吉林大学学报(工学版) ›› 2022, Vol. 52 ›› Issue (8): 1777-1785.doi: 10.13229/j.cnki.jdxbgxb20210201

• 材料科学与工程 • 上一篇

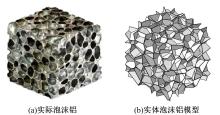

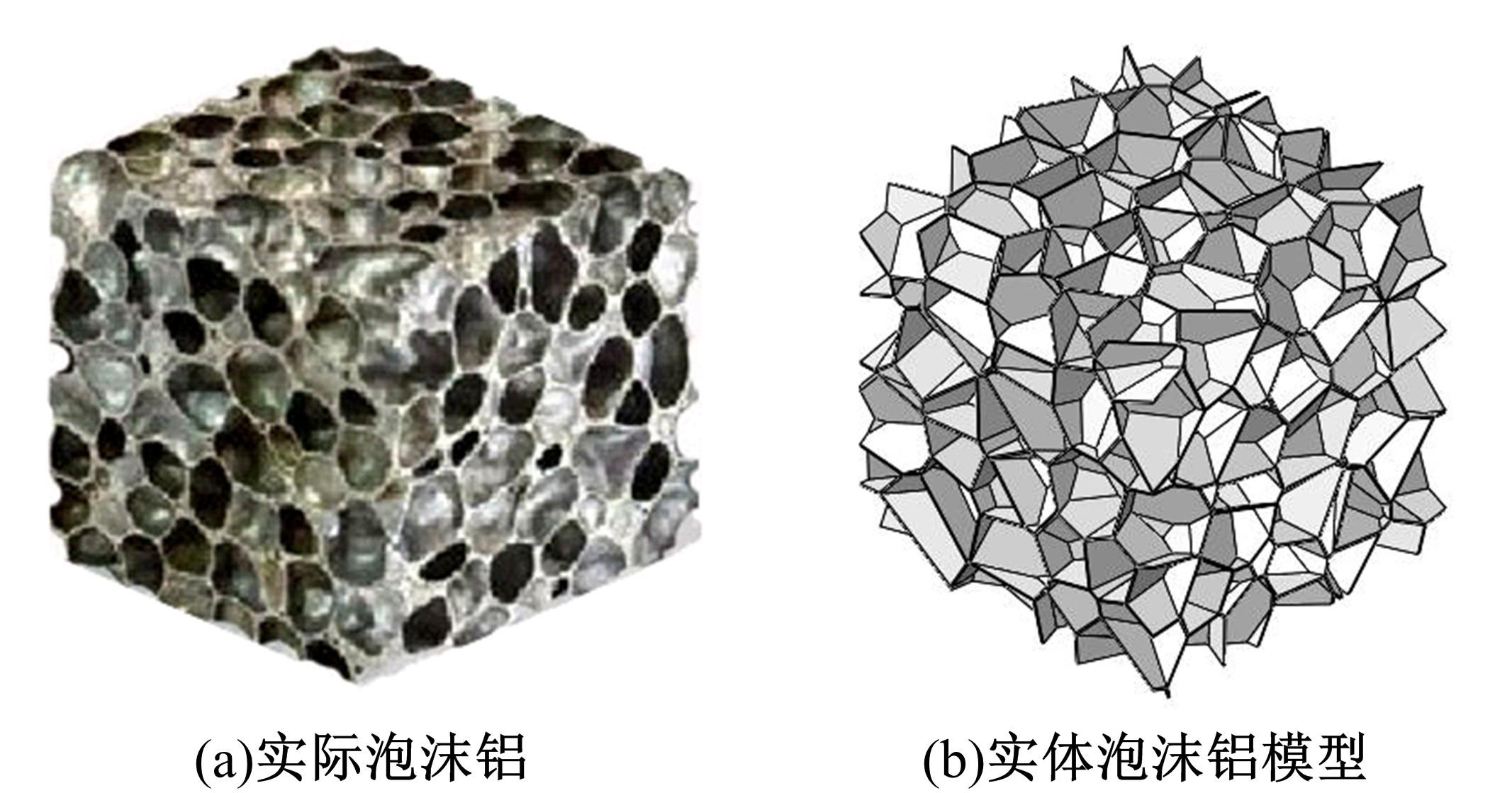

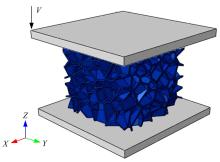

随机壁厚三维实体泡沫铝建模及压缩仿真

- 吉林大学 汽车仿真与控制国家重点实验室,长春 130022

Modeling and compression simulation of 3D solid aluminum foam with random cell wall thickness

- State Key Laboratory of Automotive Simulation and Control,Jilin University,Changchun 130022,China

摘要:

