吉林大学学报(工学版) ›› 2021, Vol. 51 ›› Issue (3): 855-865.doi: 10.13229/j.cnki.jdxbgxb20190607

元胞自动机-有限元法模拟碳当量元素对亚共晶球墨铸铁流动性的影响

王金国1,2( ),黄恺1,2,闫瑞芳1,2,任帅1,2,王志强1,2,郭劲1,2

),黄恺1,2,闫瑞芳1,2,任帅1,2,王志强1,2,郭劲1,2

- 1.吉林大学 汽车材料教育部重点实验室,长春 130022

2.吉林大学 材料科学与工程学院,长春 130022

Effect of carbon equivalent elements on fluidity of hypoeutectic ductile iron by cellular automata finite element method

Jin-guo WANG1,2( ),Kai HUANG1,2,Rui-fang YAN1,2,Shuai REN1,2,Zhi-qiang WANG1,2,Jin GUO1,2

),Kai HUANG1,2,Rui-fang YAN1,2,Shuai REN1,2,Zhi-qiang WANG1,2,Jin GUO1,2

- 1.Key Laboratory of Automotive Materials,Ministry of Education,Jilin University,Changchun 130022,China

2.College of Materials Science and Engineering,Jilin University,Changchun 130022,China

摘要:

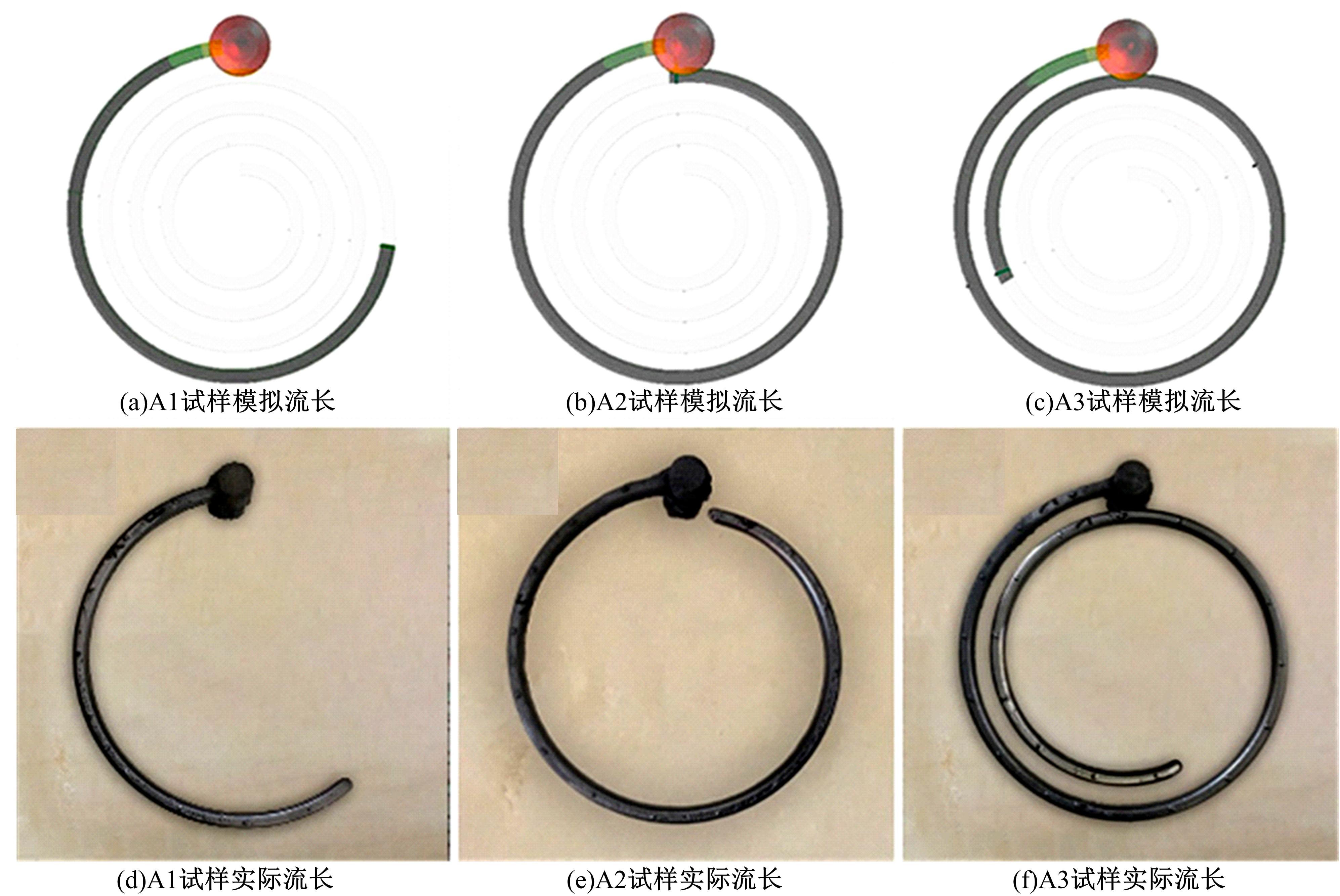

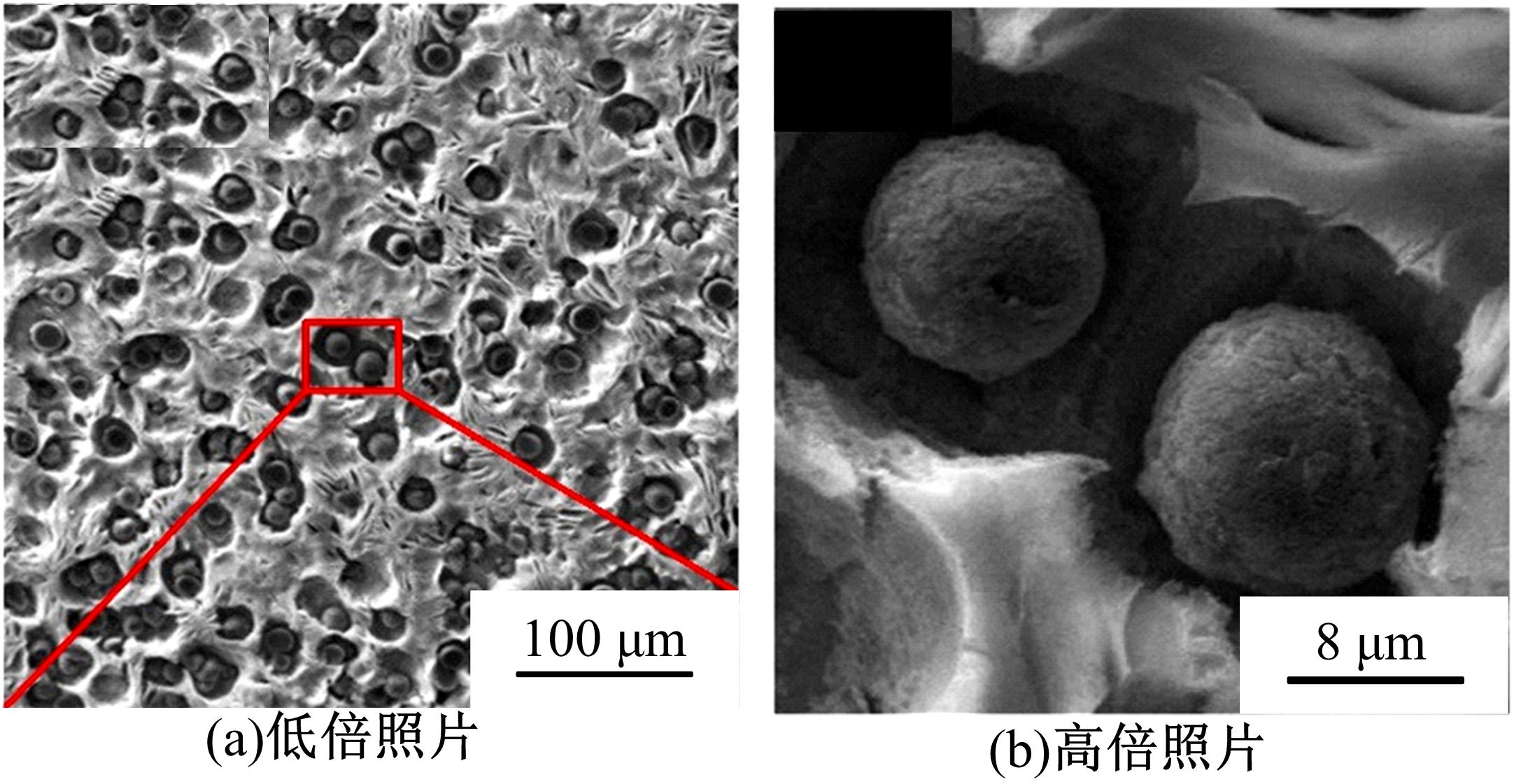

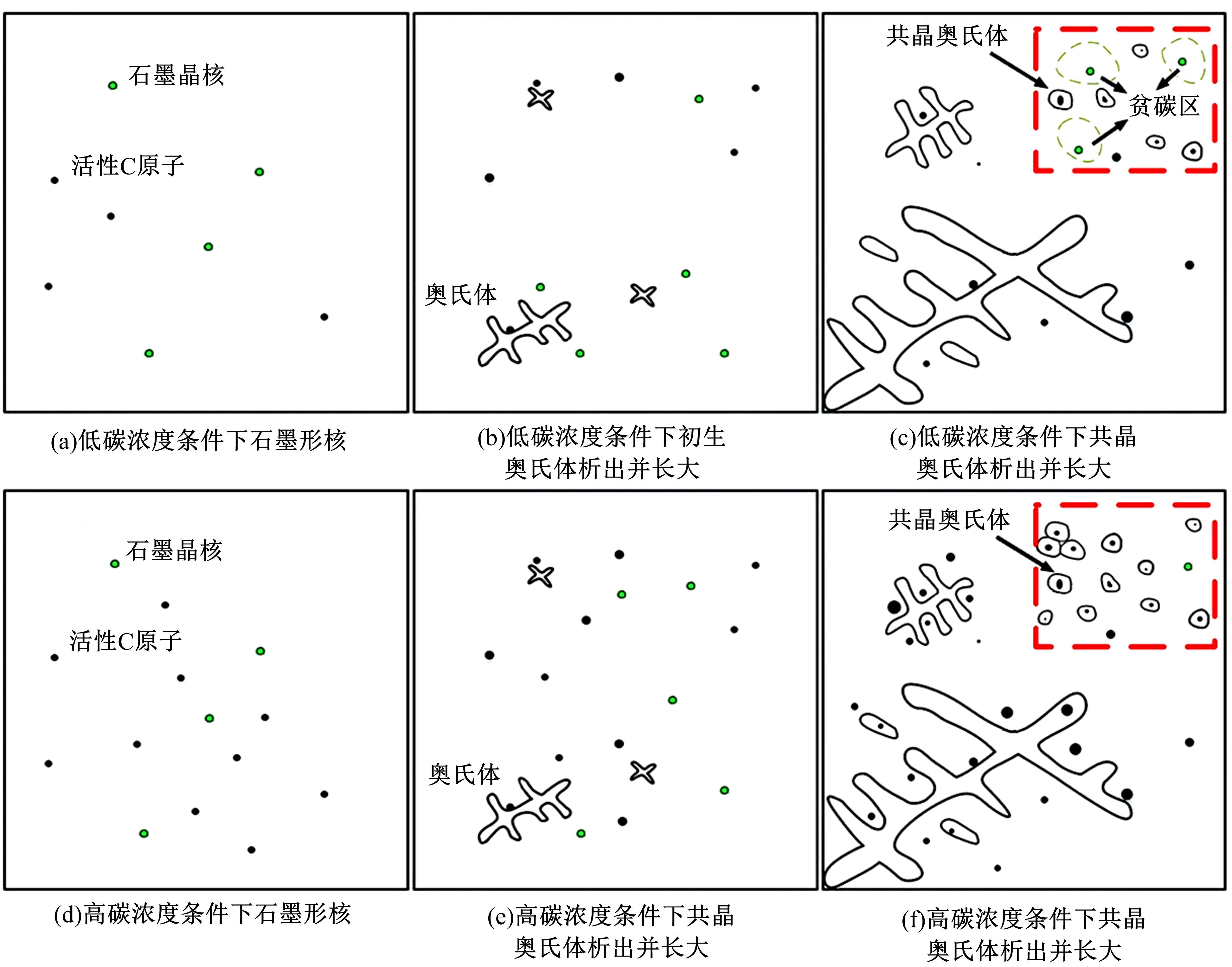

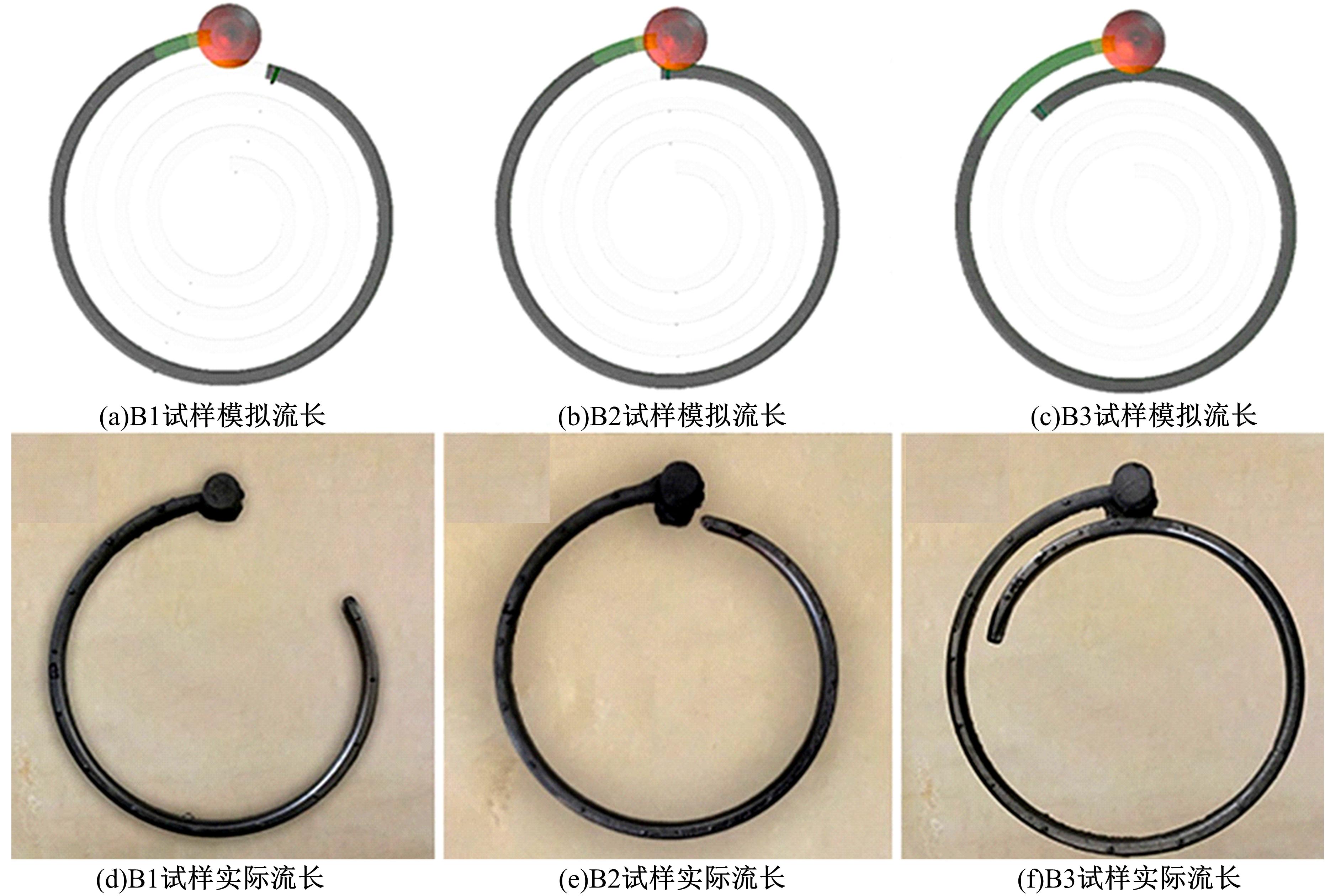

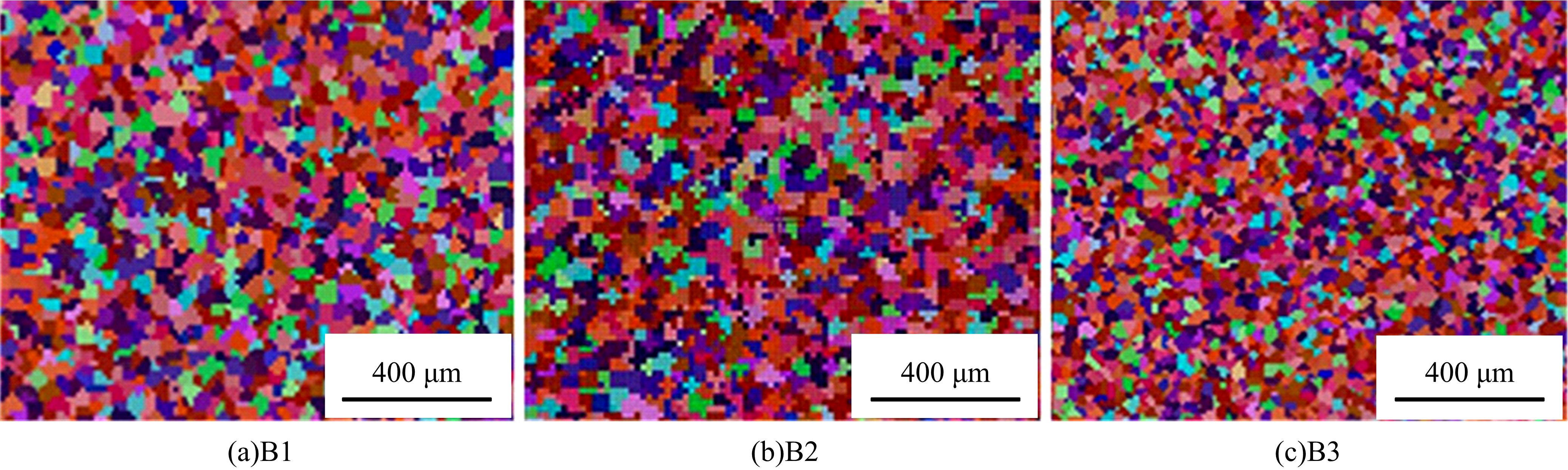

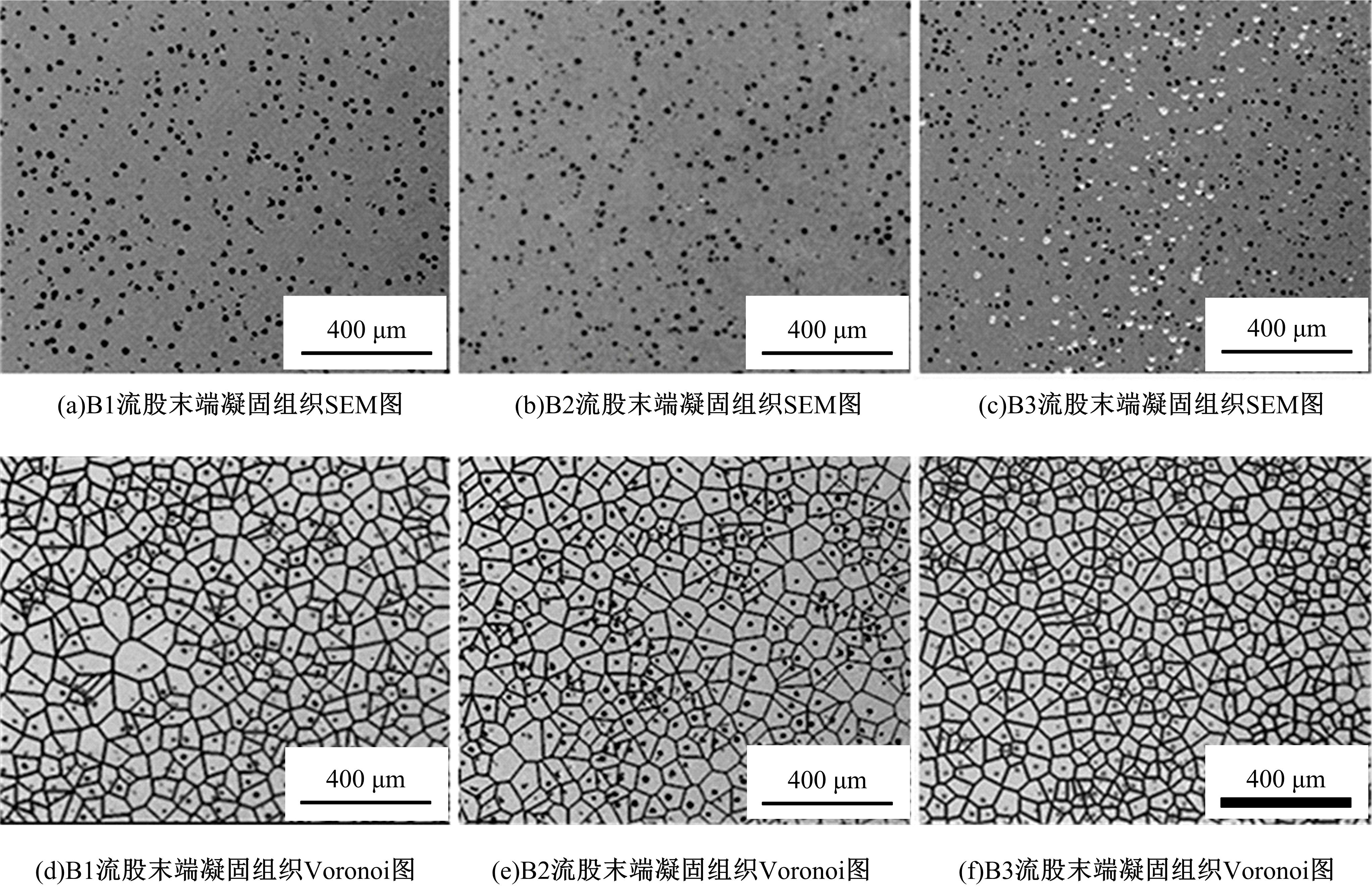

优化了元胞自动机-有限元法(CAFE)模拟球墨铸铁晶粒组织的参数系统。基于前期大量试验结果,对共晶晶粒的面形核参数和体形核参数进行了优化,并利用优化后的参数对不同碳、硅质量分数的球墨铸铁螺旋试样的流长和流股尖端的凝固组织进行了模拟。在验证试验中,针对难以观测到的球铁共晶晶粒,采用构网算法实现了晶界建模,分别将得到的螺旋试样流长、Voronoi晶粒分布图与模拟结果进行对比。结果表明:在对亚共晶球铁试样进行增碳或增硅处理后,螺旋试样流股末端的晶粒得到了细化,试样流动性得到了提高。此外,模拟结果与试验验证结果的吻合度较高,证明可通过数值模拟评价试样的流动性。

中图分类号:

- TG143.5

| 1 | 王金国, 任帅, 闫瑞芳, 等. TiC颗粒对铸态球墨铸铁组织和力学性能的影响[J]. 吉林大学学报:工学版, 2019, 49(6): 2010-2018. |

