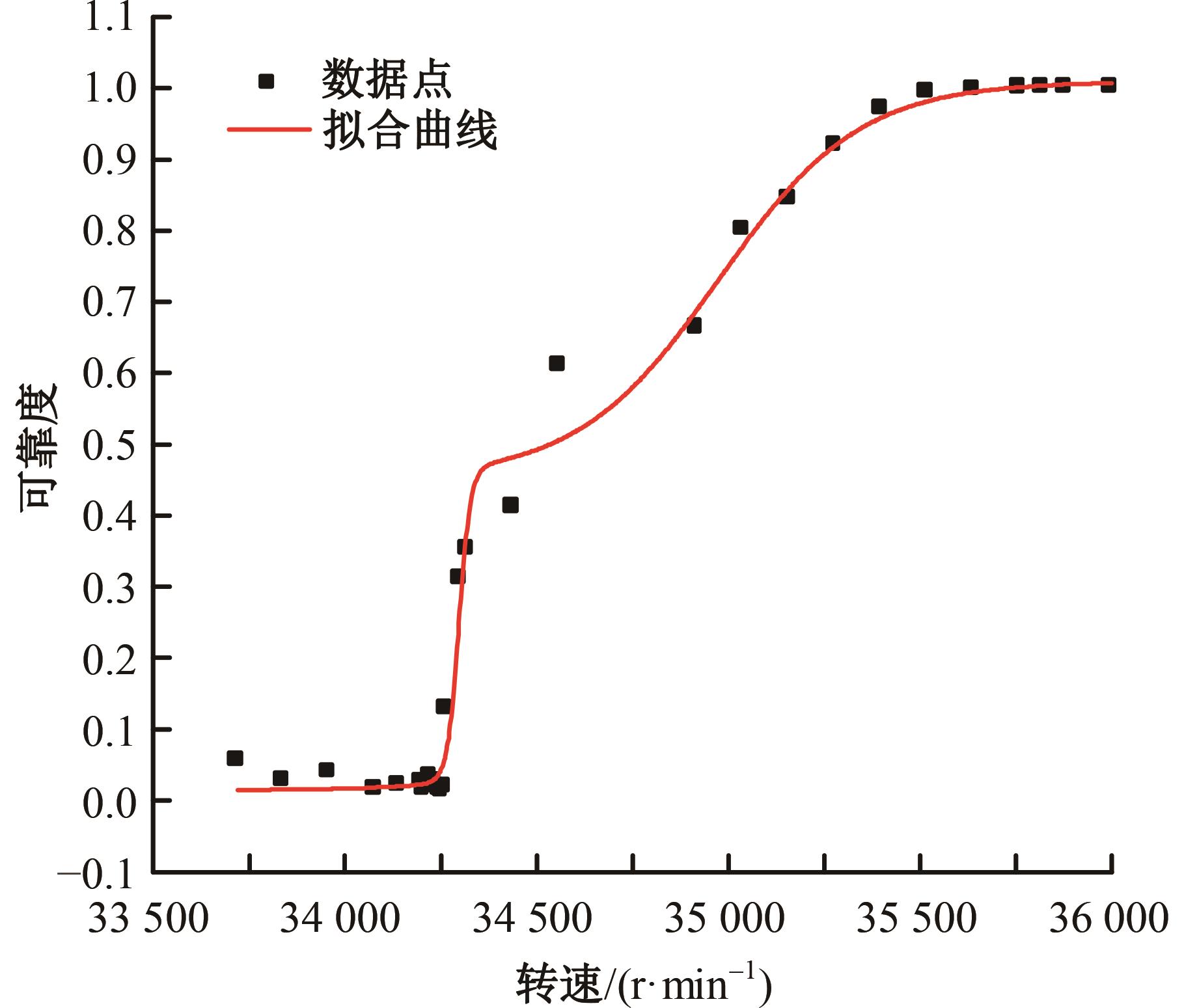

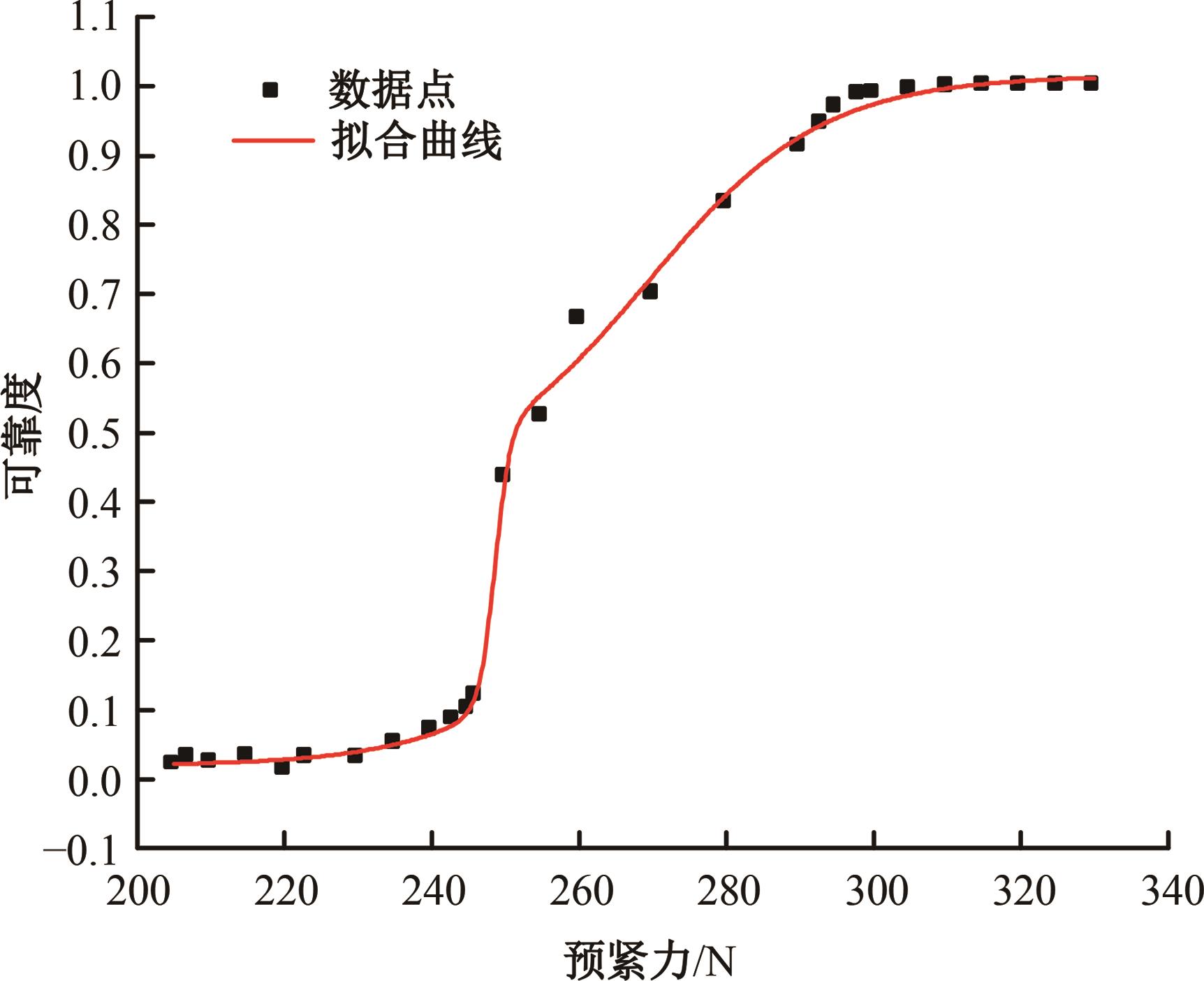

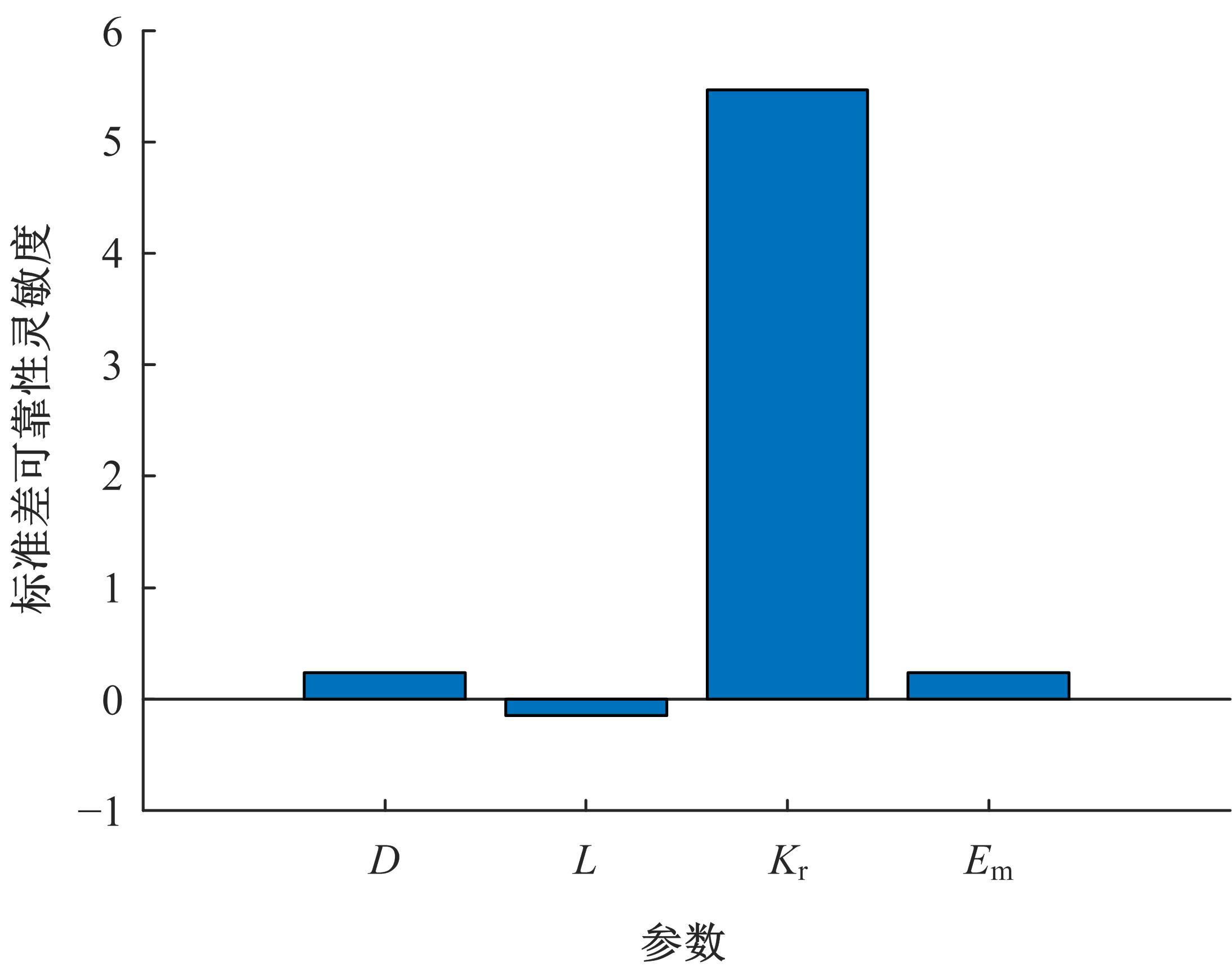

为了量化分析高速电主轴系统的结构和材料参数随机性对电主轴加工质量的影响,基于有限元法建立了电主轴-轴承-刀具系统模型,该模型考虑了质量偏心对电主轴振动特性的影响。此外,以刀尖许用振动幅度为阈值并结合Kriging理论提出了电主轴系统加工精度的可靠性分析方法。最后,采用本文方法深入分析了电主轴转速和预紧力对刀具振动的耦合影响。研究表明:由不平衡量引起的刀具刀尖的振动可靠度分别随着电主轴转速和轴承预紧力的增加而提高。

中图分类号:

- TH122

| 1 | Dai Y, Tao X S, Li Z L, et al. A review of key technologies for high-speed motorized spindles of CNC machine tools[J]. Machines,2022,10(2):145. |

| 2 | 王立平,赵钦志,张彬彬.加工中心高速电主轴综合精度分析[J].清华大学学报:自然科学版,2018,58(8):746-751. |

| Wang Li-ping, Zhao Qin-zhi, Zhang Bin-bin. Machining center high-speed motorized spindle integrated precision analysis [J]. Journal of Tsinghua University (Natural Science Edition), 2018, 58 (8): 746-751. | |

| 3 | 雷群,袁雅阁,杜建军,等.飞刀铣削中高速气浮电主轴转子动态特性研究[J].机械工程学报,2021,57(13):45-54. |

| Lei Qun, Yuan Ya-ge, Du Jian-jun, et al. Study on dynamic characteristics of air floating spindle rotor in flying cutter milling [J]. Journal of Mechanical Engineering,2021,57(13):45-54. | |