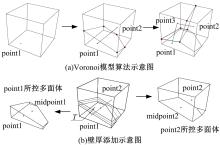

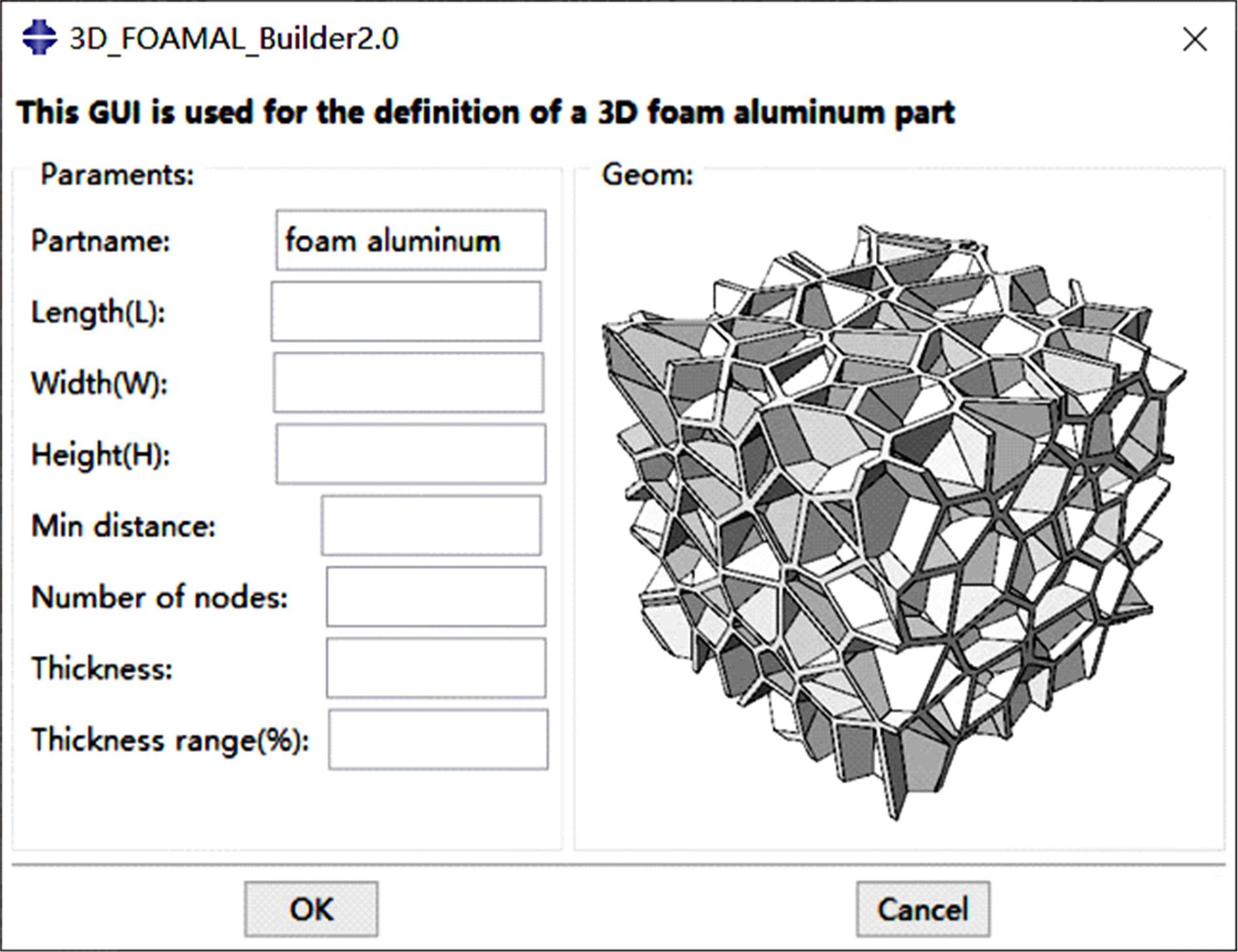

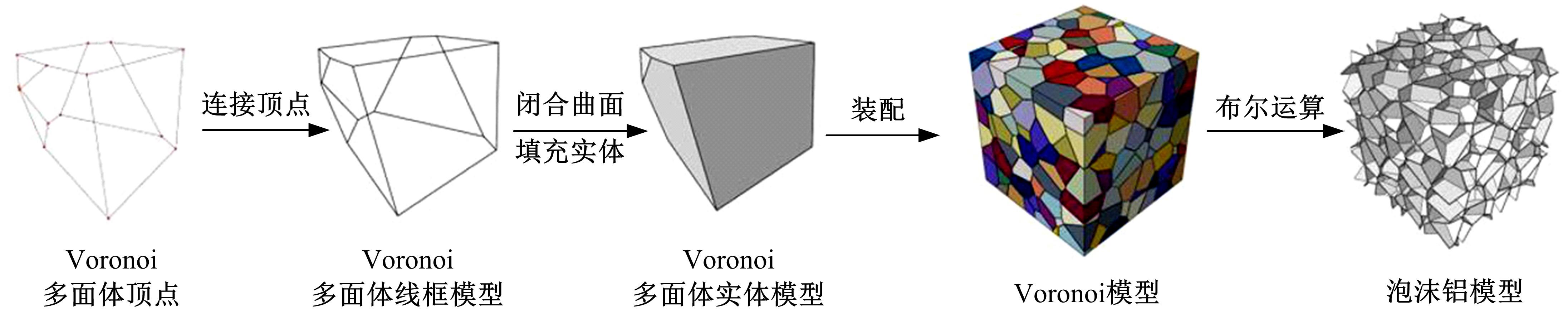

