吉林大学学报(工学版) ›› 2022, Vol. 52 ›› Issue (7): 1598-1606.doi: 10.13229/j.cnki.jdxbgxb20210129

• 交通运输工程·土木工程 • 上一篇

基于能量法的超高韧性纤维混凝土疲劳损伤特性

- 浙江大学 建筑工程学院,杭州 310012

Fatigue damage characteristics of ultra high toughness cementitious composite based on energy method

Zhang-yi GU( ),Zhi-cheng ZHANG(

),Zhi-cheng ZHANG( ),Hui LI

),Hui LI

- College of Civil Engineering and Architecture,Zhejiang University,Hangzhou 310012,China

摘要:

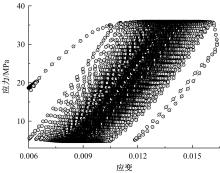

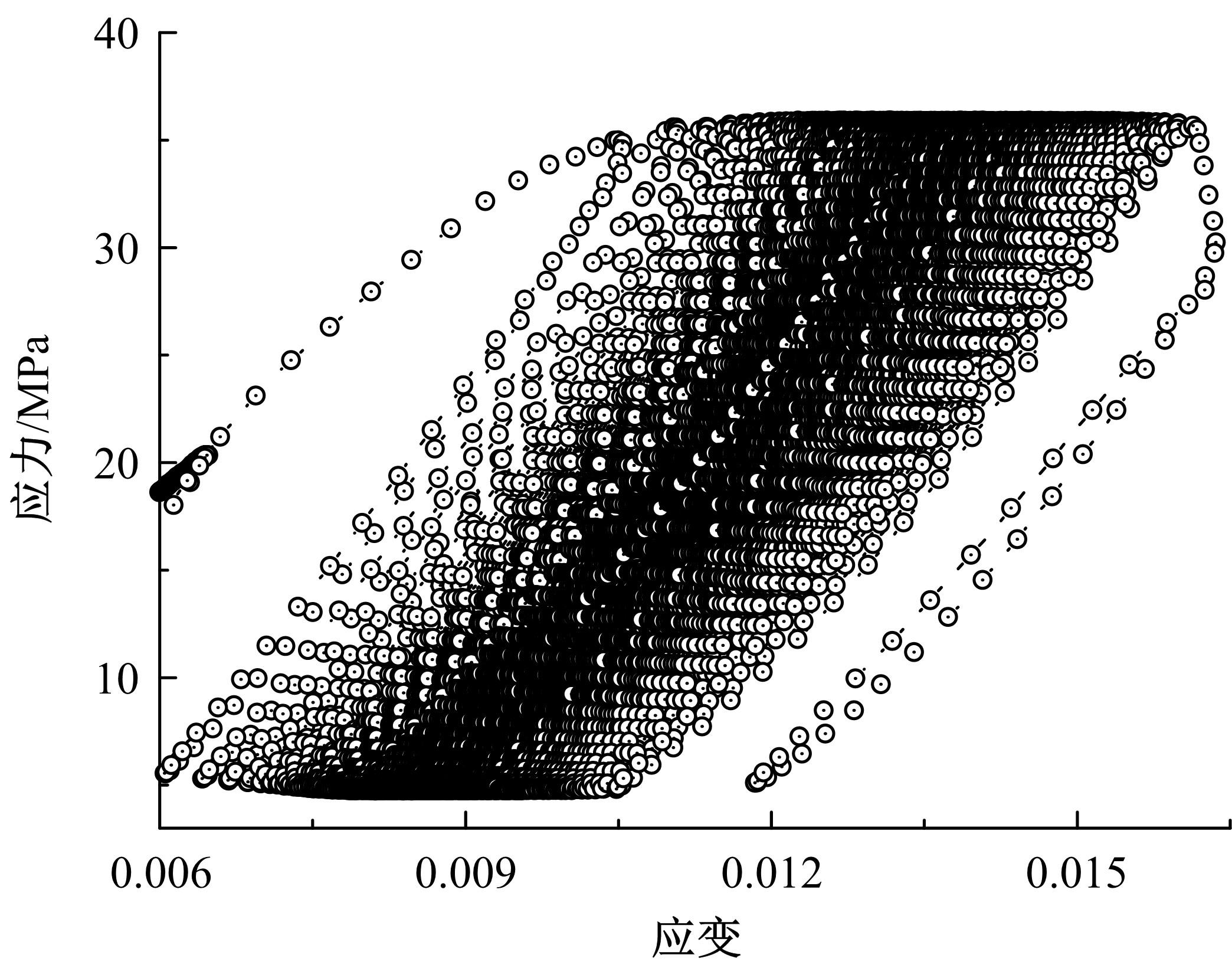

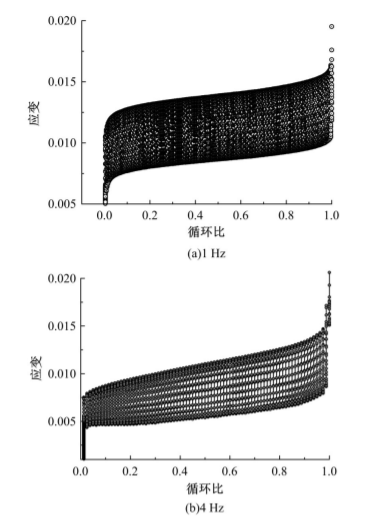

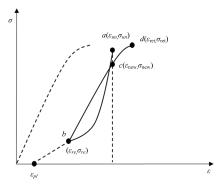

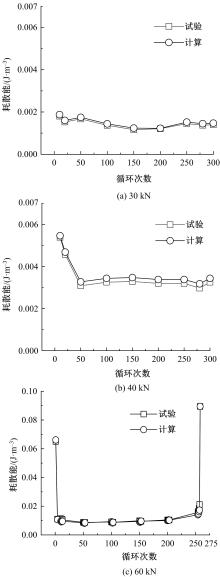

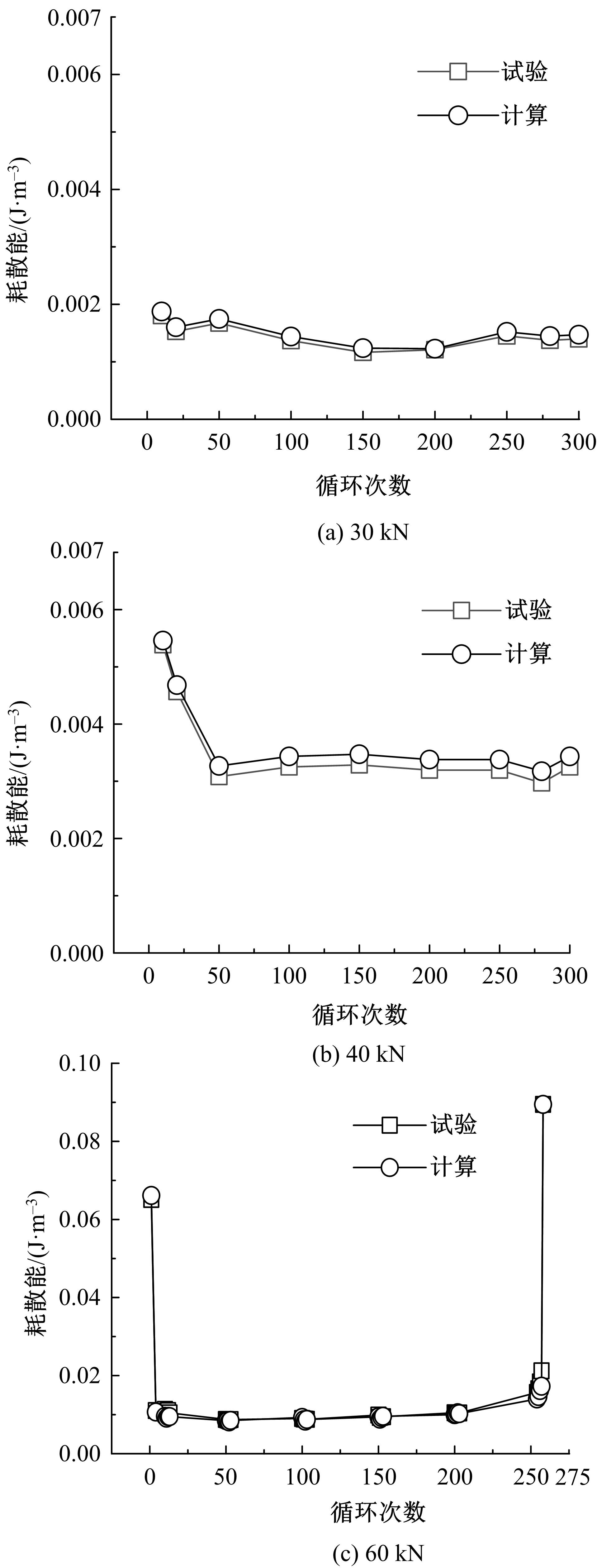

