吉林大学学报(工学版) ›› 2021, Vol. 51 ›› Issue (3): 956-964.doi: 10.13229/j.cnki.jdxbgxb20200154

基于离散元法的空隙特征对沥青混合料虚拟剪切疲劳寿命的影响

- 1.浙江大学 交通工程研究所,杭州 310058

2.安徽省交通控股集团有限公司,合肥 230088

3.河北省交通规划设计院,石家庄 050011

4.公路建设与养护技术、材料及装备交通运输行业研发中心,石家庄 050011

Effect of void characteristics on virtual shear fatigue life of asphalt mixtures using discrete element method

Yong PENG1( ),Han-duo YANG1,Xue-yuan LU2,Yan-wei LI3,4

),Han-duo YANG1,Xue-yuan LU2,Yan-wei LI3,4

- 1.Institute of Transportation Engineering,Zhejiang University,Hangzhou 310058,China

2.Anhui Transportation Holding Group Co. ,Ltd. ,Hefei 230088,China

3.Hebei Provincial Communications Planning and Design Institute,Shijiazhuang 050011,China

4.Research and Development Center of Transport Industry of Technologies,Materials and Equipments of Highway Construction and Maintenance,Shijiazhuang 050011,China

摘要:

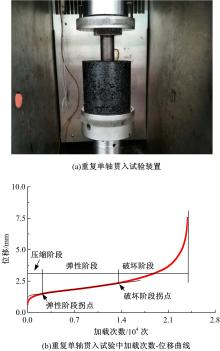