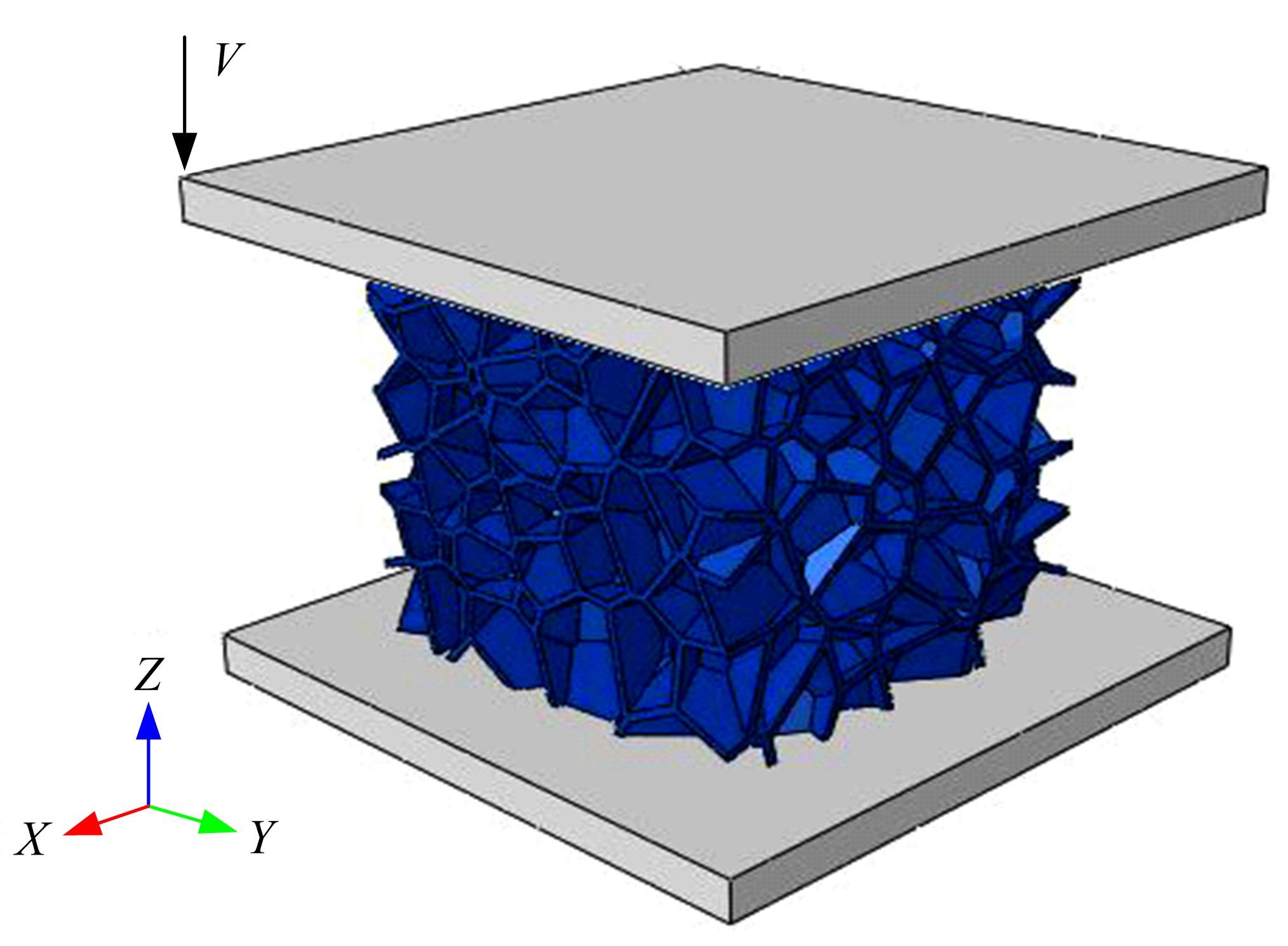

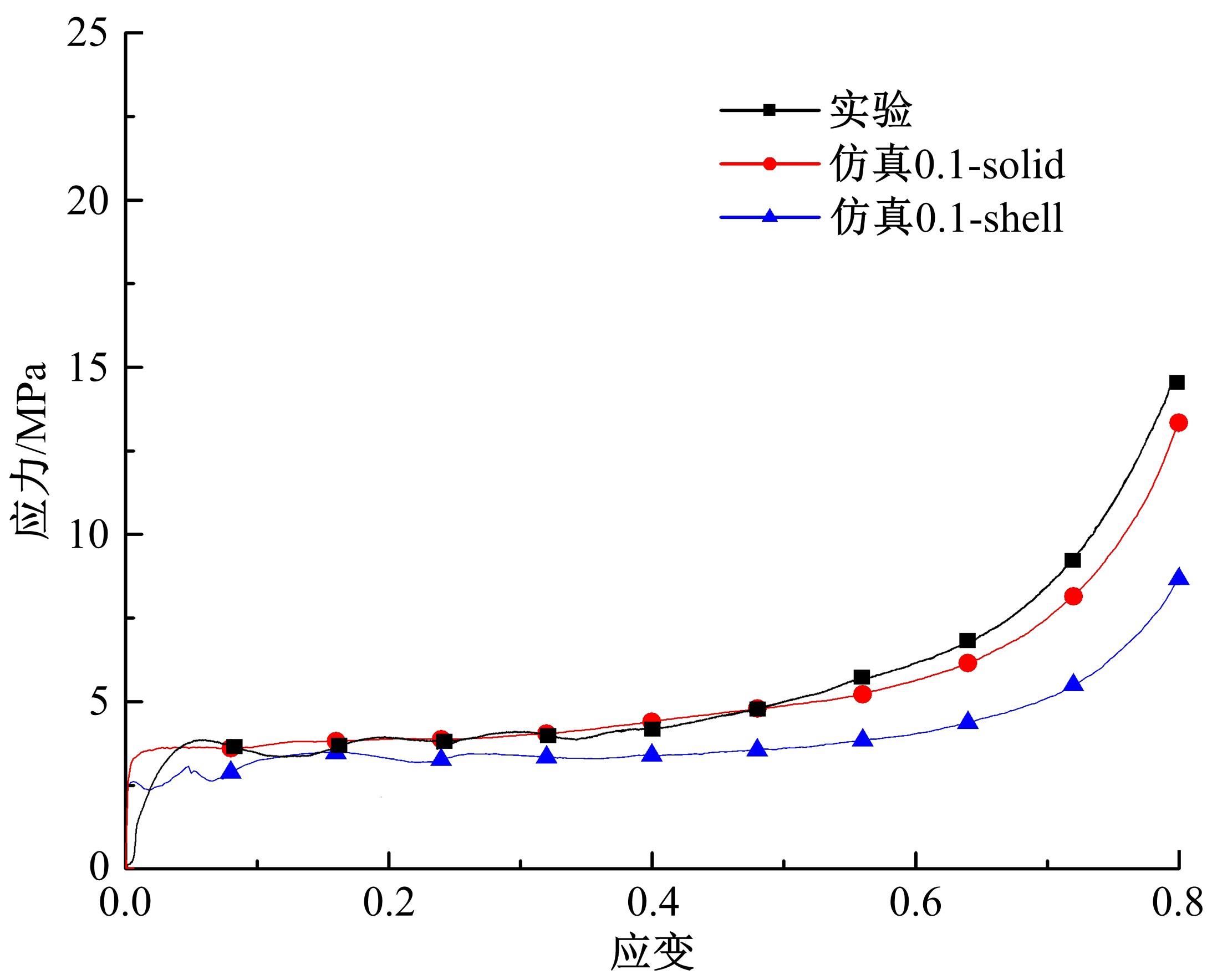

