吉林大学学报(工学版) ›› 2023, Vol. 53 ›› Issue (7): 2136-2142.doi: 10.13229/j.cnki.jdxbgxb.20220313

• 农业工程·仿生工程 • 上一篇

轮式拖拉机对称结构的振动特性

- 吉林大学 生物与农业工程学院,长春 130022

Vibration symmetry characteristics of wheeled tractor structure

Mao-jian ZHANG( ),Jing-fu JIN,Yi-ying CHEN,Ting-kun CHEN(

),Jing-fu JIN,Yi-ying CHEN,Ting-kun CHEN( )

)

- College of Biological and Agricultural Engineering,Jilin University,Changchun 130022,China

摘要:

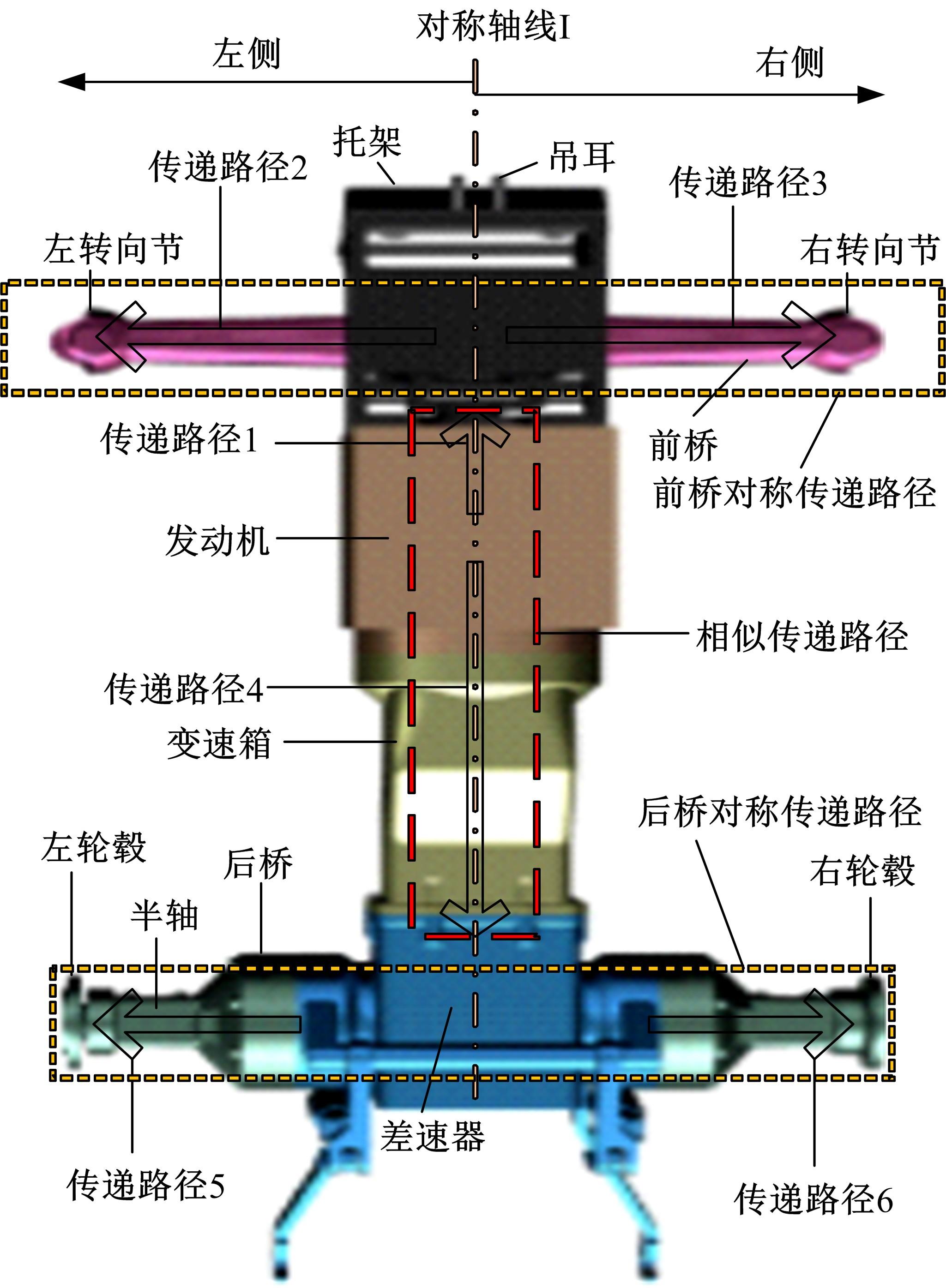

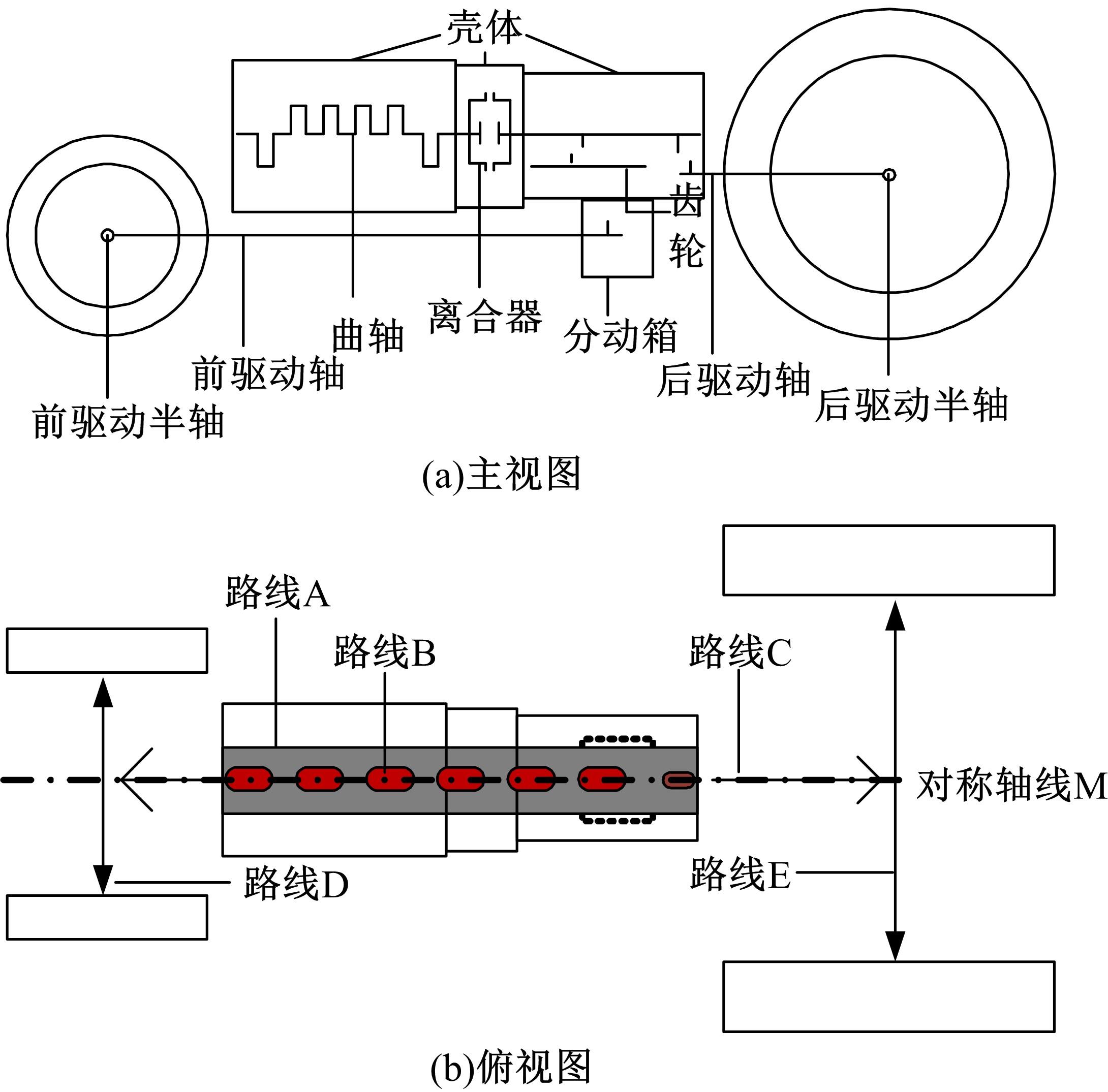

