吉林大学学报(工学版) ›› 2022, Vol. 52 ›› Issue (9): 2119-2129.doi: 10.13229/j.cnki.jdxbgxb20220016

• • 上一篇

基于Avl-Cruise的燃料电池汽车传动比及能量管理策略

- 1.吉林大学 生物与农业工程学院,长春 130022

2.吉林大学 交通学院,长春 130022

3.吉林大学 汽车工程学院,长春 130022

Transmission ratio and energy management strategy of fuel cell vehicle based on AVL⁃Cruise

Hai-lin KUI1( ),Ze-zhao WANG2,Jia-zhen ZHANG3,Yang LIU2

),Ze-zhao WANG2,Jia-zhen ZHANG3,Yang LIU2

- 1.College of Biological and Agricultural Engineering,Jilin University,Changchun 130022,China

2.College of Transportation,Jilin University,Changchun 130022,China

3.College of Automotive Engineering,Jilin University,Changchun 130022,China

摘要:

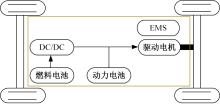

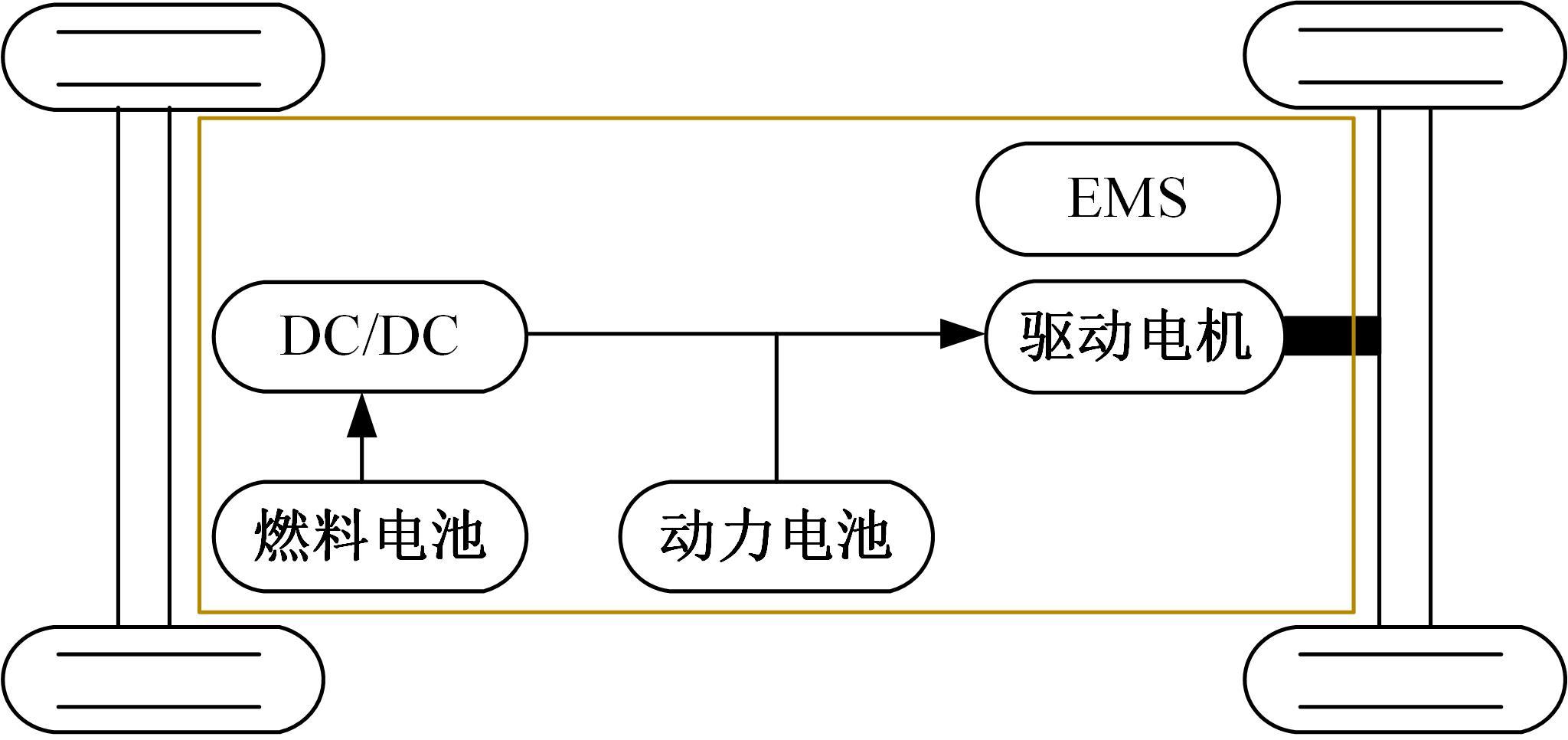

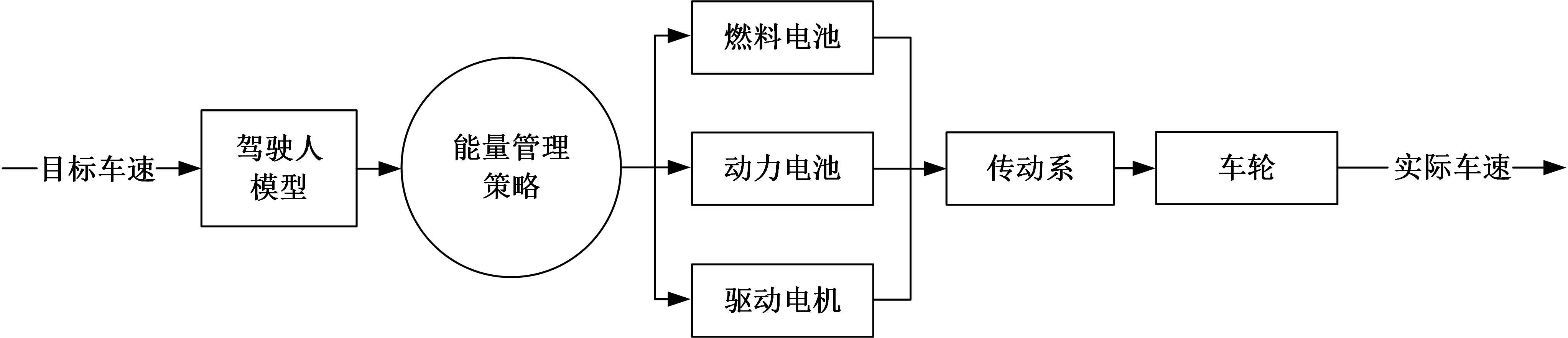