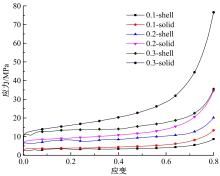

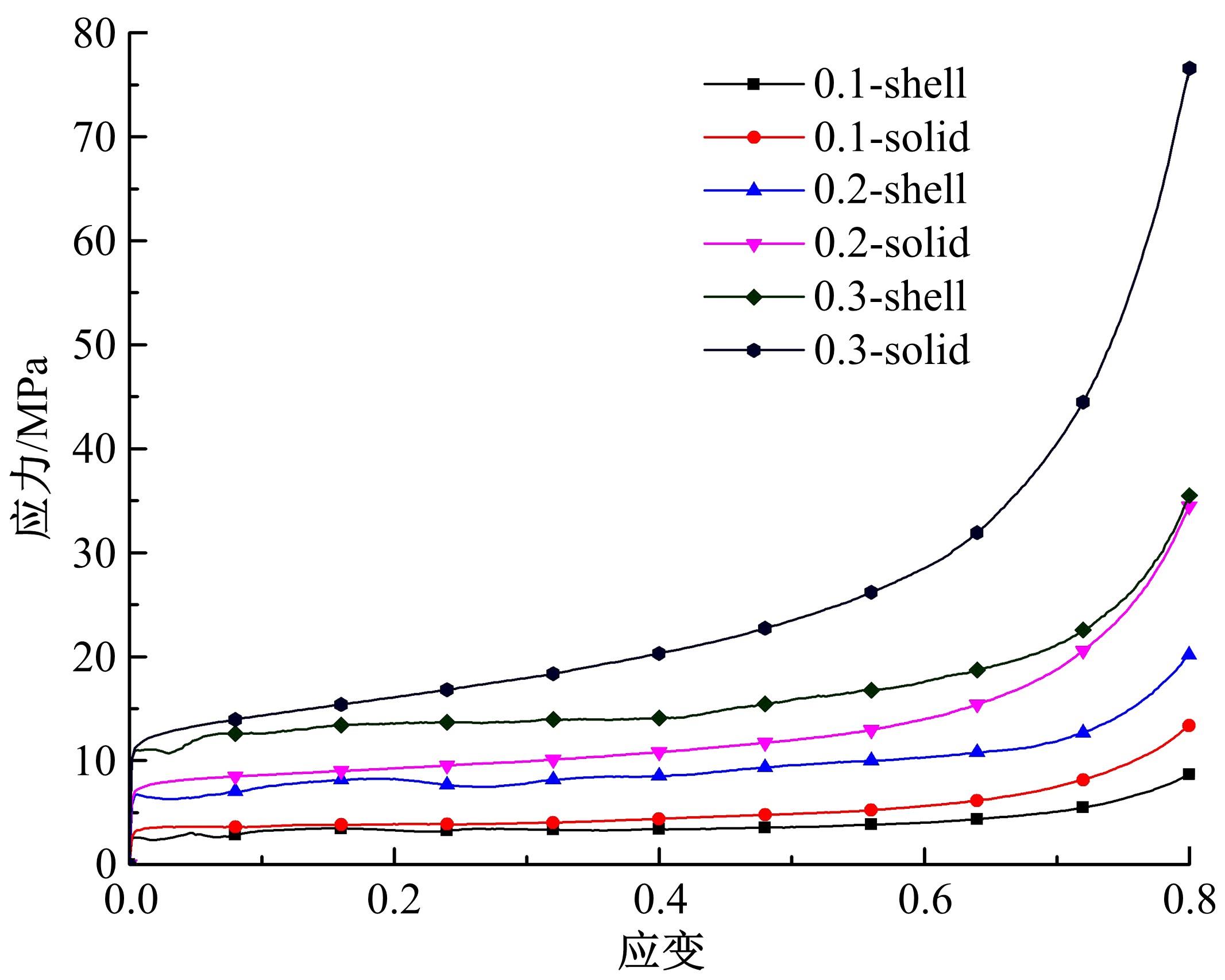

针对壳体泡沫铝模型在几何建模及仿真计算中存在的问题,基于Voronoi模型提出了具有随机壁厚的三维实体泡沫铝模型的建模方法及其实现流程。通过使用Python语言编写的ABAQUS泡沫铝建模插件建立了实体泡沫铝模型,进行了泡沫铝的准静态压缩有限元仿真分析。对实体模型和壳体模型在仿真中的力学行为、变形模式及计算所得的材料应力-应变曲线进行了对比分析。研究结果表明:实体模型的仿真结果和变形模式与实验更接近;实体模型计算得到的应力-应变曲线波动更小、更加平滑;实体模型较壳体模型在压缩过程中受力和内部结构的模式更加合理。

中图分类号:

- TG146.21

| 1 | 张士卫. 泡沫金属的研究与应用进展[J]. 粉末冶金技术, 2016, 34(3): 222-227. |

| Zhang Shi-wei. Foam metal research and application progress[J]. Powder Metallurgy Technology, 2016, 34(3): 222-227. | |

| 2 | 陈明营, 纪箴, 贾成厂, 等. 泡沫铝及其复合材料的研究进展[J]. 粉末冶金技术, 2019, 37(1): 68-73. |

| Chen Ming-ying, Ji Zhen, Jia Cheng-chang, et al. Research progress of aluminum foam and its composites[J]. Powder Metallurgy Technology, 2019, 37(1): 68-73. | |

| 3 | 张君媛, 张秋实, 刘卫国, 等.泡沫铝填充矩形截面薄壁梁压溃力理论表达式[J]. 吉林大学学报: 工学版, 2016, 46(3): 745-750. |

| Zhang Jun-yuan, Zhang Qiu-shi, Liu Wei-guo, et al. Crushing model of rectangular section thin-walled beam filled with aluminum foam[J]. Journal of Jilin University(Engineering and Technology Edition),2016, 46(3): 745-750. | |

| 4 | 刘家安, 于思荣, 朱先勇. Zn-22Al泡沫夹芯复合板的三点弯曲性能[J]. 吉林大学学报: 工学版, 2012, 42(2): 344-348. |

| Liu Jia-an, Yu Si-rong, Zhu Xian-yong. Three-point bending properties of Zn-22A1 foam sandwich panel[J]. Journal of Jilin University(Engineering and Technology Edition), 2012, 42(2): 344-348. | |

| 5 | Zhang X, Tang L, Liu Z, et al. Yield properties of closed-cell aluminum foam under triaxial loadings by a 3D voronoi model[J]. Mechanics of Materials, 2017, 104: 73-84. |

| 6 | Li Z, Zhang J, Fan J, et al. On crushing response of the three-dimensional closed-cell foam based on voronoi model[J]. Mechanics of Materials, 2014, 68: 85-94. |

| 7 | Shi X, Liu S, Nie H, et al. Study of cell irregularity effects on the compression of closed-cell foams[J]. International Journal of Mechanical Sciences, 2018, 135: 215-225. |

| 8 | Randrianalisoa J, Baillis D, Martin C L, et al. Microstructure effects on thermal conductivity of open-cell foams generated from the laguerre-voronoi tessellation method[J]. International Journal of Thermal Sciences, 2015, 98: 277-286. |

| 9 | Vengatachalam B, Poh L H, Liu Z S, et al. Three dimensional modelling of closed-cell aluminium foams with predictive macroscopic behaviour[J]. Mechanics of Materials, 2019, 136: 103067. |

| 10 | 杨宝, 汤立群, 刘逸平, 等. 冲击条件下泡沫铝的细观变形特征分析[J]. 爆炸与冲击, 2012, 32(4): 399-403. |

| Yang Bao, Tang Li-qun, Liu Yi-ping, et al. Meso deformation characteristics analysis of aluminum foam under impact[J]. Explosion and Shock Waves, 2012, 32(4): 399-403. | |

| 11 | 王巍, 安子军, 彭春彦, 等. 闭孔泡沫材料3-D几何建模及力学性能分析[J]. 塑性工程学报, 2017, 24(4): 194-200. |

| Wang Wei, An Zi-jun, Peng Chun-yan, et al. 3-D geometry modeling and mechanical properties analysis of closed-cell foams[J]. Journal of Plasticity Engineering, 2017, 24(4): 194-200. | |

| 12 | 程振, 方秦, 张锦华, 等. 闭孔泡沫金属三维细观模型建模方法[J]. 工程力学, 2017, 34(8): 212-221. |

| Cheng Zhen, Fang Qin, Zhang Jin-hua, et al. Mesoscopic methodology for the three-dimensional modelling of closed-cell metallic foam[J]. Engineering Mechanics, 2017, 34(8): 212-221. | |

| 13 | Li Q M. Compressive strain at the onset of densification of cellular solids[J]. Journal of Cellular Plastics, 2006, 42(5): 371-392. |