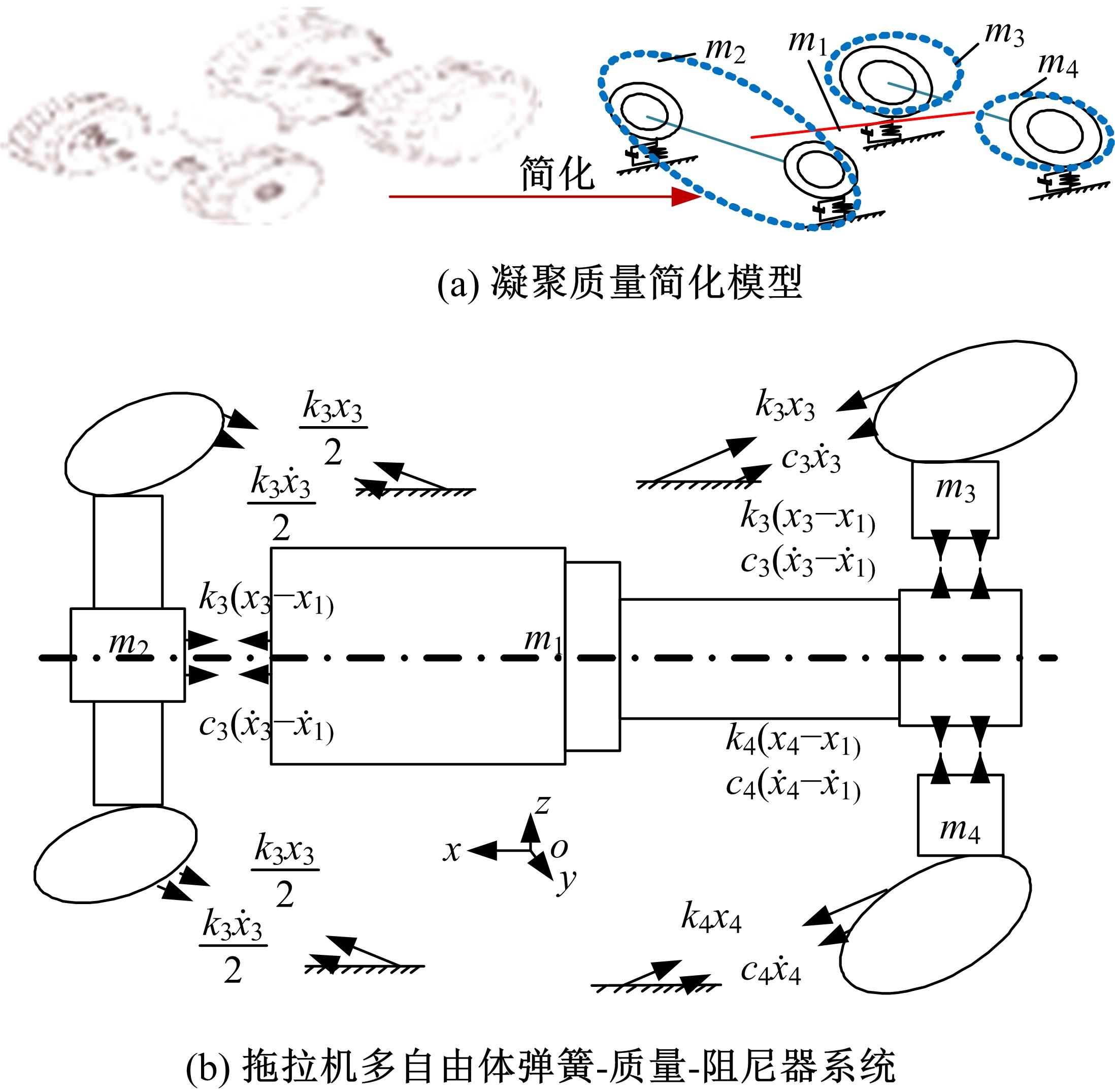

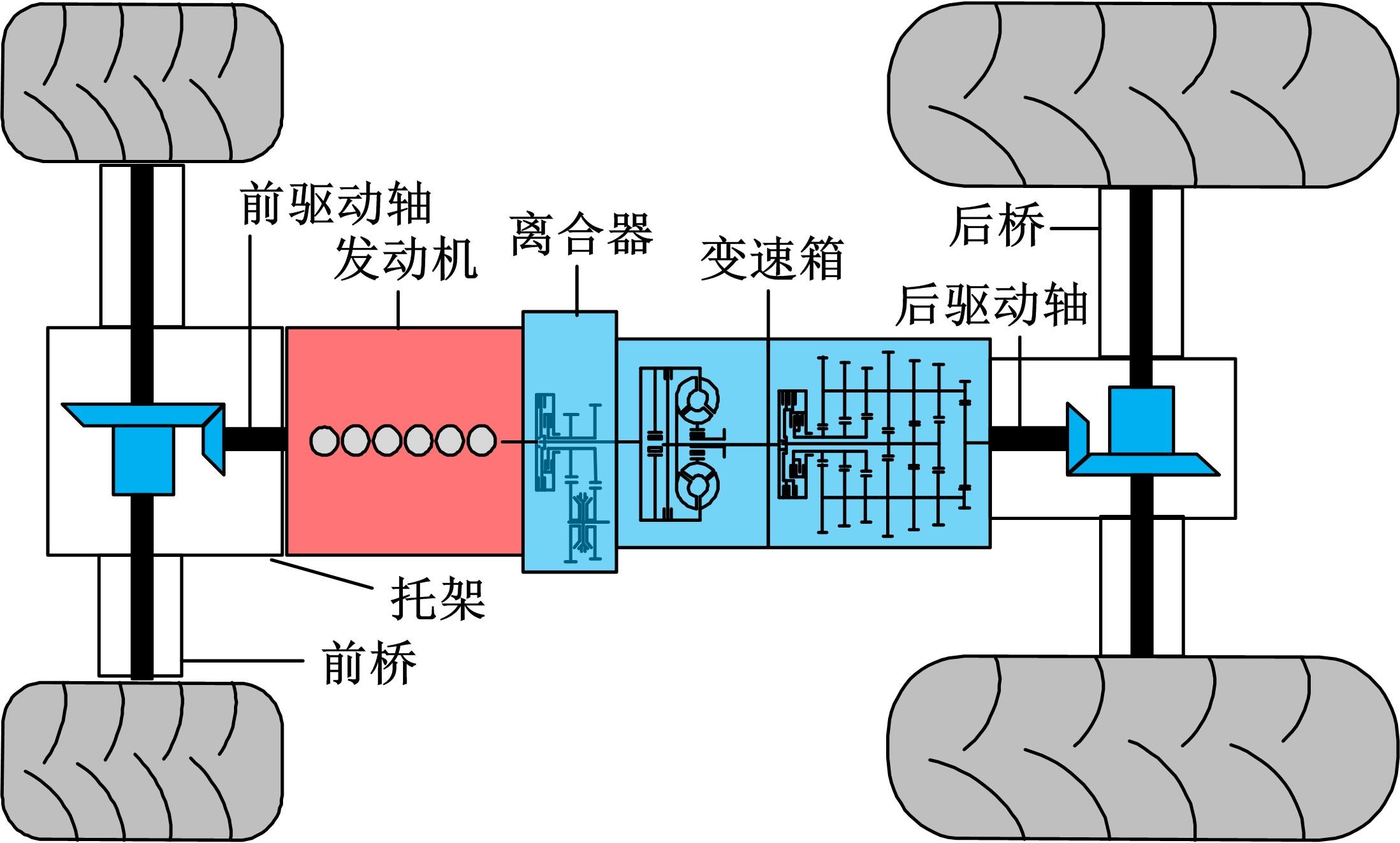

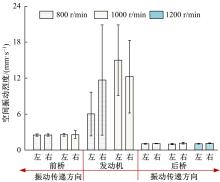

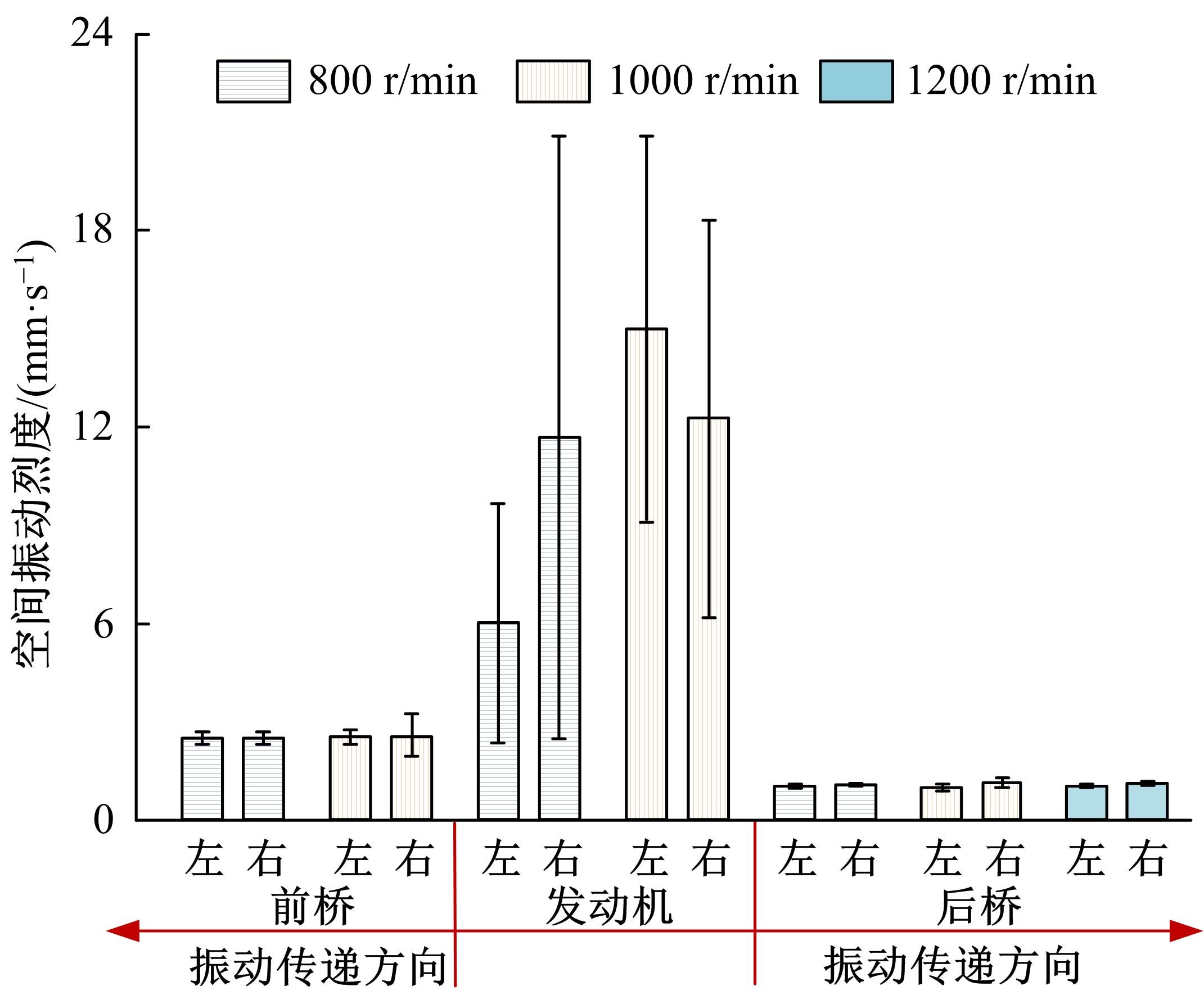

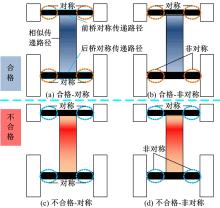