| Wang Jin-guo, Ren Shuai, Yan Rui-fang, et al. Effect of TiC particles on microstructure and mechanical properties of as cast ductile iron[J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 2010-2018. | |

| 2 | 何东野, 杨慎华, 寇淑清. 发动机曲轴箱轴承座裂解加工数值分析[J]. 吉林大学学报:工学版, 2009, 39(1): 78-82. |

| He Dong-Ye, Yang Shen-hua, Kou Shu-qing. Numerical analysis on fracture splitting technology of main bearing block of engine[J]. Journal of Jilin University(Engineering and Technology Edition), 2009, 39(1): 78-82. | |

| 3 | Pathak N, Kumar A, Yadav A, et al. Effects of mould filling on evolution of the solid-liquid interface during solidification[J]. Applied Thermal Engineering, 2009, 29(17-18): 3669-3678. |

| 4 | Vijayaram T R, Sulaiman S, Hamouda A M S, et al. Numerical simulation of casting solidification in permanent metallic molds[J]. Journal of Materials Processing Technology, 2006, 178(1-3): 29-33. |

| 5 | 张振波, 盛文斌, 孙策. 大型球墨铸铁下箱体铸造过程数值模拟及工艺优化[J]. 热加工工艺, 2019, 48(7): 113-116, 120. |

| Zhang Zhen-bo, Sheng Wen-bin, Sun Ce. Numerical simulation and process optimization of large spheroidal graphite cast iron lower box[J]. Hot Working Technology, 2019, 48(7): 113-116, 120. | |

| 6 | 陈映东, 丁旭, 沈刚, 等. 大型球墨铸铁蜗壳件砂型铸造模拟分析与工艺优化[J]. 铸造技术, 2018, 39(10): 2249-2252, 2264. |