| 4 | 蒋书运,林圣业.高速电主轴转子-轴承-外壳系统动力学特性研究[J].机械工程学报,2021,57(13):26-35. |

| Jiang Shu-yun, Lin Sheng-ye. Study on dynamic characteristics of rotor-bearing-housing system of high speed motorized spindle [J]. Journal of Mechanical Engineering,2021,57(13):26-35. | |

| 5 | 何雪浤,蒋彦收,孙志礼.基于ANSYS/PDS模块的高速电主轴刚度可靠性分析[J].机电工程,2011,28(6):645-647, 692. |

| He Xue-yu, Jiang Yan-shou, Sun Zhi-li. Stiffness reliability analysis of high-speed motorized spindle based on ANSYS/PDS module [J]. Mechanical and Electrical Engineering, 2011,28 (6): 645-647, 692. | |

| 6 | 罗静,陈一凡,张根保,等.高速电主轴可靠性优化与分析[J].现代制造工程,2018(7):93-98, 140. |

| Luo Jing, Chen Yi-fan, Zhang Gen-bao, et al. Reliability optimization and analysis of high-speed motorized spindle [J]. Modern Manufacturing Engineering, 2018 (7): 93-98, 140. | |

| 7 | Zhang Z L, Feng S, Ding Y, et al. Thermal error modeling of spindle and dynamic machining accuracy reliability analysis of CNC machine tools based on IA and LHSMC[J]. Maintenance and Reliability,2022, 24(1):100-113. |

| 8 | Xu L J, Zheng X, Zhang J, et al. Vibration characteristics of unbalance response for motorized spindle system[J].Procedia Engineering,2017,174:331-340. |

| 9 | Panda K C, Dutt J K. Optimum support characteristics for rotor–shaft system with preloaded rolling element bearings[J].Journal of Sound & Vibration,2003,260(4):731-755. |

| 10 | Alfares M A, Elsharkawy A A.Effects of axial preloading of angular contact ball bearings on the dynamics of a grinding machine spindle system[J].Journal of Materials Processing Technology,2003,136(1-3):48-59. |

| 11 | Liu J F, Tao L, Chen X A, et al. Dynamics analysis of unbalanced motorized spindles supported on ball bearings[J].Shock and Vibration,2016,2016(Pt.7):No.2787524. |

| 12 | Jorgensen, Bert R. Dynamics of spindle-bearing system at high speed including cutting load effects[J]. Manufacturing Science and Engineering, Transactions of the AMSE, ,1998,120(2):387-394. |

| 13 | 于天彪,王学智,关鹏,等.超高速磨削机床主轴系统模态分析[J].机械工程学报,2012,48(17):183-188. |

| Yu Tian-biao, Wang Xue-zhi, Guan Peng, et al. Modeling analysis of spindle system on ultra-high speed grinder[J].Journal of Mechanical Engineering,2012,48(17):183-188. | |

| 14 | 郭大庆,吴玉厚.陶瓷轴承电主轴主轴的振动模态分析[J].机电产品开发与创新,2006,19(1):13-14. |

| Guo Da-qing, Wu Yu-hou. Vibration mode analysis of ceramic bearing electric spindle [J]. Development and Innovation of Mechanical and Electrical Products,2006,19(1):13-14. | |

| 15 | 李纯洁,洪军,张进华,等.角接触球轴承动刚度的实验研究[J].西安交通大学学报,2013,47(7):68-72, 123. |

| Li Chun-jie, Hong Jun, Zhang Jin-hua, et al. Experimental study on dynamic stiffness of angular contact ball bearing [J]. Journal of Xi 'an Jiaotong University,2013,47(7):68-72, 123. | |

| 16 | 王建平,马福贵,刘宏昭,等.陶瓷球轴承接触角和预紧力对高速磨削电主轴静刚度的影响[J].机械科学与技术,2014,33(7):1018-1022. |

| Wang Jian-ping, Ma Fu-gui, Liu Hong-zhao, et al. Contact angle and preload of ceramic ball bearing are static for high speed grinding motorized spindle[J].Mechanical Science and Technology for Aerospace Engineering, 2014,33 (7) : 1018-1022. | |

| 17 | 张日升,刘维新,余纬,等.基于性能测试的电主轴预防性维修方法研究[J].制造技术与机床,2022(1):38-44. |

| Zhang Ri-sheng, Liu Wei-xin, Yu Wei, et al. Motorized spindle preventive maintenance method based on performance test research [J]. Manufacturing Technology and Machine Tool, 2022 (1) : 38-44. | |

