吉林大学学报(工学版) ›› 2020, Vol. 50 ›› Issue (1): 77-83.doi: 10.13229/j.cnki.jdxbgxb20190114

熔融沉积成型技术3D打印机加热系统的模糊自适应PID控制

- 吉林大学 机械与航空航天工程学院,长春 130022

Fuzzy self⁃adaptive PID control for fused deposition modeling 3D printer heating system

Xing-tian QU( ),Xue-xu WANG,Hui-chao SUN(

),Xue-xu WANG,Hui-chao SUN( ),Kun ZHANG,Long-wei YAN,Hong-yi WANG

),Kun ZHANG,Long-wei YAN,Hong-yi WANG

- College of Mechanical and Aerospace Engineering, Jilin University, Changchun 130022, China

摘要:

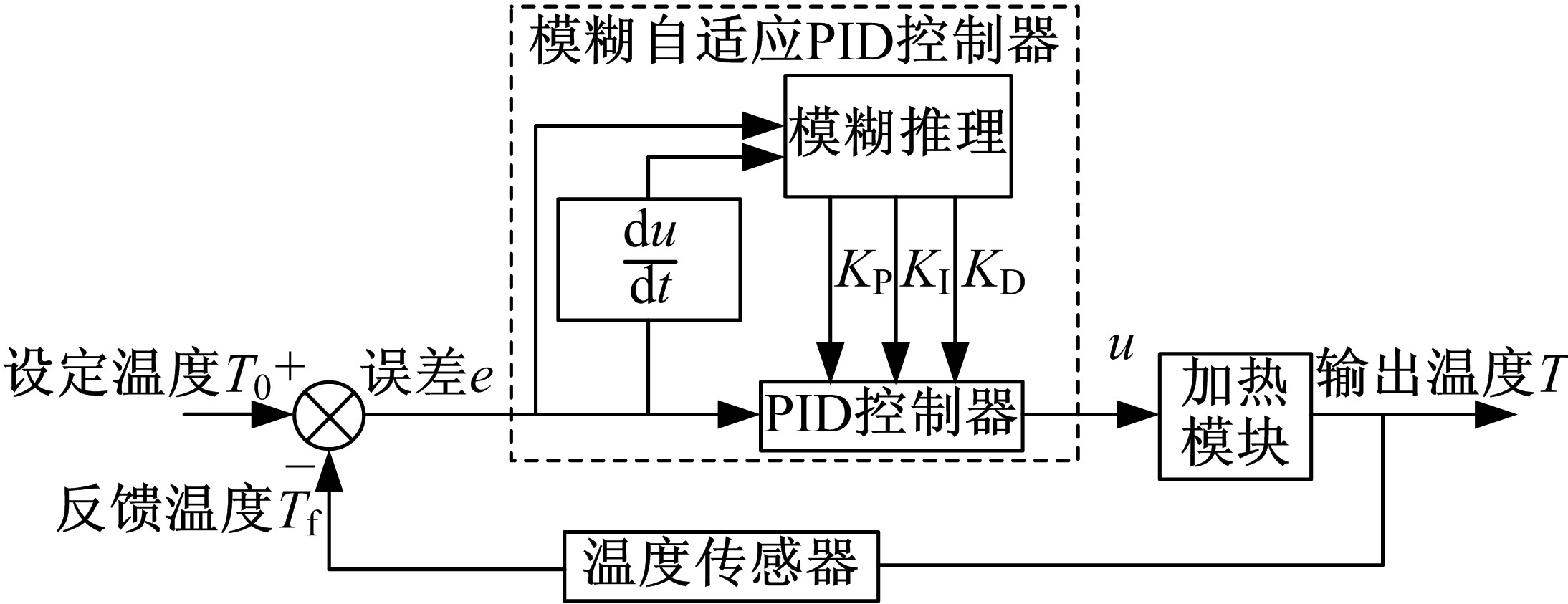