| Chen Ying-dong, Ding Xu, Shen Gang, et al. Large nodular cast iron volute parts sand ca-sting simulation analysis and process optimization[J]. Foundry Technology, 2018, 39(10): 2249-2252, 2264. | |

| 7 | 魏胜辉, 张帆, 卢景秀, 等. 球墨铸铁轴封体铸造工艺设计及数值模拟[J]. 铸造技术, 2017, 38(6): 1493-1496. |

| Wei Sheng-hui, Zhang Fan, Lu Jing-xiu, et al. Casting process design and numerical simulation of ductile iron shaft seal[J]. Foundry Technology, 2017, 38(6): 1493-1496. | |

| 8 | 赵二梅, 鲁晨光, 杨刚. 球墨铸铁壳体件制备过程的数值模拟研究[J]. 铸造技术, 2015, 36(3): 809-812. |

| Zhao Er-mei, Lu Chen-guang, Yang Gang. Numerical simulation on manufacturing process of ductile cast iron shell parts[J]. Foundry Technology, 2015, 36(3): 809-812. | |

| 9 | 张晓敏. 高韧性球墨铸铁冷却壁的组织性能研究及凝固模拟试验[D]. 郑州:郑州大学材料科学与工程学院, 2010. |

| Zhang Xiao-min. Study on the microstructure and properties of high-ductility ductile iron cooling stave and its experiment of solidified simulation[D]. Zhengzhou:School of Materials Science and Engineering, Zhengzhou University, 2010. | |

| 10 | Burbelko A A, Gurgul D, Kapturkiewicz W, et al. Cellular automaton modelling of ductile iron microstructure in the thin wall casting[J]. IOP Conference Series Materials Science and Engineering, 2012, 33(1): 012083. |

| 11 | Burbelko A A, Fraś E, Kapturkiewicz W. Modelling of dendritic growth during unidirectional solidification by the method of cellular automata[J].Materials Science Forum, 2010, 649: 217-222. |