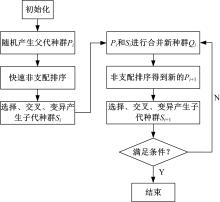

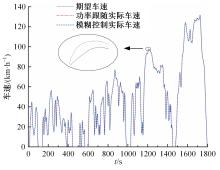

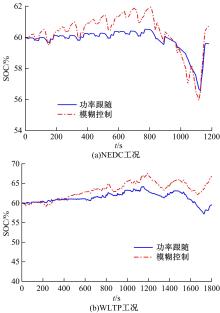

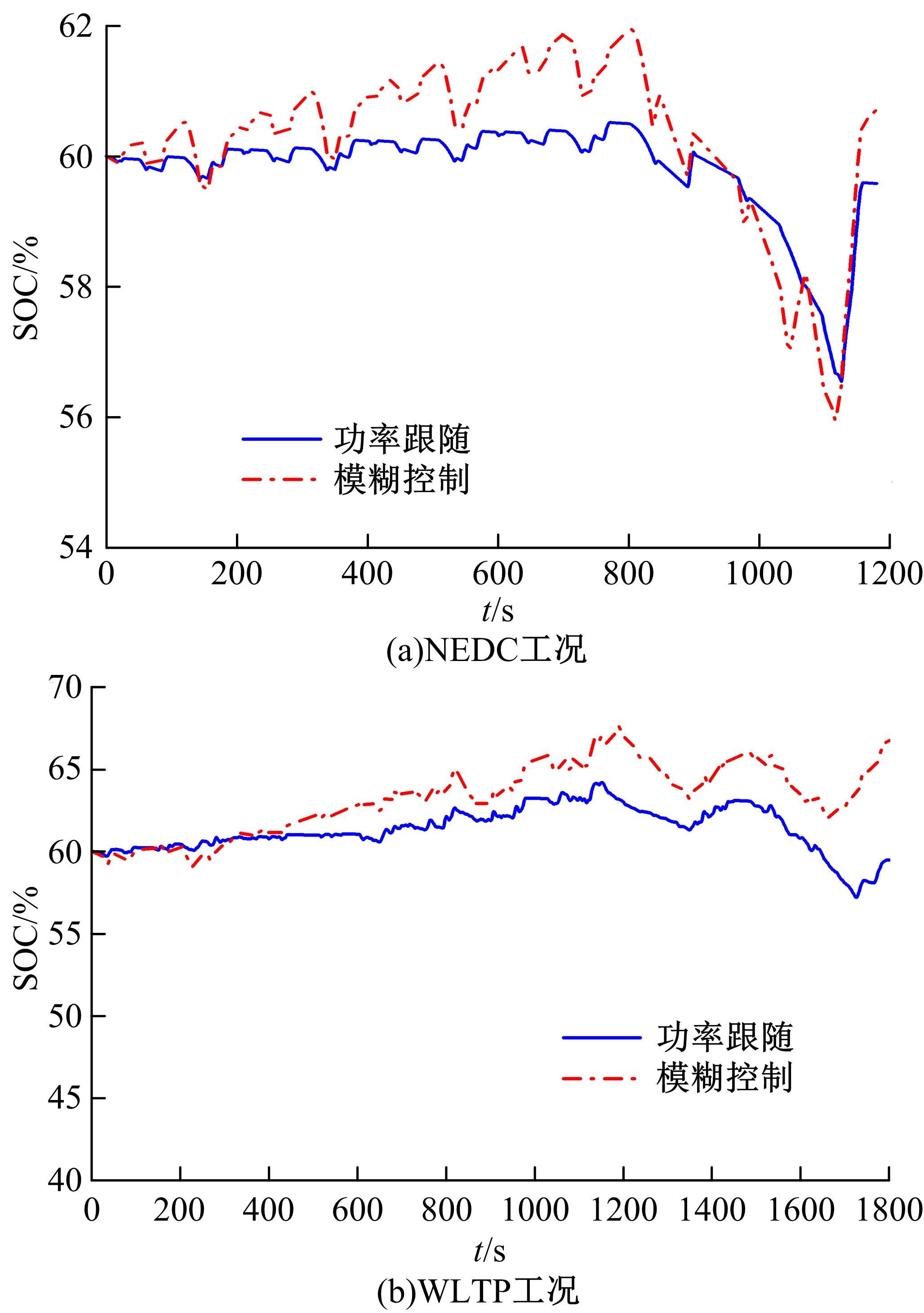

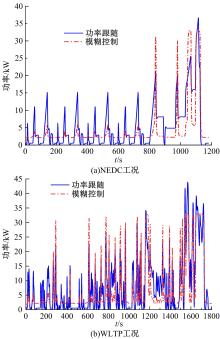

为了提高燃料电池汽车的动力性和经济性,基于Avl-Cruise对某燃料电池汽车进行了建模,并在Simulink中建立了模糊控制能量管理策略。采用Isight/Cruise联合仿真的方法将固定挡减速器优化为两挡AMT变速箱。仿真结果表明:本文模糊控制能量管理策略有效,相比于功率跟随能量管理策略,在NEDC工况和WLTP工况下经济性分别提升了16.4%和8.5%;基于模糊控制的优化传动比的燃料电池汽车对比未优化传动比的燃料电池汽车,在NEDC工况和WLTP工况下经济性分别提升了1.1%和2.8%。

中图分类号:

- U461.8

| 1 | Kendall M. Fuel cell development for New Energy Vehicles (NEVs) and clean air in China[J]. Progress in Natural Science: Materials International, 2018, 28(2): 113-120. |

| 2 | Liu F Q, Zhao F Q, Liu Z W, et al. The impact of fuel cell vehicle deployment on road transport greenhouse gas emissions: The China case[J]. International Journal of Hydrogen Energy, 2018, 43(50): 22604-22621. |

| 3 | Fu J, You H, Zhao J W, et al. An energy control strategy of fuel cell hybrid unmanned surface vehicle based on pmp algorithm[C]∥2020 Chinese Automation Congress, Shanghai, China, 2020: 6260-6264. |

| 4 | 金希计. 新能源汽车的技术原理和优缺点探究[J]. 时代汽车, 2020, 16(15): 80-81. |

| Jin Xi-ji. Research on the technical principles, advantages and disadvantages of new energy vehicle[J]. Auto Time, 2020, 16(15): 80-81. | |

| 5 | Zhao H, Wang Y, Huang X, et al. Configuration analysis and parameter matching of fuel cell electric vehicle driving system[C]∥45th Annual Conference of the IEEE Industrial Electronics Society, Lisbon, Portugal, 2019: 6388-6393. |

