吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (3): 852-864.doi: 10.13229/j.cnki.jdxbgxb.20220991

• 农业工程·仿生工程 • 上一篇

基于改进遗传算法的湿式离合器压力自适应控制

- 中国农业大学 工学院,北京 100083

Adaptive control of wet clutch pressure based on improved genetic algorithm

Yan-an ZHANG( ),Yue-feng DU,Qing-feng MENG,Xiao-yu LI,Lei LIU,Zhong-xiang ZHU

),Yue-feng DU,Qing-feng MENG,Xiao-yu LI,Lei LIU,Zhong-xiang ZHU

- College of Engineering,China Agricultural University,Beijing 100083,China

摘要:

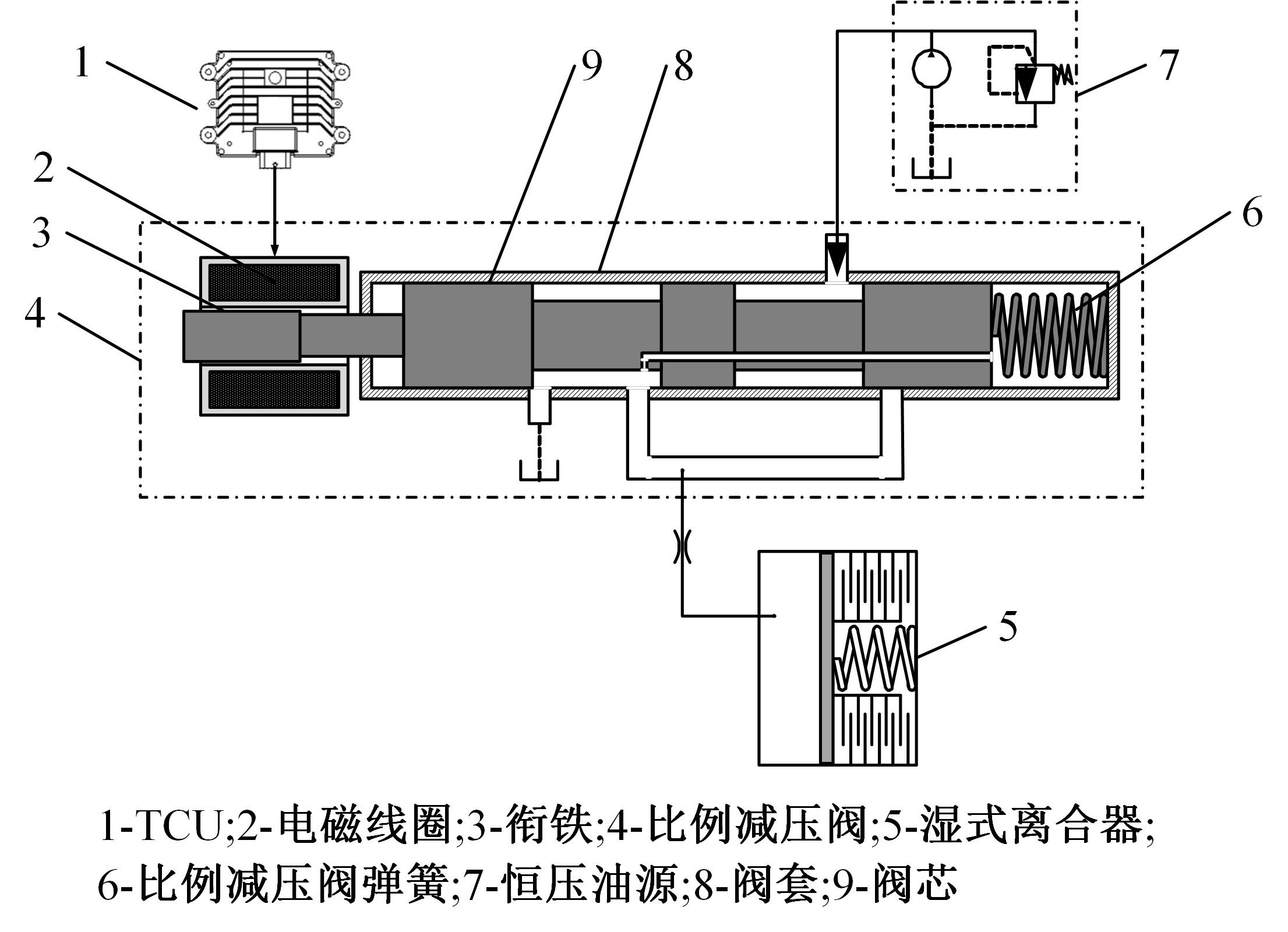

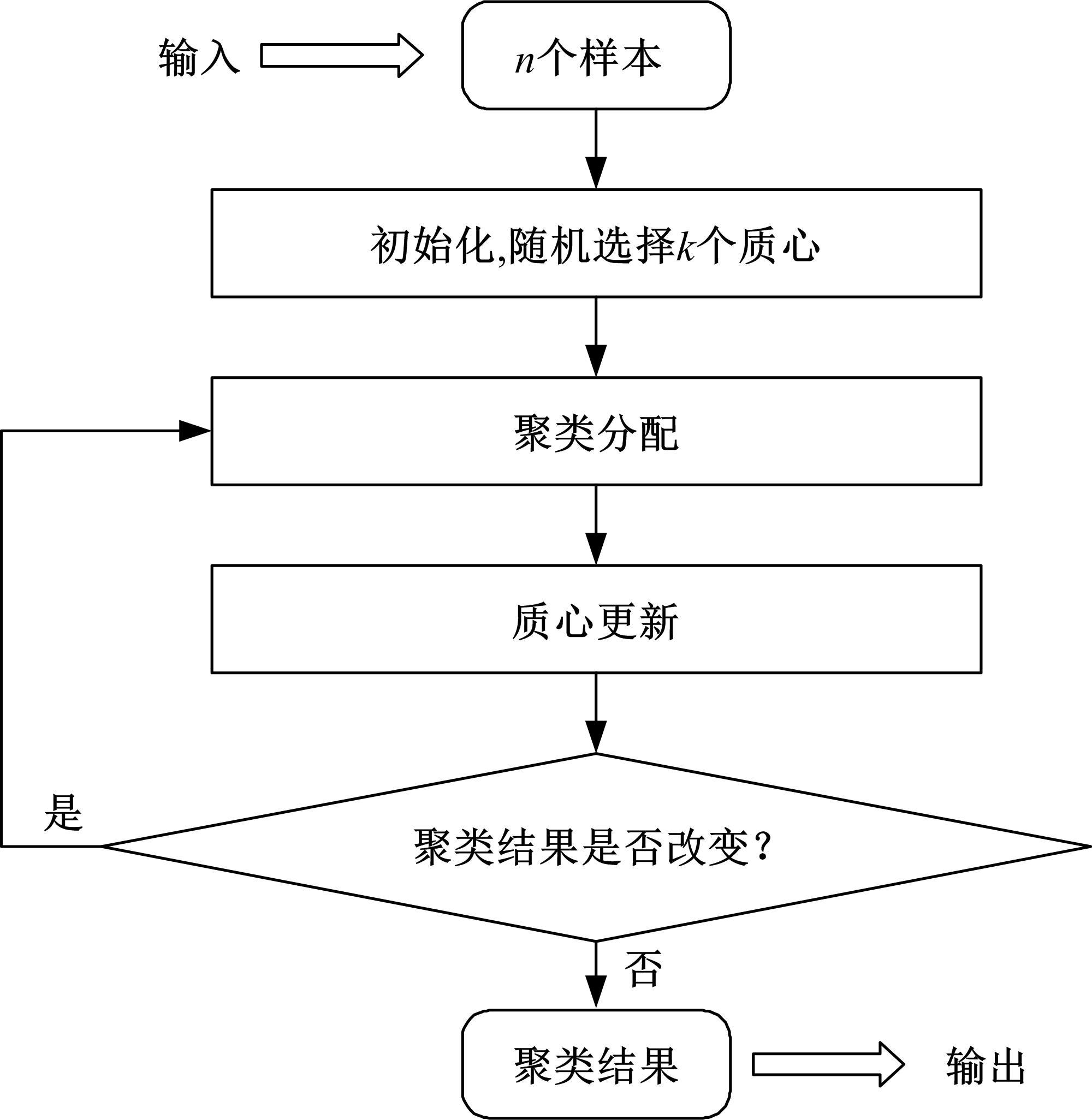

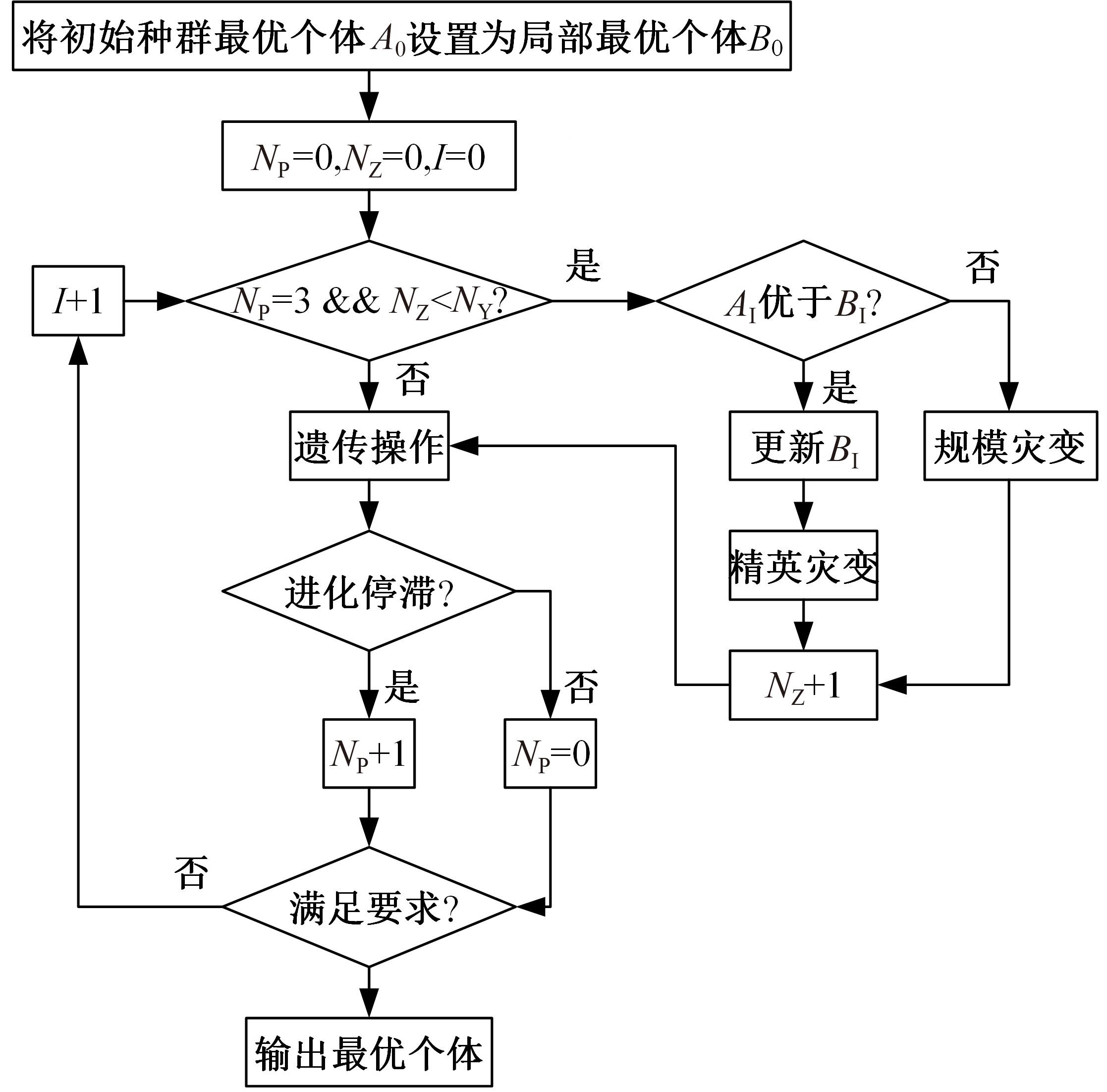

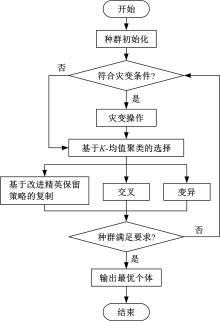

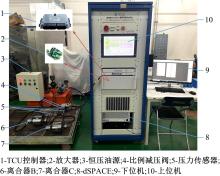

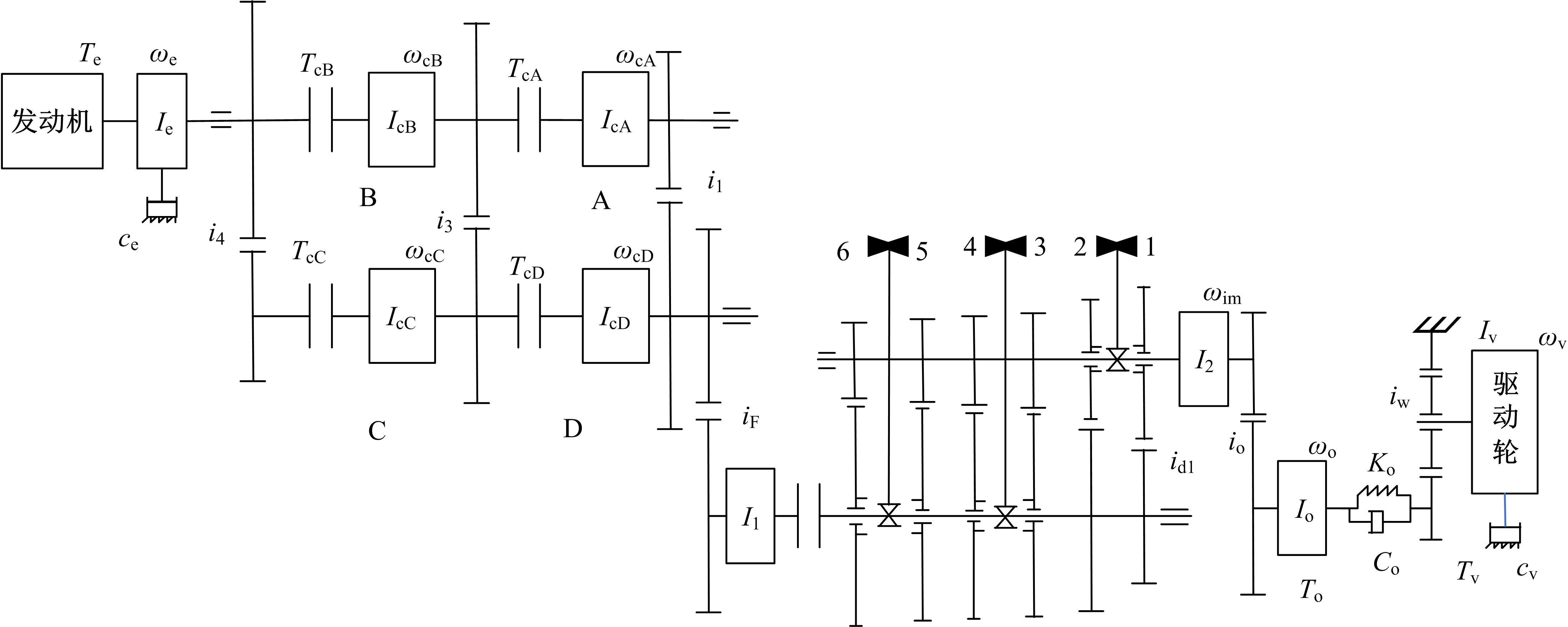