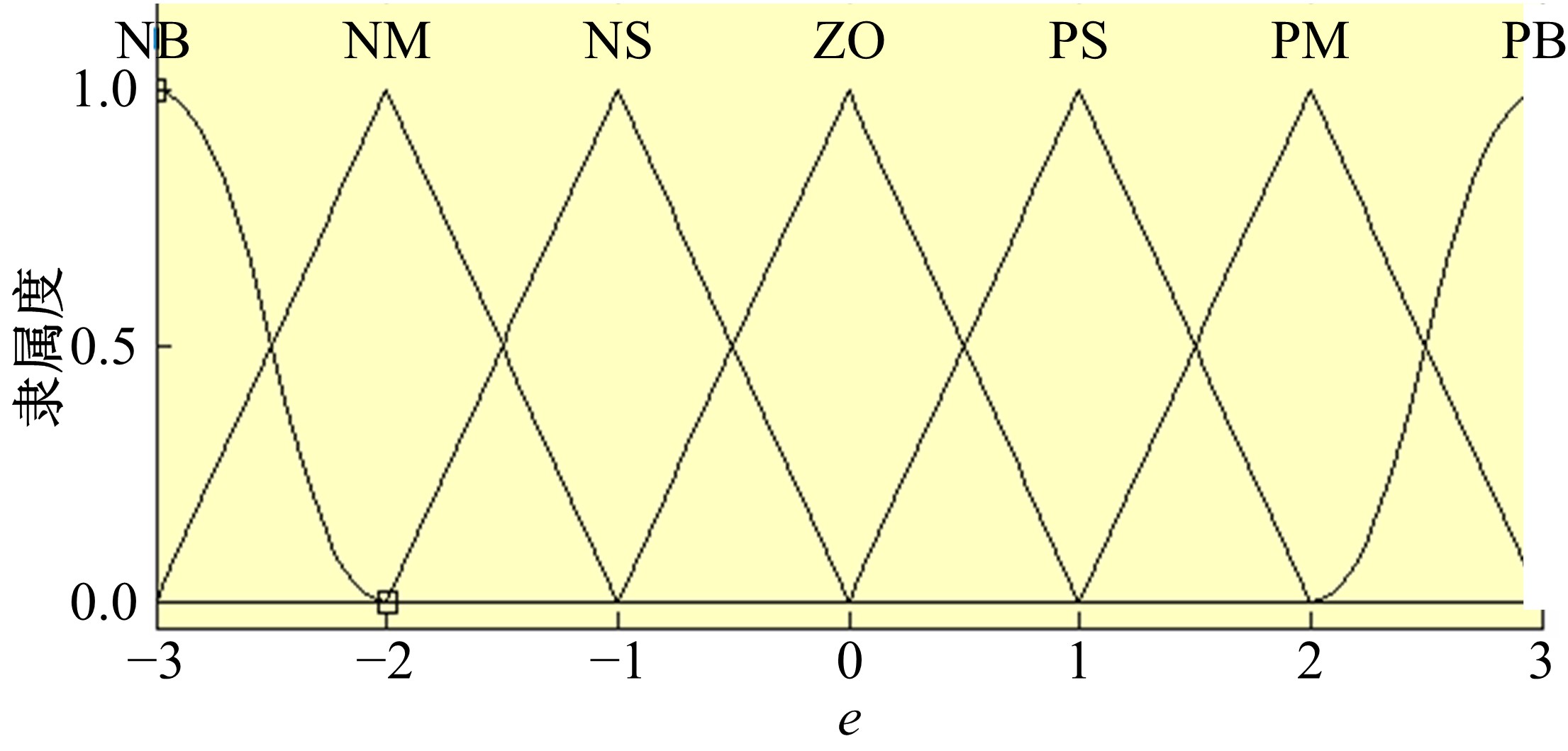

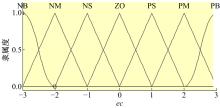

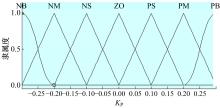

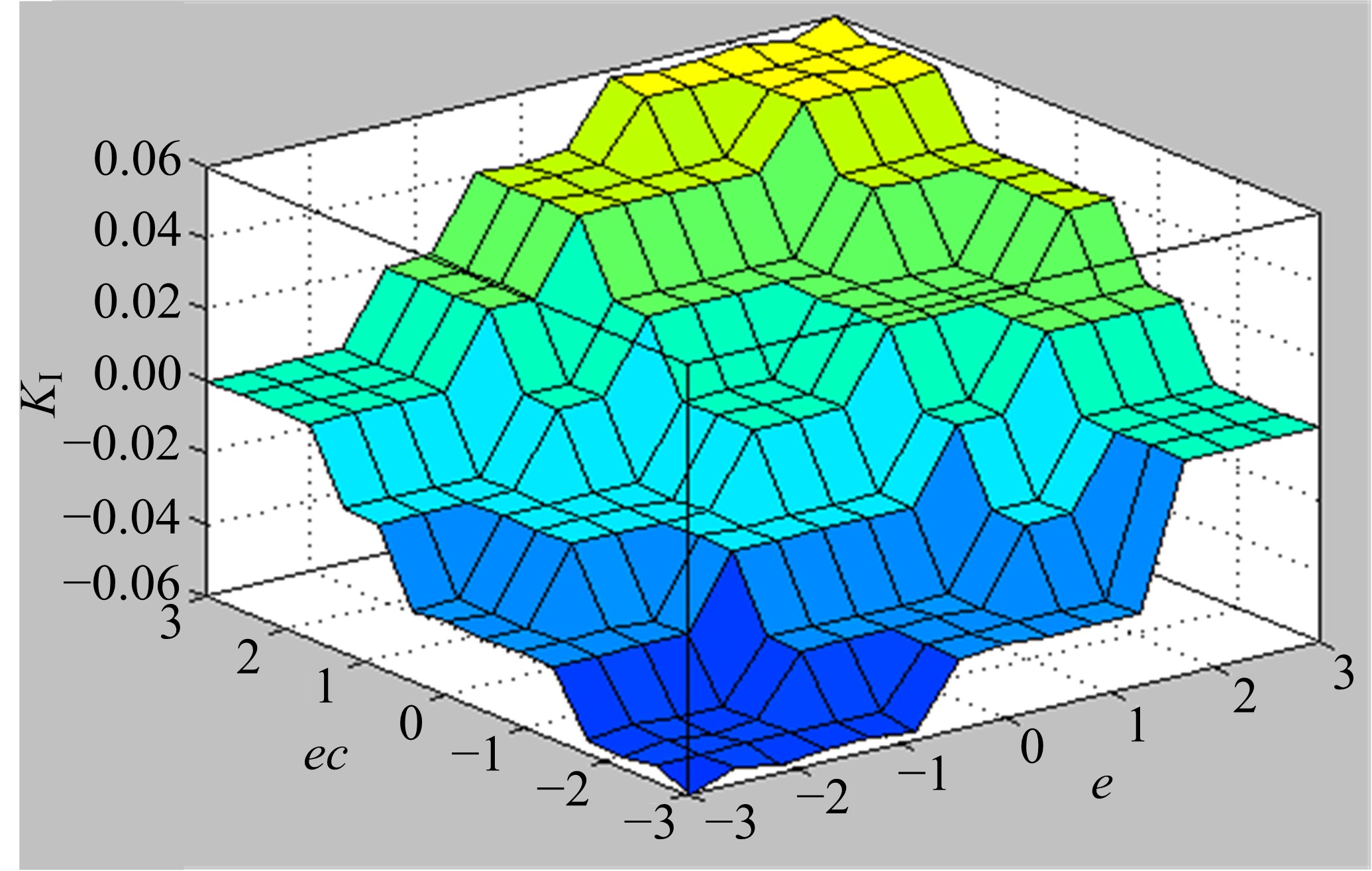

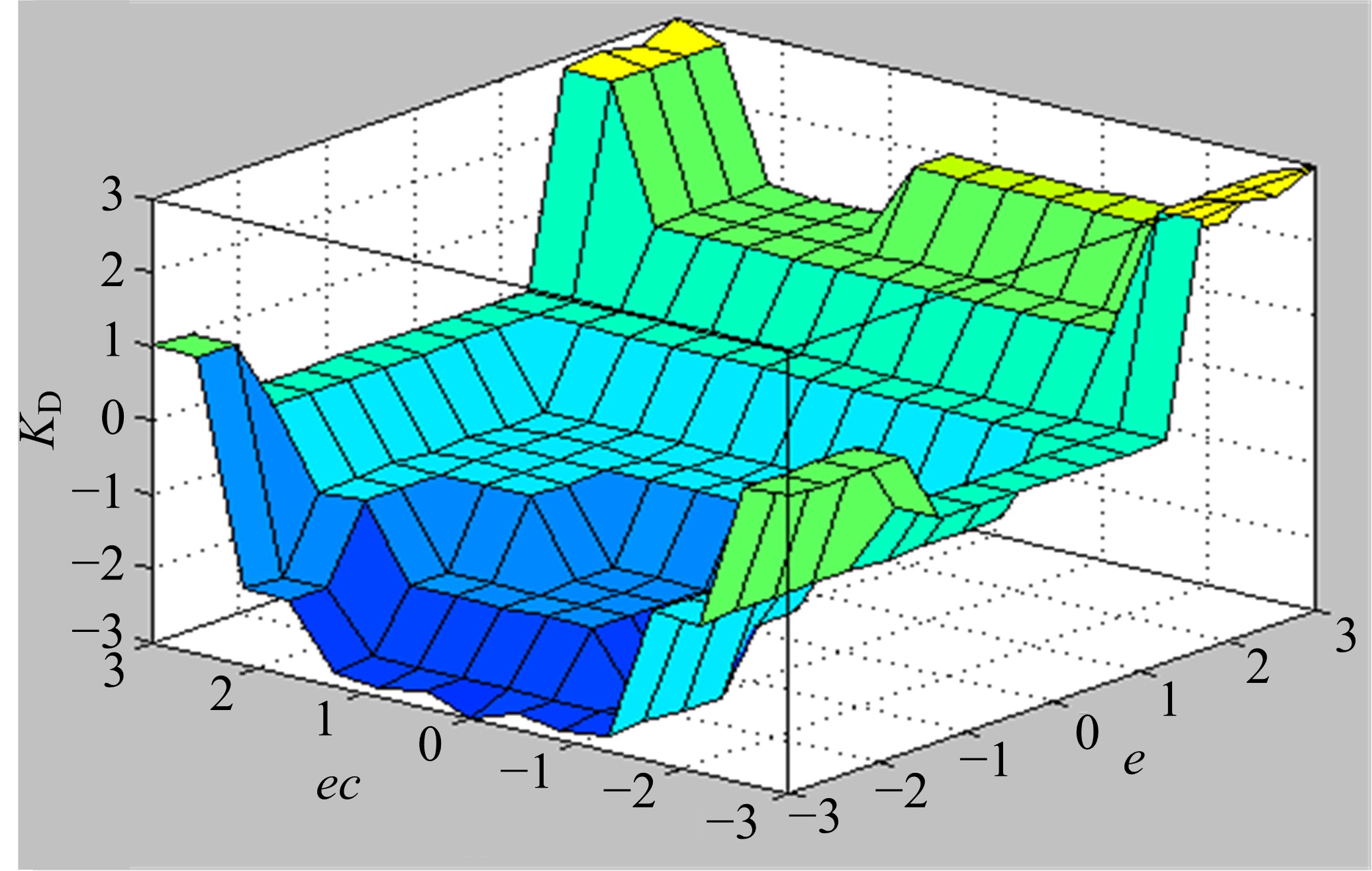

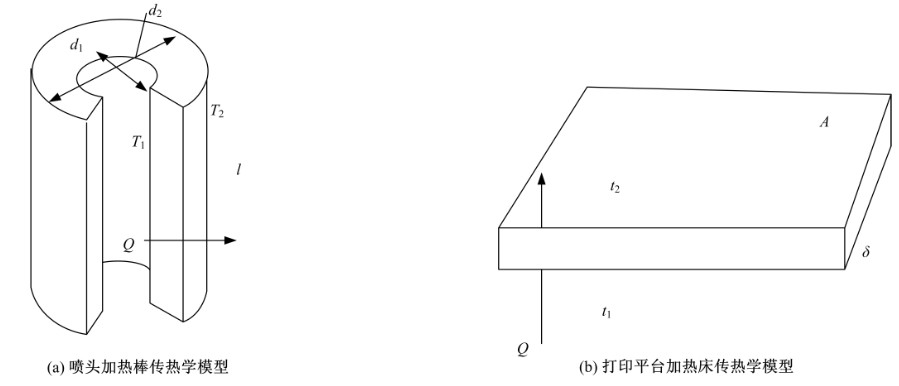

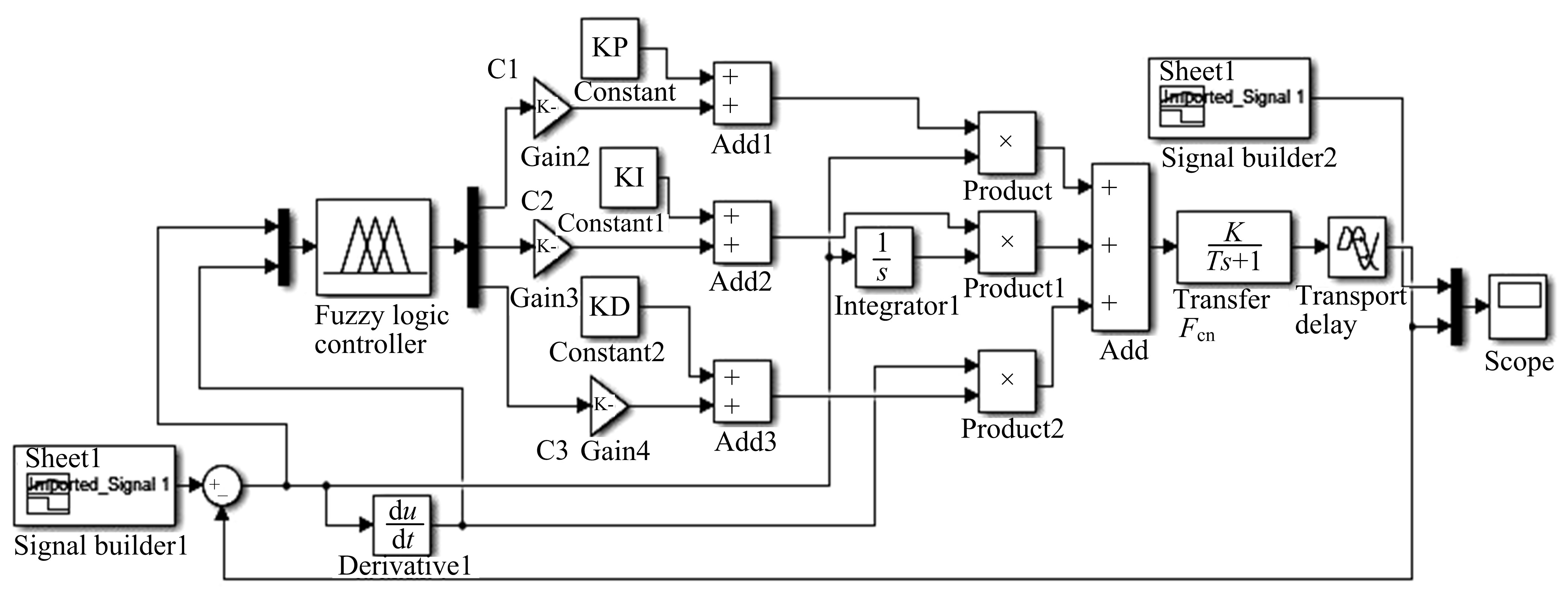

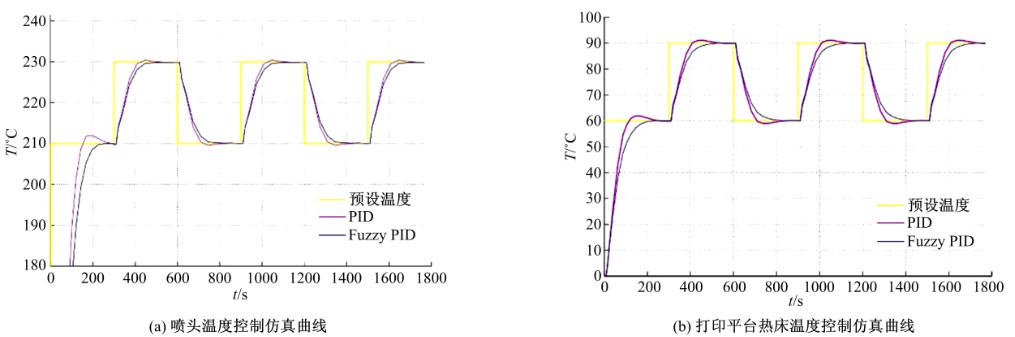

在熔融沉积成型技术(FDM)3D打印过程中,需要对打印喷头和打印平台加热床进行加热,直到打印材料所需的温度才能开始打印,由于加热系统存在的时间滞后性和稳定性差的缺点,使加热过程既耗时又浪费能源。针对以上问题,采用模糊自适应PID控制方法控制打印喷头和打印平台加热床加热过程,并建立了控制系统Matlab/Simulink仿真模型。仿真结果表明,模糊自适应PID控制方法对FDM 3D打印机加热系统的控制效果优于传统PID控制方法,具有超调量小、响应速度快、控制效果更稳定的优势。