| 12 | Zhang Lei, Zhao Hong-lei, Zhu Ming-fang. Simulation of solidification microstructure of spheroidal graphite cast iron using a cellular automaton method[J]. Acta Metallurgica Sinica Chinese Edition, 2015, 51(2): 148-158. |

| 13 | 王雪涛. 风电球墨铸铁件铸造工艺及组织数值模拟的优化[D]. 济南:山东大学材料科学与工程学院, 2017. |

| Wang Xue-tao. Numerical simulation optimization of casting processes and structure of ductile iron casting for wind power[D]. Jinan:School of Materials Science and Engineering, Shandong University, 2017. | |

| 14 | Rappaz M. Modeling and characterization of grain structures and defects in solidification[J]. Current Opinion in Solid State & Materials Science, 2016, 20(1): 37-45. |

| 15 | Lee S Y, Lee S M, Hong C P. Numerical modeling of deflected columnar dendritic grains solidified in a flowing melt and its experimenttal verification[J]. ISIJ International, 2000, 40(1): 48-57. |

| 16 | 殷竞存, 朱晓临, 郭清伟. 基于分子间作用力改进的液体表面张力处理算法[J]. 合肥工业大学学报:自然科学版, 2018, 41(11): 1574-1578. |

| Yin Jing-cun, Zhu Xiao-lin, Guo Qing-wei. An improved liquid surface tension processing algorithm based on inter-molecular forces[J]. Journal of Hefei University of Technology(Natural Science), 2018, 41(11): 1574-1578. | |

| 17 | 黄锋. 薄带双辊铸轧凝固过程组织演变的数值模拟[D]. 沈阳:东北大学材料与冶金学院, 2015. |

| Huang Feng. Numerical simulation of microst-ructure evolution during solidification of twin roll casting process[D]. Shenyang:School of Materials and Metallurgy, Northeastern University, 2015. | |

| 18 | Rivera G, Boeri R, Sikora J. Revealing and characterising solidification structure of ductile cast iron[J]. Materials Science and Technology, 2002, 18(6): 691-697. |

| 19 | Ghahremaninezhad A, Ravi-Chandar K. Deformation and failure in nodular cast iron[J]. Acta Materialia, 2012, 60(5): 2359-2368. |

| 20 | Górny M. Fluidity and temperature profile of ductile iron in thin sections[J]. Journal of Iron and Steel Research(International), 2012, 19(8): 52-59. |

| 21 | 高升. 球墨铸铁碳当量的研究及生产实践[D]. 武汉:华中科技大学材料科学与工程学院, 2005. |

| Gao Sheng. Research and production practice of carbon equivalent of nodular cast iron[D]. Wuhan:School of Materials Science and Engineering, Huazhong University of Science and Technology, 2005. | |

| 22 | 张湛, 周尧和. 液态金属停止流动机理的实验研究[J]. 西北工业大学学报, 1965(1): 29-39. |

| Zhang Zhan, Zhou Yao-he. Experimental study on the mechanism of liquid metal stopping flow[J]. Journal of Northwestern Polytechnical University, 1965(1): 29-39. | |

| 23 | 吴德海. 球墨铸铁[M]. 北京:中国水利水电出版社, 2006. |

| 24 | Carazo F D, Dardati P M, Celentano D J, et al. Nucleation and growth of graphite in eutectic spheroidal cast iron: modeling and testing[J].Metallurgical and Materials Transactions A, 2016, 47(6): 2625-2641. |

| 25 | Stefanescu D M, Alonso G, Larrañaga P, et al. On the stable eutectic solidification of iron carb-on silicon alloys[J]. Acta Materialia, 2016, 103: 103-114. |

| 26 | Ghassemali E, Hernando Jua C, Stefanescu D M, et al. Revisiting the graphite nodule in ductile iron[J]. Scripta Materialia, 2019, 161: 66-69. |

| 27 | 李桐桐. 球墨铸铁中碳元素扩散系数的计算及分析[D]. 济南:山东大学材料科学与工程学院, 2013. |

| Li Tong-tong. The calculation and analysis of carbon diffusion coefficient in ductile iron[D]. Jinan:School of Materials Science and Engineering, Shandong University, 2013. | |

| 28 | Stefanescu D. Science and Engineering of Casting Solidification[M]. Second Edition.New York: Springer, 2009. |

| 29 | Fredriksson H, Stjerndah J, Tinoco J. On the solidification of nodular cast iron and its relation to the expansion and contraction[J]. Materials Science & Engineering:A, 2005, 413/414: 363-372. |

