吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (5): 1493-1500.doi: 10.13229/j.cnki.jdxbgxb.20220849

• 农业工程·仿生工程 • 上一篇

基于改进综合因素法的农业机械可靠性分配

- 中国农业大学 工学院,北京 100083

Reliability allocation of agricultural machinery based on improved integrated factors method

Chao CHEN( ),Meng-chu DAI,Le ZHOU,Yun-dong LIANG

),Meng-chu DAI,Le ZHOU,Yun-dong LIANG

- College of Engineering,China Agricultural University,Beijing 100083,China

摘要:

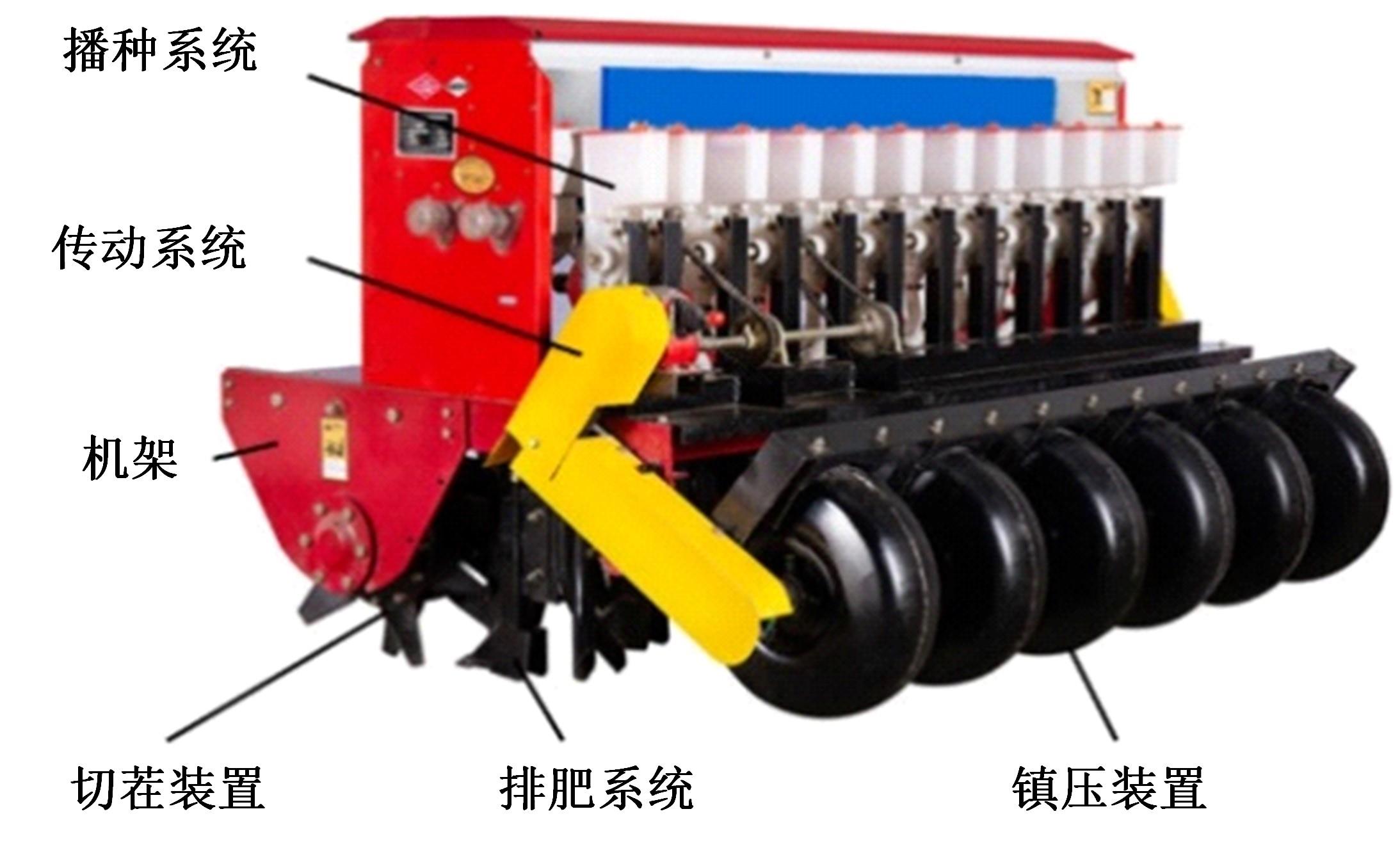

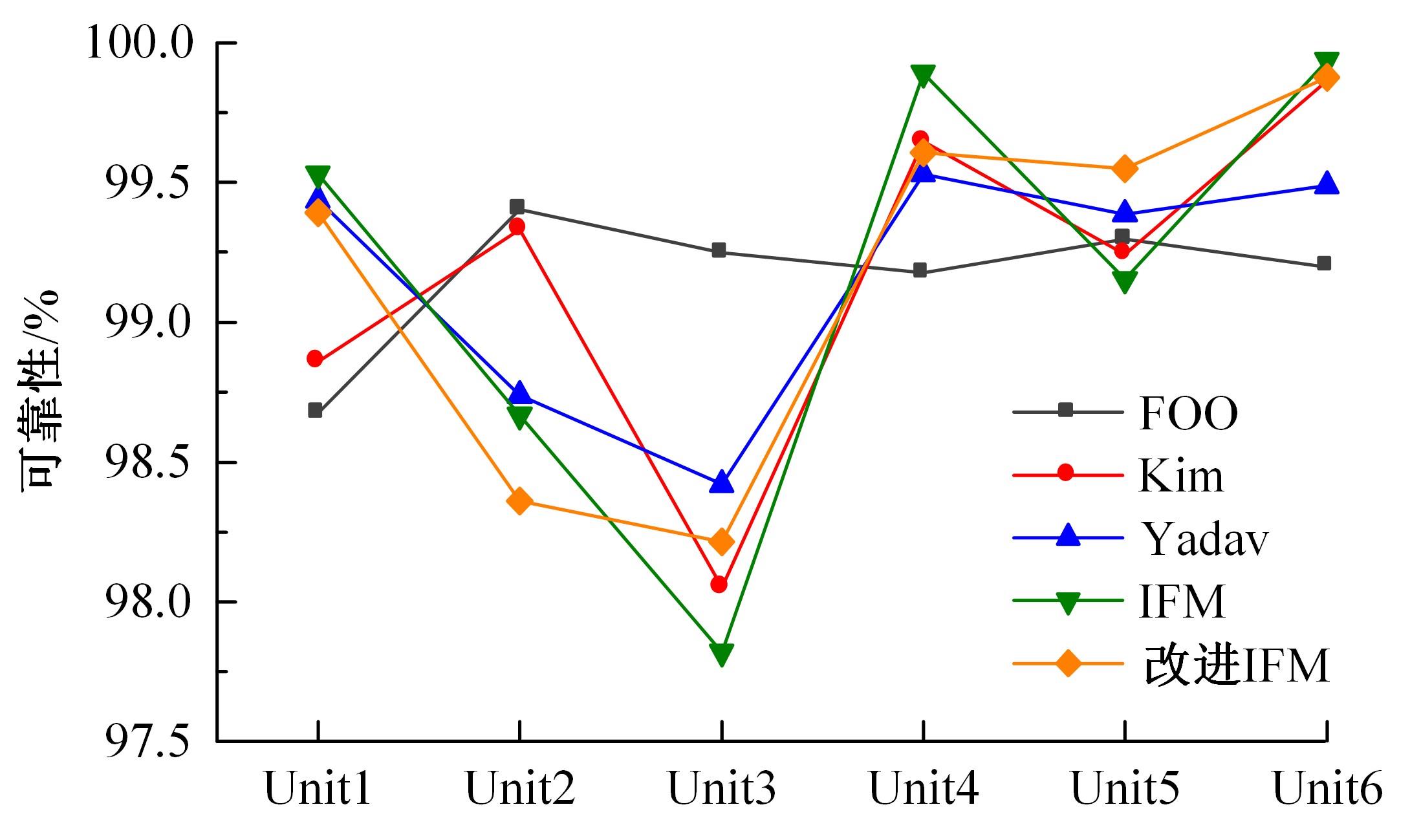

现有可靠性分配方法在农机领域应用较少,为更好地满足农机可靠性分配需求,提出了一种基于改进综合因素法(IFM)的农业机械可靠性分配方法。该方法针对农机特点综合考虑了包含子系统危害度A1、改进潜力A2、复杂度A3、维修性A4、环境条件A5和技术水平A6在内的6种影响因素,并形成子系统故障率分配的权重因子,实现了将指定的系统整体可靠性目标分配至子系统层级。针对新研发产品,给出了各影响因素取值的评价参考标准,可通过故障模式影响及危害性分析(FMECA)结合专家评分定量计算。以2BMQF-6/12免耕播种机为例,应用改进IFM对其进行可靠性分配,并与IFM及FOO、Kim、Yadav方法进行比对,验证了本文所提出方法的可行性。本文方法分配结果合理、流程完善、考虑因素相对全面,可为农机可靠性分配提供参考,为农机产品可靠性设计提供依据。