| 6 | 徐乐鹏. 某燃料电池重卡动力系统参数匹配与能量管理策略研究[D]. 太原: 太原理工大学机械与运载工程学院, 2020. |

| Xu Le-peng. Research on parameter matching and energy management strategy of a fuel cell heavy truck power system[D]. Taiyuan: College of Mechanical and Vehicle Engineering, Taiyuan University of Technology, 2020. | |

| 7 | 郭斌, 秦孔建, 卢青春, 等. 燃料电池混合动力系统构型和控制方法研究[J]. 汽车科技, 2006, 33(3): 10-14. |

| Guo Bin, Qin Kong-jian, Lu Qing-chun, et al. Research on configuration and control method of fuel cell hybrid power system[J]. Auto Sci-tech, 2006, 33(3): 10-14. | |

| 8 | 宋昱, 韩恺, 李小龙, 等. 燃料电池汽车混合度与能量管理策略研究[J]. 交通科技与经济, 2019, 21(2): 40-46, 67. |

| Song Yu, Han Kai, Li Xiao-long, et al. A study of degree of hybridization and energy management strategies for fuel cell electric vehicle[J]. Technology and Economy in Areas of Communications, 2019, 21(2): 40-46, 67. | |

| 9 | Ma S, Lin M, Lin T E, et al. Fuel cell-battery hybrid systems for mobility and off-grid applications: a review[J]. Renewable and Sustainable Energy Reviews, 2020, 135: No. 110119. |

| 10 | 宗贺辉. 氢燃料电池客车电电混合动力系统研究[D]. 郑州: 华北水利水电大学机械工程学院, 2020. |

| Zong He-hui. Research on electric-electric hybrid power system of hydrogen fuel cell bus[D]. Zhengzhou: School of Mechanical Engineering, North China University of Water Resources and Electric Power, 2020. | |

| 11 | 王骞, 李顶根, 苗华春. 基于模糊逻辑控制的燃料电池汽车能量管理控制策略研究[J]. 汽车工程, 2019, 41(12): 1347-1355. |

| Wang Qian, Li Ding-gen, Miao Hua-chun. Rasearch on energy management strategy of fuel cell vehicle based on fuzzy logic control[J]. Automotive Engineering, 2019, 41(12): 1347-1355. | |

| 12 | 张梦, 杨玉新, 罗羽, 等. 模糊逻辑应用的燃料电池汽车能量管理策略[J]. 电气自动化, 2020, 42(1): 50-53. |

| Zhang Meng, Yang Yu-xin, Luo Yu, et al. Fuel cell vehicle energy management strategy based on fuzzy logic[J]. Electrical Automation, 2020, 42(1): 50-53. | |

| 13 | Lee H, Cha S W. Energy management strategy of fuel cell electric vehicles using model-based reinforcement learning with data-driven model update[J]. IEEE Access, 2021, 9: 59244-59254. |

| 14 | Inci M, Büyük M, Demir M H, et al. A review and research on fuel cell electric vehicles: topologies, power electronic converters, energy management methods, technical challenges, marketing and future aspects[J]. Renewable and Sustainable Energy Reviews, 2021, 137: No.110648. |

| 15 | Zhan Y D, Guo Y G, Zhu J G, et al. Comprehensive influences measurement and analysis of power converter low frequency current ripple on PEM fuel cell[J]. International Journal of Hydrogen Energy, 2019, 44(59): 31352-31359. |

| 16 | Pei P C, Chen H C. Main factors affecting the lifetime of proton exchange membrane fuel cells in vehicle applications: a review[J]. Applied Energy, 2014, 125: 60-75. |

| 17 | 王季方, 卢正鼎. 模糊控制中隶属度函数的确定方法[J]. 河南科学, 2000, 18(4): 348-351. |

| Wang Ji-fang, Lu Zheng-ding. Determination method of membership function in fuzzy control[J]. Henan Science, 2000, 18(4): 348-351. | |

| 18 | 鲁楠, 唐岚, 程洋, 等. 纯电动汽车传动系统参数匹配及优化[J]. 汽车实用技术, 2019, 43(8): 47-50. |

| Lu Nan, Tang Lan, Cheng Yang, et al. Parameters matching and optimization for power-train of electrical vehicle[J]. Automobile Applied Technology, 2019, 43(8): 47-50. | |

| 19 | 叶山顶. 电动汽车无离合器AMT换档控制策略研究[D]. 北京: 北京理工大学机械工程学院, 2016. |

| Ye Shan-ding. Study on the AMT shifting control strategy for electrical vehicle[D]. Beijing: School of Mechanical Engineering, Beijing Institute of Technology, 2016. | |