| 30 | 张蕾, 赵红蕾, 朱鸣芳. 球墨铸铁凝固显微组织的元胞自动机模拟[J]. 金属学报, 2015, 51(2): 148-158. |

| Zhang Lei, Zhao Hong-lei, Zhu Ming-fang. Simulation of solidification microstruc-ture of spheroidal graphite cast iron using a cellular automaton method[J]. Acta Metallurgica Sinica, 2015, 51(2): 148-158. | |

| 31 | 井ノ山哉, 山本悟, 川野豊. 反应论铸铁学[M].庞建路,杨丽萍译. 北京:机械工业出版社, 2012. |

| 32 | 周学源. 合金元素对渗碳体长大动力学及热稳定性影响[D]. 南京:东南大学材料科学与工程学院, 2014. |

| Zhou Xue-yuan. The effect of alloy elements on the coarsening kinetics and thermal stability of cementite[D]. Nanjing:School of Materials Science and Engineering, Southeast University, 2014. |

| [1] | 田银宝,申俊琦,胡绳荪,勾健. EP/EN模数对铝合金VP-CMT焊熔滴过渡及焊道成形的影响[J]. 吉林大学学报(工学版), 2020, 50(5): 1663-1668. |

| [2] | 王金国,王志强,任帅,闫瑞芳,黄恺,郭劲. Ti添加量对球墨铸铁组织及力学性能的影响[J]. 吉林大学学报(工学版), 2020, 50(5): 1653-1662. |

| [3] | 修文翠,吴化,韩英,刘云旭. 等温热处理温度对超级贝氏体组织与性能的影响[J]. 吉林大学学报(工学版), 2020, 50(2): 520-525. |

| [4] | 宫文彪,朱芮,郄新哲,崔恒,宫明月. 6082铝合金超厚板搅拌摩擦焊接头组织与性能[J]. 吉林大学学报(工学版), 2020, 50(2): 512-519. |

| [5] | 陈学文,王继业,杨喜晴,皇涛,宋克兴. Cr8合金钢热变形行为及位错密度演变规律[J]. 吉林大学学报(工学版), 2020, 50(1): 91-99. |

| [6] | 王金国,任帅,闫瑞芳,黄恺,王志强. TiC颗粒对铸态球墨铸铁组织和力学性能的影响[J]. 吉林大学学报(工学版), 2019, 49(6): 2010-2018. |

| [7] | 徐戊矫,刘承尚,鲁鑫垚. 喷丸处理后6061铝合金工件表面粗糙度的模拟计算及预测[J]. 吉林大学学报(工学版), 2019, 49(4): 1280-1287. |

| [8] | 李于朋,孙大千,宫文彪. 6082⁃T6铝合金薄板双轴肩搅拌摩擦焊温度场[J]. 吉林大学学报(工学版), 2019, 49(3): 836-841. |

| [9] | 关庆丰,张福涛,彭韬,吕鹏,李姚君,许亮,丁佐军. 含硼、钴9%Cr耐热钢的热变形行为[J]. 吉林大学学报(工学版), 2018, 48(6): 1799-1805. |

| [10] | 关庆丰, 董书恒, 郑欢欢, 李晨, 张从林, 吕鹏. 强流脉冲电子束作用下45#钢表面Cr合金化[J]. 吉林大学学报(工学版), 2018, 48(4): 1161-1168. |

| [11] | 赵宇光, 杨雪慧, 徐晓峰, 张阳阳, 宁玉恒. Al-10Sr变质剂状态、变质温度及变质时间对ZL114A合金组织的影响[J]. 吉林大学学报(工学版), 2018, 48(1): 212-220. |

| [12] | 汤华国, 马贤锋, 赵伟, 刘建伟, 赵振业. 高性能金属铝的制备、微观结构及其热稳定性[J]. 吉林大学学报(工学版), 2017, 47(5): 1542-1547. |

| [13] | 关庆丰, 张远望, 孙潇, 张超仁, 吕鹏, 张从林. 强流脉冲电子束作用下铝钨合金的表面合金化[J]. 吉林大学学报(工学版), 2017, 47(4): 1171-1178. |

| [14] | 杨晓红, 杭文先, 秦绍刚, 刘勇兵, 刘利萍. H13钢激光熔覆钴基复合涂层的组织及耐磨性[J]. 吉林大学学报(工学版), 2017, 47(3): 891-899. |

| [15] | 关庆丰, 黄尉, 李怀福, 龚晓花, 张从林, 吕鹏. 强流脉冲电子束诱发的Cu-C扩散合金化[J]. 吉林大学学报(工学版), 2016, 46(6): 1967-1973. |

|

||