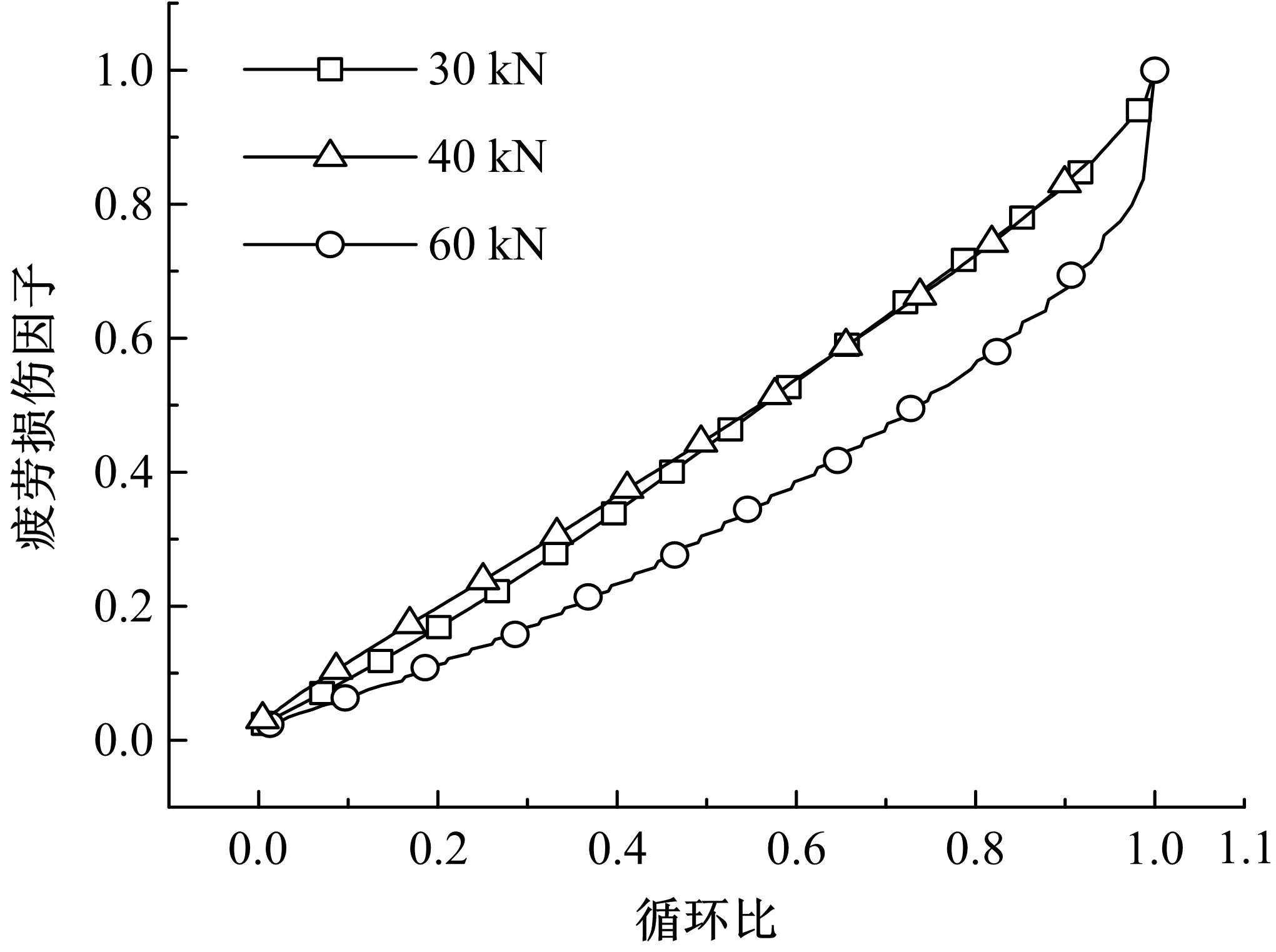

为探究超高韧性纤维混凝土材料(UHTCC)在交通荷载下的疲劳损伤性能,通过不同应力水平、频率下的单轴压缩试验得到了应力-应变曲线,结果表明:随着循环次数的增加,疲劳曲线呈疏-密-疏的3阶段规律,同时应变增长非线性程度逐渐增大。加载频率和应力水平的增加均会降低试件的疲劳寿命。在单轴压缩循环试验基础上建立本构模型,模型预测应力路径与试验结果吻合良好,验证了模型的正确性和适用性。以能量法为基础,采用耗散能指标评价UHTCC疲劳损伤程度,得到了初始损伤(2%左右)和疲劳损伤因子发展规律。此外,研究还发现在高应力比条件下疲劳开裂具有突然性。