中图分类号:

- TP18

| 1 | Berman B .3-D printing: the new industrial revolution[J]. Business Horizons, 2012, 55(2): 155-162. |

| 2 | 申玄伟 . 熔融沉积成型3D打印中翘曲变形的仿真分析与状态识别方法研究[D]. 杭州:浙江大学机械工程学院, 2018. |

| Shen Xuan-wei . Research on simulation analysis and condition recognition technique of warp deformation in FDM 3D printing[D]. Hangzhou:School of Mechanical Engineering, Zhejiang University,2018. | |

| 3 | Xu Y , Zheng Y , Du Y , et al . Adaptive condition predictive-fuzzy PID optimal control of start-up process for pumped storage unit at low head area[J]. Energy Conversion and Management, 2018, 177: 592-604. |

| 4 | Guo X , Wang J , Liao F , et al . Neuroadaptive quantized PID sliding‐mode control for heterogeneous vehicular platoon with unknown actuator deadzone[J]. International Journal of Robust and Nonlinear Control, 2019, 29(1): 188-208. |

| 5 | Gaidhane P J , Nigam M J , Kumar A , et al . Design of interval type-2 fuzzy precompensated PID controller applied to two-DOF robotic manipulator with variable payload[J]. ISA Transactions, 2019, 89: 169-185. |