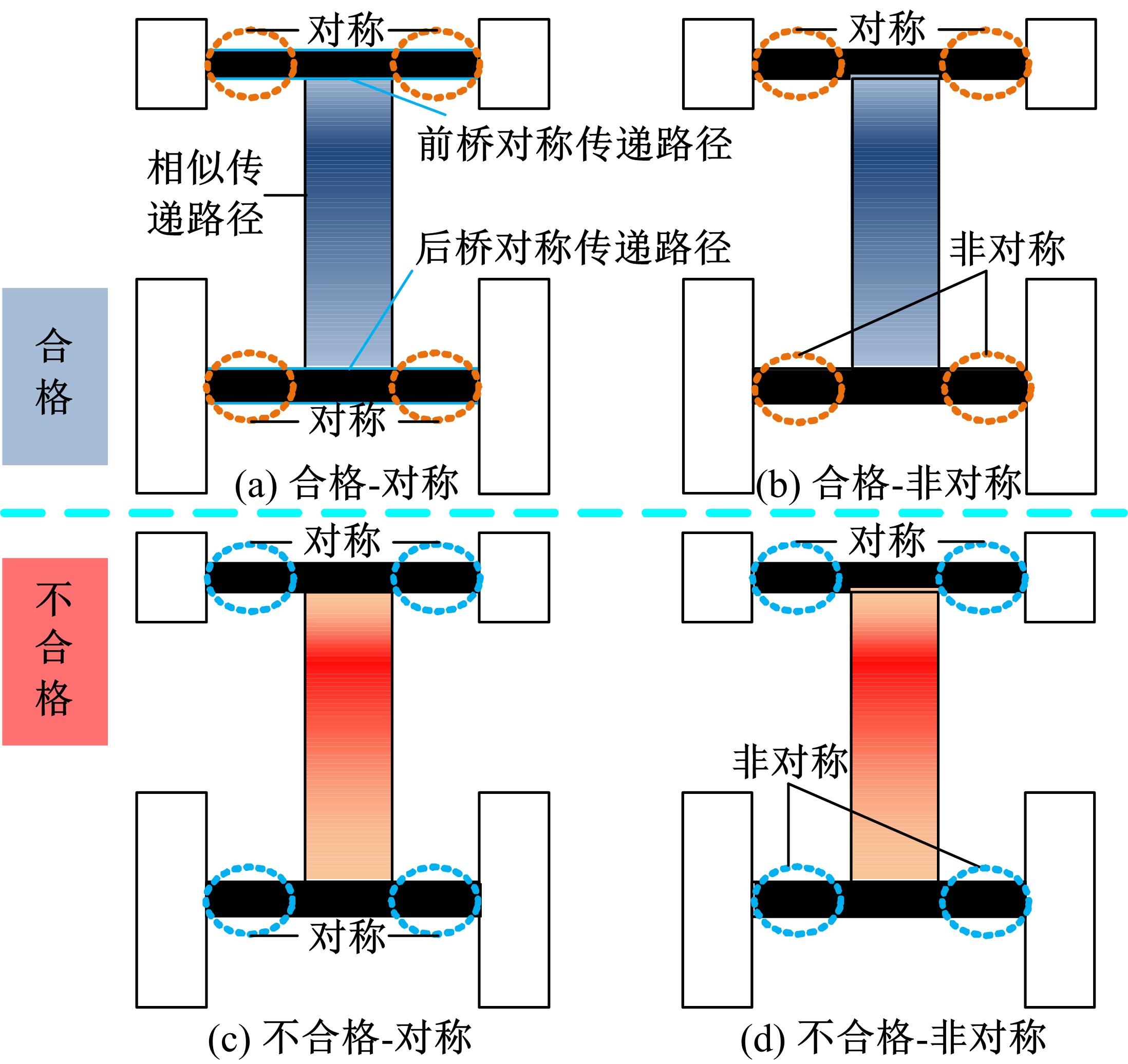

利用振动测试系统对轮式拖拉机整机及结构对称部位的振动特征进行了采集分析,以振动烈度为指标对比了对称结构上的振动相似性。试验表明,拖拉机前桥、后桥对称部位的振动特征具有对称性,对称测点的主振动方向一致,前桥和后桥对称位置振动相似度分别为93.91%和94.29%。分析认为,在特定激励下拖拉机整机及对称部位的振动特征受整机工作状态、零部件缺陷及装配质量影响;怠速条件下拖拉机对称部位的零部件及装配质量的差异改变了振动传递路径,影响对称部位的振动特征相似性。本文提出的拖拉机对称结构的振动特征对比评估方法,可为在线检测拖拉机工作状态、发现机械结构缺陷及故障提供快速甄别方法。