中图分类号:

- U414

| 1 | Wang L, Zhou S H, Shi Y, et al. Effect of silica fume and PVA fiber on the abrasion resistance and volume stability of concrete[J]. Composites Part B: Engineering, 2017, 130: 28-37. |

| 2 | Yao L, Sun Y, Guo L. Fibre bridging effect on the Paris relation of mode I fatigue delamination in composite laminates with different thicknesses[J]. International Journal of Fatigue, 2017, 103: 196-206. |

| 3 | Dieng L, Marchand P, Gomes F, et al. Use of UHPFRC overlay to reduce stresses in orthotropic steel decks [J]. Journal of Constructional Steel Research, 2013, 89(10): 30-41. |

| 4 | Liu G J, Bai E L, Xu J Y, et al. Mechanical properties of carbon fiber-reinforced polymer concrete with different polymer-cement ratios[J]. Materials, 2019, 12(21): No.3530. |

| 5 | López Deulofeu A. Study of UHPC reinforced by graphene oxide & carbon nanotubes composites and steel fibers[D]. Barcelona: Universitat Politècnica de Catalunya, 2019. |

| 6 | Li V C, Wang S, Wu C. Tensile strain-hardening behavior of polyvinyl alcohol engineered cementitious composite (PVA-ECC)[J]. ACI Materials Journal-American Concrete Institute, 2001, 98(6): 483-492. |

| 7 | Li V C, Leung C K Y. Steady state and multiple cracking of short random fiber composites[J]. Journal of Engineering Mechanics, ASCE, 1992, 188(11): 2246-2264. |

| 8 | Xu S, Reinhardt H W. Determination of double-K criterion for crack propagation in quasi-brittle fracture, Part II: analytical evaluating and practical measuring methods for three-point bending notched beams[J]. International Journal of Fracture, 1999, 98(2): 151-177. |

| 9 | 张清华,卜一之,李乔. 正交异性钢桥面板疲劳问题的研究进展[J]. 中国公路学报, 2017, 30(3): 14-30. |

| Zhang Qing-hua, Bu Yi-zhi, Li Qiao. Review on fatigue problems of orthotropic steel bridge deck[J]. China Journal of Highway and Transport, 2017, 30(3): 14-30. | |

| 10 | Huang B T, Li Q H, Xu S L, et al. Tensile fatigue behavior of fiber-reinforced cementitious material with high ductility: experimental study and novel P-S-N model[J]. Construction and Building Materials, 2018, 178(7): 349-359. |

| 11 | Fardis M N, Khalili H H. FRP-encased concrete as a structural material[J]. Magazine of Concrete Research, 1982, 34(121): 191-202. |

| 12 | Lam L, Teng J G. Stress-strain model for FRP-confined concrete under cyclic axial compression[J]. Engineering Structures, 2009, 31(2): 308-321. |

| 13 | Hany N F, Hantouche E G, Harajli M H. Axial stress-strain model of CFRP-confined concrete under monotonic and cyclic loading[J]. Journal of Composites for Construction, 2015, 19(6): 1-16. |

| 14 | 王震宇,李洪鹏. 重复荷载作用下碳纤维约束混凝土加卸载准则[J]. 建筑结构, 2009, 39(7): 100-103, 70. |

| Wang Zhen-yu, Li Hong-peng. Loading and unloading criteria of FRP-confined concrete under cyclic compression[J]. Building Structure, 2009, 39(7): 100-103, 70. | |

| 15 | 李辉,罗雪,张裕卿. 基于耗散伪应变能的沥青疲劳动力学表征[J]. 中国公路学报, 2020, 33(10): 115-124. |

| Li Hui, Luo Xue, Zhang Yu-qing. Pseudo energy-based kinetic characterization of fatigue in asphalt binders[J]. China Journal of Highway and Transport, 2020, 33(10): 115-124. | |

| 16 | Li Q, Huang B, Xu S, et al. Compressive fatigue damage and failure mechanism of fiber reinforced cementitious material with high ductility[J]. Cement and Concrete Research, 2016, 90: 174-183. |

| 17 | 黄博滔. 超高韧性纤维混凝土材料及其功能梯度结构疲劳性能研究[D]. 杭州: 浙江大学建筑工程学院, 2018. |

| Huang Bo-tao. Fatigue performance of strain-hardening fiber-reinforced cementitious composite and its functionally-graded structures[D]. Hangzhou: College of Civil Engineering and Architecture, Zhejiang University, 2018. | |