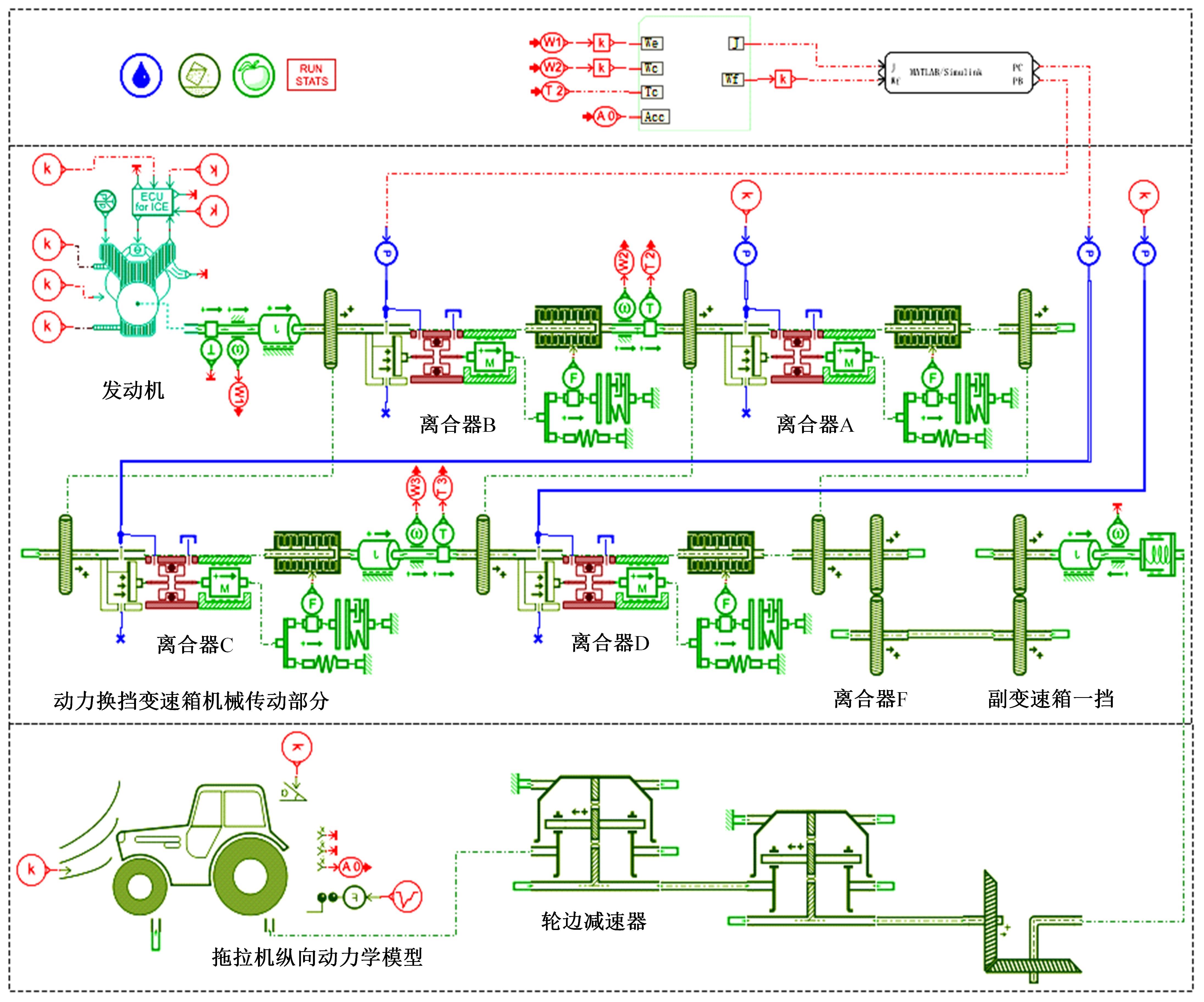

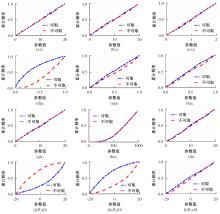

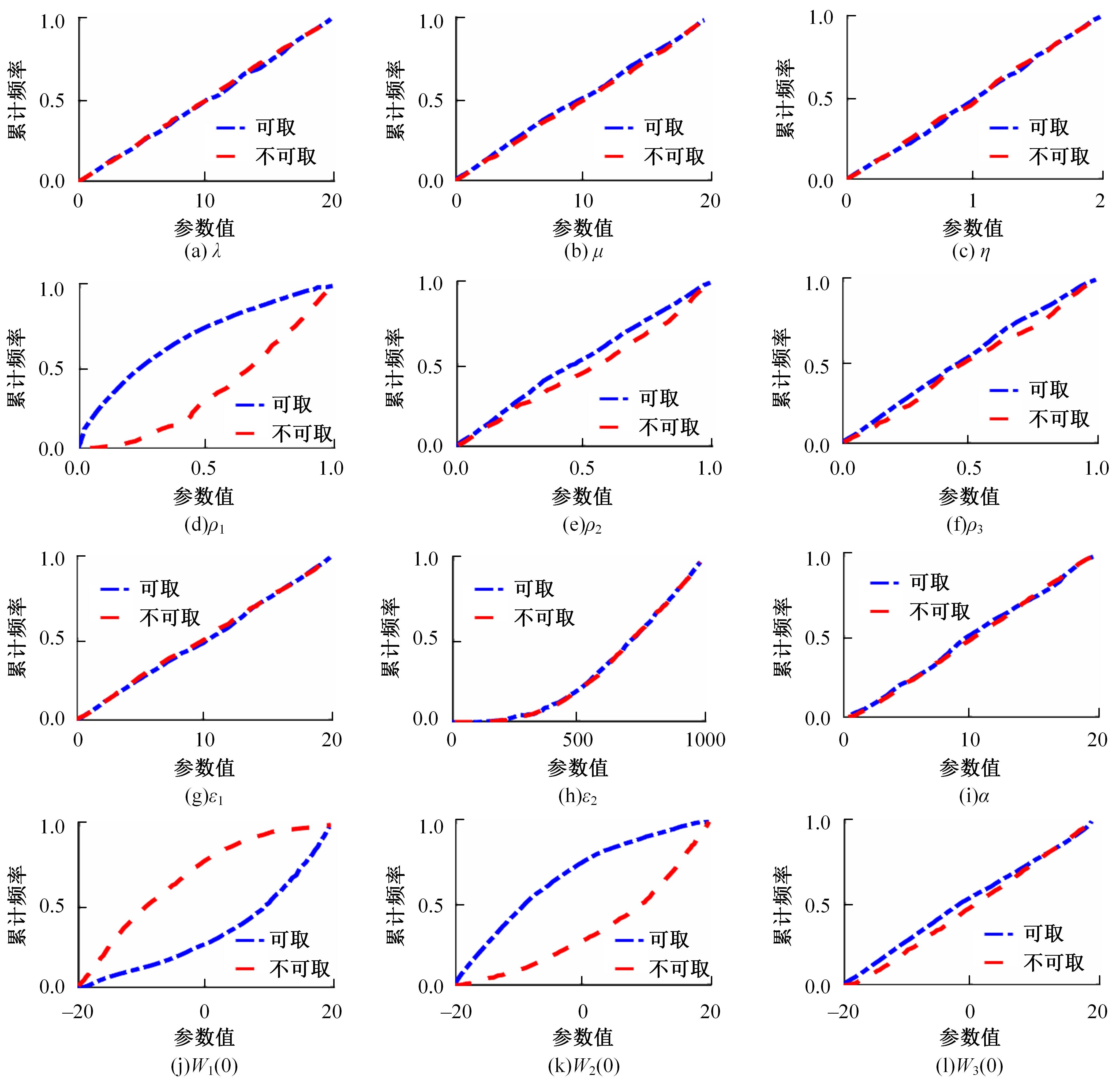

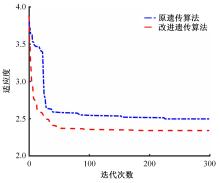

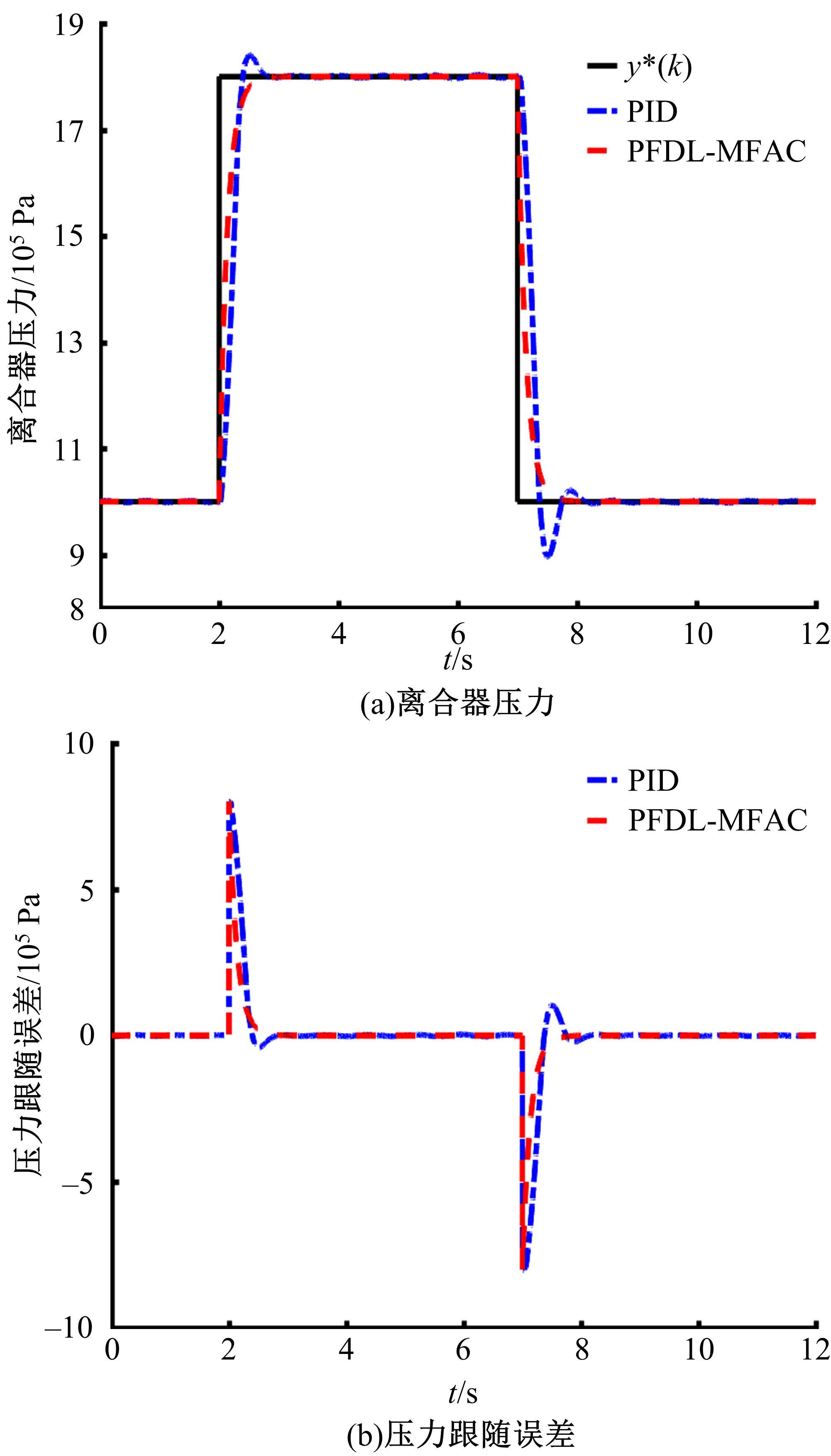

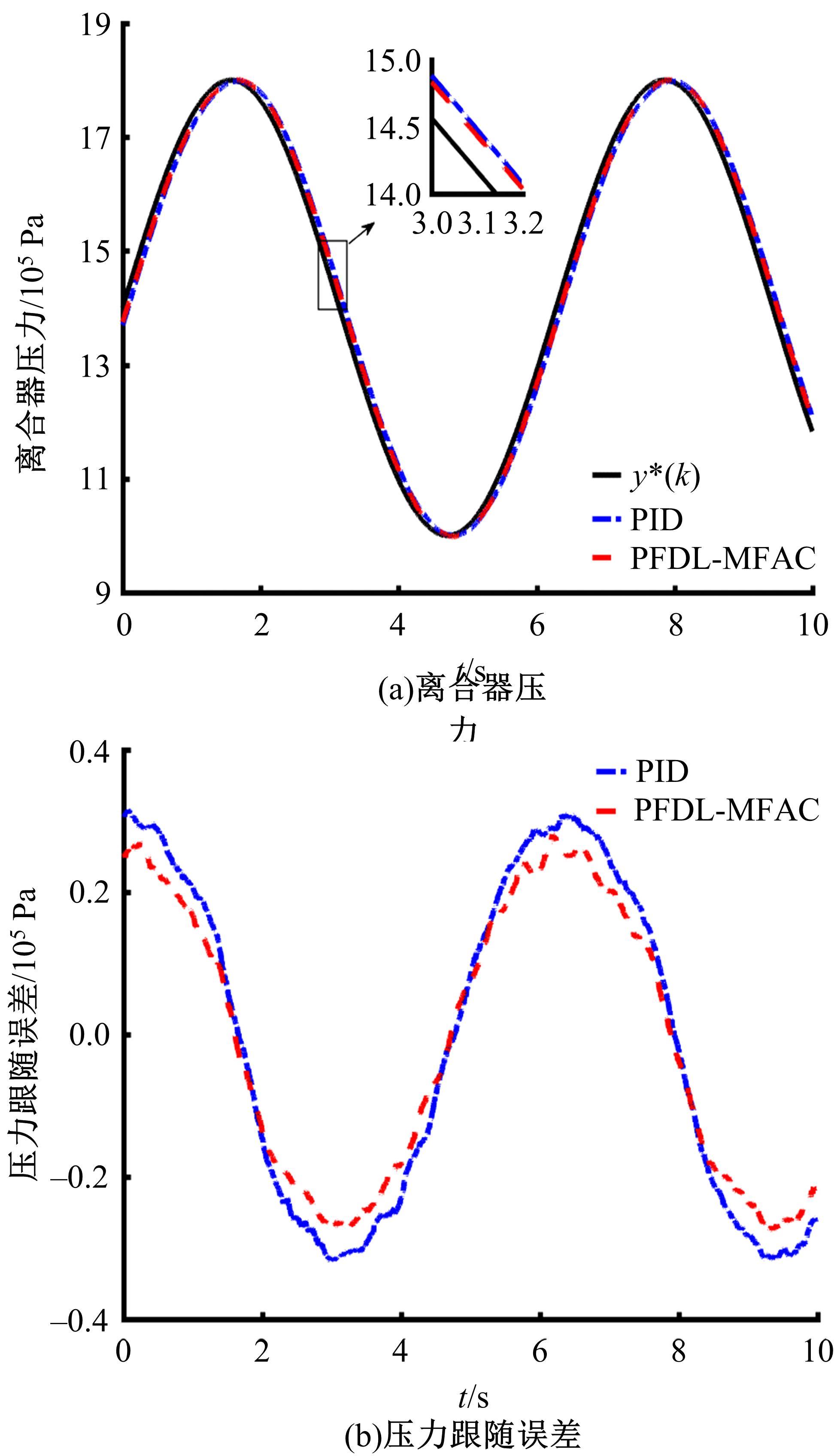