| 14 | Liu Y, Yu J, Zheng Z, et al. A numerical study on the rate sensitivity of cellular metals[J]. International Journal of Solids and Structures, 2009, 46(22): 3988-3998. |

| [1] | 王金国,黄恺,闫瑞芳,任帅,王志强,郭劲. 元胞自动机-有限元法模拟碳当量元素对亚共晶球墨铸铁流动性的影响[J]. 吉林大学学报(工学版), 2021, 51(3): 855-865. |

| [2] | 田银宝,申俊琦,胡绳荪,勾健. EP/EN模数对铝合金VP-CMT焊熔滴过渡及焊道成形的影响[J]. 吉林大学学报(工学版), 2020, 50(5): 1663-1668. |

| [3] | 王金国,王志强,任帅,闫瑞芳,黄恺,郭劲. Ti添加量对球墨铸铁组织及力学性能的影响[J]. 吉林大学学报(工学版), 2020, 50(5): 1653-1662. |

| [4] | 修文翠,吴化,韩英,刘云旭. 等温热处理温度对超级贝氏体组织与性能的影响[J]. 吉林大学学报(工学版), 2020, 50(2): 520-525. |

| [5] | 宫文彪,朱芮,郄新哲,崔恒,宫明月. 6082铝合金超厚板搅拌摩擦焊接头组织与性能[J]. 吉林大学学报(工学版), 2020, 50(2): 512-519. |

| [6] | 陈学文,王继业,杨喜晴,皇涛,宋克兴. Cr8合金钢热变形行为及位错密度演变规律[J]. 吉林大学学报(工学版), 2020, 50(1): 91-99. |

| [7] | 王金国,任帅,闫瑞芳,黄恺,王志强. TiC颗粒对铸态球墨铸铁组织和力学性能的影响[J]. 吉林大学学报(工学版), 2019, 49(6): 2010-2018. |

| [8] | 徐戊矫,刘承尚,鲁鑫垚. 喷丸处理后6061铝合金工件表面粗糙度的模拟计算及预测[J]. 吉林大学学报(工学版), 2019, 49(4): 1280-1287. |

| [9] | 李于朋,孙大千,宫文彪. 6082⁃T6铝合金薄板双轴肩搅拌摩擦焊温度场[J]. 吉林大学学报(工学版), 2019, 49(3): 836-841. |

| [10] | 关庆丰,张福涛,彭韬,吕鹏,李姚君,许亮,丁佐军. 含硼、钴9%Cr耐热钢的热变形行为[J]. 吉林大学学报(工学版), 2018, 48(6): 1799-1805. |

| [11] | 关庆丰, 董书恒, 郑欢欢, 李晨, 张从林, 吕鹏. 强流脉冲电子束作用下45#钢表面Cr合金化[J]. 吉林大学学报(工学版), 2018, 48(4): 1161-1168. |

| [12] | 赵宇光, 杨雪慧, 徐晓峰, 张阳阳, 宁玉恒. Al-10Sr变质剂状态、变质温度及变质时间对ZL114A合金组织的影响[J]. 吉林大学学报(工学版), 2018, 48(1): 212-220. |

| [13] | 汤华国, 马贤锋, 赵伟, 刘建伟, 赵振业. 高性能金属铝的制备、微观结构及其热稳定性[J]. 吉林大学学报(工学版), 2017, 47(5): 1542-1547. |

| [14] | 关庆丰, 张远望, 孙潇, 张超仁, 吕鹏, 张从林. 强流脉冲电子束作用下铝钨合金的表面合金化[J]. 吉林大学学报(工学版), 2017, 47(4): 1171-1178. |

| [15] | 杨晓红, 杭文先, 秦绍刚, 刘勇兵, 刘利萍. H13钢激光熔覆钴基复合涂层的组织及耐磨性[J]. 吉林大学学报(工学版), 2017, 47(3): 891-899. |

|

||