| 6 | 刘晓峰 . 覆带起重机起升系统双马达同步控制技术研究[D]. 长春:吉林大学机械科学与工程学院, 2012. |

| Liu Xiao-feng . Research on synchronous control technology of dual-motor in crawler crane lifting system[D]. Changchun: College of Mechanical Science and Engineering, Jilin University, 2012. | |

| 7 | 李静, 余春贤 . 基于模糊与PID的车辆底盘集成控制系统[J]. 吉林大学学报:工学版, 2013, 43(增刊1): 509-513. |

| Li Jing , Yu Chun-xian . Vehicle chassis integrated control system based on fuzzy and PID[J]. Journal of Jilin University (Engineering and Technology Edition), 2013, 43(Sup.1): 509-513. | |

| 8 | 曹婧华, 孔繁森, 冉彦中, 等 . 基于模糊自适应PID控制的空压机背压控制器设计[J]. 吉林大学学报:工学版, 2018, 48(3): 781-786. |

| Cao Jing-hua , Kong Fan-sen , Ran Yan-zhong ,et al . Back pressure controller design of air compressor based on fuzzy self-adaptive PID control[J]. Journal of Jilin University (Engineering and Technology Edition), 2018, 48(3): 781-786. | |

| 9 | Chehadeh M S , Boiko I . Design of rules for in-flight non-parametric tuning of PID controllers for unmanned aerial vehicles[J]. Journal of the Franklin Institute, 2019, 356(1): 474-491. |