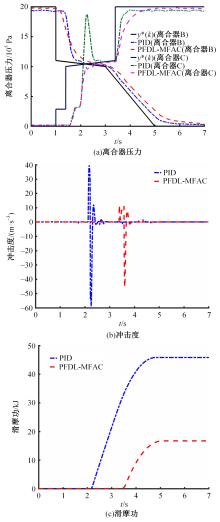

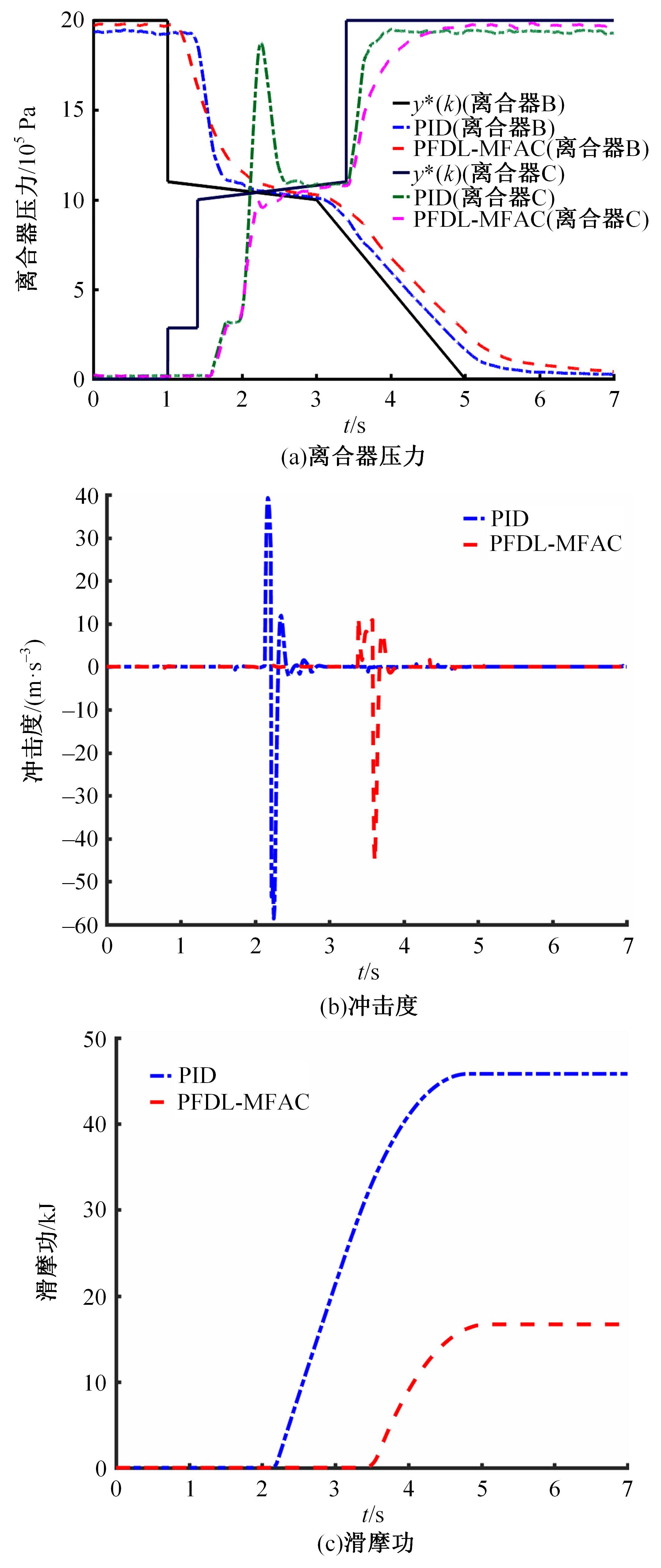

以提升拖拉机动力换挡变速箱(PST)湿式离合器压力控制准确性为目标,提出了一种基于改进遗传算法的湿式离合器压力无模型自适应控制方法。首先,分析并建立了湿式离合器液压系统数学模型,基于偏格式动态线性化的无模型自适应控制(PFDL-MFAC)算法构建了离合器压力控制器。然后,引入变比例精英保留策略、K-均值聚类算法和灾变策略改进遗传算法,提出了基于灵敏度分析和改进遗传算法的PFDL-MFAC控制器参数整定方法。最后,开展了基于拖拉机自动变速箱控制单元(TCU)硬件在环试验平台的离合器压力控制试验。结果表明:改进遗传算法的收敛速度和优化精度更好;与PID控制相比,PFDL-MFAC的离合器压力响应速度更快、鲁棒性更好,满足拖拉机湿式离合器压力控制要求;同时,基于本文算法的变速箱换挡品质更优,研究成果可为动力换挡拖拉机换挡品质的提升提供基础。

中图分类号:

- S219.032.1

| 1 | Zhao Jing, Xiao Mao-hua, Bartos P, et al. Dynamic engagement characteristics of wet clutch based on hydro-mechanical continuously variable transmission[J]. Journal of Central South University, 2021, 28(5): 1377-1389. |

| 2 | 刘永刚, 张静晨, 万有刚, 等. 基于知识的双离合器自动变速器换挡智能控制[J]. 机械工程学报, 2021, 57(17): 185-195. |

| Liu Yong-gang, Zhang Jing-chen, Wan You-gang, et al. Intelligent knowledge-based shifting control of dual clutch transmission[J]. Journal of Mechanical Engineering, 2021, 57(17): 185-195. | |

| 3 | 席志强. 拖拉机动力换挡变速器控制系统研究[D]. 西安: 西安理工大学机械与精密仪器工程学院, 2016. |

| Xi Zhi-qiang. Study on control system of tractor powershift transmission[D]. Xi'an: School of Mechanical and Precision Instrument Engineering, Xi'an University of Technology, 2016. | |

| 4 | 杨猛. 拖拉机动力换挡变速器换挡品质优化与控制研究[D]. 合肥: 合肥工业大学汽车与交通工程学院, 2020. |

| Yang Meng. Research on optimal of shifting quality and control of tractor power shift transmission[D]. Hefei: School of Automotive and Transportation Engineering, Hefei University of Technology, 2020. | |

| 5 | 刘玺, 程秀生, 冯巍. 湿式双离合器自动变速器换挡最优控制[J]. 农业工程学报, 2011, 27(6): 152-156. |

| Liu Xi, Cheng Xiu-sheng, Feng Wei. Optimal control of gearshift in wet dual-clutch automatic transmission[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2011, 27(6): 152-156. | |

| 6 | 杜岳峰, 傅生辉, 毛恩荣, 等. 农业机械智能化设计技术发展现状与展望[J]. 农业机械学报, 2019, 50(9): 1-17. |

| Du Yue-feng, Fu Sheng-hui, Mao En-rong, et al. Current status and prospects of intelligent design technology for agricultural machinery[J]. Journal of Agricultural Machinery, 2019, 50(9): 1-17. | |

| 7 | 闫祥海. 拖拉机动力换挡传动系虚拟试验关键技术研究[D]. 洛阳: 河南科技大学车辆与交通工程学院, 2020. |

| Yan Xiang-hai. Research on the key technologies of virtual test of tractor powershift transmission[D]. Luoyang: College of Vehicle and Traffic Engineering, Henan University of Science and Technology, 2020. | |

| 8 | 马彪, 李国强, 李和言, 等. 基于改进平均流量模型的离合器接合特性仿真[J]. 吉林大学学报: 工学版, 2014, 44(6): 1557-1563. |

| Ma Biao, Li Guo-qiang, Li He-yan, et al. Simulation of wet clutch engagement characteristics based on advanced average flow model[J]. Journal of Jilin University (Engineering and Technology Edition), 2014, 44(6): 1557-1563. | |

| 9 | Balau A E, Lazar C. State-space model of an electro-hydraulic actuated wet clutch[J]. IFAC Proceedings Volumes, 2010, 43(7): 506-511. |

| 10 | Ouyang T, Li S, Huang G, et al. Mathematical modeling and performance prediction of a clutch actuator for heavy-duty automatic transmission vehicles[J]. Mechanism and Machine Theory, 2019, 136: 190-205. |

| 11 | 曾云鹏. 湿式离合器系统建模及压力控制研究[D]. 长春: 吉林大学汽车工程学院, 2021. |

| Zeng Yun-peng. Research on modeling and pressure control of wet clutch system[D]. Changchun: College of Automotive Engineering, Jilin University, 2021. | |

| 12 | 张银涛. 湿式双离合器自动变速器液压控制系统仿真研究与分析[D]. 广州: 华南理工大学机械与汽车工程学院, 2020. |

| Zhang Yin-tao. Simulation research and analysis on hydraulic control system of wet dual clutch transmission[D]. Guangzhou: School of Mechanical & Automotive Engineering, South China University of Technology, 2020. | |

| 13 | 邱明明. 考虑动态特性的DCT双离合器接合过程多滑模控制方法研究[D]. 合肥: 合肥工业大学汽车与交通工程学院, 2015. |

| Qiu Ming-ming. Study on multiple sliding mode control method for DCT dual clutch engagement with dynamic characteristics[D]. Hefei: School of Automotive and Transportation Engineering, Hefei University of Technology, 2015. | |

| 14 | 于鸿昶, 刘奇芳, 陈虹. DCT离合器电液控制阀的非线性压力控制[J]. 吉林大学学报: 信息科学版, 2014, 32(5): 484-492. |

| Yu Hong-chang, Liu Qi-fang, Chen Hong. Nonlinear pressure control for clutch electro-hydraulic control valve of DCT[J]. Journal of Jilin University (Information Science Edition), 2014, 32(5): 484-492. | |

| 15 | Hu H, Wu H, Zhang Z, et al. Research on trajectory tracking control for wet clutch engagement based on SMC[J]. Procedia Engineering, 2011, 15: 2742-2746. |

| 16 | 傅生辉, 顾进恒, 李臻, 等. 基于MFAPC的动力换挡变速箱湿式离合器压力控制方法[J]. 农业机械学报, 2020, 51(12): 367-376. |

| Fu Sheng-hui, Gu Jin-heng, Li Zhen, et al. Pressure control method of wet clutch for PST of high-power tractor based on MFAPC algorithm[J]. Journal of Agricultural Machinery, 2020, 51(12): 367-376. | |

| 17 | 赵栩杨, 卜旭辉, 余威, 等. 拒绝服务攻击下的MIMO非线性系统无模型自适应控制[J]. 控制理论与应用, 2022, 39(2): 373-382. |

| Zhao Xu-yang, Bu Xu-hui, Yu Wei, et al. Model free adaptive control for MIMO nonlinear systems under Denial-of-Service attacks[J]. Control Theory & Applications, 2022, 39(2): 373-382. | |

| 18 | 姚文龙, 亓冠华, 池荣虎, 等. 具有未知负载扰动的水井钻机电液伺服系统无模型自适应控制[J]. 控制理论与应用, 2022, 39(2): 231-240. |

| Yao Wen-long, Qi Guan-hua, Chi Rong-hu, et al. Model-free adaptive control for water well drilling rig electro-hydraulic servo with unknown load disturbance[J]. Control Theory & Applications, 2022, 39(2): 231-240. | |

| 19 | 魏立新, 赵默林, 范锐, 等. 基于改进鲨鱼优化算法的自抗扰控制参数整定[J]. 控制与决策, 2019, 34(4): 816-820. |

| Wei Li-xin, Zhao Mo-lin, Fan Rui, et al. Parameter tuning of active disturbance rejection control based on ameliorated shark smell optimization algorithm[J]. Control and Decisions, 2019, 34(4): 816-820. | |