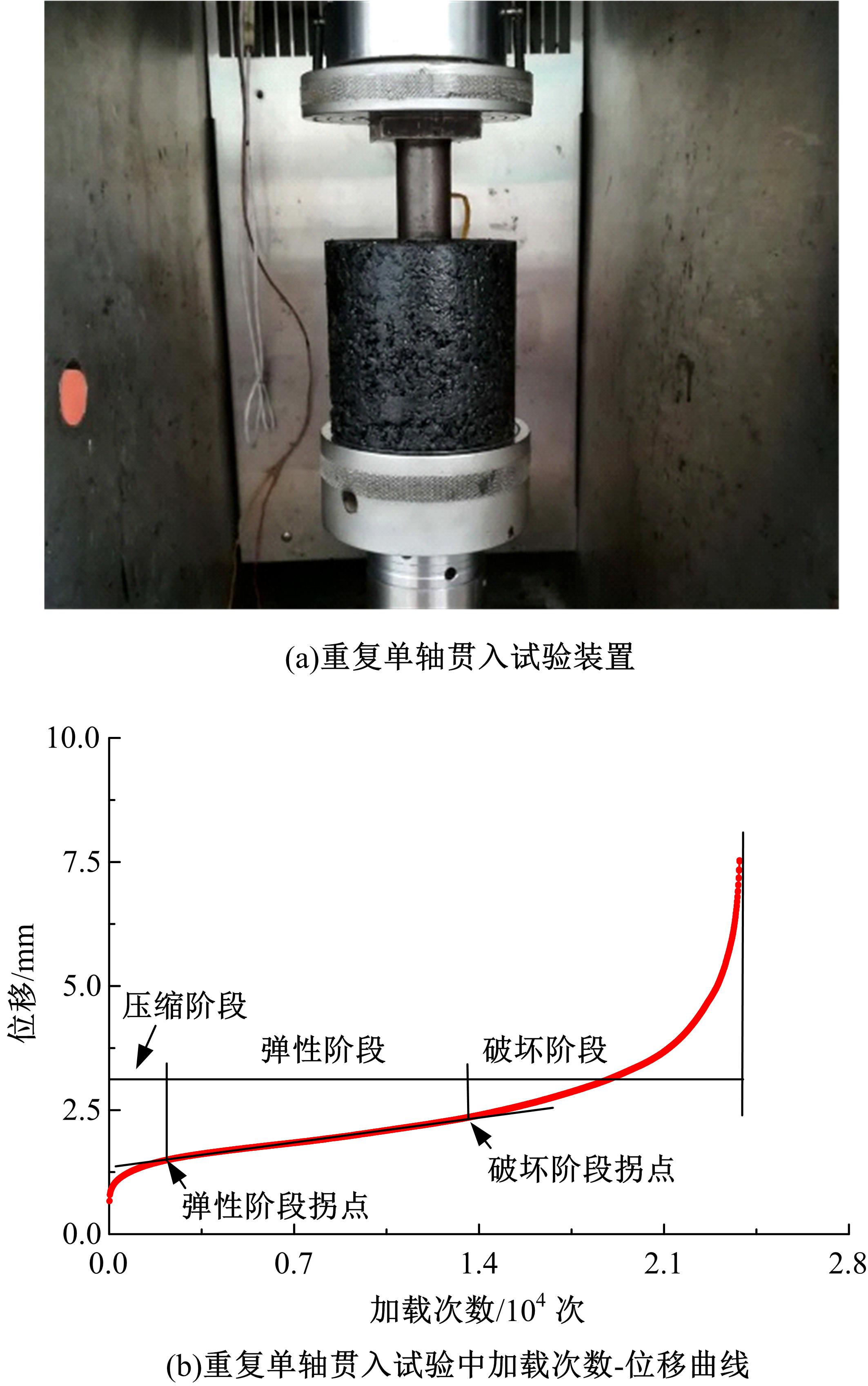

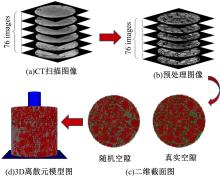

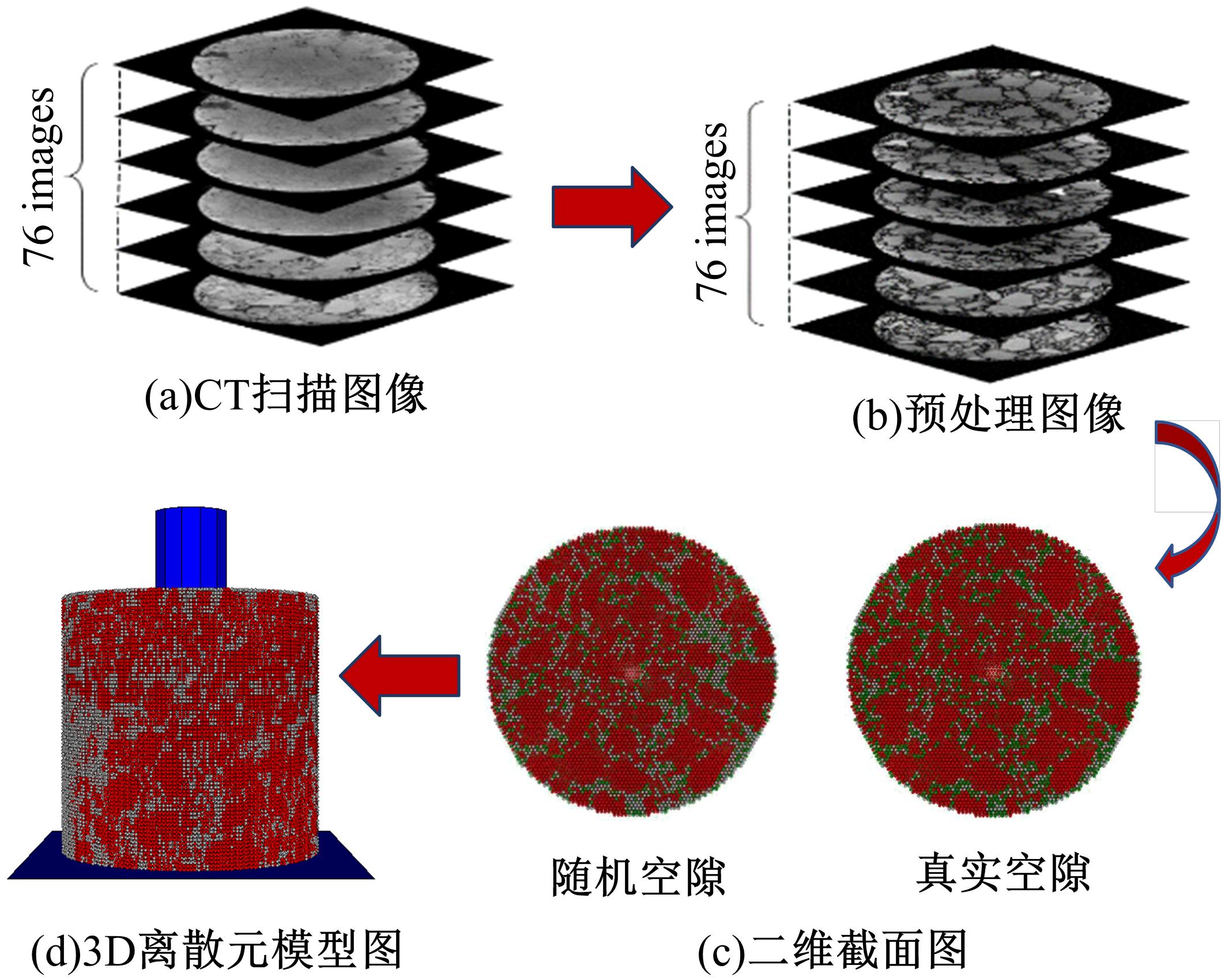

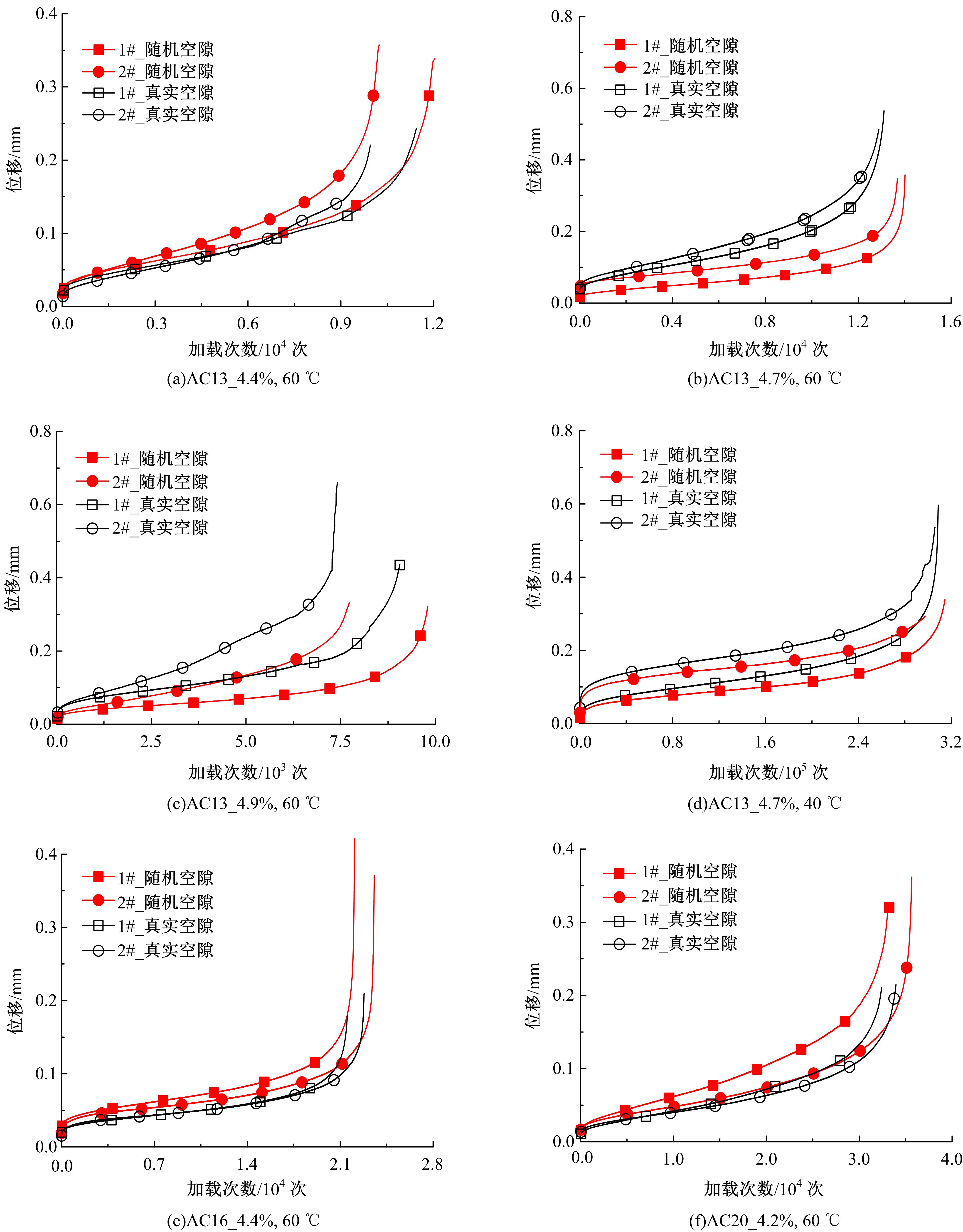

基于图像技术和三维离散元法,建立了具有真实空隙大小和分布以及随机空隙大小和分布的沥青混合料剪切疲劳微观力学模型,通过模拟不同集料粒径、用油量以及温度下的沥青混合料剪切疲劳寿命,研究了空隙分布特征对沥青混合料虚拟剪切疲劳寿命的影响,并将部分模拟结果与试验结果进行对比。结果表明:基于三维离散元法可以模拟沥青混合料剪切疲劳寿命,空隙特征对沥青混合料虚拟剪切疲劳寿命有较大影响。在相同模型参数条件下,具有真实空隙大小和分布的沥青混合料剪切疲劳寿命小于具有随机空隙大小和分布的沥青混合料剪切疲劳寿命,但与试验结果更为接近。此外,集料粒径和用油量也对沥青混合料剪切疲劳寿命有着显著影响。沥青混合料剪切疲劳寿命随集料粒径的增大而提高;在相同集料级配和试验温度时,在最佳用油量条件下的沥青混合料剪切疲劳寿命最大;在相同的集料级配和用油量时,沥青混合料剪切疲劳寿命随温度的升高而降低。

中图分类号:

- U414

| 1 | Monismith C L. Analytically based asphalt pavement design and rehabilitation[J]. Transportation Research Record, 1992, 1354(1):5-26. |

| 2 | Roberts F L, Kandhal P S, Brown E R, et al. Hot Mix Asphalt Materials, Mixture Design and Construction[M]. 2nd Edition. Lanham Md: National Asphalt Pavement Association, 1996. |