| 20 | 詹长书, 王清. 基于改进遗传算法电动汽车变速器参数设计与优化[J]. 重庆理工大学学报: 自然科学版, 2020, 34(2): 1-5. |

| Zhan Chang-shu, Wang Qing. Design and optimazation of transmission parameters of electric vehicle based on improved genetic algorithm[J]. Journal of Chongqing University of Technology(Natural Science), 2020, 34(2): 1-5. | |

| 21 | 王南, 刘庆阳, 周莎莎, 等. 基于Isight平台NSGA-Ⅱ方法的3-PRS并联机构多目标优化[J]. 机械设计与制造, 2015, 52(12): 198-201. |

| Wang Nan, Liu Qing-yang, Zhou Sha-sha, et al. Multi-objective optimization of 3-PRS parallel mechanism based on NSGA-Ⅱ method of Isight platform[J]. Machinery Design and Manufacture, 2015, 52(12): 198-201. |

| [1] | 刘继宗,吴小平,孔维华. 基于鱼群优化算法的有轨电车用燃料电池混合动力系统参数配置[J]. 吉林大学学报(工学版), 2022, 52(9): 2004-2013. |

| [2] | 王克勇,鲍大同,周苏. 基于数据驱动的车用燃料电池故障在线自适应诊断算法[J]. 吉林大学学报(工学版), 2022, 52(9): 2107-2118. |

| [3] | 杨子荣,李岩,冀雪峰,刘芳,郝冬. 质子交换膜燃料电池运行工况参数敏感性分析[J]. 吉林大学学报(工学版), 2022, 52(9): 1971-1981. |

| [4] | 胡云峰,于彤,杨惠策,孙耀. 低温环境下燃料电池启动优化控制方法[J]. 吉林大学学报(工学版), 2022, 52(9): 2034-2043. |

| [5] | 都京,赵洪辉,王宇鹏,丁天威,魏凯,王恺,韩令海. 基于AMESim模型的燃料电池发动机排氢策略优化及整车搭载验证[J]. 吉林大学学报(工学版), 2022, 52(9): 2069-2076. |

| [6] | 张冲,胡云峰,宫洵,孙耀. 燃料电池阴极流量无模型自适应滑模控制器设计[J]. 吉林大学学报(工学版), 2022, 52(9): 2085-2095. |

| [7] | 张佩,王志伟,杜常清,颜伏伍,卢炽华. 车用质子交换膜燃料电池空气系统过氧比控制方法[J]. 吉林大学学报(工学版), 2022, 52(9): 1996-2003. |

| [8] | 陈凤祥,张俊宇,裴冯来,侯明涛,李其朋,李培庆,王洋洋,张卫东. 质子交换膜燃料电池氢气供应系统的建模及匹配设计[J]. 吉林大学学报(工学版), 2022, 52(9): 1982-1995. |

| [9] | 刘镇宁,江柯,赵韬韬,樊文选,卢国龙. 大功率质子交换膜燃料电池测试系统的开发及试验[J]. 吉林大学学报(工学版), 2022, 52(9): 2025-2033. |

| [10] | 池训逞,侯中军,魏伟,夏增刚,庄琳琳,郭荣. 基于模型的质子交换膜燃料电池系统阳极气体浓度估计技术综述[J]. 吉林大学学报(工学版), 2022, 52(9): 1957-1970. |

| [11] | 裴尧旺,陈凤祥,胡哲,翟双,裴冯来,张卫东,焦杰然. 基于自适应LQR控制的质子交换膜燃料电池热管理系统温度控制[J]. 吉林大学学报(工学版), 2022, 52(9): 2014-2024. |

| [12] | 张恒,詹志刚,陈奔,隋邦杰,潘牧. 气体扩散层各向异性传输特性的孔尺度模拟[J]. 吉林大学学报(工学版), 2022, 52(9): 2055-2062. |

| [13] | 陈凤祥,伍琪,李元松,莫天德,李煜,黄李平,苏建红,张卫东. 2.5吨燃料电池混合动力叉车匹配、仿真及优化[J]. 吉林大学学报(工学版), 2022, 52(9): 2044-2054. |

| [14] | 武小花,余忠伟,朱张玲,高新梅. 燃料电池公交车模糊能量管理策略[J]. 吉林大学学报(工学版), 2022, 52(9): 2077-2084. |

| [15] | 高青,王浩东,刘玉彬,金石,陈宇. 动力电池应急冷却喷射模式实验分析[J]. 吉林大学学报(工学版), 2022, 52(8): 1733-1740. |

|

||