| 18 | 师汉民.机械振动系统[M].2版.武汉:华中科技大学出版社,2004. |

| 19 | 恩溪弄,张义民,黄贤振.车削颤振时变可靠性分析[J].东北大学学报:自然科学版,2019,40(10):1442-1447. |

| Xi-nong En, Zhang Yi-min, Huang Xian-zhen. Time-varying reliability analysis of turning chatter [J]. Journal of Northeastern University (Natural Science Edition),2019,40(10):1442-1447. | |

| 20 | 刘阔,李晓雷,王健.一种基于Kriging模型的机械结构可靠性分析方法[J].东北大学学报:自然科学版,2017,38(7):1002-1006. |

| Liu Kuo, Li Xiao-lei, Wang Jian. An analysis method of mechanical structural reliability based on the Kriging model[J]. Journal of Northeastern University( Natural Science),2017,38(7):1002-1006. | |

| 21 | Sun Z L, Wang J, Li R, et al. LIF: a new Kriging based learning function and its application to structural reliability analysis[J]. Reliability Engineering and System Safety, 2017,157: 152-165. |

| [1] | 陈超,戴孟初,周乐,梁云东. 基于改进综合因素法的农业机械可靠性分配[J]. 吉林大学学报(工学版), 2024, 54(5): 1493-1500. |

| [2] | 汪少华,张启睿,施德华,殷春芳,李春. 双行星排式混合动力传动系统非线性振动响应特性分析[J]. 吉林大学学报(工学版), 2024, 54(4): 890-901. |

| [3] | 王世俊,罗冠炜. 含多种碰撞约束振动系统的周期运动转迁特性[J]. 吉林大学学报(工学版), 2024, 54(4): 902-916. |

| [4] | 樊学平,周衡,刘月飞. 基于Gaussian Copula-贝叶斯动态模型的桥梁构件时变可靠性分析[J]. 吉林大学学报(工学版), 2024, 54(2): 485-493. |

| [5] | 张刘,曾庆铭,赵寰宇,范国伟. 基于Lyapunov理论的卫星大挠性太阳能帆板分布式自适应振动抑制控制方法[J]. 吉林大学学报(工学版), 2023, 53(9): 2676-2685. |

| [6] | 程亚兵,杨泽宇,李岩,安立持,徐泽辉,曹鹏宇,陈璐翔. 基于混合动力汽车正时齿形链系统的振动噪声特性[J]. 吉林大学学报(工学版), 2023, 53(9): 2465-2473. |

| [7] | 刘强,高大湧,刘献礼,贾儒鸿,周强,白峥言. 减振镗杆振动控制研究进展[J]. 吉林大学学报(工学版), 2023, 53(8): 2165-2184. |

| [8] | 黄贤振,孙楷铂,栾晓刚,胡兵. 螺栓预紧连接可靠性灵敏度分析[J]. 吉林大学学报(工学版), 2023, 53(8): 2219-2226. |

| [9] | 姜世杰,陈丕峰,胡科,黄绪震,战明. 利用振动提高熔丝成型制品结合颈的机理分析[J]. 吉林大学学报(工学版), 2023, 53(7): 1920-1928. |

| [10] | 张茂健,金敬福,陈奕颖,陈廷坤. 轮式拖拉机对称结构的振动特性[J]. 吉林大学学报(工学版), 2023, 53(7): 2136-2142. |

| [11] | 金辰,曾孟源,吴荻非. 基于振动传递的水泥混凝土路面接缝损伤感知[J]. 吉林大学学报(工学版), 2023, 53(6): 1736-1745. |

| [12] | 杨艳,侍玉青,张晓蓉,罗冠炜. 一类多刚性限幅振动系统的动态稳定性分析[J]. 吉林大学学报(工学版), 2023, 53(2): 364-375. |

| [13] | 黄智,闵杰,周涛,杨健,肖力行,李林泽. 超声振动辅助砂带磨抛钛合金的磨削力建模分析[J]. 吉林大学学报(工学版), 2023, 53(11): 3069-3077. |

| [14] | 白丽丽,姜封国,周玉明,曾枭. 基于改进鲸鱼算法的结构可靠性优化设计[J]. 吉林大学学报(工学版), 2023, 53(11): 3160-3165. |

| [15] | 宋震,柳杰. 旋转机械振动频率时间序列预测算法[J]. 吉林大学学报(工学版), 2022, 52(8): 1764-1769. |

|

||