| 3 | 彭勇,孙立军. 空隙率对沥青混合料性能的影响[J]. 武汉理工大学学报:交通科学与工程版,2009,33(5):826-829. |

| Peng Yong, Sun Li-jun. Effects of air void content on asphalt mixture performance[J]. Journal of Wuhan University of Technology (Transportation Science and Engineering), 2009, 33(5):826-829. | |

| 4 | Elliot R P, Ford M C, Ghanim J M, et al. Effect of aggregate gradation variation on asphalt concrete mix properties[J]. Transportation Research Record, 1992, 1317(1):52-60. |

| 5 | Yue Z Q, Bekking W, Morin I. Application of digital image processing to quantitative study of asphalt concrete microstructure[J]. Transportation Research Record, 1995, 1492(1):53-60. |

| 6 | Obaidat M T, Msaeid H R, Gharaybeh F, et al. An innovative digital image analysis approach to quantify the percentage of voids in mineral aggregates of bituminous mixtures[J]. Canadian Journal of Civil Engineering, 1998, 25(6):1041-1049. |

| 7 | Masad E, Muhunthan B, Shashidhar N, et al. Internal structure characterization of asphalt concrete using image analysis[J]. Journal of Computing in Civil Engineering (Special Issue on Image Processing), 1999, 13(2):88-95. |

| 8 | Rao C B. Development of 3-D image analysis techniques to determine shape and size properties of coarse aggregate[D]. Urbana-Champagne: Department of Civil Engineering, University of Illinois at Urbana-Champaign, 2001. |

| 9 | Kose S. Development of a virtual test procedure for asphalt concrete[D]. Madison City: Department of Civil and Environmental Engineering, University of Wisconsin-Madison, 2002. |

| 10 | Sefidmazgi N R, Tashman L, Bahia H. Internal structure characterization of asphalt mixtures for rutting performance using imaging analysis[J]. Road Materials and Pavement Design, 2012, 13(Sup.1):21-37. |