中图分类号:

- S219.1

| 1 | Li J Y, Li X Q, Li Y D, et al. A new method of tractor engine state identification based on vibration characteristics[J]. Processes, 2023, 11(2):No.303. |

| 2 | Qi Bei-bei. Intelligent fault monitoring system of new energy tractor engine for big data[J]. INMATEH―Agricultural Engineering, 2021, 64(2): 205-214. |

| 3 | 李耀明,庞靖,徐立章,等. 基于振动激励溯源的谷物联合收获机清选筛制造缺陷定位[J]. 农业工程学报,2019,35(5):10-17. |

| Li Yao-ming, Pang Jing, Xu Li-zhang, et al. Manufacturing defect location of cleaning screen of grain combine harvester based on vibration excitation tracing[J]. Transactions of the Chinese Society of Agricultural Engineering, 2019, 35(5): 10-17. | |

| 4 | 丁翰韬,陈树人,周巍伟,等. 喂入量扰动下联合收获机振动特性机理研究[J]. 农业机械学报,2022,53():20-27, 51. |

| Ding Han-tao, Chen Shu-ren, Zhou Wei-wei, et al. Mechanism analysis of combine harvester's vibration characteristics under feeding interference[J]. Transactions of the Chinese Society for Agricultural Machinery, 2022, 53(Sup.2): 20-27, 51. | |

| 5 | 柳剑,王世友,李巧菲. 基于任务多样性的农机装备维修策略研究[J]. 农业机械学报,2022,53():69-74, 218. |

| Liu Jian, Wang Shi-you, Li Qiao-fei. Maintenance strategy of agricultural machinery equipment based on task variety[J]. Transactions of the Chinese Society for Agricultural Machinery, 2022, 53(Sup.2): 69-74, 218. | |

| 6 | Xue Li-jun, Jiang Hong-hua, Zhao Ye-hui, et al. Fault diagnosis of wet clutch control system of tractor hydrostatic power split continuously variable transmission[J]. Computers & Electronics in Agriculture, 2022, 194: No.106778. |

| 7 | Mandal S K, Shekh M I, Kumar S, et al. Failure analysis of PTO shaft of an agricultural tractor[J]. Materials Today: Proceedings, 2022,66:3924-3929. |

| 8 | Qi Bei-bei. Intelligent fault monitoring system of new energy tractor engine for big data[J]. INMATEH―Agricultural Engineering, 2021, 64(2): 205-214. |

| 9 | .Mechanical vibration-measurement and evaluation of machine vibration—part 1: general guidelines [S]. |

| 10 | .机械振动:在非旋转部件上测量评价机器的振动 [S]. |

| 11 | 樊新海,李胜利,安钢,等. 装甲车辆传动装置振动烈度监测与评估[J]. 兵工学报,2009,30(3):272-275. |

| Fan Xin-hai, Li Sheng-li, An Gang, et al. Vibration severity monitoring and evaluation for armored vehicle transmission[J]. Acta Armamentarii,2009,30(3):272-275. | |

| 12 | 吉林大学. 一种拖拉机整机装配质量评价方法和检测装置[P].中国:CN111174999A,2020-05-19. |

| 13 | 王连冰,薛静远,韩丽曼,等. 无线三轴振动测试系统的设计[J]. 吉林大学学报:信息科学版,2020,38(2):206-212. |

| Wang Lian-bing, Xue Jing-yuan, Han Li-man, et al. Design of wireless triaxial vibration test system[J]. Journal of Jilin University(Information Science Edition), 2020,38(2):206-212. | |

| 14 | 李贤哲,刘孟楠,徐立友,等. 拖拉机串联式液力机械复合传动系统设计与试验[J]. 农业机械学报,2022,53(1):406-413. |

| Li Xian-zhe, Liu Meng-nan, Xu Li-you, et al. Design and test of tractor serial hydraulic and mechanical hybrid transmission system[J]. Transactions of the Chinese Society for Agricultural Machinery, 2022, 53(1): 406-413. | |