| 18 | Arthur M, Gonzalo R. Effect of the loading frequency on the compressive fatigue behavior of plain and fiber reinforced concrete[J]. International Journal of Fatigue, 2015, 70: 342-350. |

| 19 | 刘问. 超高韧性水泥基复合材料动态力学性能的试验研究[D]. 大连: 大连理工大学土木工程学院, 2012. |

| Liu Wen. Experimental study on dynamic mechanical properties of ultra-high toughness cementitious composites[D]. Dalian: School of Civil Engineering, Dalian University of Technology, 2012. | |

| 20 | Teng J G, Lam L, Lin G, et al. Numerical simulation of FRP-Jacketed RC columns subjected to cyclic and seismic loading[J]. Journal of Composites for Construction, 2016, 20(1): 1-13. |

| 21 | 李天涛. 基于能量耗散的强震岩体震裂损伤特性及其孕灾机理研究[D]. 成都: 成都理工大学环境与土木工程学院, 2017. |

| Li Tian-tao. Seismic damage characteristics of rock based on energy dissipation and disaster-pregnant mechanism of strong earthquake[D]. Chengdu: College of Environment and Civil Engineering, Chengdu University of Technology, 2017. |

| [1] | 刘璐,周华西,陈传海,龚梦辉,冯虎田,周长光. 基于竞争失效模型的滚珠丝杠副可靠性设计建模[J]. 吉林大学学报(工学版), 2022, 52(2): 458-465. |

| [2] | 孟广伟,任传鑫,李锋,魏彤辉. 随机载荷作用下的结构疲劳寿命区间分析[J]. 吉林大学学报(工学版), 2022, 52(1): 46-52. |

| [3] | 严庆光,冯梓轩,李湘吉,王瑛玮. 一机六件等应力三点弯曲疲劳试验机的研制[J]. 吉林大学学报(工学版), 2021, 51(6): 2013-2020. |

| [4] | 程东辉,范永萱,王彦松. RC类活性粉末混凝土钢筋粘结-滑移本构模型[J]. 吉林大学学报(工学版), 2021, 51(4): 1317-1330. |

| [5] | 庄蔚敏,王鹏跃,高瑞娟,解东旋. 温热成形对AA5754铝合金静态力学性能的影响[J]. 吉林大学学报(工学版), 2021, 51(3): 847-854. |

| [6] | 彭勇,杨汉铎,陆学元,李彦伟. 基于离散元法的空隙特征对沥青混合料虚拟剪切疲劳寿命的影响[J]. 吉林大学学报(工学版), 2021, 51(3): 956-964. |

| [7] | 张姝玮,郭忠印,杨轸,柳本民. 驾驶行为多重分形特征在驾驶疲劳检测中的应用[J]. 吉林大学学报(工学版), 2021, 51(2): 557-564. |

| [8] | 陈学文,王继业,杨喜晴,皇涛,宋克兴. Cr8合金钢热变形行为及位错密度演变规律[J]. 吉林大学学报(工学版), 2020, 50(1): 91-99. |

| [9] | 石舟,寇淑清. 36MnVS4裂解连杆性能分析及轻量化设计[J]. 吉林大学学报(工学版), 2019, 49(6): 1992-2001. |

| [10] | 杨德磊,童乐为. 支管受轴向受拉工况下CHS-CFSHS T型节点应力集中系数计算公式[J]. 吉林大学学报(工学版), 2019, 49(6): 1891-1899. |

| [11] | 刘义伦,王卿,刘驰,李松柏,何军,赵先琼. 蠕变和人工时效对2524铝合金疲劳裂纹扩展性能的影响[J]. 吉林大学学报(工学版), 2019, 49(5): 1636-1643. |

| [12] | 叶辉,朱艳荣,蒲永锋. 纤维增强复合材料应变率效应的数值仿真[J]. 吉林大学学报(工学版), 2019, 49(5): 1622-1629. |

| [13] | 罗开玉,邢月华,柴卿锋,吴世凯,尹叶芳,鲁金忠. 激光冲击强化对2Cr13不锈钢腐蚀 疲劳性能的影响[J]. 吉林大学学报(工学版), 2019, 49(3): 850-858. |

| [14] | 毛宇泽, 王黎钦. 鼠笼支撑一体化结构对薄壁球轴承承载性能的影响[J]. 吉林大学学报(工学版), 2018, 48(5): 1508-1514. |

| [15] | 王春生, 邹丽, 杨鑫华. 基于邻域粗糙集的铝合金焊接接头疲劳寿命影响因素分析[J]. 吉林大学学报(工学版), 2017, 47(6): 1848-1853. |

|

||