| 11 | 彭勇,孙立军,王元清,等. 数字图像处理在沥青混合料均匀性评价中的应用[J]. 吉林大学学报:工学版,2007,37(2):334-337. |

| Peng Yong, Sun Li-jun, Wang Yuan-qing, et al. Application of digital image processing in evaluating homogeneity of asphalt mixture[J]. Journal of Jilin University (Engineering and Technology Edition), 2007, 37(2):334-337. | |

| 12 | Tashman L, Masad E, D'angelo J, et al. X-ray tomography to characterize air void distribution in superpave gyratory compacted specimens[J]. International Journal of Pavement Engineering, 2002, 3(1):19-28. |

| 13 | Masad E, Button J. Implications of experimental measurements and analyses of the internal structure of hot-mix asphalt[J]. Transportation Research Record, 2004, 1891(1):212-220. |

| 14 | Chen J S, Huang B S, Shu X. Air-void distribution analysis of asphalt mixture using discrete element method[J]. Journal of Materials in Civil Engineering, 2013, 25(10):1375-1385. |

| 15 | 王聪,郭乃胜,赵颖华,等. 不同成型方法和级配的沥青混合料内部空隙特征[J]. 吉林大学学报:工学版,2014,44(1):74-80. |

| Wang Cong, Guo Nai-sheng, Zhao Ying-hua, et al. Air voids distribution of asphalt mixtures in different compaction methods and aggregate gradations[J]. Journal of Jilin University (Engineering and Technology Edition), 2014, 44(1):74-80. | |

| 16 | Kose S, Guler M, Bahia H, et al. Distribution of strains within hot-mix asphalt binders: applying imaging and finite-element techniques[J]. Transportation Research Record, 2000, 1728(1):21-27. |

| 17 | Soares J B, de Freitas F A C, Allen D H. Considering material heterogeneity in crack modeling of asphaltic mixtures[J]. Transportation Research Record, 2003, 1832(1):113-120. |

| 18 | Dai Q L, Sadd M H, You Z P. A micromechanical finite element model for linear and damage-coupled viscoelastic behaviour of asphalt mixture[J]. International Journal for Numerical and Analytical Methods in Geomechanics, 2006, 30:1135-1158. |

| 19 | Rotherburg L, Bogobowecz A, Haas R, et al. Micromechanical modeling of asphalt concrete in connection with pavement rutting problems[C]∥International Conference on Asphalt Pavements, Nottingham, United Kingdom, 1992:01404192. |

| 20 | Buttlar W, You Z. Discrete element modeling of asphalt concrete: microfabric approach[J]. Transportation Research Record, 2007, 1757(1):111-118. |

| 21 | Abbas A, Masad E, Papagiannakis A, et al. Modelling asphalt mastic stiffness using discrete element analysis and micromechanics-based models[J]. International Journal of Pavement Engineering, 2005, 6(2):137-146. |

| 22 | Kim H, Wagoner M P, Buttlar W. Simulation of fracture behavior in asphalt concrete using a heterogeneous cohesive zone discrete element model[J]. Journal of Materials in Civil Engineering, 2008, 20(8):552-563. |

| 23 | You Z, Liu Y, Dai Q. Three-dimensional microstructural-based discrete element viscoelastic modeling of creep compliance tests for asphalt mixtures[J]. Journal of Materials in Civil Engineering, 2011, 23(1):79-87. |

| 24 | Peng Y, Harvey J, Sun L J. Micromechanical modeling of aggregate homogeneity influence on the indirect tensile strength of asphalt mixtures using the three-dimensional discrete element method[J]. Journal of Materials in Civil Engineering, 2017, 29(11):04017211. |

| 25 | Peng Y, Bao J X. Micromechanical analysis of asphalt-mixture shear strength using the three-dimensional discrete element method[J]. Journal of Materials in Civil Engineering, 2018, 30(11):04018302. |

| 26 | Ma T, Zhang D Y, Zhang Y, et al. Effect of air voids on the high-temperature creep behavior of asphalt mixture based on three-dimensional discrete element modeling[J]. Materials and Design, 2016, 89:304-313. |

| 27 | Ma T, Zhang Y, Zhang D Y, et al. Influences by air voids on fatigue life of asphalt mixture based on discrete element method[J]. Construction and Building Materials, 2016, 126:785-799. |