| 15 | 史丽晨,李坤,王海涛,等. 拖拉机行星齿轮箱故障响应特性动力学仿真及验证[J]. 农业工程学报,2018,34(7):66-74. |

| Shi Li-chen, Li Kun, Wang Hai-tao, et al. Fault response characteristics of tractor planetary gearbox based on dynamical simulation and its validation[J]. Transactions of the Chinese Society of Agricultural Engineering, 2018, 34(7): 66-74. | |

| 16 | 方增强,李 娜,史洪涛,等. 拖拉机方向盘振动异常的分析与改进[J]. 机械制造,2022,60(3):79-83. |

| Fang Zeng-qiang, Li Na, Shi Hong-tao, et al. Analysis and improvement of abnormal vibration of steering wheel of tractor[J]. Machinery, 2022, 60(3): 79-83. |

| [1] | 朱光强,李天宇,周福君,王文明. 鲜食玉米仿生摘穗装置设计与试验[J]. 吉林大学学报(工学版), 2023, 53(4): 1231-1244. |

| [2] | 曾山,黄登攀,杨文武,刘伟健,文智强,曾力. 三角履带式再生稻收割机底盘的设计与试验[J]. 吉林大学学报(工学版), 2022, 52(8): 1943-1950. |

| [3] | 魏国粱,张青松,王彪,何坤,廖庆喜. 油菜直播机扣垡犁体参数分析与试验[J]. 吉林大学学报(工学版), 2022, 52(7): 1709-1718. |

| [4] | 温昌凯,谢斌,宋正河,韩建刚,杨倩雯. 拖拉机耐久性加速结构试验设计方法[J]. 吉林大学学报(工学版), 2022, 52(3): 703-715. |

| [5] | 刘佳杰,马兰,向伟,颜波,文庆华,吕江南. 4QM-4.0型麻类青饲料联合收获机研制[J]. 吉林大学学报(工学版), 2022, 52(12): 3039-3048. |

| [6] | 曾百功,黎奎良,叶进,任丽丽,Rashidov Jaloliddin,张明. 工厂化上海青流水线收割装置的设计与试验[J]. 吉林大学学报(工学版), 2022, 52(11): 2756-2764. |

| [7] | 万星宇,廖庆喜,蒋亚军,单伊尹,周宇,廖宜涛. 饲用油菜机械化收获切碎过程离散元仿真与试验[J]. 吉林大学学报(工学版), 2022, 52(11): 2735-2745. |

| [8] | 朱光强,李天宇,周福君. 鲜食玉米仿生摘穗柔性夹持输送装置设计与试验[J]. 吉林大学学报(工学版), 2022, 52(10): 2486-2500. |

| [9] | 梁荣庆,钟波,蒙贺伟,孙志民,坎杂. 4QJ⁃3型青贮燕麦捡拾割台的研制[J]. 吉林大学学报(工学版), 2021, 51(5): 1887-1896. |

| [10] | 袁佳诚,王昌,何坤,万星宇,廖庆喜. 油菜联合收获机筛下物组分质量比对清选性能的影响[J]. 吉林大学学报(工学版), 2021, 51(5): 1897-1907. |

| [11] | 王刚,刘慧力,贾洪雷,郭春江,丛永健,屈明浩. 触碰定位式玉米行间除草装置的设计与试验[J]. 吉林大学学报(工学版), 2021, 51(4): 1518-1527. |

| [12] | 丛茜,徐金,马博帅,张晓超,陈廷坤. 基于虚拟仿真的拖拉机后悬挂检测装置设计与实验[J]. 吉林大学学报(工学版), 2021, 51(2): 754-760. |

| [13] | 付君,张屹晨,程超,陈志,唐心龙,任露泉. 刚柔耦合式小麦脱粒弓齿设计及试验[J]. 吉林大学学报(工学版), 2020, 50(2): 730-738. |

| [14] | 薛钊,付君,陈志,王锋德,韩少平,任露泉. 青饲玉米收获机械切碎装置参数优化试验[J]. 吉林大学学报(工学版), 2020, 50(2): 739-748. |

| [15] | 程超,付君,郝付平,陈志,周德义,任露泉. 清选筛运动参数对玉米芯轴堵筛规律的影响[J]. 吉林大学学报(工学版), 2020, 50(1): 351-360. |

|

||