| 20 | 王立平, 孔祥昱, 于广. 基于遗传算法的并混联机床电机伺服控制参数整定[J]. 清华大学学报: 自然科学版, 2021, 61(10): 1106-1114. |

| Wang Li-ping, Kong Xiang-yu, Yu Guang. Motor servo control parameter tuning for parallel and hybrid machine tools based on a genetic algorithm[J]. Journal of Tsinghua University (Science and Technology), 2021, 61(10): 1106-1114. | |

| 21 | 王素珍, 辛诚, 孙国法. 连续搅拌反应釜的自适应输出反馈控制及参数整定[J]. 控制理论与应用, 2021, 38(10): 1587-1596. |

| Wang Su-zhen, Xin Cheng, Sun Guo-fa. Adaptive output feedback control and parameter tuning for continuous stirred tank reactor[J]. Control Theory & Applications, 2021, 38(10): 1587-1596. | |

| 22 | 胡黄水, 赵思远, 刘清雪, 等. 基于动量因子优化学习率的BP神经网络PID参数整定算法[J]. 吉林大学学报: 理学版, 2020, 58(6): 1415-1420. |

| Hu Huang-shui, Zhao Si-yuan, Liu Qing-xue, et al. BP network PID parameter tuning algorithm based on momentum factor optimized learning rate[J]. Journal of Jilin University (Science Edition), 2020, 58(6): 1415-1420. | |

| 23 | 商晓波. 湿式离合器接合过程理论分析及试验研究[D]. 杭州: 浙江大学机械工程学院,2019. |

| Shang Xiao-bo. Theoretical analysis and experimental study on engagement process of wet clutch[D]. Hangzhou: School of Mechanical Engineering, Zhejiang University, 2019. | |

| 24 | 侯忠生, 金尚泰. 无模型自适应控制——理论与应用[M]. 北京: 科学出版社, 2013. |

| 25 | 王海, 刘根锋, 侯忠生. 高速列车数据驱动无模型自适应容错控制[J]. 控制与决策, 2022, 37(5): 1127-1136. |

| Wang Hai, Liu Gen-feng, Hou Zhong-sheng. Data-driven model-free adaptive fault tolerant control for high-speed trains[J]. Control and Decisions, 2022, 37(5): 1127-1136. | |

| 26 | 徐立友, 刘海亮, 周志立, 等. 拖拉机双离合器自动变速器换挡品质评价指标[J]. 农业工程学报, 2015, 31(8): 48-53. |

| Xu Li-you, Liu Hai-liang, Zhou Zhi-li, et al. Evaluation indexes of shifting quality for dual clutch transmission for tractor[J]. Transactions of the Chinese Society of Agricultural Engineering, 2015, 31(8): 48-53. |

| [1] | 陈学深,熊悦淞,程楠,马旭,齐龙. 自适应振动式稻田株间柔性机械除草性能试验[J]. 吉林大学学报(工学版), 2024, 54(2): 375-384. |

| [2] | 王永烁,康建明,彭强吉,陈英凯,方会敏,牛萌萌,王少伟. 果树株间避障除草机设计与试验[J]. 吉林大学学报(工学版), 2023, 53(8): 2410-2420. |

| [3] | 郑长江,胡欢,杜牧青. 考虑枢纽失效的多式联运快递网络结构设计[J]. 吉林大学学报(工学版), 2023, 53(8): 2304-2311. |

| [4] | 金小俊,孙艳霞,于佳琳,陈勇. 基于深度学习与图像处理的蔬菜苗期杂草识别方法[J]. 吉林大学学报(工学版), 2023, 53(8): 2421-2429. |

| [5] | 田国红,代鹏杰. 基于单亲遗传算法的无人驾驶汽车主动避撞方法[J]. 吉林大学学报(工学版), 2023, 53(8): 2404-2409. |

| [6] | 吕锋,李念,冯壮壮,张杨航. 面向用户的个性化产品服务系统协同过滤推介方法[J]. 吉林大学学报(工学版), 2023, 53(7): 1935-1942. |

| [7] | 惠迎新,陈嘉伟. 基于改进遗传算法的挤扩支盘群桩优化方法[J]. 吉林大学学报(工学版), 2023, 53(7): 2089-2098. |

| [8] | 张茂健,金敬福,陈奕颖,陈廷坤. 轮式拖拉机对称结构的振动特性[J]. 吉林大学学报(工学版), 2023, 53(7): 2136-2142. |

| [9] | 李艳波,柳柏松,姚博彬,陈俊硕,渠开发,武奇生,曹洁宁. 考虑路网随机特性的高速公路换电站选址[J]. 吉林大学学报(工学版), 2023, 53(5): 1364-1371. |

| [10] | 杨红波,史文库,陈志勇,郭年程,赵燕燕. 基于NSGA⁃II的斜齿轮宏观参数多目标优化[J]. 吉林大学学报(工学版), 2023, 53(4): 1007-1018. |

| [11] | 马敏,胡大伟,舒兰,马壮林. 城市轨道交通网络韧性评估及恢复策略[J]. 吉林大学学报(工学版), 2023, 53(2): 396-404. |

| [12] | 应沛然,曾小清,沈拓,袁腾飞,宋海峰,王奕曾. 基于冗余工序编码的高速列车节能驾驶智能算法[J]. 吉林大学学报(工学版), 2023, 53(12): 3404-3414. |

| [13] | 朱劲松,秦亚婷,刘周强. 预应力UHPC-NC组合梁截面优化设计[J]. 吉林大学学报(工学版), 2023, 53(11): 3151-3159. |

| [14] | 耿端阳,孙延成,王宗源,王其欢,明家锐,杨昊霖,徐海港. 玉米籽粒直收机板齿式脱粒装置设计与试验[J]. 吉林大学学报(工学版), 2023, 53(11): 3281-3292. |

| [15] | 谢守勇,张小亮,刘凡一,刘军,苑晓亮,刘伟,王鹏. 基于钵苗力学特性取投苗装置动力学分析与试验[J]. 吉林大学学报(工学版), 2023, 53(11): 3293-3304. |

|

||