| 28 | Ren J L, Sun L. Characterizing air void effect on fracture of asphalt concrete at low-temperature using discrete element method[J]. Engineering Fracture Mechanics, 2017,170:23-43. |

| 29 | 邵显智. 沥青混合料抗剪性能影响因素及剪切疲劳试验研究[D]. 上海:同济大学交通运输工程学院,2005. |

| Shao Xian-zhi. Study on influence factors and fatigue experiment about shear properties of asphalt mixtures[D]. Shanghai: College of Transportation Engineering, Tongji University, 2005. | |

| 30 | Peng Y, Gao H, Lu X Y, et al. Micromechanical discrete element modeling of asphalt mixture shear fatigue performance[J]. Journal of Materials in Civil Engineering, 2020, 32(7):04020183. |

| [1] | 朱伟刚,朱超,张亚球,魏海斌. 基于卷积格网曲面拟合滤波算法的数字高程模型构建及质量评价[J]. 吉林大学学报(工学版), 2021, 51(3): 1073-1080. |

| [2] | 程永春,李赫,李立顶,王海涛,白云硕,柴潮. 基于灰色关联度的矿料对沥青混合料力学性能的影响分析[J]. 吉林大学学报(工学版), 2021, 51(3): 925-935. |

| [3] | 宫亚峰,逄蕴泽,王博,谭国金,毕海鹏. 基于吉林省路况的新型预制装配式箱涵结构的力学性能[J]. 吉林大学学报(工学版), 2021, 51(3): 917-924. |

| [4] | 阳恩慧,徐加秋,唐由之,李奥,邱延峻. 温拌剂对沥青断裂和老化性能的影响[J]. 吉林大学学报(工学版), 2021, 51(2): 604-610. |

| [5] | 戴文亭,司泽华,王振,王琦. 剑麻纤维水泥加固土的路用性能试验[J]. 吉林大学学报(工学版), 2020, 50(2): 589-593. |

| [6] | 方宇,孙立军. 基于生存分析的城市桥梁使用性能衰变模型[J]. 吉林大学学报(工学版), 2020, 50(2): 557-564. |

| [7] | 王芳,李晓光,郭慧,胡佳. 基于驾驶员视觉兴趣区的沙漠草原公路曲线间直线段线形指标优化[J]. 吉林大学学报(工学版), 2020, 50(1): 114-120. |

| [8] | 王英,李萍,念腾飞,姜继斌. 基于动水冲刷作用的沥青混合料短期水损害特性[J]. 吉林大学学报(工学版), 2020, 50(1): 174-182. |

| [9] | 万平,吴超仲,马晓凤. 基于ROC曲线和驾驶行为特征的驾驶愤怒强度判别阈值[J]. 吉林大学学报(工学版), 2020, 50(1): 121-131. |

| [10] | 熊锐,乔宁,褚辞,杨发,关博文,盛燕萍,牛冬瑜. 掺盐沥青胶浆低温流变及粘附特性[J]. 吉林大学学报(工学版), 2020, 50(1): 183-190. |

| [11] | 朱春凤,程永春,梁春雨,肖波. 硅藻土⁃玄武岩纤维复合改性沥青混合料路用性能试验[J]. 吉林大学学报(工学版), 2020, 50(1): 165-173. |

| [12] | 狄胜同,贾超,乔卫国,李康,童凯. 橡胶集料混凝土细观损伤特性的加载速率效应[J]. 吉林大学学报(工学版), 2019, 49(6): 1900-1910. |

| [13] | 张云龙,周刘光,王静,吴春利,吕翔. 冻融对粉砂土力学特性及路堤边坡稳定性的影响[J]. 吉林大学学报(工学版), 2019, 49(5): 1531-1538. |

| [14] | 彭勇,高华,万蕾,刘贵应. 沥青混合料劈裂强度影响因素数值模拟[J]. 吉林大学学报(工学版), 2019, 49(5): 1521-1530. |

| [15] | 李晓珍,柳俊哲,戴燕华,贺智敏,巴明芳,李玉顺. 碳化作用下水泥浆内亚硝酸根离子的含量分布[J]. 吉林大学学报(工学版), 2019, 49(4): 1162-1168. |

|

||