中图分类号:

- S220

| 1 | 国务院. 国务院关于加快推进农业机械化和农机装备产业转型升级的指导意见[EB/OL]. [2018-12-29]. . |

| 2 | 中华人民共和国农业农村部农业机械化管理司. 2020年玉米免耕播种机质量调查报告[EB/OL]. [2021-02-20]. . |

| 3 | 郝庆波, 杨兆军, 陈传海, 等. 基于区间层次分析法的数控机床可靠性预计[J]. 吉林大学学报:工学版, 2012, 42(4): 845-850. |

| Hao Qing-bo, Yang Zhao-jun, Chen Chuan-hai, et al. Reliability prediction for NC machine tool based on interval AHP[J]. Journal of Jilin University (Engineering and Technology Edition), 2012, 42(4): 845-850. | |

| 4 | 宋林, 王立平, 吴军, 等. 基于信息物理融合和数字孪生的可靠性分析[J]. 吉林大学学报:工学版, 2022, 52(2): 439-449. |

| Song Lin, Wang Li-ping, Wu Jun, et al. Reliability analysis based on cyber-physical system and digital twin[J]. Journal of Jilin University (Engineering and Technology Edition), 2022, 52(2): 439-449. | |

| 5 | Kuo W, Prasad V R, Tillman F A, et al. Optimal reliability design:fundamentals and applications[M]. Cambridge: Cambridge University Press, 2006. |

| 6 | Salazar D, Rocco C M, Galvan B J. Optimization of constrained multiple-objective reliability problems using evolutionary algorithms[J]. Reliability Engineering & System Safety, 2006, 91(9): 1057-1070. |

| 7 | Yalaoui A, Chu C, Chatelet E. Reliability allocation problem in a series-parallel system[J]. Reliability Engineering & System Safety, 2005, 90(1): 55-61. |

| 8 | Kapur K C, Lamberson L R. Reliability in engineering design[M]. New York: John Wiley & Sons, 1977. |

| 9 | Catelani M, Ciani L, Patrizi G, et al. Reliability allocation procedures in complex redundant systems[J]. IEEE Systems Journal, 2017,12(2):1-11. |

| 10 | Advisory Group of Reliability of Electronic Equipment (AGREE) Reliability of military electronic equipment[M]. Washington, DC: Office of the Assistant Secretary of Defense Research and Engineering, 1957. |

| 11 | 向宇,黄大荣,黄丽芬. 基于灰色关联理论AGREE方法的BA系统可靠性分配[J]. 计算机应用研究,2010,27(12):4489-4491. |

| Xiang Yu, Huang Da-rong, Huang Li-fen. Reliability allocation of BA system based on grey relative theory and AGREE[J]. Application Research of Computers, 2010, 27(12):4489-4491. | |

| 12 | Anderson R T. Reliability design handbook[M]. Genoal: IIT Research Institute, 1976. |

| 13 | Di Bona G, Silvestri A, et al. Reliability target assessment based on integrated factors method (IFM): a real case study of a sintering plant[J]. Journal of Failure Analysis and Prevention, 2016, 16(6):1038-1051. |

| 14 | Di Bona G, Falcone D, Silvestri A, et al. IFM target 2.0: an innovative method to define reliability target for prototype systems[J]. The International Journal of Advanced Manufacturing Technology, 2018, 95(9-12): 3349-3367. |

| 15 | Department of Defense of USA. MIL-H , Electronic design reliability handbook[S]. |

| 16 | Kim K O, Yang Y, Zuo M J. A new reliability allocation weight for reducing the occurrence of severe failure effects[J]. Reliability Engineering & System Safety, 2013, 117:81-88. |

| 17 | Yadav O P, Zhuang X. A practical reliability allocation method considering modified criticality factors [J]. Reliability Engineering & System Safety, 2014, 129:57-65. |

| 18 | 张玉刚,孙杰,喻天翔. 考虑不同失效相关性的系统可靠性分配方法[J]. 机械工程学报,2018,54(24):206-215. |

| Zhang Yu-gang, Sun Jie, Yu Tian-xiang. A reliability allocation method considering failure correlation based on vine copula[J]. Journal of Mechanical Engineering, 2018,54(24):206-215. | |

| 19 | Zhang Y G, Yu T, Song B. A reliability allocation method of mechanism considering system performance reliability[J]. Quality and Reliability Engineering, 2019, 35(7): 2240-2260. |