| 10 | Wang J , Yang G . Data-driven approach to accommodating multiple simultaneous sensor faults in variable-gain PID systems[J]. IEEE Transactions on Industrial Electronics, 2019, 66(4): 3117-3126. |

| 11 | Sahoo B P , Panda S . Improved grey wolf optimization technique for fuzzy aided PID controller design for power system frequency control[J]. Sustainable Energy, Grids and Networks, 2018, 16: 278-299. |

| 12 | Bakhtiari-Shahri M , Moeenfard H . Optimal design of a stable fuzzy controller for beyond pull-in stabilization of electrostatically actuated circular micro-plates[J]. Journal of Vibration and Acoustics, 2018, 141(1): No.011019. |

| [1] | 刘富,安毅,董博,李元春. 基于ADP的可重构机械臂能耗保代价分散最优控制[J]. 吉林大学学报(工学版), 2020, 50(1): 342-350. |

| [2] | 马常友, 高海波, 丁亮, 于海涛, 邢宏军, 邓宗全. 机器人末端执行器自更换机构设计及对接策略[J]. 吉林大学学报(工学版), 2019, 49(6): 2027-2037. |

| [3] | 马苗苗,潘军军,刘向杰. 含电动汽车的微电网模型预测负荷频率控制[J]. 吉林大学学报(工学版), 2019, 49(5): 1644-1652. |

| [4] | 于树友,谭雷,王伍洋,陈虹. 基于三步法的汽车主动四轮转向控制[J]. 吉林大学学报(工学版), 2019, 49(3): 934-942. |

| [5] | 温海营,任翔,徐卫良,丛明,秦文龙,胡书海. 咀嚼机器人颞下颌关节仿生设计及试验测试[J]. 吉林大学学报(工学版), 2019, 49(3): 943-952. |

| [6] | 顾万里,王萍,胡云峰,蔡硕,陈虹. 具有H∞性能的轮式移动机器人非线性控制器设计[J]. 吉林大学学报(工学版), 2018, 48(6): 1811-1819. |

| [7] | 李战东,陶建国,罗阳,孙浩,丁亮,邓宗全. 核电水池推力附着机器人系统设计[J]. 吉林大学学报(工学版), 2018, 48(6): 1820-1826. |

| [8] | 赵爽,沈继红,张刘,赵晗,陈柯帆. 微细电火花加工表面粗糙度快速高斯评定[J]. 吉林大学学报(工学版), 2018, 48(6): 1838-1843. |

| [9] | 王德军, 魏薇郦, 鲍亚新. 考虑侧风干扰的电子稳定控制系统执行器故障诊断[J]. 吉林大学学报(工学版), 2018, 48(5): 1548-1555. |

| [10] | 闫冬梅, 钟辉, 任丽莉, 王若琳, 李红梅. 具有区间时变时滞的线性系统稳定性分析[J]. 吉林大学学报(工学版), 2018, 48(5): 1556-1562. |

| [11] | 张茹斌, 占礼葵, 彭伟, 孙少明, 刘骏富, 任雷. 心肺功能评估训练系统的恒功率控制[J]. 吉林大学学报(工学版), 2018, 48(4): 1184-1190. |

| [12] | 董惠娟, 于震, 樊继壮. 基于激光测振仪的非轴对称超声驻波声场的识别[J]. 吉林大学学报(工学版), 2018, 48(4): 1191-1198. |

| [13] | 张士涛, 张葆, 李贤涛, 王正玺, 田大鹏. 基于零相差轨迹控制方法提升快速反射镜性能[J]. 吉林大学学报(工学版), 2018, 48(3): 853-858. |

| [14] | 田彦涛, 张宇, 王晓玉, 陈华. 基于平方根无迹卡尔曼滤波算法的电动汽车质心侧偏角估计[J]. 吉林大学学报(工学版), 2018, 48(3): 845-852. |

| [15] | 王林, 王洪光, 宋屹峰, 潘新安, 张宏志. 输电线路悬垂绝缘子清扫机器人行为规划[J]. 吉林大学学报(工学版), 2018, 48(2): 518-525. |

|

||