| 20 | Li G, Zhong Y, Chen C, et al. Reliability allocation method based on linguistic neutrosophic numbers weight Muirhead mean operator[J]. Expert Systems with Applications, 2022, 193: No. 116504. |

| 21 | . 故障模式、影响及危害性分析指南 [S]. |

| 22 | 蒋平, 李浩泽, 杜洪恿, 等. 基于FMECA方法的旋耕机可靠性分析[J]. 中国农机化学报, 2019, 40(12): 212-216. |

| Jiang Ping, Li Hao-ze, Du Hong-yong, et al. Reliability analysis of rotary tiller based on FMECA method[J]. Journal of Chinese Agricultural Mechanization, 2019, 40(12): 212-216. | |

| 23 | Wang Yi-qiang, Richard C.M. Yam, Ming J. Zuo,et al. A comprehensive reliability allocation method for design of CNC lathes[J]. Reliability Engineering & System Safety, 2001, 72(3): 247-252. |

| 24 | Department of Defense. MIL HDBK 217F, Reliability Prediction of Electronic Equipment[Z]. |

| [1] | 张国忠,丁凯权,李正博,陈龙,唐楠锐,刘婉茹,黄海东,周勇,王洪昌. 基于泥鳅体表的水稻直播机仿生滑板设计与试验[J]. 吉林大学学报(工学版), 2024, 54(5): 1482-1492. |

| [2] | 张伏,娄立民,钱丹,王世强,冯春凌,赵一荣. 大方捆打捆机压缩机构优化设计及试验[J]. 吉林大学学报(工学版), 2024, 54(4): 1166-1174. |

| [3] | 冯斌,张涛,梁涛,张莹,唐兴隆,王关平. 电驱式青贮饲料打捆裹膜机设计与试验[J]. 吉林大学学报(工学版), 2024, 54(2): 564-573. |

| [4] | 胡斌,袁成林,解彦宇,郭孟宇,罗昕,潘峰,李俊伟. 基于水泵负压输送的切膜排杂装置设计与试验[J]. 吉林大学学报(工学版), 2024, 54(1): 268-280. |

| [5] | 马帅,徐丽明,许述财,牛丛,闫成功,谭好超. 刮刷组合式葡萄藤防寒土清土机设计与试验[J]. 吉林大学学报(工学版), 2024, 54(1): 294-312. |

| [6] | 史瑞杰,戴飞,赵武云,杨发荣,张锋伟,赵一鸣,曲浩,王天福,郭军海. 自走式藜麦联合收割机设计及试验[J]. 吉林大学学报(工学版), 2023, 53(9): 2686-2694. |

| [7] | 周鹏飞,陈学庚,蒙贺伟,梁荣庆,张炳成,坎杂. 滚筒式机收膜杂除土装置设计及试验[J]. 吉林大学学报(工学版), 2023, 53(9): 2718-2731. |

| [8] | 刘伟健,罗锡文,曾山,文智强,曾力. 履带式再生稻收获机田间转弯机理和性能试验[J]. 吉林大学学报(工学版), 2023, 53(9): 2695-2705. |

| [9] | 石林榕,赵武云. 西北寒旱农区胡麻滚勺式精量穴播器的设计及试验[J]. 吉林大学学报(工学版), 2023, 53(9): 2706-2717. |

| [10] | 张茂健,金敬福,陈奕颖,陈廷坤. 轮式拖拉机对称结构的振动特性[J]. 吉林大学学报(工学版), 2023, 53(7): 2136-2142. |

| [11] | 耿端阳,纪晓琦,牟孝栋,李华彪,杨昊霖,姚艳春,武继达. 构树收获割台设计与试验[J]. 吉林大学学报(工学版), 2023, 53(7): 2152-2164. |

| [12] | 曹肆林,谢建华,杨豫新,刘永瑞,卢勇涛,孙博. 侧排式棉秸秆还田及残地膜回收联合作业机的设计与试验[J]. 吉林大学学报(工学版), 2023, 53(5): 1514-1528. |

| [13] | 张学军,黄爽,史增录,于永良,周鑫城,靳伟,陈勇,洪佳. 残膜捡拾打包机的设计与试验[J]. 吉林大学学报(工学版), 2023, 53(4): 1220-1230. |

| [14] | 陈永,陈学庚,何浩猛,罗昕,余幸,胡斌. 基于灌溉引水渠介质的膜秆分离装置设计与试验[J]. 吉林大学学报(工学版), 2023, 53(4): 1245-1256. |

| [15] | 朱光强,李天宇,周福君,王文明. 鲜食玉米仿生摘穗装置设计与试验[J]. 吉林大学学报(工学版), 2023, 53(4): 1231-1244. |

|

||